“Dan Yeoman’s Beams-powered KE70 is a testament to just how good a project can be if you stick to your guns and see it through ”

If you’re a fan of vintage tin then finding that elusive ‘one lady owner’ shell, which has never been modified or hacked up, is pretty much the holy grail in this day and age. What would make it even sweeter is if you got in there before the price of said model skyrocketed into the online-buyers’ stratosphere.

Christchurch local Dan Yeoman pretty much hit the Toyota KE70 jackpot when searching for a new daily driver eight years ago, as he elaborated to NZPC. “I am the fourth owner: the first two were the old lady and old man who bought it from new. I have the original sales book, and it still has the original key and everything. It was a real original, tidy car. When the lady passed she gifted it to her next-door neighbour, a solo mother. Who somehow managed to blow up the standard 4K by driving it to Dunedin without any oil or water, but it was otherwise mint. I bought it for about $900, as I had a reconditioned 4K sitting at home. I picked up the KE on a Friday, put the engine in on Saturday, and got a WOF on Sunday before driving straight to SURFAB to cut the springs, and that was my daily for the next year.”

At the same time Dan was in the process of building another KE70 shell as a project. Having already started collecting parts for that shell, he was prepping it for a roll cage when he found an almighty rust hole in the wiper tray, one that you could almost get your head through. Needless to say it was beyond repair in what was considered a cheap car back then. Dan’s focus soon switched to modifying his $900 daily, as he explained. “I stripped the rusted shell as I had already purchased all the T3 arms and stuff out of the States. I thought ‘Oh well f**k it, this is a good base to use,’ so went from there, and it just got way out of hand.”

That was nearly seven years ago, which was when we first laid eyes on the project at SURFAB. Back then it was still going to be a streeter, and not the clubsport racer you see before you. “It was always going to run a wide set of old wheels, I was planning to do it as a road car, but it quickly got to the point where it was basically a race car without a roll cage. It was at this point that I was like ‘OK if I’m doing this I’m going to do it properly, and turn it into a ’70s/’80s race car, do the big flares, the ducktail, the chin spoiler, and get rid of all the chrome, etc.”

