Words: René Vermeer Photos: Glen McNamara

You’d be damn right if you thought we don’t feature enough classic Japanese tin these days. It’s not for the sake of trying; it’s because they’re getting harder and harder to find and therefore modify — especially in New Zealand, where almost everywhere is coastal and rust starts to become a real problem — plus there’s the problem of getting the parts. With the Nissan Sunny platform used as a utility vehicle ever since the ’70s, these vehicles are often flogged, thrashed, and left for dead. When Leah Davies decided to get stuck into her first-ever project car, she definitely wanted a smaller Japanese ute. With local searches not proving fruitful, she cast her net wider — to Japan, where these utes are still alive and kicking in much larger numbers.

“I had decided that I wanted a Sunny ute — they are not as common here in NZ and I loved how small they are. We found this one from Japan with only 84,000kms on the clock. It was originally a ute for a yard in Japan, and they used it for transporting equipment and goods,” Leah told us, when we asked when and how she chose this exact car. It makes sense, too, as in New Zealand the Sunny is a rarity, with only six showing as registered. With a tidy, blank canvas arriving at Leah’s doorstep, thanks to Autohub, it was time to get to work, assess the newly landed ute, and make a plan and a budget for what would become of this bite-sized ute. “This was my first big project, and was something I could do with my dad. We decided on keeping it fairly stock in the body, but were keen to make it perform well and be reliable without going overboard.

As it was a joint project, Dad and I had to compromise with each other on what we wanted,” Leah said. “Dad wanted it to keep it stock, and I was getting a lot of influence from the Sunny trucks over in Japan that were lowered with wide wheel arches.” One of the standout features of Leah’s ute is most definitely the paintwork. With all of the bodywork completed in the garage with Leah’s dad, that would appear to have borne the brunt of the time and money, but Leah and her dad decided to step it up a notch. The underfloor has been completely resealed. It’s got a custom rear tray, new factory chrome and stainless trimming throughout, new grille, new rear lamps, and new bumpers — the extent of this coming about because Leah wasn’t a fan of the original colour

Once the bodywork was completed, the ute was sent off to Charlie’s Custom Paint and Pinstriping for the final coat. Unlike most repaints these days — in factory-spec drab whites, greys, and blacks — Leah opted for a custom candy apple red, with a new lower front dam being the only exterior major upgrade. Wheels were a huge part of this build. Although Leah wasn’t going to be filling out widened steel arches, the wheels are still wide for the ute’s size. “I always wanted some classic Japanese wheels on the truck, but, with deciding not to flare the guards, and instead keep the body stock, it made finding the right size difficult, as wide wheels wouldn’t fit.

I sourced the Longchamps in Japan and shipped them to Pine Engineering, [which] used the centres and created new barrels for me to fit to the truck,” Leah explained. To complete the all-round aesthetics, the interior was retrimmed by Ian Goodwin Car Upholstery, complete with new, moulded carpets. The interior also saw a few brand-new components: factory dash top, glovebox, shelf, and centre console. “One thing I didn’t realise when I purchased this car was how small the cabin is! There really is no room in there, and it can be a bit uncomfortable to drive. My legs are almost too long to use the clutch comfortably!” Leah laughed.

