A closer look at a few Kiwi innovators that deliver top-tier components locally and abroad

The world over, us Kiwis are known for our can-do attitude when it comes to almost anything. Our unwillingness to let the thought ‘it cannot be done’ beat us in our conquests has seen many of the world’s greatest inventions, especially in the motorsport and automotive sector, come to fruition. Legendary names from years gone by, the likes of Bruce McLaren, John Brittan, and Possum Bourne, are still recognized as the pinnacle of success and adorn walls of note all over the globe, not just for their driving prowess but for the innovations that they delivered to the world in order to achieve those accolades.

We’re pretty lucky in the fact that if we hit a roadblock on the way to achieving what our minds have created, there are talented people waiting for you to pick up the phone and spin a yarn — you wouldn’t be hard-pressed to find at least one person game enough to take on even the craziest of ideas. That’s not to say everything we try always works out, but it’s usually the first step towards an eventual solution that will go on to revolutionize the way things are done. Here in New Zealand, we are very lucky to have that bunch of accomplished and seriously clever people who continue to top the local market with their own innovations, and export them to the rest of the world for the simple reason that they remain unbeaten.

Be that leading the charge when it comes to perfecting cylinder-head flow with the likes of Horsepower Heads; locally manufacturing lightweight, strong and cost-effective sequential gearboxes at TT Industries; or producing the keys to building super-tough rotaries, including designs that no one else in the world has been able to replicate, such as those by Precision Engineering — tag along with us as we yarn up a storm with some of our greatest innovators to find out what they offer and how they got there.

Horsepower Heads

Horsepowerheads.com / 03 377 0974

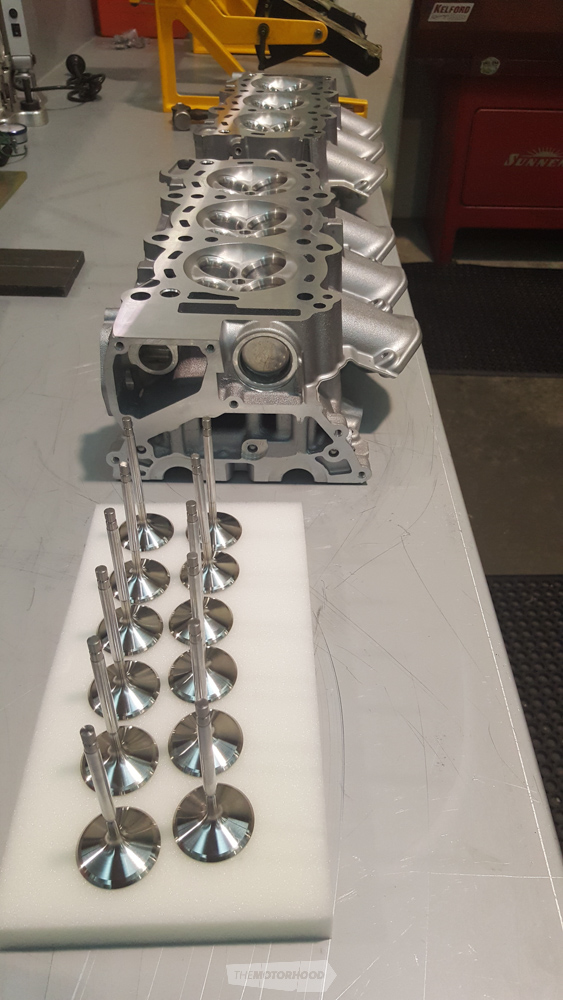

The Kiwi can-do attitude will lead us to cracking into almost anything ourselves. However, when it comes to the complex art of head porting, there’s a lot that can go wrong and see a good motor turn into a lemon really quickly. Luckily for us, there’s an innovative local company that specializes in professional CNC cylinder-head porting — Horsepower Heads.

Boasting more than 30 years of experience, founder Kevin Ban has been behind countless race wins and national championship titles, here and overseas. It started in the mid ’80s, when Kevin picked up a job at Tauranga Motor Reconditioners and qualified as an automotive machinist.

