GM’s LS series of aluminium V8 engines has been a breath of fresh air in the V8 performance market over the last decade. Love it or hate it, the LS engine family has taken the world by storm. Moving on from the success and popularity of the classic small-block Chev, GM applied some new technology in the form of EFI to a proven and reliable concept. The result was a modular series of V8 engines that have taken GM into the modern age and spawned a massive aftermarket focused on getting the most out of these engines.

While some modern technology has crept in, one aspect that the LS family shares with the old small-block Chev engine is pushrod valve actuation. In a modern world obsessed with efficiency, this seems like a backward step, but you can’t argue with the results. The deliberate move by GM engineers to retain a pushrod OHV engine design has resulted in a lightweight and compact engine package. You only need to compare the engine with something like the quad-cam Ford Coyote engine to see this first-hand.

What the LS gives up in outright efficiency, it makes up for in capacity, and, if you are looking at an engine swap, the LS V8 is one of the easiest and most cost-effective options available. The basic design of the LS V8 includes a strong and reliable alloy block with race-inspired six-bolt main bearing caps. The basic strength has been one of the reasons why the LS has been so popular with enthusiasts, easily supporting the addition of superchargers or turbos.

With huge support from aftermarket manufacturers as well as factory support from GM itself, buying, modifying, and tuning an LS V8 really is almost too easy. For those new to the LS family, though, the wide range of variants can seem confusing, so here’s the low-down.