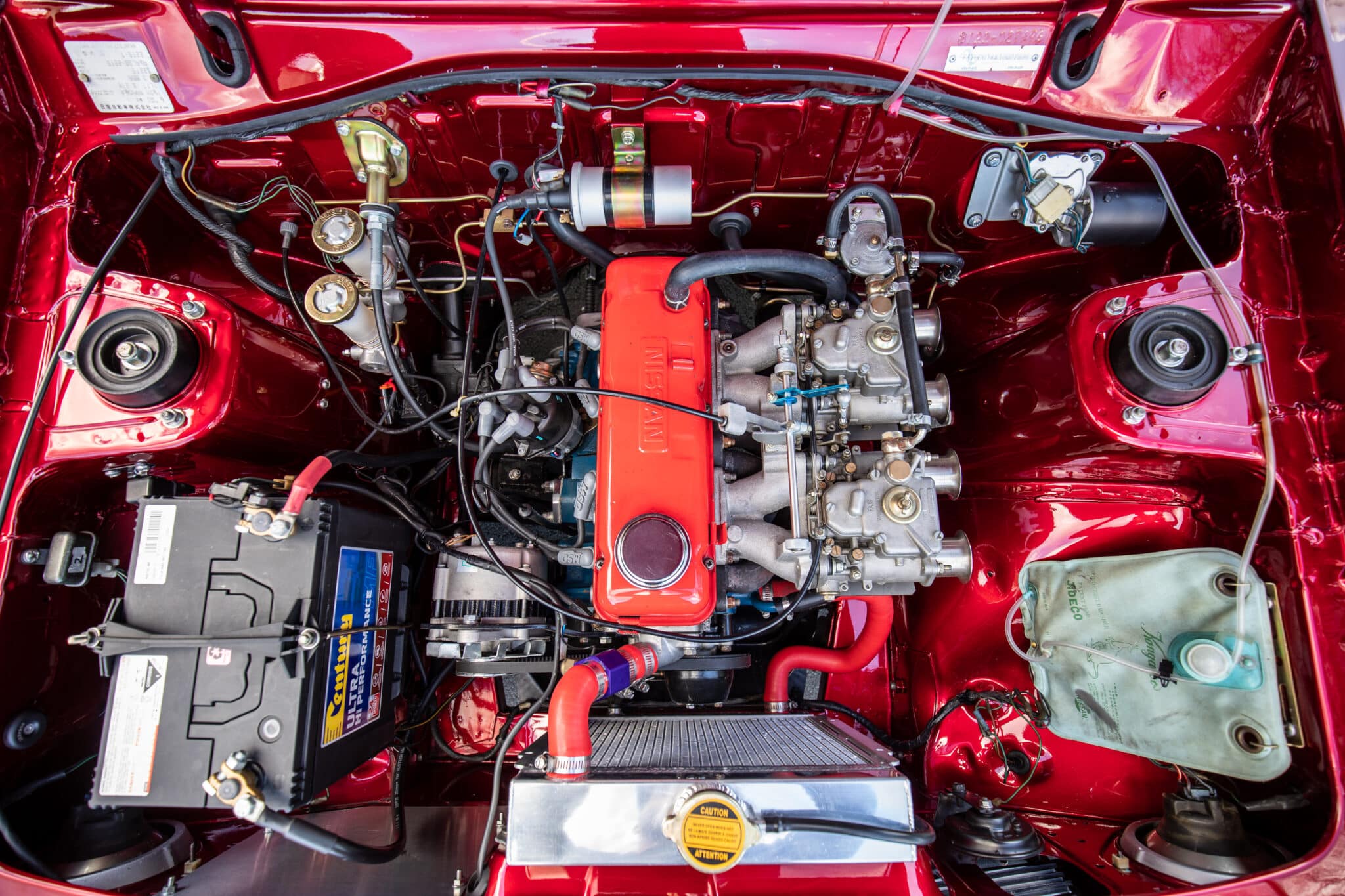

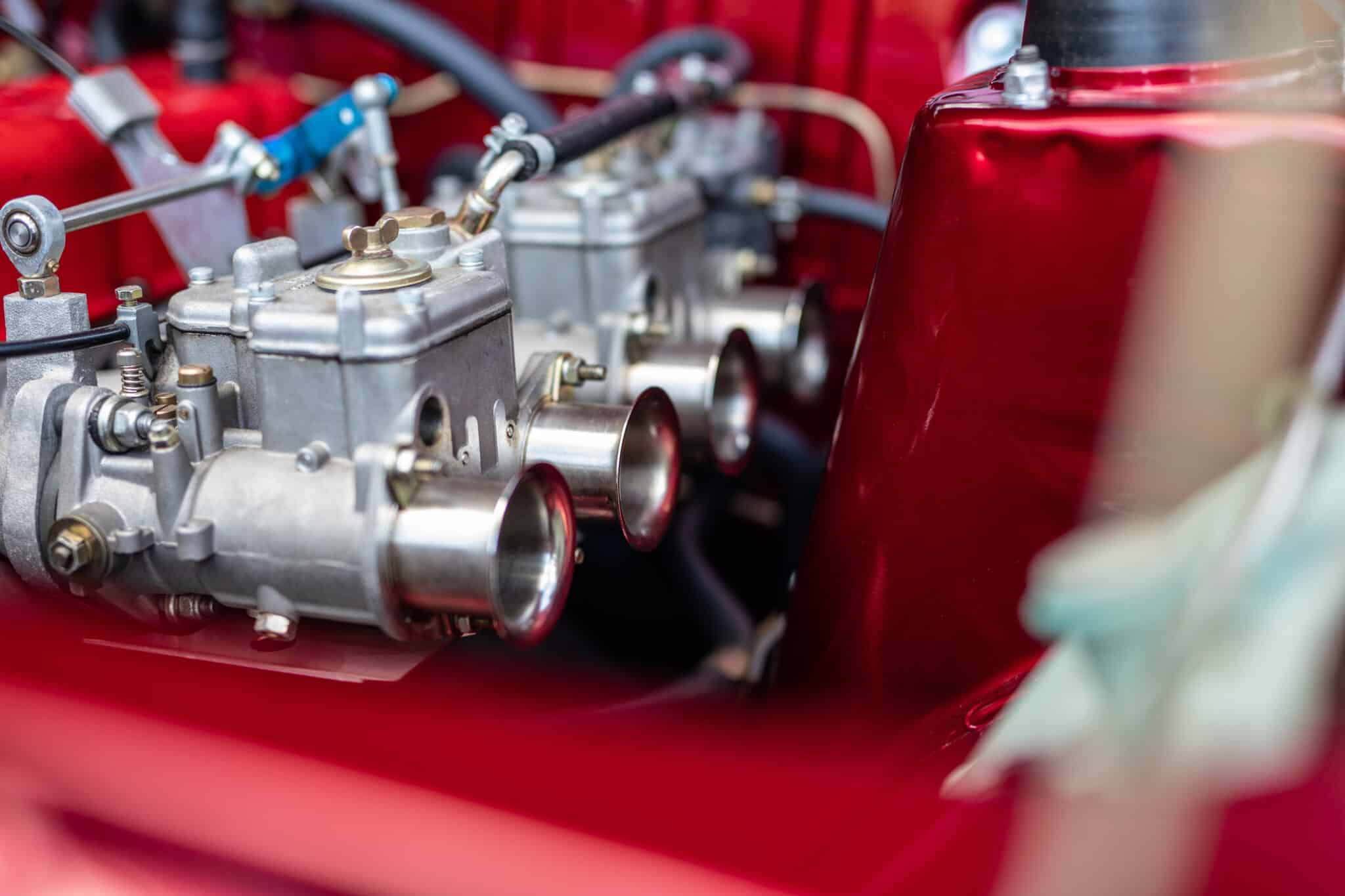

The ute was powered by a 1200cc A12 engine from the factory, but Leah was dead-set from the get-go on repowering it with something different. An A15, 1500cc engine was chosen for ease of conversion, then seriously tickled by none other than Tony at Marsh Motorsport. The A15 was slightly stroked, the entire rotating assembly balanced, including the flywheel, the head flowed with larger valves, a custom performance cam fitted, and a custom exhaust system installed — all fed by two Weber DCOEs, with a four-port direct-flow manifold from Weber Specialties in Silverdale. After spinning up 97kW at the wheels, it’s a fair whack more than what it came with from the factory — keep in mind, this little ute is very light. “It was run at over 8000rpm without issue,” Leah continued. “Now that I have driven the car a few times, I may look at reducing the choke tubes and jets in the carbs to offer a little more torque and smoothness down low, at the expense of top-end horsepower.

The current power curve is focused on high-rev power, and this will make it a more usable, everyday driving car with lower-rev performance. For now, though, I am happy with it and am just going to enjoy driving it as much as I can.” This build has given Leah a heap more confidence in building cars, as almost everything had to be thought about, planned, modified, painted, or replaced at home in the shed. Although it went wildly over the $15,000 budget to rebuild the original motor and get it ready for New Zealand’s roads, she doesn’t regret it.

“The car is still immaculate, and has not had much use. I’ve taken it to a few shows, where it has picked up some awards, so now the only plans are to drive and enjoy it this summer. Overall, I am happy with the outcome for my first build, and am really proud of all the hard work that has gone into it.” It’s an incredible feat, and one that could inspire many readers — a proper, old-school, in-out restoration, using local and international talent to get it done. Mostly, though, it was just Leah and her dad, at home in the shed, slogging it out until it was finished. If you see Leah and her ute at a local car show, you should definitely take a closer look — the attention to detail is epic.

_________________________________________________________________________________________________

This article originally appeared in New Zealand Performance Car issue 299