“As a teenager, a lot of my weekends were spent at Bay Park Raceway. Evenings were spent at the speedway, and days at the circuit, racing a Ford Escort at club level,” Kevin recalls. “I quickly learnt that port flow and camshafts were the key to power. I didn’t have any money to go and buy many big-brand go-fast bits, but I had use of a great machine shop, so I learnt to make and modify things myself.”

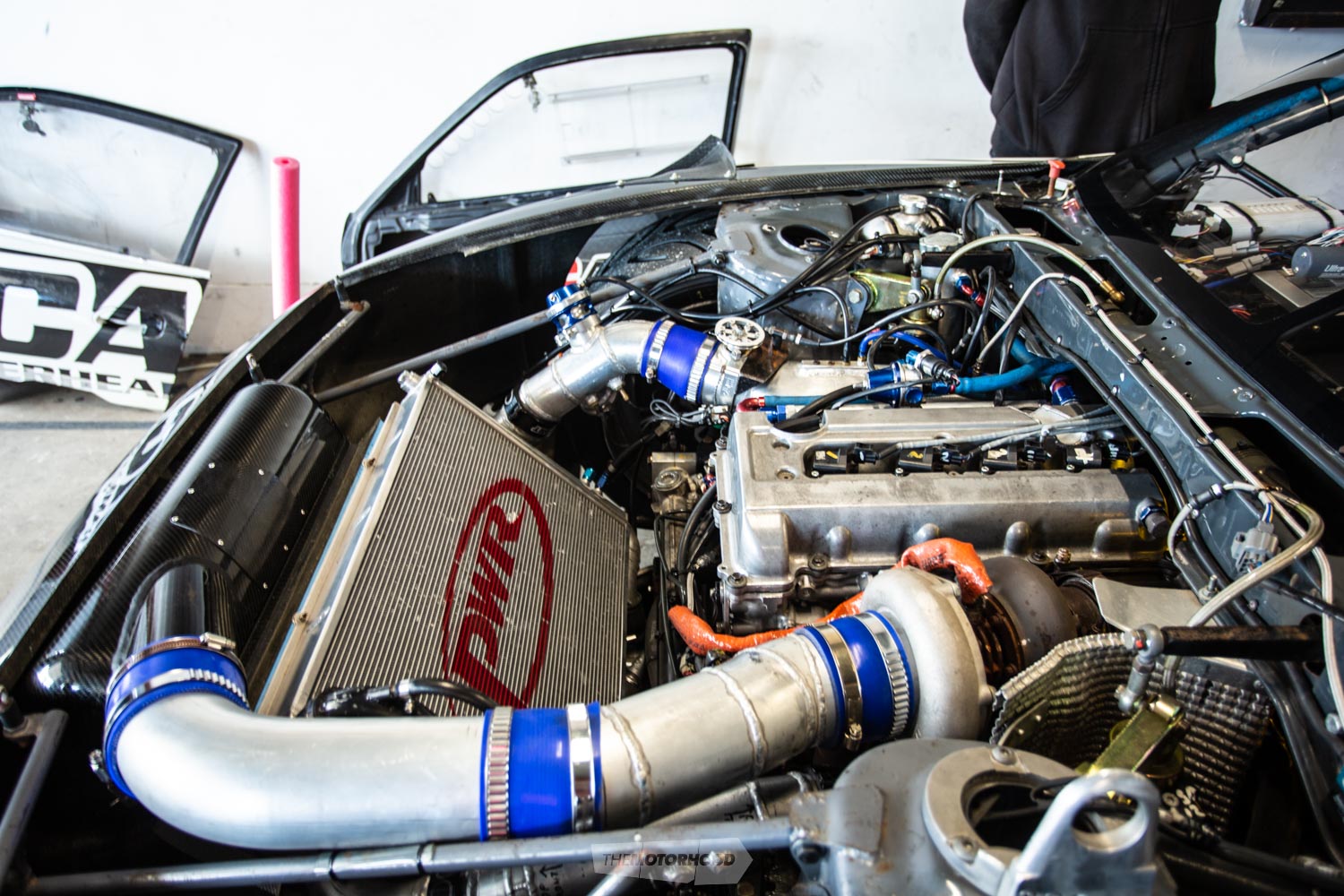

Horsepower Heads was launched in 2016. With a never-say-it-can’t-be-done attitude, the company continually innovates and doesn’t believe in following the pack. This approach has seen its work proven in New Zealand and across the ditch in some of the fastest speedway, drag racing, and Time Attack cars, including the 2017 World Time Attack Challenge (WTAC)–winning MCA Hammerhead S13.