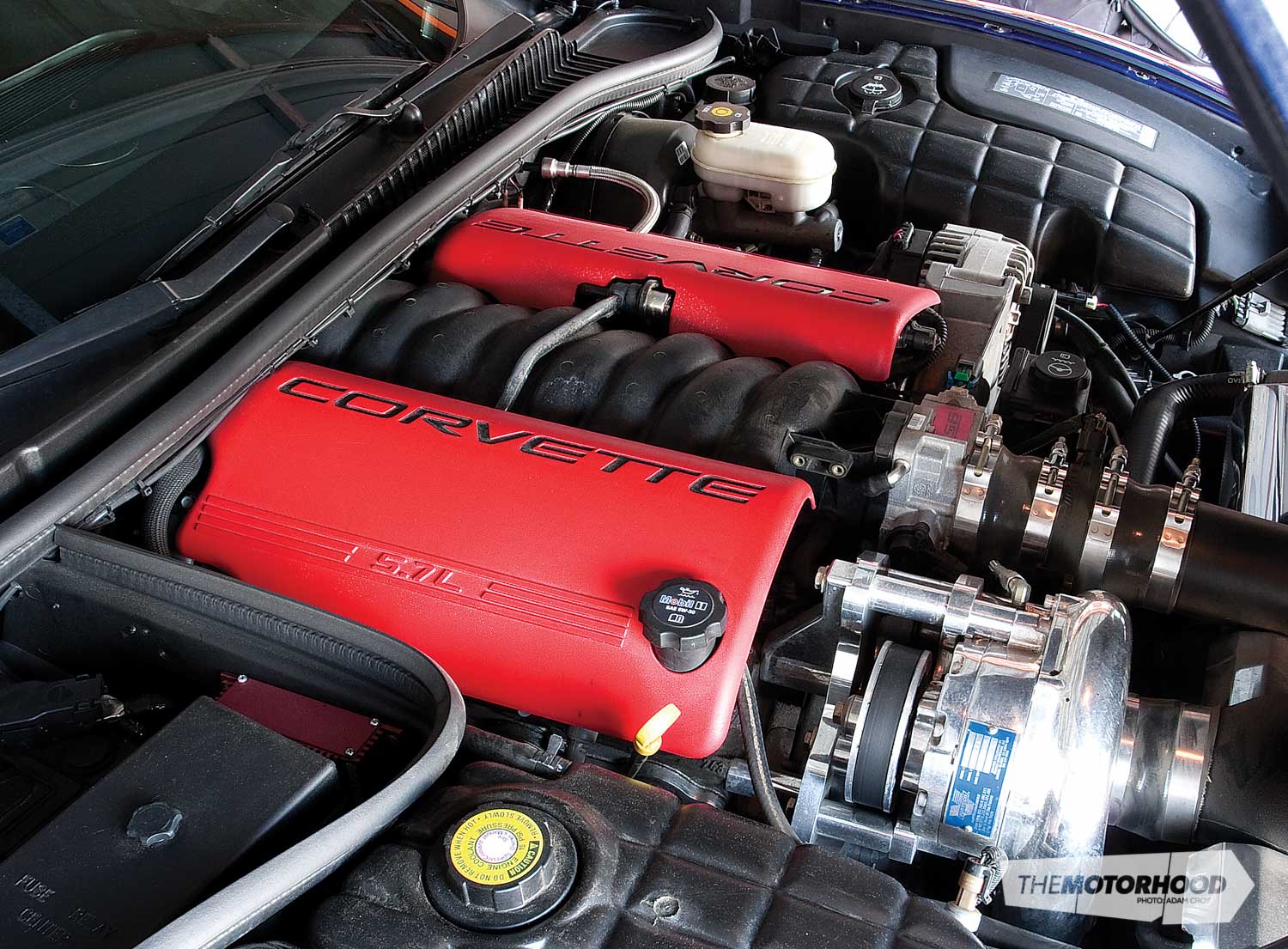

LS1

The LS1 was the first of General Motors’ Gen 3 engines to meet worldwide acclaim, and is possibly the most recognized and acknowledged model in the LS line-up. Displacing 5.7 litres, thanks to a 99mm bore and a 92mm stroke, it produces anywhere from 220kW to 285kW, depending on the specific model and year of manufacture. A special Callaway modified variant known as the C4B was also produced in limited numbers, and produced 300kW. The LS1 is fitted with cathedral port cylinder heads and has a compression ratio of 10.25:1.

Produced: 1997–2007

Found in: VT-VZ Holden/HSV, Camaro, Corvette, Pontiac GTO, Pontiac Firebird

Power: 220–285kW (300kW for Callaway C4B variant)

Torque: 446–520Nm

What is a six-bolt bottom end?

Supporting the crankshaft is critical to the reliability of any engine. Normally the crankshaft journals are supported by a bearing cap, which is bolted into the engine block. The most common way of bolting the bearing cap to the block is with two bolts (one either side of the crankshaft). In performance applications, it is common to use four bolts (two per side) or six bolts (two per side with a further two cross-bolts through the side of the engine block) to provide the ultimate support.

LS6

The LS6 was a higher performance variant of the LS1, introduced for the C5 Corvette Z06 from 2002 to 2004. The LS6 retains the same basic architecture as the LS1, as well as the LS1’s capacity of 5.7 litres. The increased performance came from a more aggressive camshaft design with greater lift and duration as well as a higher compression ratio of 10.5:1 and a higher flowing MAF sensor.

Produced: 2002–2004

Found in: C5 Corvette Z06

Power: 302kW

Torque: 540Nm

LS3

The LS3 is a further refinement of the LS2 engine package, taking engine capacity to 6.2 litres thanks to a 103mm bore. One of the biggest improvements on the LS3 was the move to the rectangular port cylinder heads shared with the L76/L98 engine. These offer improved flow over the early cathedral port LS1/LS2 heads. Compression ratio in the LS3 is 10.7:1.

Produced: 2008–2013

Found in: Corvette, Pontiac G8, VE, HSV, Camaro SS

Power: 317–325kW

Torque: 570–580Nm

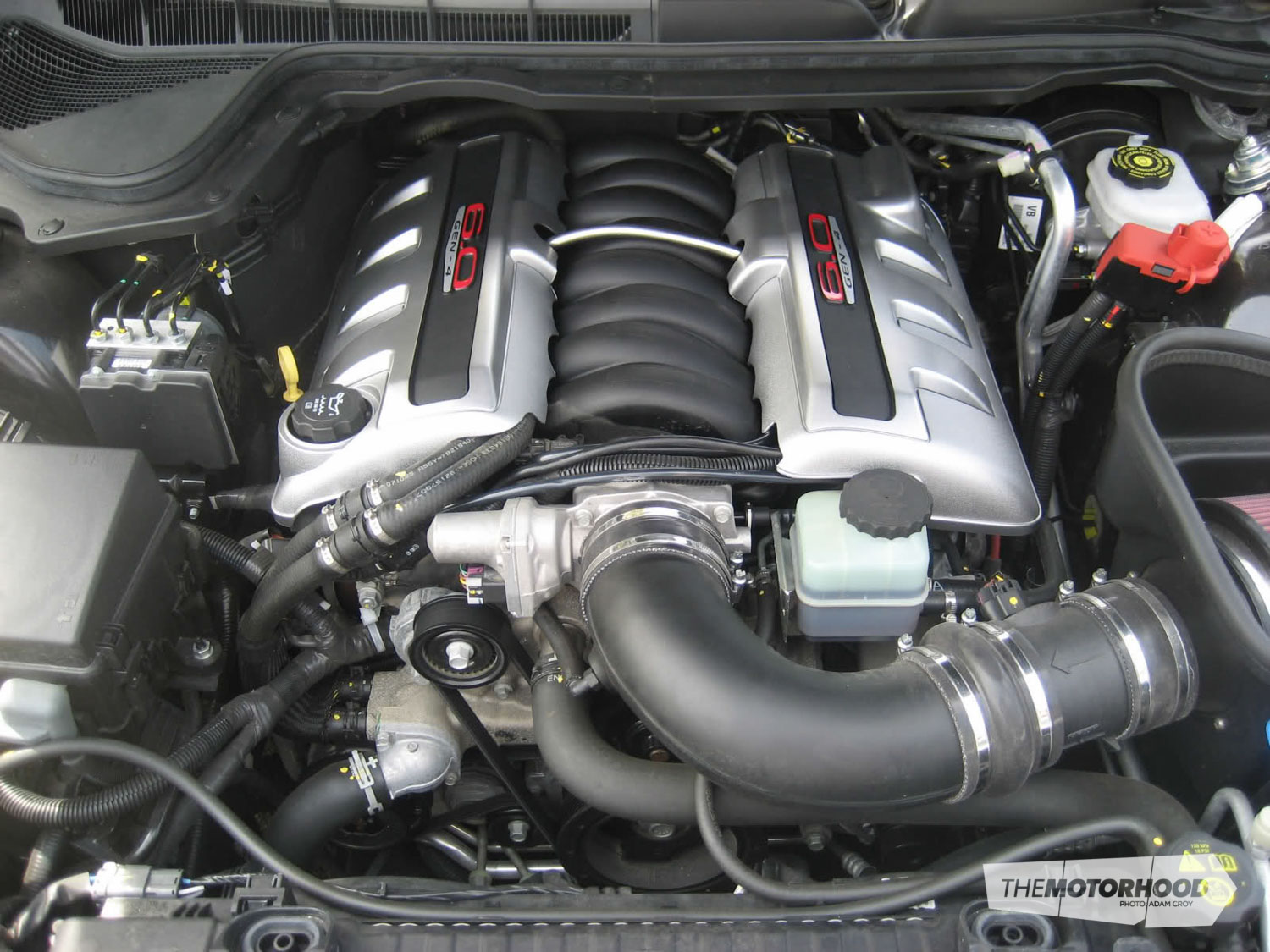

LS2

In 2005, GM superseded the Gen 3 engine series with the new Gen 4 series. The LS2 is closely related to the architecture of the LS1, but enjoys a larger 6.0-litre displacement. The LS2 gains its extra 300cc of capacity thanks to an increased bore (now 101.6mm). The compression ratio was also increased to 10.9:1.

On this side of the world, the LS2 is most commonly found in the HSV VZ-VE models, while in the US the engine was fitted to a wide range of chassis, including the Chevy Trailblazer, Cadillac CTS-V, and Pontiac GTO.

Produced: 2005–2008

Found in: HSV VZ-VE, Pontiac GTO, Cadillac CTS-V

Power: 300–307kW

Torque: 542–550Nm

L76

The L76 is a variation of the LS2 made specifically for Holden Australia’s requirements. The L76 engine retains the 6.0-litre capacity and adds displacement on demand (DOD), which is also known as active fuel management (AFM). This technology allows four cylinders to be shut down by the ECU during cruise situations to improve fuel economy. The cylinders are shut down thanks to a special set of hydraulic lifters.