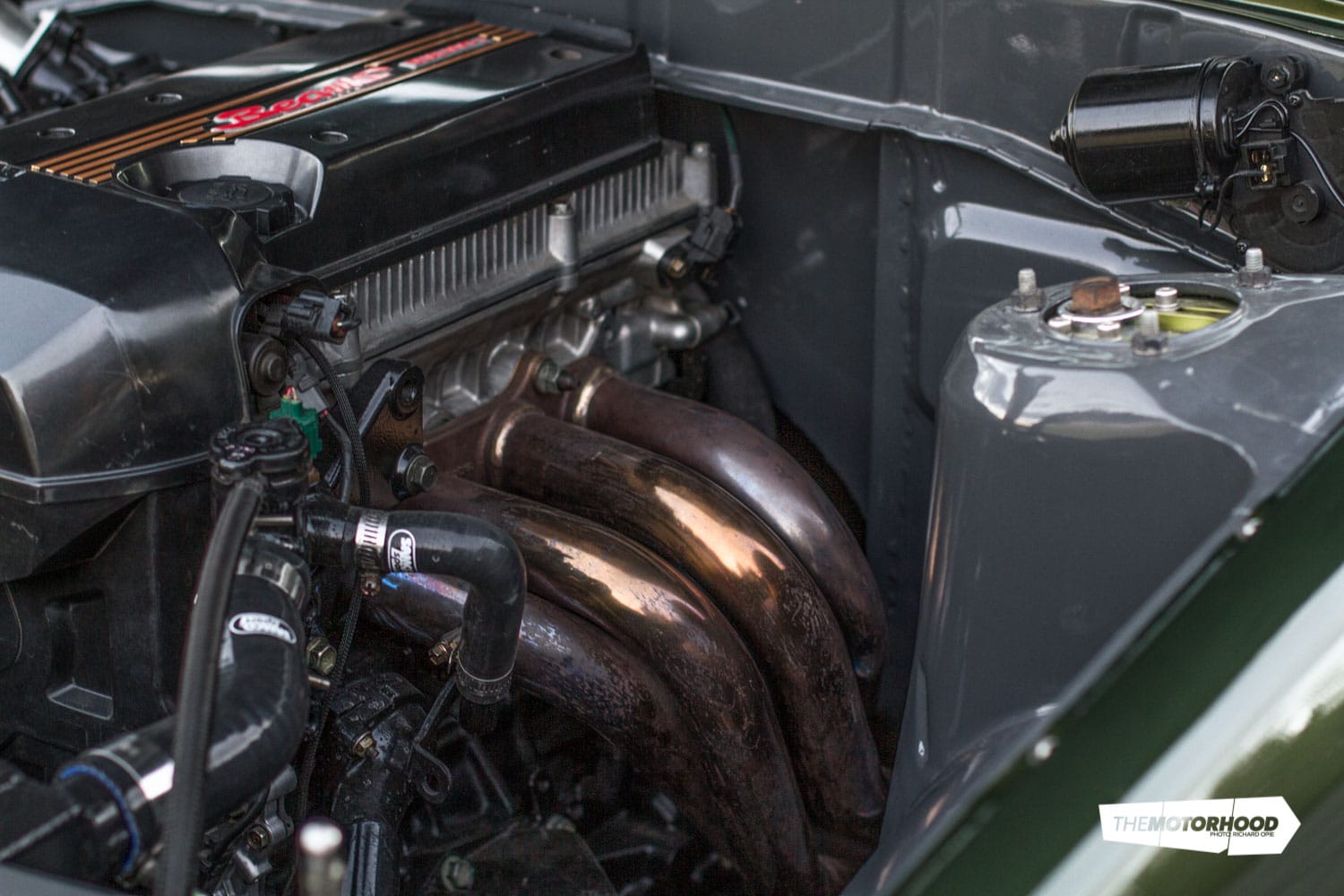

Even back then the colour scheme was set in stone. But there was one element of the build that remained fairly fluid for some time. You see the Toyota 3SGE BEAMS powerplant wasn’t the first option sitting in the bay. Originally it was to be powered by a rotary, first a 13B, and then a 13B turbo. “I had a 13B turbo race block sitting in there, that was when I was still looking to build a street car, but if I was going to race I wanted to be able to race in a class, and a 13B turbo would have put me in the class with all the big boys, and that gets expensive.” From a 13B Dan moved to a 20V 4AGE, but realizing that a standard BEAMS would make more power than a modified 20V, and given the fact that Altezza six-speed gearboxes are not only cheaper, but also stronger and better shifters at high rpm than the T50, the decision to swap to a 3SGE wasn’t a hard one.

What was hard was finding the correct-model block in good condition. That frustration was thanks to both rip-off merchants selling him ‘good condition’ engines that were completely lunched, or sending him auto-spec 3SGEs. Dan explained the differences, “The auto model makes 15hp [11kW] less than the manual ones thanks to milder cams and lower 10.5:1 compression versus 11.1:0. It also has a water-to-oil cooler, stainless valves and smaller buckets versus the manual’s titanium valves.”

The ITBs use silicone joiners to connect the custom engine and throttle plates. This not only helps isolate the ITBS from heat — a problem the SURFAB AE suffered, with a full-alloy intake that kept cracking — it also allowed them to tune the intake length back-to-back on the dyno to find the optimum power band

After the third 3SGE to find its way into the KE was also found to be junk, that was enough of that! “I got it in and fired it up but it was rattly as hell. I wondered if it was just the VVTi gears, but we got it on the dyno and Phil noticed it was running rough, and that something was not quite right. He just did what he could with the tune so I could get it to the first Street Meat Expression Session.

The rear four-link has been raised into the body to retain the correct geometry, and thanks to the rose-jointed T3 arms the diff has great articulation and 50mm of travel. Basically the body now hits the ground before the suspension will bottom out. Up front the lower arms have been modified with rose joints, and T3 castor arms have also been used

At that point it had been five years, and I just really wanted to drive it.” Dan continued, “I had no windscreen, no bonnet, no boot, and the doors were zip-tied on. We just took it out for a shakedown to test out all the ideas that I had put into it to see if they actually worked or not. Things like the way we routed the brake lines, and stuff that I had done to the suspension, which wasn’t the norm. In my head and in theory it seemed good, but sometimes that stuff doesn’t really work.”

View fullsize

View fullsize

The car performed just as Dan had hoped (apart from the engine), so it was time to get it finished once and for all. It was stripped for panel and paint and the engine was also pulled. This time, as he was sick of purchasing wrecks from wreckers, Dan decided to build a motor. “The engine is basically made out of four engines. I used the block, and bought another engine for $50 which had a stuck valve and used the crank, rods and pistons. I had CARAID clean out and tidy up the head a little. I bought another auto engine for $100 and used the valves, as you can’t resurface the titanium ones.” It then all went together with new bearings and seals, etc.