Horsepower Heads’ passion lies in supplying world-class products and services to racers — its range of Toyota 1UZ manifolds for Super Stock racing is one good example. It offers CNC porting to suit an ever-expanding range of engines. Programmes are developed in-house to cater for your specific application. Machining is carried out on a Rottler P69 five-axis CNC machining centre that is specifically designed for head porting.

“A great cylinder head begins with good understanding of the intended purpose of the engine. We’re all about the engine maths here,” explains Kevin. “Before cutting, we design the valve and port size, as well as the port and combustion shapes to suit your needs. Each engine model we serve has many different port-, chamber-, and valve-size configurations. Most important, the programmes are flexible, we don’t try to sell a one-size-fits-all package.”

If a programme for your engine model is not available, Kevin can create it — first, by using traditional hand-porting methods and flow testing until he’s happy with the result, and then copying it into the CNC machine.

“Remember, all the best CNC porting programmes came from years of development through grinding ports by hand!” he says.

It’s easy to see why Horsepower Heads is the go-to for high-end head work, both locally and internationally. The company continues to innovate and push the boundaries by staying on top of the game with relentless research and programme development, offering undoubtedly the best services for New Zealand racers that you’ll find here or overseas.

Precision Engineering

Precisionengltd.co.nz / precisioneng2014@gmail.com / 09 415 3264

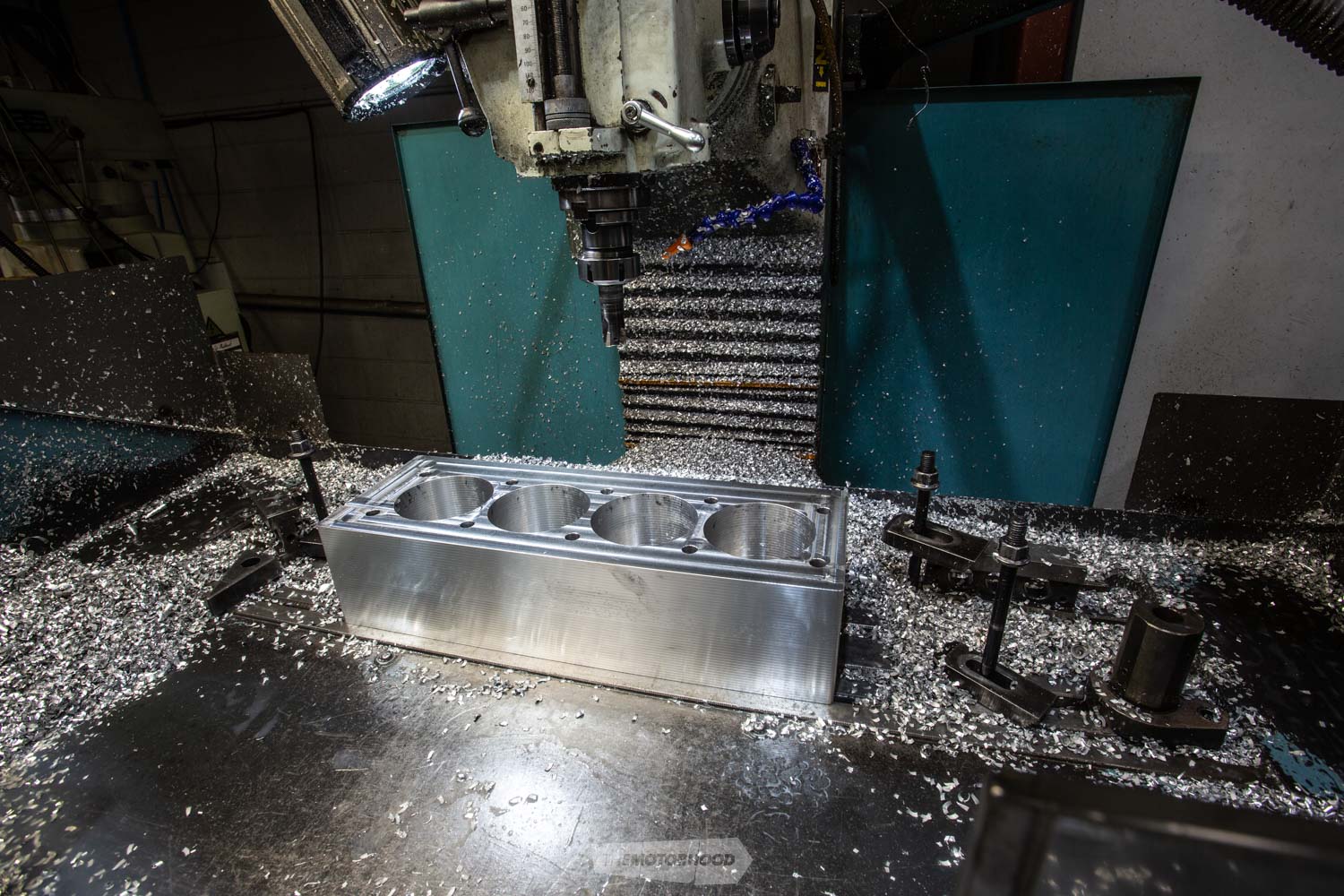

Building, or rebuilding, motors when you can still get your hands on parts from the manufacturer is all well and good, until the maker decides to pull the pin and the pieces required become gradually harder and harder to find. This is especially the case when it comes to one of the most sought-after rotary combinations, the 20B, or even in cases when we never had access to the parts in the first place — as with the quad-rotor screamers. Making the components required to enable people to build these motors requires a serious amount