We all have build ideas burning away at the back of our minds, but it’s not often that we have the impetus to build each and every one of them

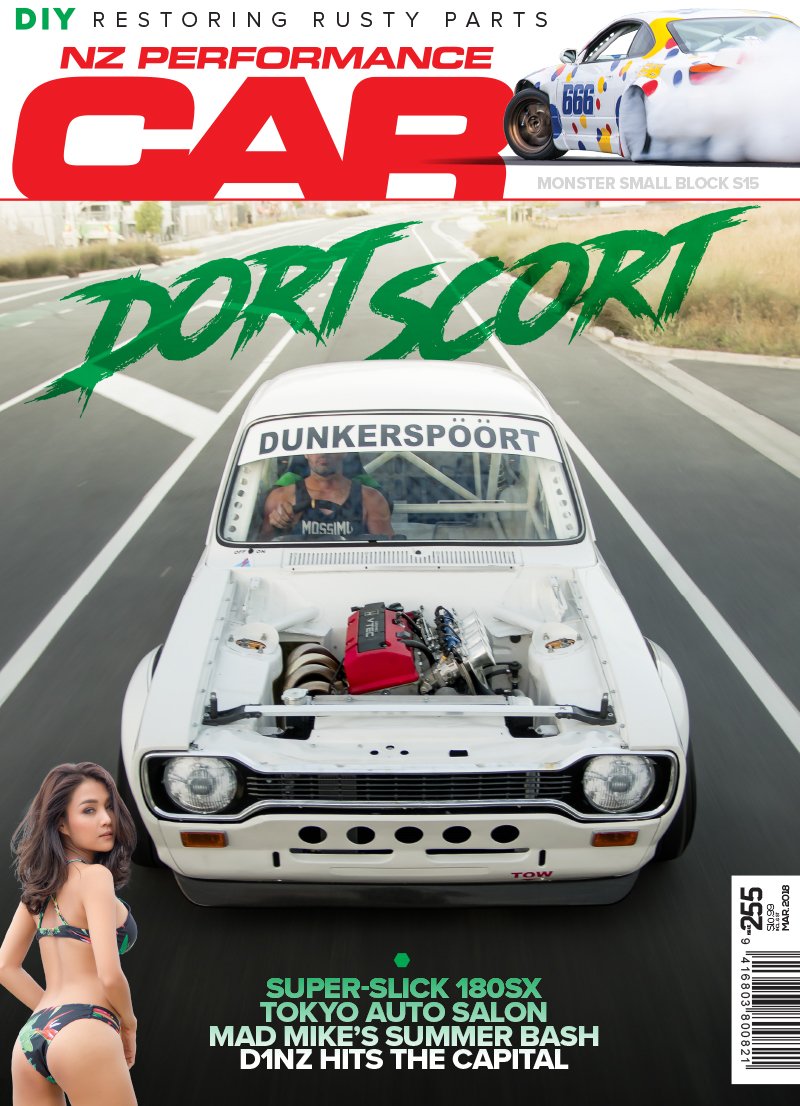

We lost count at 150,” a good mate of Brendan Duncker exclaims, as the friends do their best to recount the number of cars that Brendan has owned and built over the years. Even if he were nudging 80 years old, that would be a staggering figure, but he hasn’t even reached half that age. However, we aren’t here to recall the cars that have come before it or the ones that will inevitably come after; what we have come for is to see his latest creation, a project Brendan tells us that he had been wanting to build for a very long time: taking an old chassis and injecting in a modern driveline, with the purpose of swapping lock to lock while frying tyres. It’s an idea that he has carried since his first car, a Mk1 Lotus Cortina replica.

Although he’s a bit of a Toyota specialist these days, as the man behind Niteparts and Convert Motorsports, in his early years, he owned a real mixed bag — everything from rotaries to Anglias and Escorts. “I started doing a little research and found that an Escort’s wheelbase was exactly the same as an AE [86’s], and then, with the bubble arches, it’s the same width as well,” he says.