When it came to finishing the body, a lot of hard work had already been carried out years earlier. The chassis had been sandblasted and seam welded before a coat of epoxy was applied. It was also at this stage that the engine bay and interior had been painted in what Dan describes as battleship grey.

All the body pieces had also been customized to suit the KE70 with the help of Mike Bamber, as there are very few off-the-shelf components available. “The ducktail is originally from a 240Z race car. We lengthened it 30mm and then spliced the edges, taking out a slit to give it a curve, as the 240 is very straight compared to the KE.” The chin spoiler was also heavily modified, but not to the extent of the flares.

“The flares were 90mm CBY from an AE86. They had a big kick out for the rear bumper, and taper out towards the front door. So we cut them in half and spliced the two front tapered sections together, got them fitting right and then took a mould of that. We now have a mould of the chin spoiler, ducktail, the boot and bonnet. That way, down the line we can do them in carbon. Stuff like that we can do and not have the car off the road. I have had enough of not being able to use it. So from now on I’ll stick to the kind of little bits that I can do here and there while keeping it driveable.”

The good news is Dan still intends to get it road legal, and is working towards that WOF on the windscreen. But it’s racing that his focus remains fixed to, and he intends to compete in the Clubsport 1600–2000cc class this coming summer. There is also a new southern class, Modern Classic Saloons, which features a pretty stacked grid thanks to the relaxed rules, and will see the KE up against everything from Civics to Escorts and Mustangs, and even the odd GT-R. There was also some talk of running in the Southern Endurance Series further down the line, once he’s had a little more seat time.

We don’t know about you, but that certainly made our ears prick up, as we think it would be pretty cool to see it banging doors with half-million-dollar GT3 machines, then driving out the gates and home again once the race is over. We will certainly be putting our hands up to be co-drivers in this very cool retro racer.

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

Tuning menu

- MAKE AND MODEL: 1980 Toyota Corolla (KE70)

Heart

- Engine: Toyota 3SGE Beams, four cylinder, 2000cc

- Block: Rebuilt factory, winged gated sump

- Head: Steel valves, heavy duty springs

- Intake: 70mm trumpets, 20-valve blacktop throttle bodies (bored to 48mm and larger butterflies) SURFAB intake manifold port, matched to head, silicone runners

- Exhaust: Tanabe 4-2-1 headers, 2.5-inch stainless system, dual crossflow mufflers

- Fuel: SURFAB custom-alloy fuel tank with internal surge tank, FC RX-7 internal fuel pump, -6 braided Aeroflow fittings and line, Tomei FPR

- Ignition: Factory coil on plug

- ECU: Link G4 Storm

- Cooling: SURFAB custom dual-pass radiator with filler neck relocated to engine, Samco hoses, seven-row oil cooler, Double Brown overflow can

- Extra: Deloomed, hidden brake lines

Drive

- Gearbox: Altezza six-speed

- Clutch: Exedy heavy duty

- Flywheel: Lightweight billet

- Diff: Shortened Hilux diff with custom mounts shortened and aligned by Royce Clive Engineering, 4.5:1 LSD head