The L76 is a mixed bag, as it benefits from the same high-flowing rectangular port cylinder heads as those fitted to the LS3 and L98, but suffers from a conservative camshaft design that was required to work with the AFM. The result is that the L76 produces 10kW less power than the almost identical L98.

The AFM system is a pain if you intend to fit a performance camshaft, as you will need to replace the special AFM lifters with a conventional set, adding significant expense to the job.

Produced: 2006–2010

Found in: Holden VZ, VE Commodore, Pontiac G8

Power: 260kW

Torque: 510Nm

L98

The L98 is a modified version of the L76 with the AFM hardware removed. The L98 still retains a capacity of 6.0 litres, as well as the high-flowing rectangular port cylinder heads from the LS3/L76. Thanks to a slightly more aggressive cam profile than the L76, the L98 produces 270kW.

In stock form, the L98 produces less power than the similar LS2 engine due to the more conservative camshaft design. With equal cam profiles, the L98 outperforms the LS2 thanks to the superior head flow. These engines are what you will find in most VE Holden Commodores.

Produced: 2006–2010

Found in: Holden VZ, VE Commodore

Power: 270kW

Torque: 530Nm

LS7

The LS7 engine takes the Gen 4 LS block architecture to the limit, working on the principle that bigger is better. The LS7 achieves a capacity of 7.0 litres, thanks to an increased stroke of 101.6mm and a bore of 104.8mm. The LS7 block uses

pressed-in sleeves to achieve sufficient block strength with the larger bore.

The crankshaft is forged steel, as are the main bearing caps. To reduce reciprocating weight, the connecting rods are made of titanium. Despite the engine’s capacity and long stroke, it offers a high factory redline of 7000rpm and, in its native Corvette Z06 chassis, it is also equipped with a

dry-sump lubrication system. The LS7 is the same engine chosen by the V8 SuperTourer class.

Produced: 2006–2014

Found in: Corvette Z06, Camaro

Power: 377kW

Torque: 640Nm

LSA

The LSA is a 6.2-litre variant with close similarities to the LS9 engine. Notable differences include the use of a smaller 1900cc supercharger, and a slightly reduced compression ratio of 9.0:1. The LSA is the engine chosen by HSV to power the range-topping VF GTS, with a power output of 430kW and 754Nm.