This was the green light that Brendan needed, because, with his extensive knowledge in setting up AEs to drift, he knew that the concept would not just work but work well. The search began for a Mk1 shell, and just in the nick of time, as prices were beginning to sky rocket: “I managed to find just a bare shell, which was all I really needed. I thought that it was going to be hell, but then I started bare-metaling it; I soda blasted it, then had it sandblasted, and I found it was pretty good underneath. I had Dean Smith help me smooth a couple [of] bits, and it had a tiny lead repair from the ’70s, but, apart from that, it was mint, which was kinda the icing on the cake, as usually these things are well rotten.”

The one area that did need attention was the floor, which needed a compete repro stiched in. Not bad for a near-on 50-year-old piece of Ford engineering, really. With the minimal repairs out of the way, it was now on to the good stuff of building a race car. Power was never going to be excessive, and whatever was lacking there would be made up for with a lack of mass.

Brendan would subscribe to the school of featherweight. Fibreglass adorns each corner, the bonnet, the doors, and the boot, and even these lightweight pieces have had their innards chopped to the nth degree. This is where the old-school tech melts with the new school. A side effect of this weight loss is bang-on aesthetics, reminiscent of any old Escort racer. “I’ve taken out everything that I could. It’s super simple compared to the green car, which I spent ages doing all the little trim bits on,” he says.

The green car Brendan mentions is one that you’ll probably remember. We mean, who can forget a vivid green 18A three-rotor-powered AE86? That project played a big role in building Duncker’s knowledge base, a forerunner to this Escort, which has plenty of the same wizardry recreated underneath.

It’s now a mix of Ford, Toyota, Nissan, Honda, and custom parts all working in concert. The front cross member — an AE86 power-steering item — has been cut and shut to suit the Escort rails. Each sprung assembly is made up of Niteparts HyperLock3 knuckles with rose-jointed and boxed S14 lower arms, and Chaser castor arms. Even the Parts Shop Max coilovers belong in a Silvia, as do the brakes. It’s a package that he has run in AEs countless times, but the bonus in the Escort chassis is the significantly narrower chassis rails, which equals one thing: more lock.

“The stock-width AE86 diff housing utilizes a billet full spool and big axle kit from Weir Performance. The four-link and Watt’s link are lightweight alloy and completely adjustable for dialling in grip”

In the rear, the AE parts continue, with a stock-length AE86 diff housing stuffed full of some killer parts from Weir Performance in the US, with Weir’s billet full spool and big axle kit. A custom four-link utilizing lightweight alloy arms also uses a Watt’s link to control side movement, and those S14 coilovers are mounted high inside the chassis. With a lack of weight pushing the car downward, all of this adjustment creates the grip needed.

“With a light car, it’s so different to drive,” says Brendan. “When they are set up right, you can use the throttle to push off if you need to. It all comes down to throttle application; it’s a strange feeling, but it’s cool, and definitely fun. There is also a good amount of scrub off being this light.” The exact weight is estimated to be around 100kg lighter than his AE, meaning it weighs in at around 700kg, making it insanely light. Masses of power were never going to be required.

Brendan recalls that the impetus for running the Honda F20C first came during his D1NZ competition days: “Me and Jock Bennet used to race down the back straight of Puke when I had a built 3S-GE and he had a stock F20C. His AE had a full-steel body and I was all fibreglass, yet we would be neck and neck.” Originally, it was going to be kept simple with a stock manifold and even stock ECU, but, once he decided to wire in a Link G4+ Monsoon, a set of OBX individual throttle bodies (ITBs) soon followed. But, inside, the engine remains factory, with any changes external.

On the hot side of the engine, some of Duncker’s signature headers can be found, which weave their way around the steering shaft and under the car. They run four into two, into one, merging just under the driver’s seat. Typical of his headers, they feature a conical design with an expansion chamber just after the merge, and, of course, they are equal length. “I learnt a lot doing the 3S in the green car before I did the three-rotor. It’s amazing what you can get in rpm and be able to pull out of something kinda conservative just by changing the way the headers work,” he says. As a little added security, there’s also a NOS system, which will deliver an 80hp (60kW) shot at high rpm. It will allow the wheels to spin a little harder when most required.