Support

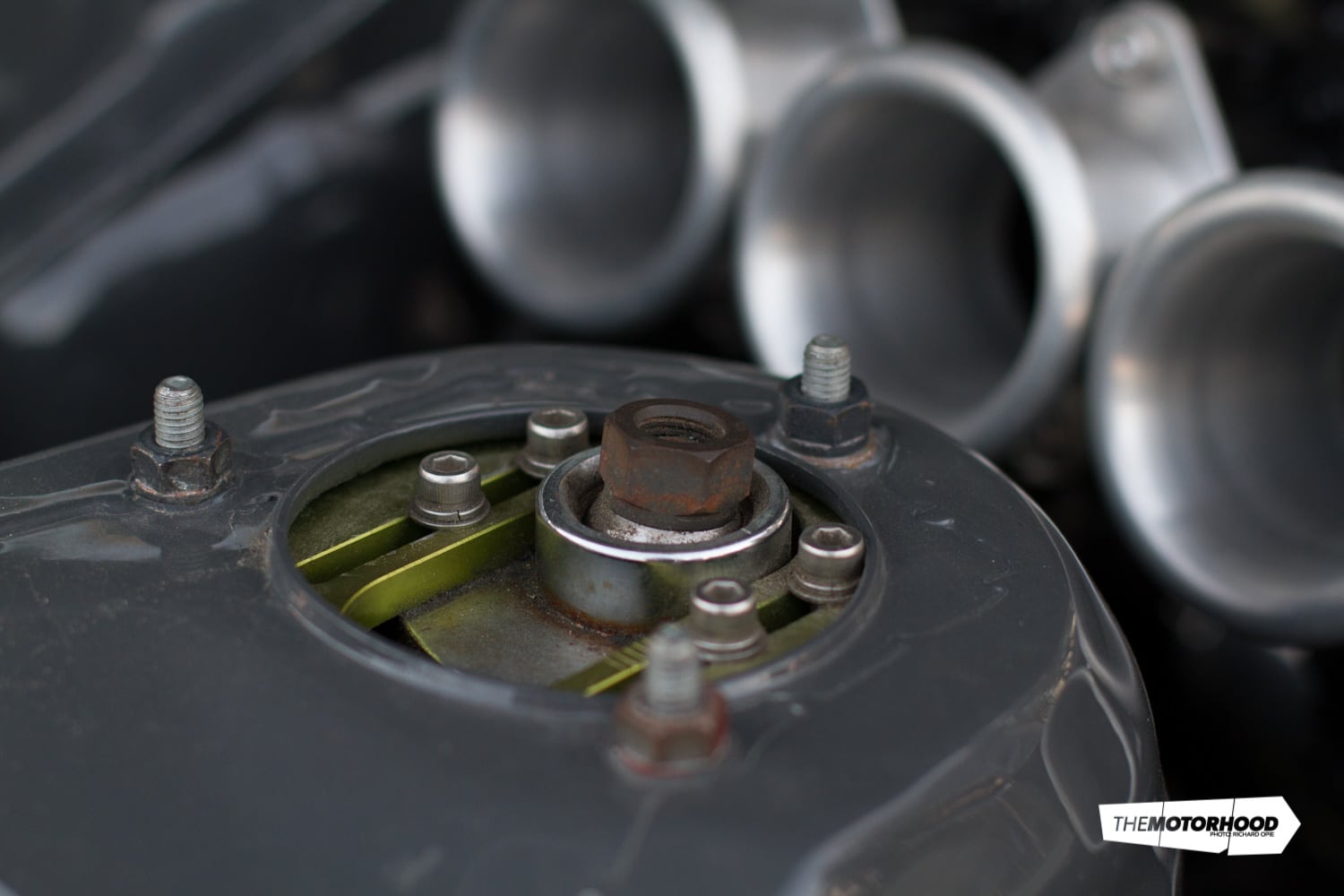

- Struts: (F) HSD coilovers, (R) Yellowspeed coilovers

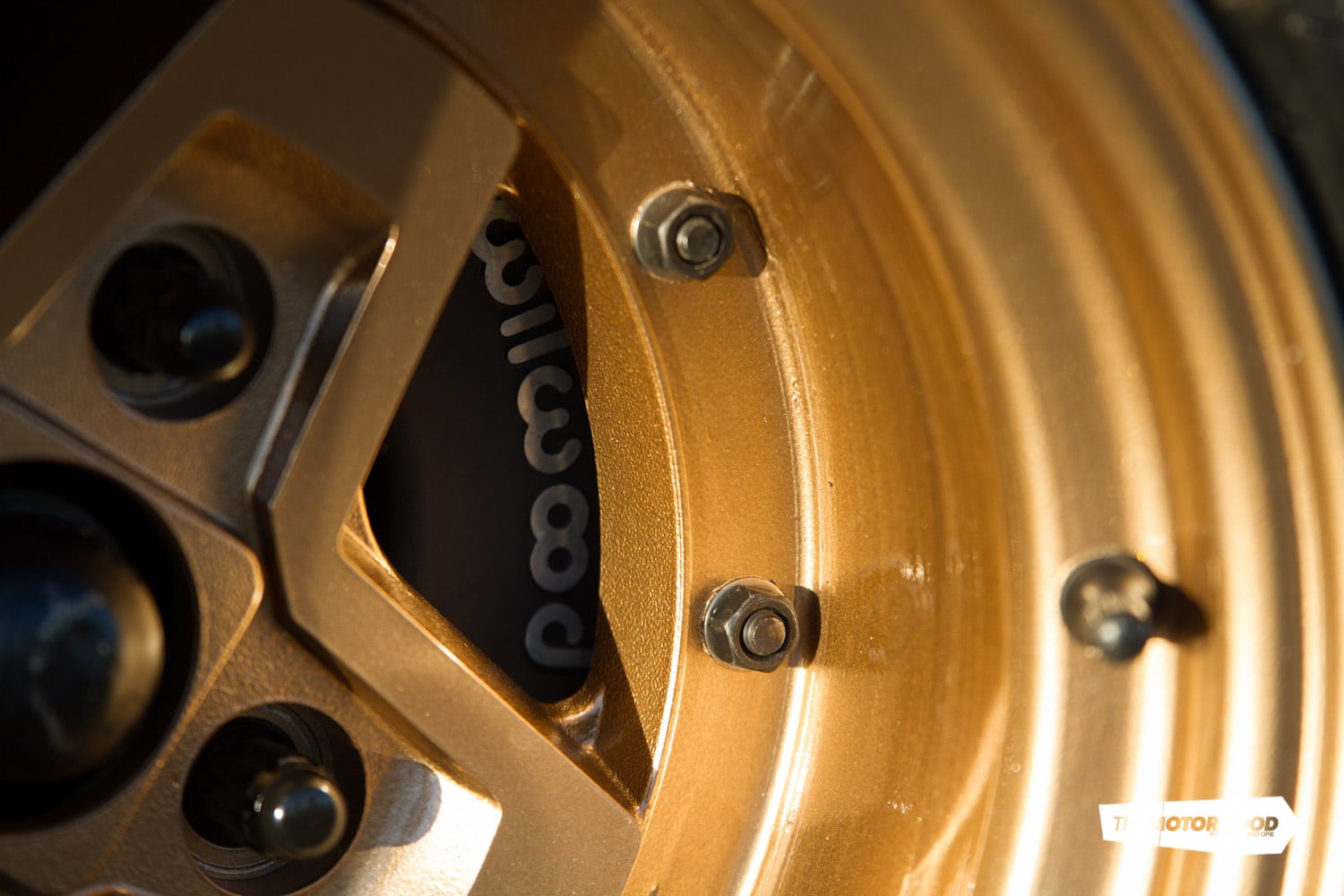

- Brakes: Wilwood reverse-swing pedal box, Wilwood front-/rear-bias adjuster, SURFAB hydraulic handbrake (F) Wilwood Dynalite four-pot calipers, 255mm vented rotors, Craig Young CNC caliper bracket, Wilwood braided lines, Wilwood race pads (R) Nissan two-pot calipers, 255mm vented rotors, braided lines, EBC Green pads, Craig Young CNC caliper bracket

- Extra: (F) RCAs, T3 castor arms, SURFAB adjustable LCAs, Whiteline adjustable sway bar, AE86 power-steer knuckles (R) T3 five-link, Whiteline adjustable sway bar, raised five-link mounts

Shoes

- Wheels: Monday — Enkei silver stars 13×9-inch (-25)

Tuesday — SSR XR4 Longchamps 13×8.5-inch (-20)

Wednesday — Focus Racing Spoke 13×9-inch (-25)

Thursday — Advan A3A 13×9-inch (-25)

Friday — Enkei Apache and Hayashi Command 13×9-inch (-25) - Tyres: Michelin TRS slicks, Avon slicks, Yokohama A048 semi slicks, Nankang Prestige road tyres

Exterior

- Paint: Rover green painted by The Englishman

- Enhancements: Bamber Motorsport chin spoiler, ducktail, flares and fibreglass bumpers, Lexan windows, 3SGE rod tow hooks, race stripes and signage by Jonny Martin

Interior

- Seats: Racetech R100, Racetech harness

- Steering wheel: Vintage suede wheel, SURFAB quick-release hub

- Instrumentation: ASUS tablet display

- Extra: SURFAB eight-point roll cage, semi-tubbed rear arches, arches in rear doors raised, new gearbox tunnel, full rewire, Broadway mirror, metallic-charcoal woodgrain dash and door cards

Power

- Power: 143kW (192hp) at the wheels

This article was originally published in NZ Performance Car Issue No. 223. You can pick up a print copy or a digital copy below: