After eight years of constant development, you’d think Brady would be content with his RX-2 — but, as we found out, he may never finish chopping, changing, and tweaking

Words: Marcus Gibson Photos: Richard Opie

What is it that defines you as a car nut? Is it the constant grease under your fingernails, the empty bank account, the fact that you have shined your wheels for the fifth time this week or spend most nights as a recluse in your shed, pouring every last spare moment into your project? When it comes to ’Naki engineer Brady, we reckon it’s his devotion to perfection, the one-man pursuit of which has seen his RX-2 sedan remain in an almost constant state of evolution over the past eight years, and it’s a pursuit that Brady openly admits may never stop.

“I picked it up as a uncertified, no reg, no WOF car with a standard 13B motor with an injection set-up. The day after buying it, I pulled the motor out, and, with a friend’s help, we bridge-ported and built the NA [naturally aspirated] set-up in the shed.”

Over the next seven years, the 13B took some severe punishment, both on and off the track, racking up countless kilometres all over the North Island, and, all the while, Brady was constantly working at perfecting it with different intake and exhaust set-ups in the quest for more NA power, something we all know is not easy to come by.

Over this time, the chassis was also developing from its original incarnation as a bump-stopped sedan with a locked diff and 13-inch Modgies. Not that there is anything wrong with this, but, as Brady got older, he wanted something that would be both practical and good looking. While, thankfully, the ride height wasn’t sacrificed, almost all the factory underpinnings were to get the suspension functional. A new tunnel is in place, three-inch higher and wider, along with a tubbed rear floorpan to allow for the lower and larger Hilux diff. With the new seriously short diff came a new rose-jointed four-link and Watt’s link — all engineered with revised geometry by Brady in his garage at home. But the chassis work didn’t stop there; it was strengthened both front and rear, and the engine bay was fully seam-welded.

Although it was getting radical under the skin, Brady has always been a firm believer in keeping it clean and simple on the exterior: “My goal with the car is to build a strong/reliable car that presents itself well, takes a beating, but it has to look plain just like a good Kiwi rotary should be. My vision of this is black, loud, and low, with wheels that finish a car. I’m not one to have shiny engine bays, pretty/bright paint or over-the-top interiors; just basic/original-looking with a twist of old-school Japanese-inspired look.” This was exactly the brief in 2014, when the shell was stripped for a bare-metal respray in preparation for his wedding. RE Automotive took charge, and, while it worked on the factory tin, the chrome was sent off to be re-dipped. The night before the wedding, Brady and Todd from RE Automotive were in the shed, piecing the RX back together. The following day, his nuptials were consummated in true rotary fashion with a big flaming burnout, something Brady is getting a bit of a reputation for.

Anyone who’s owned an RX-2 will know that getting it this low is no easy feat. The factory floor pan was tubbed and raised in the rear, while the gearbox tunnel received similar modifications