of engineering wizardry and know-how, and, while many have tried, almost all have failed to make the components viable, with one notable exception: the current world leader when it comes to producing aftermarket four-rotor and three-rotor short-cranks, a Kiwi-owned and -operated company by the name of Precision Engineering. You’ve probably heard of it before, seeing as its owner, Jeff Bruce, is credited with producing the first four-rotor crank outside of Mazda’s own — that original unit lived inside Bryce McEwan’s ‘FOURRE’ FD RX-7, which was featured back in NZ Performance Car Issue No. 87 from 2004 — and served as the blueprint for every aftermarket four-rotor in existence, which includes those used in Mad Mike Whiddett’s ‘MADBUL’ and ‘HUMBUL’ RX-7s, and ‘RADBUL’ MX-5.

A fitter and turner by trade, Jeff tells us that he worked for a number of engineering companies before deciding to go out on his own: “A couple of friends and I opened shops by each other, making all sorts of pieces. I started making flywheels after one guy needed one, then a friend saw it and wanted one too. All of a sudden, I was making lots,” explains Jeff. “That led into making rotary flywheels. One day, someone saw that a company in England had made a three-rotor out of two 12As and asked if I could do the same. That’s when I invented the three-rotor short-shaft that uses the 13B centre plates (50mm), but it was around the same time that the 20Bs started coming in as Jap imports, so they weren’t very popular because you could get the real thing still.”

Although, as time went on, the quantity of 20B parts began to be whittled away, and, as the unique thicker 20B centre plate (70mm) became harder to obtain, consumers looked towards the aftermarket for solutions. This was where Jeff continued to design and produce three-rotor short-cranks that meant two 13B centre plates (50mm) could be used instead of the 20B’s unique centre plate (70mm). They became hugely popular, and remain one of the most in-demand options that he offers today, along with all the unique internal parts, bar the 70mm centre plate, for the 20B. And it was from his work with these three-rotors that Jeff came up with the idea for his now-famous four-rotor design.

“You’d see the odd video of the Mazda four-rotors, but there were only 20-odd in the world, and the average person, of course, couldn’t buy one because the cars were a couple million each,” explains Jeff. “I looked at it, and to make my own four-rotor was really just an extension of the three-rotor short-crank units that I was making already. A double-ended version, but the back has a spline for a counterweight, as opposed to a taper system that Mazda uses. That’s how I made the four-rotor cranks.”

He also tells us that even the six-rotor is similar in concept: the same crank with an extra piece on each end. It sounds easy on paper, but the issue is trying to keep it straight, due to the length, when making one: “Keeping things straight is always a challenge,” he says. Although the six-rotor is what Jeff calls a “boutique” motor, with only two complete examples currently in existence: the Pulse Performance Race Engineering (PPRE) RX-4 and an M6 BMW in South Africa. A third, incomplete kit is in Australia.

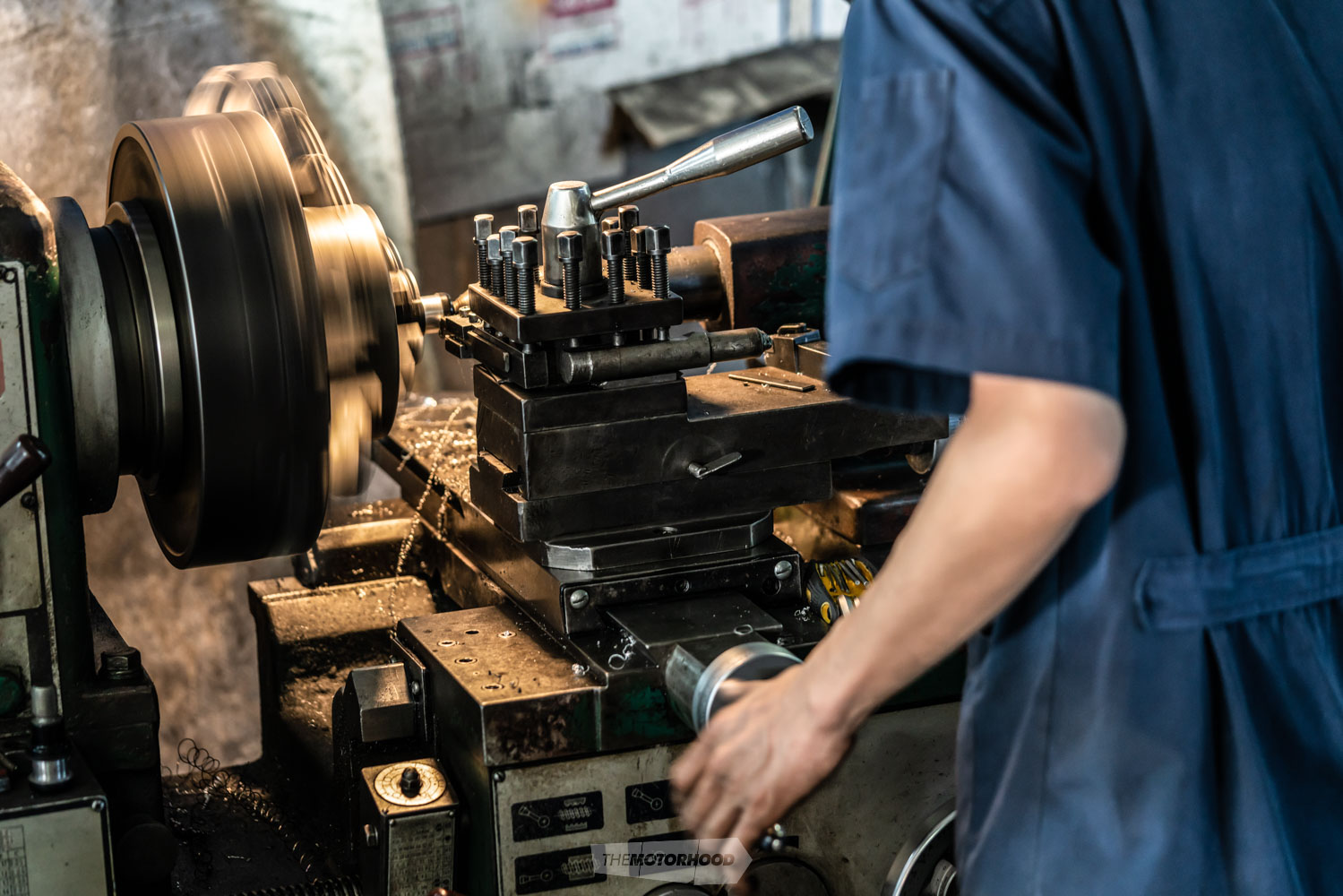

For all of his kits — which include 13B cranks; 20B cranks; three-rotor short-cranks; and, of course, the quad- and six-rotor cranks — nearly all work is completed in-house at Precision Engineering, only outsourcing the more specialized tasks, such as heat treatment. There are currently two types of crank available, an OEM-spec one, which rates roughly 31–32 on the Rockwell hardness scale, and an X40, which is hardened and toughened, suited to the likes of boosted applications, rated to 40 on the Rockwell scale. At the time of writing, Jeff is about to release the next generation, which he’s called ‘X50’, and he says it’s 30 per cent stronger than the X40, handling of boost thrown at it in testing.

