data-animation-override>

“It’s pretty easy to make a ton of power these days, but building a successful circuit car requires more than just dyno figures; it’s a balancing act between power, grip, and driver talent — three departments the Smyths’ new RX-7 seems to have covered”

Truth be told, we car folk are pretty lucky SOBs when it comes to building cars in this day and age. Making power is a relatively cheap exercise. You select a bunch of parts, and, wham bam, you’re making a zillion kilowatts, right? Now, that is all well and good if you like to brag on the internet or mash the pedal from point A to point B in some sort of automotive-peacock display, but all-out power is not a one-ingredient recipe for making a fast circuit car. Cutting fast lap times requires a very-well-balanced diet of power, grip and handling, and then you need a driver capable of making the most of that diet. One such wheelman is Graeme Smyth, a name familiar to readers of these pages due to his exploits in SS2000, D1NZ, and the Australian GT Series, as well as endurance racing back here on home soil. Many will remember his first-generation RX-7 from issue 186; now, we’ll meet its successor — a 13B bridgeport FD RX-7 that, like the first car, is a joint project with his dad Kerry, and built to the limit of the SS2000 rule book — and with front-running credentials.

While the Smyths’ first-generation RX-7 might have been a very well-developed package, when this third-gen turned up as a rolling body, they knew the newer-generation RX would be a far more competitive chassis for the very special 13B that was on order from Xtreme Rotaries in Australia, as Graeme recalled: “We had already maxed that car out with a 12A; we were at the point where it was not going to go a hell of a lot faster with the 13B. Plus, we were also paranoid about scratching a door or a guard, as it’s getting harder to find parts for [these cars]. This popped up as a rolling body, so we figured we might as well leave the 12A in the old car and keep running it.”

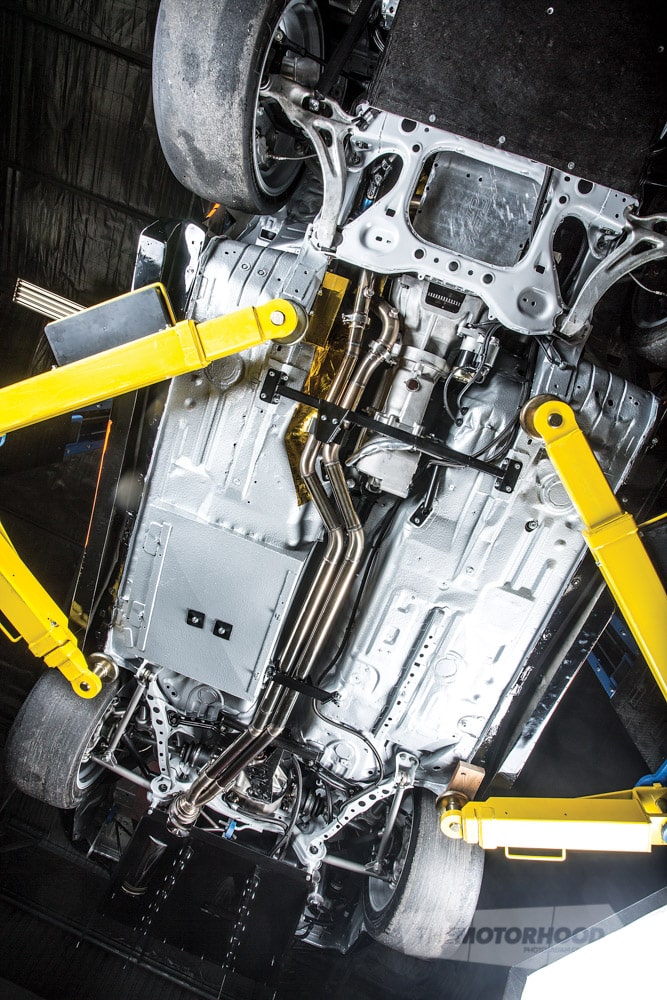

A race-car driver Graeme may be, but he sits in a very unique position compared with most, as he is a race-car fabricator by day, so the entire build was handled in-house at SMS Fabrication. The car was originally built as a race machine in New Zealand with a 20B turbo, but was only raced four times before being stripped. What they ended up with was the roll-caged rolling chassis with an independent-rear-suspension (IRS)-converted nine-inch diff, and, in typical NZPC-build fashion, nearly everything else has changed along the way — some things three or four times, Graeme told us. We guess having it sitting in his shop for three years and there being no real rush meant that he could perfect each and every component — and, of course, lots can change in three years, including Graeme’s own skill set, experience, and knowledge.

Driving has taken him all over Australasia and to places like Bathurst. While he was officially at those events to pedal the Trass Family Motorsport (TFM) 458 GT3, you can be assured the fabricator side of him was also soaking up ideas from all the hard-core race machinery and picking up information and solutions to implement on his own build: “You get a lot of time on race weekend, especially when running with the V8 supercars, as you’re not the main event, so you get a lot of down time to wander around and take in lots of ideas. Things like ducting and aero — a lot of people just go and slap on wings and splitters, etc., without mounting them properly or anything. Yeah, it probably looks cool, but it probably doesn’t work as well as it should. So, it’s been a matter of understanding how it works, how to mount it, and where to mount it. A lot of that has come from GT. Ducting was another thing — learning how to get air in and out effectively.” While the FD has nowhere near the level of aero that a GT car has, the aero package that the RX has ended up with is right on the size limit of what SS2000 allows, and, in many ways, it mimics what can be found on Andy Duffin’s FD. In fact, the front splitter is actually the fibreglass test pilot that Andy used to test with before making a carbon version, something that saved the team a ton of time in development, as Kinetic Sim had done the hard yards for Andy.

Joining the aero is a ton of FRP body panels to help reduce weight to 1100kg, which is below the class minimum. This means that they will run ballast on the right-hand side to offset Graeme’s body weight, so, on the scales, the car has nearly a perfect weight balance on all four corners. Should they run in GT2, this weight could be dropped and the car again go on a diet, getting it closer to 1000kg.

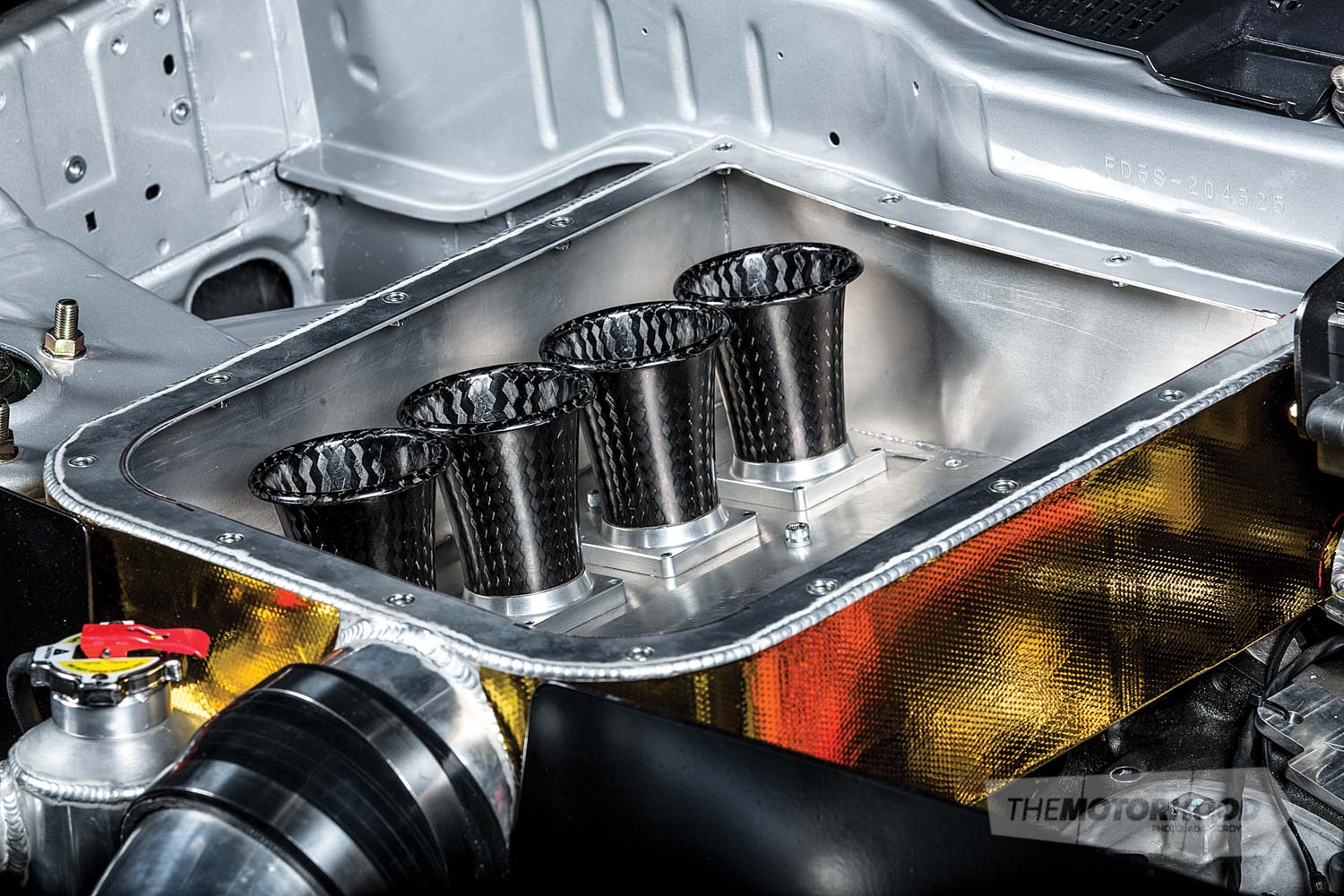

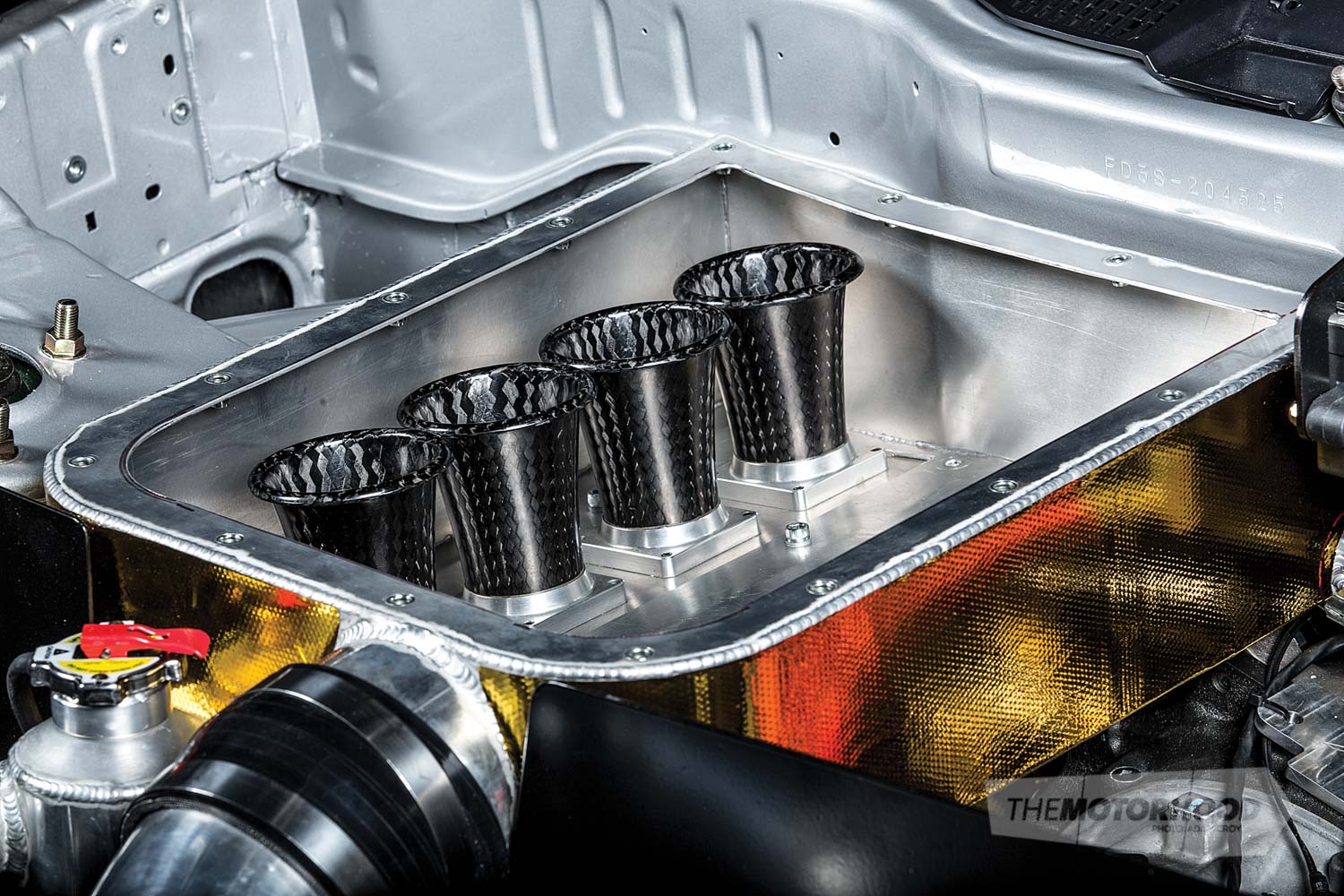

When you stack this car up next to similar RX-7s, like Andy’s car in SS2000 trim and Brett Killip’s 12A FD, you can see it should be a class front runner, especially with the very well-developed 13B under the bonnet. But, unlike what you might expect from a New Zealand–built machine, the 13B is actually a bridgeport and not a peripheral port (PP), as Graeme explained to NZPC: “It’s not your average bridgeport; all the development over there [in Australia] goes into bridgeports, because that’s what they are allowed to run in IPRA [Improved Production Racing Australia]. The same goes for the quad throttle bodies — it’s what all their development goes into. They are quite a small throttle body, but, when you have four, they add up to more air than you would [get with an] … IDA. There is more torque down low, and, to us, it must [be] more reliable, as you don’t have the apex seal running over a large port. The ports are huge; even the rotors have been CNC machined to allow for a bigger port. It’s something we haven’t seen over here yet, but it’s big on drag cars in Australia and the States.”

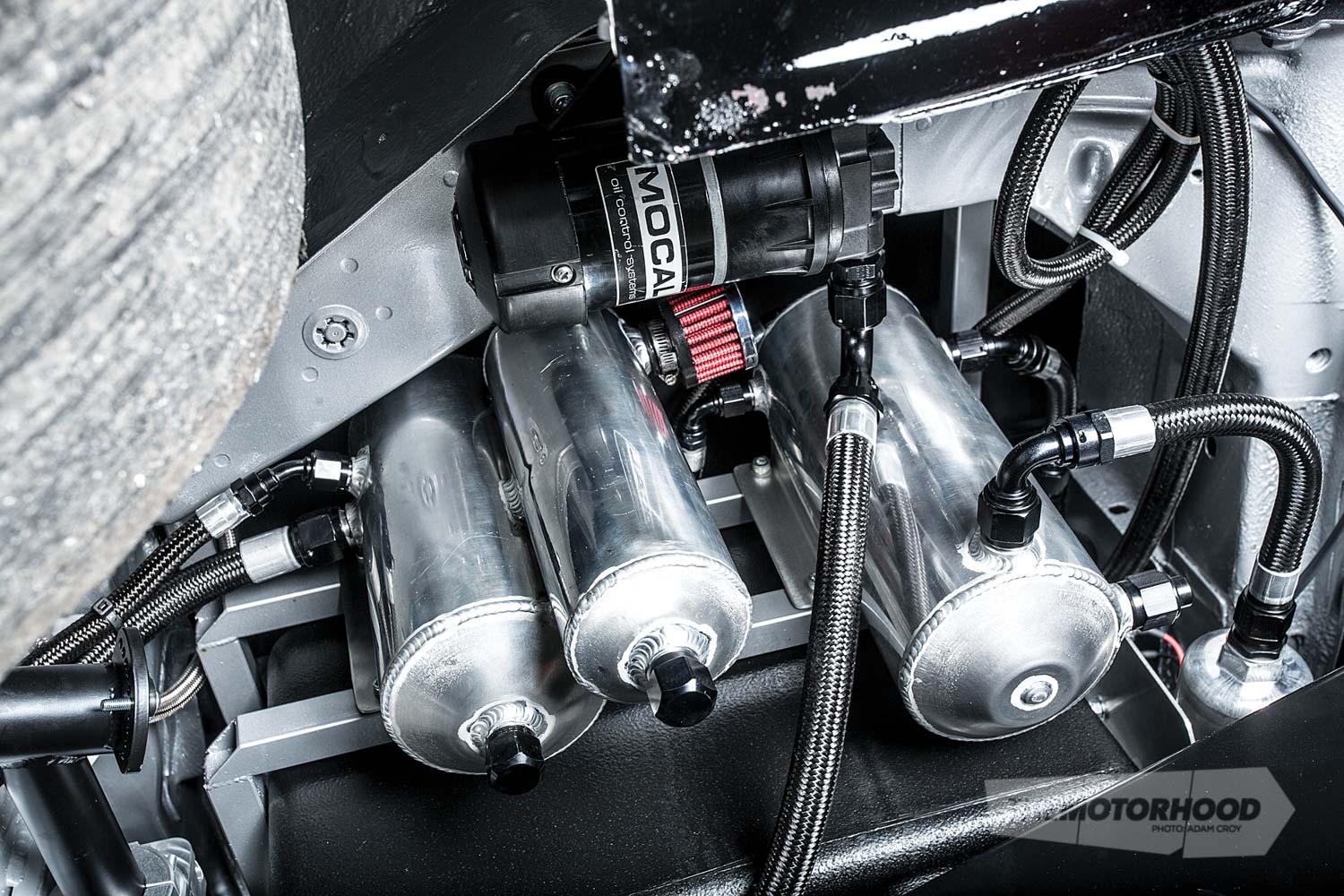

The engine actually arrived at SMS dyno tuned and ready to bolt in, complete with plenty of Xtreme’s drool-worthy CNC billet pieces attached, including the dry-sump system. On the dyno, it made 276kW (370hp) — and that’s not at the flywheel, people, so yes, Graeme’s sentiments about it being not your average bridgeport are spot on.