Produced: 2009–2013

Found in: HSV VF GTS, Cadillac CTS-V

Power: 415–430kW

Torque: 747–754Nm

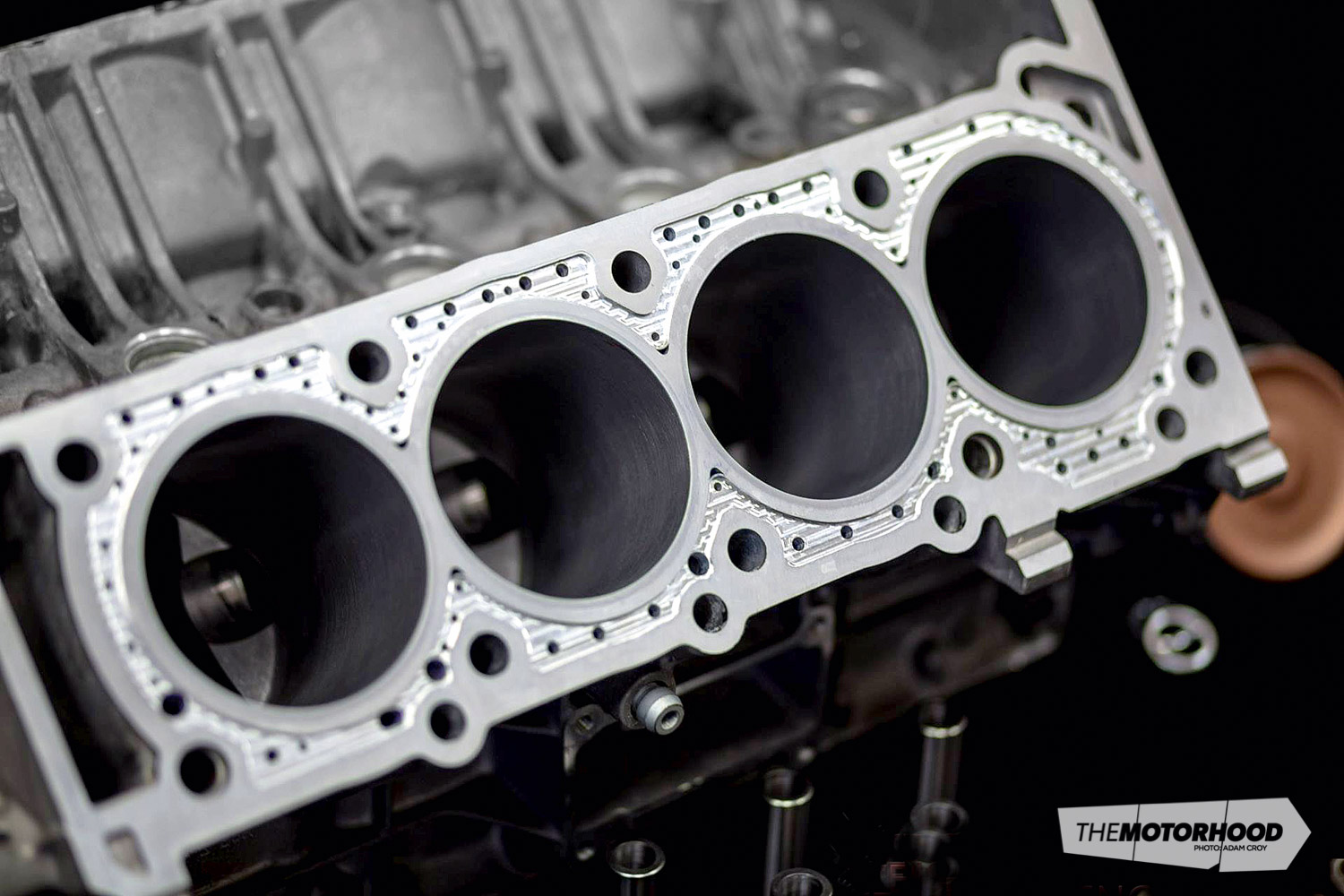

Sleeved blocks

The alloy block of the LS engine is nice and light, but it is also weaker than an iron block. In very high power applications, this can allow the bores to distort, leading to head gasket failure and even cracking of the bores. A common approach to fixing this is to machine out the factory alloy cylinders and fit ductile iron sleeves in their place.

Ductile iron is much stronger, improving block strength; however, it is an expensive exercise and has its own set of risks, such as the sleeves dropping, which results in the head gasket leaking.