“Speed holes are a weight-loss staple; even the fibreglass panels haven’t escaped the hole saw”

At the time of writing, the car is all ready to spin the rollers at GDS Performance, so a figure can’t be given, but the fact that it’s basically a stock F20C with nothing more than BC valve-spring retainers, a figure between 186kW and 224kW should flash up on the screen — just enough to deliver the kind of power-to-weight ratio that will never fail to bring a smile to the driver’s face.

As it turns out, that driver might not be Duncker, as he has already had people banging on his door wanting to own it. If he decides to keep it, even in the interim, the options for its use are wide open. “It’s very close to being D1 legal now,” he says. “I was intending to do Pro-Sport and have some fun, but I think, now, and for the time and effort I’ve put into it, it’s more for having fun.”

Competition or not, whoever gets to sit behind the wheel is clearly in for one hell of a ride. It just goes to prove that you don’t have to choose a typical chassis for a drift project; it all comes down to the set-up.

Brendan Duncker

Age: 38

Location: Auckland

Occupation: Technical manager at D1NZ and owner of Niteparts

Build time: One year

Length of ownership: Two years

Previously owned cars: All of them

Thanks: Tarran, Nick, and Chuckie at S Club; JP, Beau, and Jase at RDevelopments; Dean at Mobile Panel; Nick and the NST team; Chris at Strongs; Jerry at Big Brown; Glenn at GDS Automotive; and, of course, Billy, Mav, and Rick

It’s clear that Brendan is a perfectionist. Although he classes this build as very basic in terms of the finer details, each little piece has been executed to perfection

Heart

ENGINE: Honda F20C, 2000cc, four-cylinder

BLOCK: Factory

HEAD: BC valve-spring retainers

INTAKE: 50mm OBX throttle bodies, OBX port-matched manifold, Pipercross air filter

EXHAUST: 2.5-inch stainless, Niteparts four-into-two-into-one equal-length headers, single rear muffler

FUEL: 25-litre cell, DeatschWerks pumps, custom surge tank, 480cc Siemens injectors

IGNITION: Factory

ECU: Link G4+ Monsoon

COOLING: Dual-pass alloy radiator

EXTRA: 60kW NOS direct-port kit

Driveline

GEARBOX: Honda S2000 six-speed (pre-facelift)

CLUTCH: Toda Hyper single-plate

FLYWHEEL: 3.5kg Toda billet

DIFF: Toyota AE86 (4.3 ratio), Weir Performance billet full spool, Weir Performance billet axle kit

Support

STRUTS: Parts Shop Max S14 coilovers: (F) 6kg spring, (R) 4kg spring

BRAKES: Wilwood pedal box, bias valve, hydro handbrake; (F) S14 calipers and rotors, (R) S14 calipers and rotors

EXTRA: Modified AE86 front cross member, AE86 steering column, Holden Astra power-steering pump, Niteparts adjustable alloy four-link, Niteparts adjustable Watt’s link, Niteparts HyperLock3 knuckle kit and lower control arms, JZX110 castor arms

Shoes

WHEELS: 15×9-inch Rota RKR

TYRES: 195/50R15 Dunlop Star Spec II

Exterior

PAINT: Resprayed in Ford Diamond White

ENHANCEMENTS: Fibreglass bonnet, guards, doors, wing and boot; carbon-fibre front chin spoiler; Mike Shaw fibreglass headlight covers; Big Brown Mexico strips; Lexan windows

Interior

SEATS: Recaro SPG

STEERING WHEEL: OMP

INSTRUMENTATION: Tablet PC

EXTRA: Carbon-fibre dash, 10-point roll cage

This article originally appeared in NZ Performance Car issue No. 255 — you can get your hands on a print copy by clicking the cover below: