Lock your girl’s DMs, because Fritz Leaning is bringing the heat to a street near your house with his 400kW carby-fed quad-rotor

Project cars — most of us have a love-hate relationship with what are essentially our grandest dreams embodied in metal shapes either sitting in the shed or rotting on the driveway. While it’s all fun and games to undertake any project and get your teeth stuck in, the reality is that it’s going to take three times longer than you expect, and you’re generally going to be missing out on a ton of fun that your mates are having during that time. You’re forced to ride scrub in their cars, dreaming of the day that you, too, can join in, knowing all too well the mammoth task that awaits you at home.

Fritz Leaning is no stranger to building cars; he’s had his fair share over the years, all with a healthy dose of style and a hint of death machine thrown in. His most ambitious was a Mk3 Supra he was building from the ground up, which wasn’t going to be finished any time soon. The fast approach of summer 2015 led to the creation of one badass FD. “I had always wanted an FD, and the Supra was so far from being finished that I decided to just bite the bullet and get one to have some fun while I built the Supra,” he explains.

Picking up a standard black S6 from a local dealer, Fritz got straight into ‘ruining’ a perfectly fine stock example in the only way he knew how: slamming it on a set of big-dished wheels and slapping on the widest of all kits — the BN Sports — before giving it lick of Jet Black. Summer was sorted — or so he thought. Three months into his ownership, while rolling the Mount, things all came to a grinding halt due to a pesky injector issue that was unable to be remedied easily, thanks to Mazda’s over-complex engineering of the 13B-REW.

The 26B is predominantly made up of S6 FD parts, including plates, rotors, and housings. The centre plates have been modified to take stationary gears, something that they do not hold in two-rotor applications. The housings have also had 43mm PP sleeves added. The crank itself is of a three-piece design that allows the two outer lobes to bolt on during engine assembly

Fritz was back to having no running car — only, this time, he’d doubled his driveway burdens. The FD sat for some time while he mulled over what to do. His mind started to wander in the direction of engine builds, and, after chatting to a mate, Willy, things quickly escalated from building a single-turbo 13B, to a 20B, to going all-in and building a 26B peripheral-port (PP).

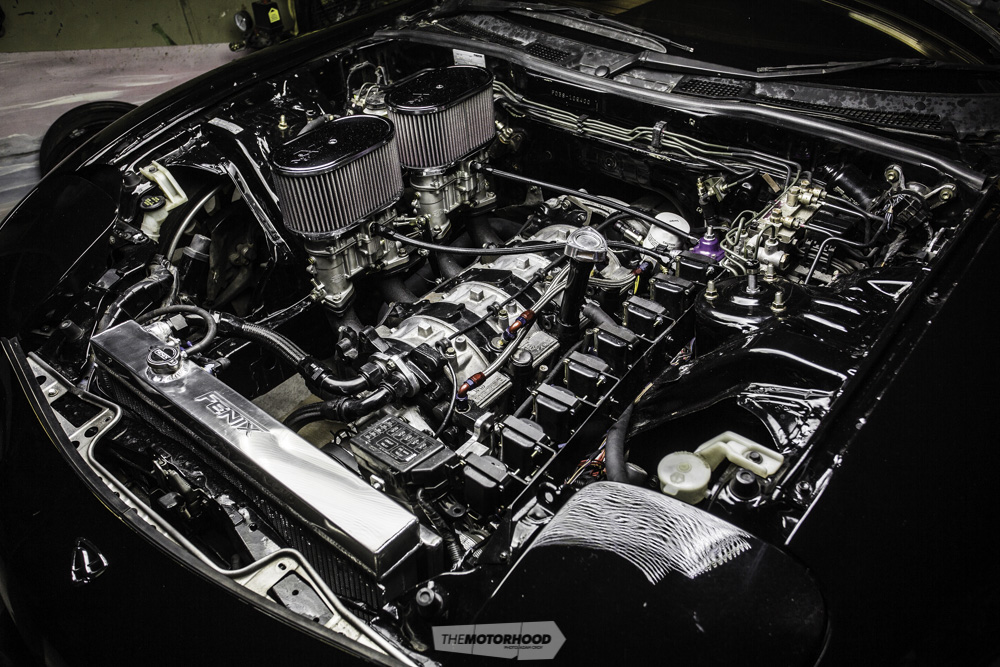

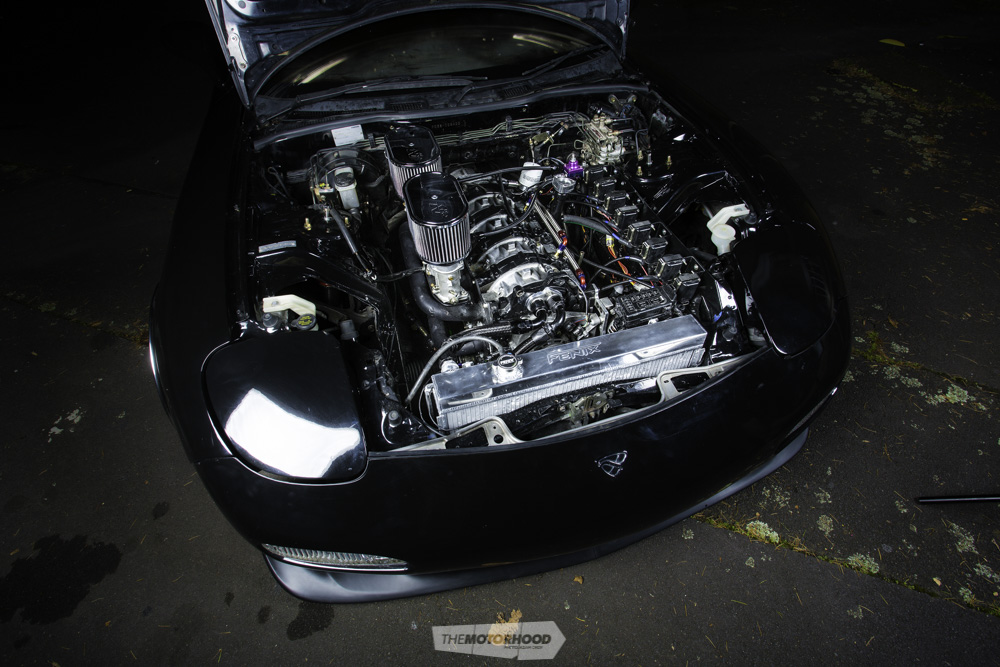

The plan was to do things a little out-the-box and run a pair of IDA carbs to keep costs down. Using the remains of the FD S6 block, Willy got to work piecing together his first ever 26B. Jeff from Precision Engineering was tasked with carving a piece of billet steel into one of his three-piece cranks, while also inserting the 43mm PP sleves of Willy’s design into four S6 housings, and modifying the centre plates for stationary gears.

While the engine was apart, the oil galleries were modified to ensure good oil flow, as the boys planned on avoiding the need to dry sump the engine. Oil feeds send oil directly to each stationary gear, ensuring that the heart of the beast is well protected at all rpm. Pushing the factory oil pump to lube twice the real estate was a bit of an unknown, so, rather than risk bolting the motor straight into the FD, it was run in and tuned on an engine dyno to ensure all was working in harmony.

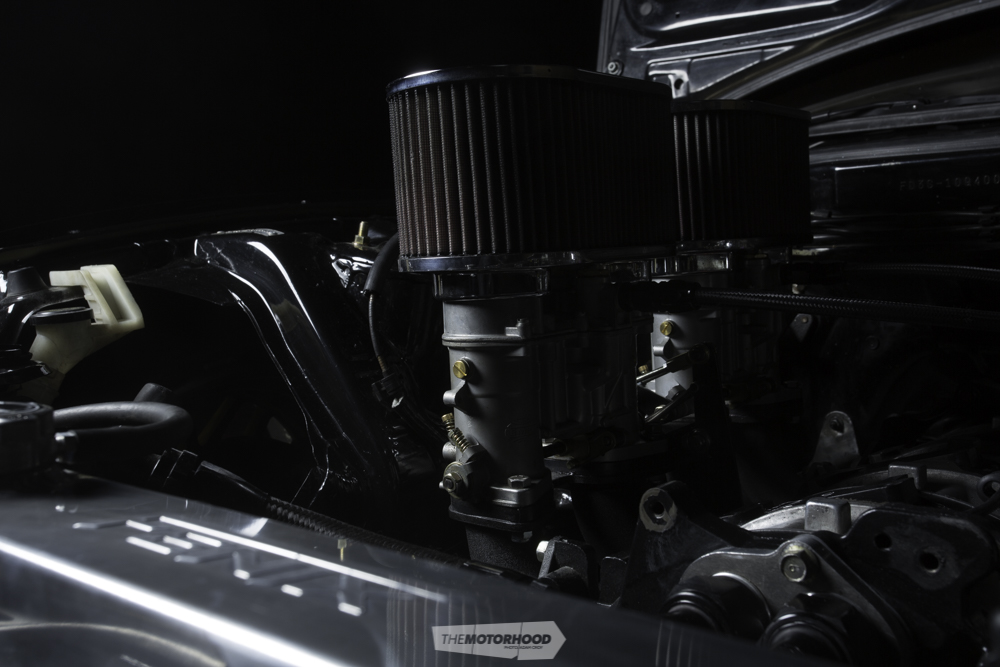

Running a MicroTech LT16S on the ignition side only, sitting on a custom steel manifold, two 51mm Empi IDAs feed a pair of S6 rotors each. The exhaust runs twin two-into-one primaries that merge into one three-inch reducer that flares out to five inches in the quest to create a scavenger effect. The combination (well, half of it) is something tried and true on two-rotor PPs.

As soon as the boys started banging 9500rpm on the engine dyno, the results were exactly double what they’d expected with a 13B, despite the fact that the redline is lower and that the jetting used is smaller than that of the two-rotor. Everything was happy days, including the oil pressure. The screen flashed up a best result of 439kW and 508Nm at the flywheel — all with the added bonus of zero lag. Fritz was understandably amping to get the engine fitted to the FD and take it for a wild test drive around the block (closed roads, of course).

The shell had also seen a few upgrades while lying in wait. The big BN kit was now long gone in favour of a more factory approach, consisting of Luxury Sports over-fenders, an S8 front lip, and a roof and boot spoiler, all covered in a fresh coat of Jet Black. While Fritz may have narrowed up the body considerably, he was not about to settle for something weak in the wheel department. Ignoring any kind of recommendations from Work Wheels, a set of 18×10.5-inch (-24) VS-XX wheels was ordered for the front and the rear. The fitment is wild, and, with rubber-band 225s holding on for dear life, the 20kg Coby springs are the only things saving the guards from being blown off.

Things are kept pretty street on the inside, with a Cusco bolt-in roll cage, a pair of Racetech 1000 seats, and gold mirror tints all round to ensure comfort for those brave enough to sit within

With the goal of debuting at Chrome Expression Session set and the date fast approaching — they had a little over a week to get the car wired and running after the dyno session — the guys worked around the clock to ensure that the deadline was met. With days to spare, the test drive took place, and, as Fritz explains it, “The throttle pedal was possessed. It felt as if there was a demon trying to escape out of the exhaust.”

Despite that, the power curve ensures that it’s extremely predictable to drive and drift, and it loves nothing more than surpassing that 9000rpm mark often, as the rear tries to overtake the front. Having sat shotgun as the big man mashes the pedal with finesse, we can attest to the fact that this car is as wild in behaviour as it is in looks. But, surprisingly, it has plenty of grip for a car with 20kg rear springs. When you’re dealing with a fitment like this, sometimes sacrifices need to be made.

The fact that this car was built almost entirely in the backyard by a small handful of dudes, with little to no professional assistance, goes to show what can be achieved when the boys get together to create something out the gate. And if you don’t think that a near-on-600hp, carby-fed rotary is out the gate, you need your head checked.

Expect to be seeing a whole lot more of this FD in the very near future, as summer is almost here and Fritz has a whole lotta lost seat time to make up for. Oh, and that Supra? Well, let’s just say that it’s since gone to a better home, so Fritz can spend more time enjoying the sound of four rotors screaming.

Being a painter by trade, Fritz handled the paintwork himself in his customary Jet Black — a colour he specializes in

Fritz Leaning

Age: 25

Location: Auckland

Occupation: Jet Black spray technician

Build time: Two years

Length of ownership: Three years

Thanks: The bro, Willy, for building a sweet motor; Luke Hodge, Mark Strawbridge, Samuel Brown, and Mitch Cowley, for being my day ones; Dean Mills, for the tints; my boss at Wakefield Car painters, for letting me paint the thing; my parents, for letting me borrow their van (parts hauler); Hayden Lanks at Continental Tyres; Chris Haeger at Segedins; Max Weston at NZAD; all the Yung City Boyz; and my crew at Lowcally Known

Heart

ENGINE: 26B PP, 2600cc, quad-rotor

BLOCK: S6 housings with 43mm PP sleeves, S6 plates with stationary-gear modifications, S6 rotors, Precision Engineering crankshaft , factory Mazda seals, S6 stationary gears, oil-passage modifications

INTAKE: Twin Empi 51mm IDAs, Custom PP manifold, twin K&N filters

EXHAUST: Twin two-into-one two-inch primaries, twin 2.5-inch-into-three-inch reducer, three-inch to five-inch cone flare, five-inch exhaust, twin Coby resonators, Adrenalin R muffler

FUEL: Twin Carter fuel pumps, MagnaFuel fuel-pressure regulator, twin -8 fuel lines, -6 carb feeds

IGNITION: S6 factory pickup, 12x Bosch HEC coils, 7mm NGK leads

ECU: LT16S

COOLING: Fenix Radiator, Davies Craig electric water pump (EWP), -16 braided lines, Alloy oil cooler, Billet oil pedestal

EXTRA: Solid engine mounts, custom coil bracket

Driveline

GEARBOX: Factory S6 5-speed with reverse delete

CLUTCH: 7.25-inch Quartermaster twin-plate

FLYWHEEL: Chromolly

DIFF: Green Brothers Racing full spool

Support

STRUTS: Custom BC Gold coilovers, 20kg Coby springs

BRAKES: (F) Mazda four-pot calipers, (R) Factory

Shoes

WHEELS: 18×10.5-inch (-24) Work VS-XX

TYRES: (F) 225/35R18 Continental, (R) 225/40R18 Continental

Exterior

PAINT: Jet Black sprayed by Fritz

ENHANCEMENTS: Luxury Sports 25mm front fenders, Luxury Sports 50mm rear fenders, S8 factory front lip, RE Amemiya boot spoiler, Luxury Sports roof spoiler, gold mirror tints

Interior

SEATS: Racetech 1000

STEERING WHEEL: OMP

INSTRUMENTATION: MicroTech LCD touchscreen dash, Autometer Sport Comp oil-temp gauge

ICE: JVC head deck

EXTRA: Cusco bolt-in half cage

Performance

POWER: 439kW at the flywheel

TORQUE: 508Nm

PETROL: 98 octane

This article originally appeared in NZ Performance Car issue No. 250 — you can get your grubby mitts on a print copy by clicking the cover below