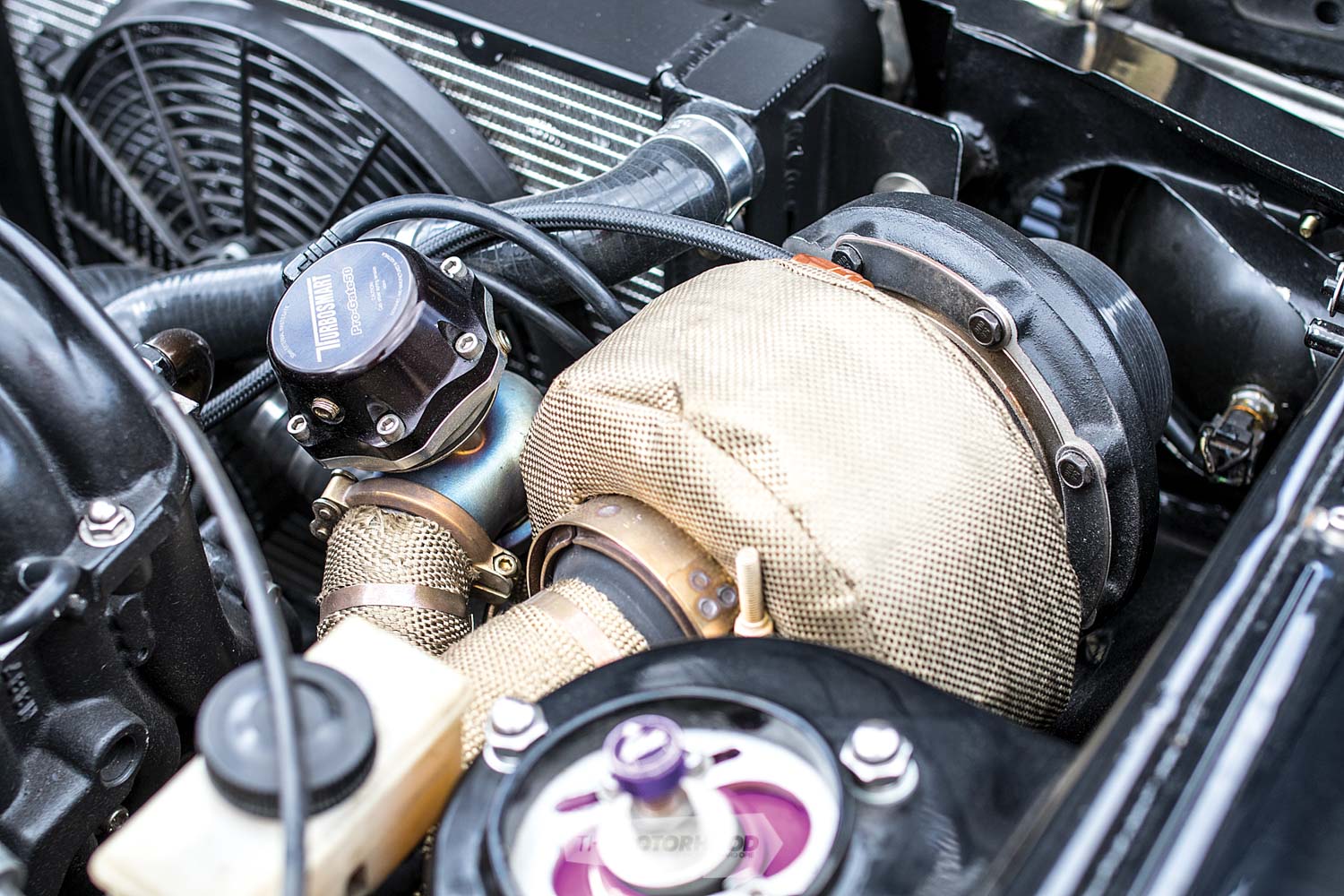

After seven years and six Toyota W-series gearboxes, it was then time for a new challenge in the engine department. Brady had started collecting the parts to build a 20B peripheral-port (PP) and even got as far as building the headers before an opportunity arose that he couldn’t refuse. “The chance came up to swap my complete NA set-up for a freshly built S7 turbo block,” he explained. The deal was struck, and Brady set about building his turbo set-up, using a BorgWarner SX366, before Todd coated everything in either gloss or satin black. It’s a package that will stay in the engine bay for some time now: “The decision was made to sell the 20B PP parts, as the engine bay now had modifications to house a turbo set-up.”

With the new turbo package going in, the driveline that had seen countless boxes destroyed from 10,500rpm clutch dumps had to be sorted. The twin-plate clutch was ditched in favour of a custom single-plate to lessen the stress transferred through the gearbox, and that seems to be working great, if the beat-down it was given at REunion is anything to go by. But even though this set-up — which made 338kW on 19psi — is working fine, Brady is already ripping it down to change the boost side of things with a new turbo manifold and pre-turbo water/meth injection — all in the search for power. It’s just what he does and will always do.

The rear end consists of a Hilux Surf LSD that has been shortened and converted to disc brake. The four-link and Watt’s link have also been custom built by Brady, with adjustable rod joints throughout

Brady told us contentment is a foreign feeling: “I guess I can say [that] I have an addiction to continuous tinkering, and, as a result, the RX-2 has seen many, many changes over the years, every one to make it that slight bit better or more practical,” but, that said, “I have grown too attached to the car and could never bring myself to sell it, so since I’m so committed to the one car, this build will never be 100 per cent finished, as I will always find something to change, or paint black.”

Driver/owner: Brady Gopperth

Age: 30

Location: Taranaki

Occupation: Engineer

Build time: Eight years ongoing

Length of ownership: Eight years

Thanks: My wife, for putting up with the late nights in the shed and compulsive car-part buying; Mum and Dad, for all those years pulling cars apart in their shed and never putting away Dad’s tools; Todd at RE Automotive, for the paint and all the touch-ups; Green Brothers, for supplying parts and info; all the local guys and good mates, for being there and having the right tools on offer when I needed them

Heart

ENGINE: Mazda 13B (FD S7), 1300cc, twin-rotor

BLOCK: Bridge-ported S7 plates; enlarged exhaust ports; lightened, balanced, and clearanced S7 rotors; solid dowels; stud kit; six-window stationary gears; baffle plate

INTAKE: Ported upper manifold, Green Brothers water/meth injection, three-inch alloy intercooler plumbing

EXHAUST: 3.5-inch steel exhaust, Adrenalin R resonator, Mazsport rear muffler, 2.25-inch wastegate exhaust

TURBO: BorgWarner SX366, 0.91 twin-scroll rear housing, custom two-inch manifold

WASTEGATE: Turbosmart 20mm Progate

BOV: Turbosmart 50mm Raceport

FUEL: 60-litre fuel cell, Bosch 044 main pump, Bosch 044 lift pump, custom in-tank cradle, custom surge tank, Russell 305mm fuel filter, -8 AN fittings, custom hardlines, Green Brothers fuel-rail kit, Injector Dynamics ID1000 primary injectors, Bosch 1680cc secondary injectors, Sard fuel-pressure regulator

IGNITION: High Performance smart coils with built-in insulated-gate bipolar transistor (lGBT) igniters, Green Brothers custom leads

ECU: Microtech LT16

COOLING: Fenix Performance radiator, PWR oil cooler, Davies Craig EWP115 electric water pump (EWP),

356mm fan

EXTRA: De-loomed engine bay, 700ml oil catch-can, flat black and gloss black engine components,

side-mount alternator bracket, flat firewall, smoothed and seam-welded engine bay, welded strut towers

Driveline

GEARBOX: Toyota W57, Green Brothers billet selector forks, Green Brothers steel bellhousing, custom short-shifter

CLUTCH: Five-puck single-plate, Green Brothers pressure plate, Quartermaster release bearing

FLYWHEEL: Lightweight 300mm chromoly

DIFF: Shortened Toyota Hilux Surf housing, shimmed 4.3 limited-slip, modified 30-spline axles

Support

STRUTS: (F) Three-way adjustable D2 coilovers, camber plates, 10kg springs, (R) three-way adjustable Ksport coilovers, 8kg springs

BRAKES: (F) FC RX-7 calipers and rotors, (R) FC RX-7 calipers and rotors ; line locker

EXTRA: Custom rose-jointed Watt’s link, custom rose-jointed four-link, revised pickups and geometry, 25mm RCSs, larger front sway bar, modified hubs with 4.4×113 conversion, tunnel raised and widened by three-inches, tubbed rear floorpan, flat boot floor, strengthened rear chassis, strengthened front chassis for steering box

Shoes

WHEELS: (F) 15×8-inch (-12) Work Meister S1,

(R) 15×9-inch (-20) Work Meister S1

TYRES: (F) 195/45R15 Falken ZE, (R) 195/45R15 — anything I can get my hands on cheap

Exterior

PAINT: Gloss black bare-metal respray by RE Automotive

ENHANCEMENTS: Factory

Interior

SEATS: Retrimmed factory, rear seat modified to suit gearbox tunnel

STEERING WHEEL: Momo

INSTRUMENTATION: EWP controller, Turbosmart e-Boost2, Microtech hand controller, Auto Meter 33⁄8-inch tacho, electronic speedo, Auto Meter 25⁄8-inch fuel-pressure gauge, oil-pressure gauge

Performance

POWER: 338kW on 19psi / 298kW on 14psi