Part four of Rene’s Japan odyssey takes us to Tomei’s headquarters in Machida

As the saying goes, if you want the treats you better put in the mahi. Before Damian and I flew to Japan, we knew that some of the best Up Garages, museums, and tuning houses were off the beaten track — and, by off the beaten track, I mean well off it. Not that it bothered us; we were committed to the cause and determined to track down those hidden gems for which Japan is so well known.

A must for any car guy is a trip to an Up Garage, so why not the biggest in Japan, sitting two hours outside of Tokyo? Although, as we were staying just north of the city, that turned into a three-hour trip; I said we were committed, right?! As we transferred to our final train bound for Machida, the part-English, part-Japanese signs had vanished and transformed into Japanese only. I looked over to Damian, with a concerned look upon my face. “Damian,” I said, “we are deep inside the Matrix now — there’s no going back!”

After spending the morning shopping and browsing the spectacular shelves of Up Garage Machida — yes, we travelled three hours to go car-part shopping! — we checked Google Maps, as we knew that Tomei Auto Parts, a company founded by Seiichi Suzuki in 1968, was in the same town. Surprisingly, it was only 200m down the road. Up Garage bags in hand, we made the swift shuffle down the street until we saw the words ‘Tomei’ bolted on the side of a bland concrete building.

Walking into Tomei was an interesting experience. It was dead quiet, the showroom was incredibly small and dimly lit, and around 10 people sat behind a false wall — staring at us as though we were from another planet. It was at this point that we realized that this was simply an office and their nine-to-five. It kind of all made sense; we build these companies and their achievements up as iconic — which they are — but, for them, it’s their bread and butter, and they were here working on a Saturday.

Thankfully, Damian’s well-selected clothing for the day, a Tomei hoodie, caught someone’s eye, and a very friendly English-speaking lad came over to introduce himself. After I told him I sell Tomei products in New Zealand, he asked us, “Would you like to have a tour of the workshop? It’s a Saturday, and I have nothing to do — I have been watching YouTube all day.”

After having a quick chuckle, Damian and I couldn’t say yes fast enough, followed by our best attempt at a Japanese ‘thank you’ — arigat¯o gozaimashita!

Back outside, we noticed a fellow traveller carrying an Up Garage bag. He was on his tippy-toes, trying to peep inside the Tomei entrance.

“We’re heading down for a tour of the workshop — would you like to join?” our Japanese guide asked him, making an educated guess as to why he was there.

With three automotive enthusiasts in tow, our guide went around the back to the workshop entrance. Sitting outside was a sign-written Nissan Skyline GT-R R35, a Subaru Levorg, and a D1GP / Formula D comp car.