“These will be available in 20B cranks soon, for all the serious customers looking to throw 80psi of boost at them,” Jeff tells us. “Especially the drag guys, who are starting to lean more and more on them!”

Precision Engineering remains the only manufacturer of commercially available four- and six-rotor cranks, despite others attempting to reproduce them overseas to no success, and continues to top the world with strengthened 13B, 20B, and three-rotor short-cranks. Precision also produces a range of rotating components — “everything that spins, we make”.

TT Industries

Ttindustries.com /03 547 1517

Transferring drive to the wheels through the gearbox is one of the most critical points in any power train, not only for the fact that they are the biggest drains on the drive that is being transferred, but also in terms of maintaining long-term reliability without overbearing the chassis with added weight. As the benchmarks of power outputs have continued to creep higher and higher, and factory units failed beyond maintainable levels, drivers and motorsport car builders looked towards the aftermarket for solutions, but, with most performance components, prices were high, weights were heavy to compensate for added strength, and options were limited. Enter Bruce Verdon at TT Industries (TTi), who, after shifting from South Africa and bringing his machine shop with him, set up the company in 2003.

An engineer by trade, Bruce had all the gear-cutting facilities needed to whip up the required components and had many years’ experience in making spline shafts, gears, and the like. “I’ve been involved with motor racing for over 40 years, and, when I got here, I had made all the pieces for them, but never made a complete gearbox,” explains Bruce. “I started out making gearboxes for Norton motorcycles, as they had a separate gearbox. That’s how I got started. I made the patterns for cases, designed my own internals, and put them in.”

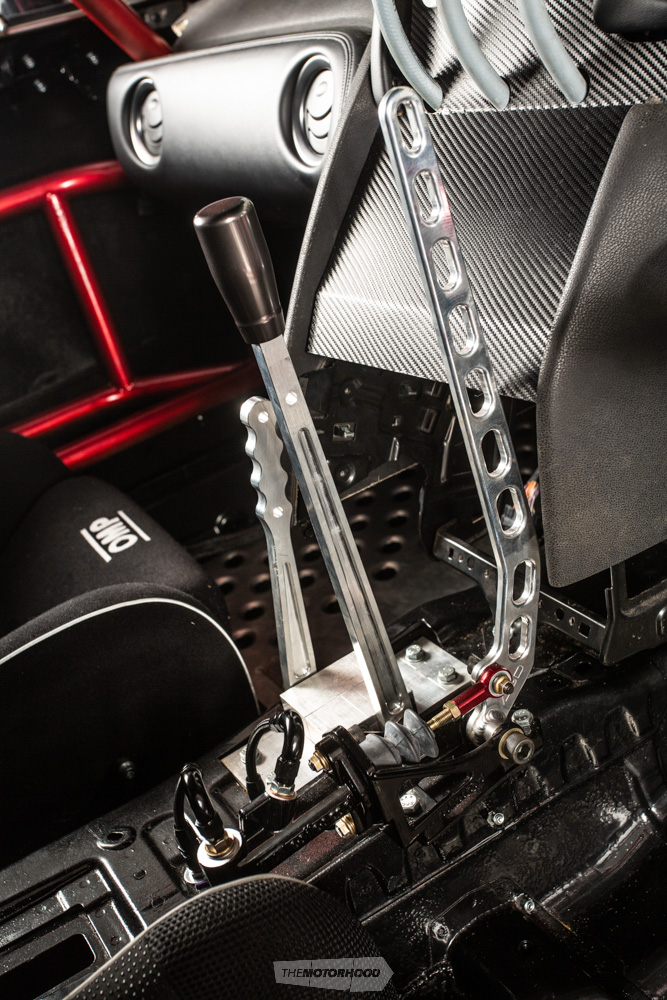

Having begun selling these in 2004, they proved to be a huge success among local riders. The internals were completely redesigned with metric bearings, a custom shifting mechanism — the works. When they started to sell rapidly overseas, Bruce switched focus to developing new options: those that could be used in car-based motorsports.

“I used the profits from the motorcycle sales to begin developing a sequential gearbox for cars. That took from 2009 until 2012 before we had a completed unit ready for the public, as we wanted to get it right,” explains Bruce. “It was important that we really tested the limits of what they could handle and only initially sold them to New Zealand buyers to ensure that any teething issues could be rectified fast and easily. Thankfully, we had done our testing right and there weren’t many issues to note.”

TTi imports all its own materials from Germany to ensure a consistently high grade of steel, and all machine work is done in-house at its factory in Nelson, while the casings are cast in Auckland to the company’s specific designs and specifications — making TTi the only New Zealand–designed and –manufactured gearbox producer in the world.

The key areas of focus for the products are a low cost for the consumer; reliability and strength; ease of installation; and, of course, being as lightweight as possible. This ethos has seen the products become popular options among the club racers, drifters, and high-end race cars, such as Andy Duffin’s Time Attack FD RX-7.

“We’ve found that the most popular options are coming from the drift sectors, both locally and overseas. It used to be the six-speed unit, but the drifters have started to prefer the five-speed now. Those are our most popular units,” Bruce tells us. “Outside of New Zealand, it’s Asia that has been buying our products mostly. For the same purpose: drifting. The feedback from over there has been great. They are very happy dealing with us.”

The gearboxes are a ‘generic’ sequential box that can be fitted into many chassis through the use of adaptors and bellhousings. For example, an SR20 conversion uses the original bellhousing, clutch, and throw-out bearing, with an adaptor to bolt everything to the TTi gearbox. Bruce adds, “It can be supplied with a linkage kit, which allows the gear levers to be mounted to where the drivers want them, where it is a comfortable position for them to shift from, and then the levers engage the levers on the gearbox itself.

“Sequential boxes are much quicker, and changing gears often gives you around a two-second lap advantage on most circuits, utilizing straight-cut gears that are designed with large teeth to be as strong as possible, meaning better reliability. If you use the gearbox properly, it is so much quicker. It’s an absolute dream to drive a sequential.”

The TTi gearboxes are available for a massive range of engine and chassis options. Bruce tells us that those used for RB applications were initially the most popular, but there has been a switch to 2JZ applications in more recent times. He is constantly watching current trends to develop the bellhousing and adaptors for anything that hasn’t already been requested, and all the bellhousing and adaptor packages are compatible with the TTi four-, five-, and six-speed gearboxes. They also keep a full stock of spare components on the off chance that you manage to break something or simply to rebuild them back to new in-house at TTi at the end of a race season — a process that sees the designs constantly accessed and scrutinized to ensure optimal performance.

So, when it comes to bang-for-buck performance, ease of access, repair, and constant development, you cannot go past what TTi is doing for us locally and the reputation they’ve built for Kiwis overseas.

This article originally appeared in NZ Performance Car issue No. 265