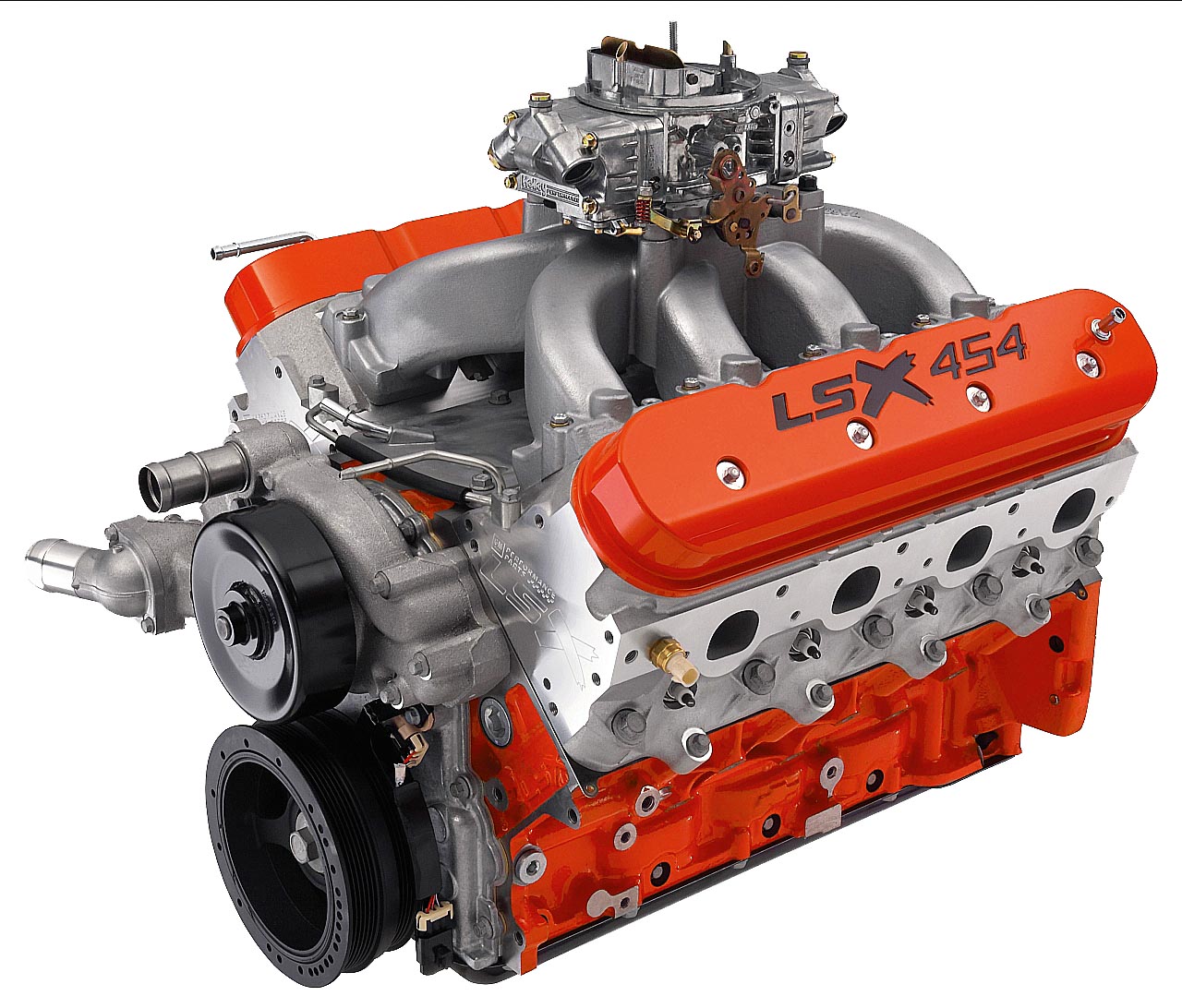

LSX

With the popularity of the LS range of engines, and their universal adoption for just about any performance application — from street rods to purpose-built drag vehicles — the limits of the alloy LS block can become a problem. While the lightweight alloy block is one of the engine’s advantages, it can also be its downfall. Aluminium just doesn’t have the strength and reliability when you start bolting on serious superchargers, big turbos, or a large shot of nitrous.

While conventional aftermarket fixes for this are available in the form of ductile iron sleeves, buying and fitting these is an expensive exercise, and some sleeved blocks continue to give trouble, with the liners or sleeves dropping and affecting head-gasket seal. In 2006, GM Performance Parts addressed the problem by releasing the LSX block.

The LSX block follows the same bore spacing and bolt pattern as a conventional LS alloy block, but uses cast-iron material for improved strength. Performance-oriented features include extra-thick cylinder walls, allowing for bore of up to 106mm, a thick deck surface, an extra head stud per cylinder for improved head clamping, priority oiling for the main bearings, and billet six-bolt main caps located by dowels.

GM Performance Parts offers the LSX both as a block only and as a complete crate engine. The LSX block is rated as being capable of supporting 1865kW (2500hp).

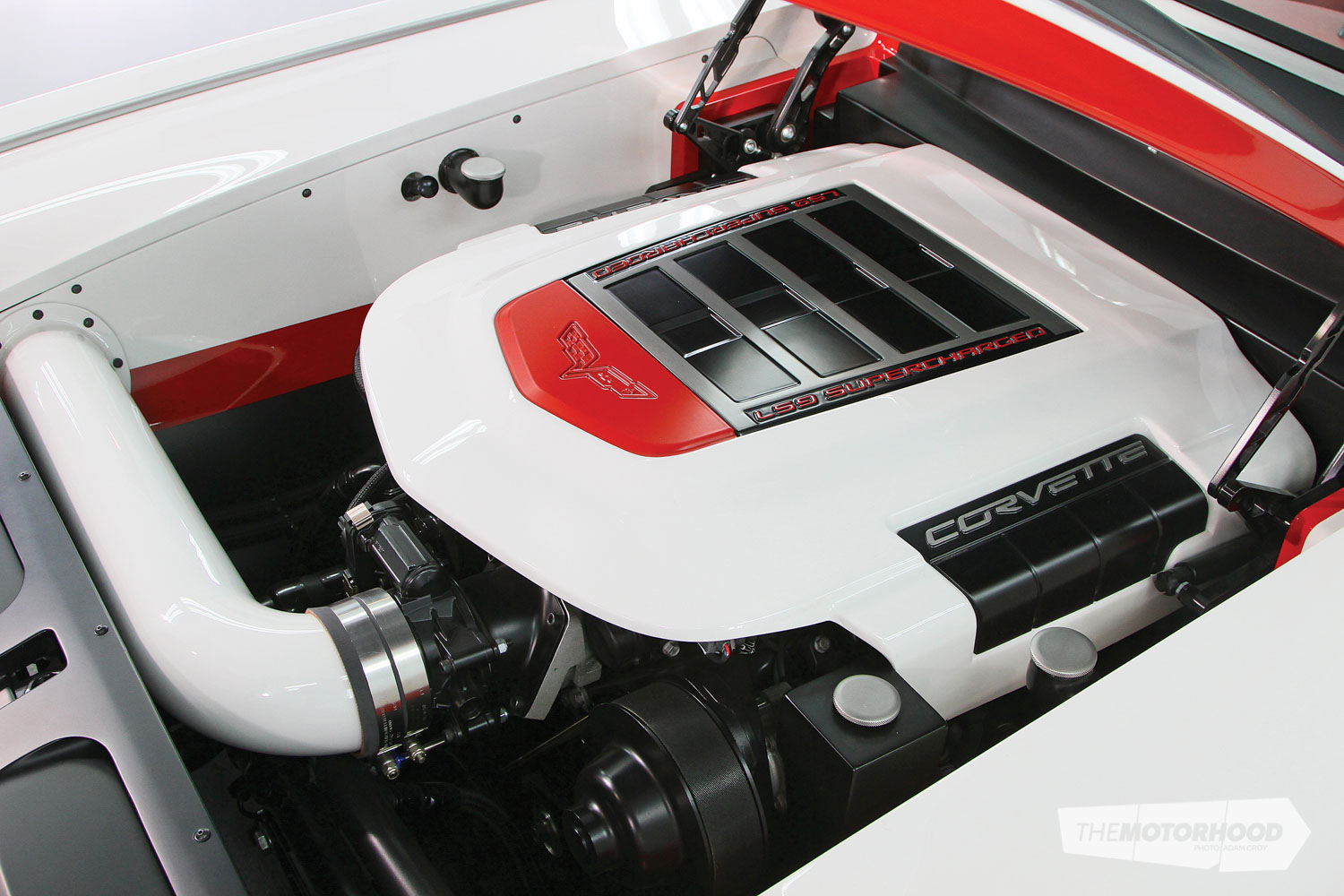

LS9

The LS9 was built for the Corvette ZR1 and was designed from the ground up with supercharging in mind. The basis for the LS9 is the 6.2-litre LS3 block with a 103mm bore. Compression ratio was dropped to 9.1:1 to handle the forced induction, which was supplied by a 2300cc Eaton positive displacement supercharger.

Produced: 2009–2013

Found in: Corvette ZR1, Hennessey, Venom

Power: 476kW

Torque: 819Nm

LQ9

While not so common on our side of the world, the LQ9 is achieving some impressive results in the US, where it is both more plentiful and considerably cheaper than its alloy-block cousins. Designed as a truck engine (Chev Silverado, etc.), the LQ9 shares many similarities with the LS-series, but the LQ9 uses a cast-iron block. In a truck application, the extra weight of cast iron isn’t an issue, but in the performance aftermarket world, the LQ9 block offers a significant strength advantage over the alloy LS block. Think of it like a budget-spec LSX block, and you will be close to the mark. While its output in stock form is nothing to write home about, it really comes into its own once you add turbos, a supercharger, or a large shot of nitrous. The LQ9 shares the same bore and stroke as the LS2, and uses a 10:1 compression ratio.

Produced: 2002–2007

Found in: Cadillac Escalade, Chevy, Silverado, GMC Sierra

Power: 257kW

Torque: 515Nm