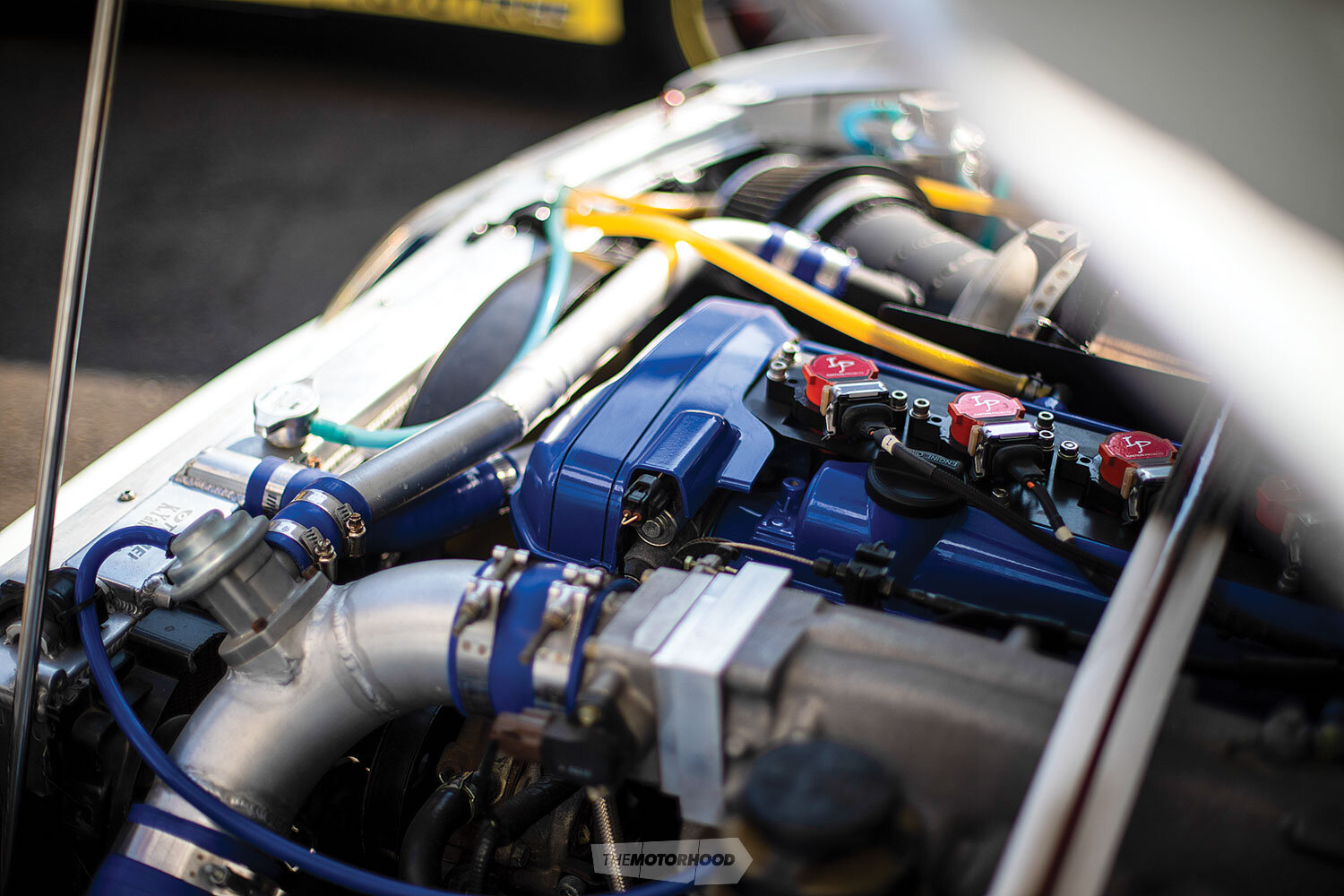

Our guide explained that the R35 was his work vehicle, then fired it up so that we could listen to the prototype Tomei exhaust system the team was currently working on. Oh, what a noise! Fortunately, though, he could that tell a near-stock R35 wasn’t going to impress us seasoned tuner folk, so he pulled the covers off the D1GP car driven by Kenji Yamanaka. After absolutely zero convincing whatsoever, the bonnet was propped up so we could take in the powerhouse that lay dormant. Our guide talked us through the gigantic 3.6-litre stroker-kit details, before rattling off a list of other D1GP and Formula D drivers who demand the use of Tomei’s stroker — the biggest on the market at this time. I flexed my Garrett knowledge and made an educated guess at the turbo size, knowing the capacity. With nitrous, the 2JZ utilizes a GT4088R turbo, helping the JZ produce around 746kW at the wheels — no doubt an easy figure to obtain with this combination and in-house knowledge.

Finally, we made our way through the small unassuming workshop door and into the prototyping room. There was plenty we couldn’t photograph, for obvious reasons, but the rest was fair game. Sorry about the lack of overall room shots — it was simply not allowed for the media. That’s cool with me; I like taking time with the smaller details, and these rooms were bursting at the seams with them. EJ20s, 4G63s, RB25/26s, 1JZs, and SR20s were lying around the shop in impeccable order, used for the production and test fitting of manifolds, turbos, and camshafts.

We asked our guide’s thoughts on the latest offering from Subaru — the FA series — and he explained that he much prefers the EJ platform. He then went on to tell us that he has a project car of his own: a V7 Subaru WRX STi. Subaru lovers, you’ll be happy to hear that Tomei hasn’t stopped the development of EJ20/25 parts, and won’t be stopping anytime soon.

We’d spent a good amount of time drooling already, but the next room was where the fabrication for Tomei’s exhaust and intake systems takes place. We were pleased to see that the fabricator is a serious enthusiast too. He loves American cars and collects Hot Wheels! Pie-cut intake pipes and exhausts were everywhere — no doubt a few products in the making. An interesting thing to note about Tomei’s workshop is that the machinery used there is all very old school. The lathe appeared to be from the ’50s or ’60s. We were told that the quality of the machine is perfect, and it’s still accurate to this day, so why change?

Up next was the engine-building room, where the race engines are assembled. Tuners such as Mine’s and Top Secret have their engines built here, a fact that I found most interesting but not surprising. After we bumped into several RB26 engines, it became clear that the development and use of this engine hasn’t died off either. We walked through the dyno room, which is being used for storage, and then our tour was over; however, the famous Japanese hospitality wasn’t. We followed one another back upstairs into the showroom, where we were presented with a gift: a goodie bag full of Tomei trinkets, stickers, and catalogues. The team thanked us in English for coming all this way from New Zealand to experience the brand, and, with that, we parted ways.

Tomei was one of the biggest surprises of my trip to Japan. With no expectation of what the visit would be like, we were warmed by the staff’s willingness to talk shop and show us their products and cars. Again, arigat¯o gozaimashita, Tomei!