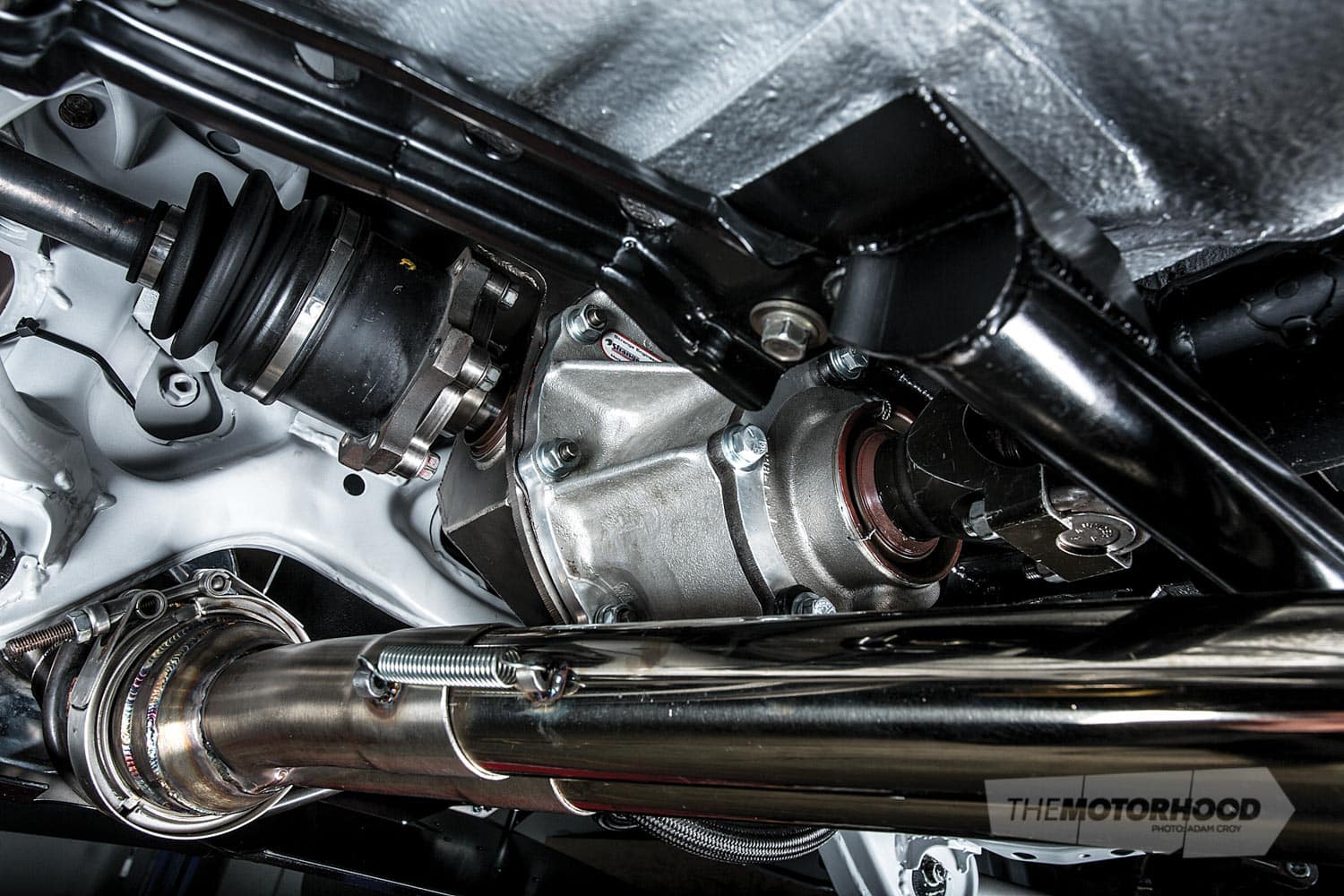

But, when discussing circuit racing, we try not to get too hung up on the dyno figures. Sure, you need power, but more important is how often the car is on the throttle — the bigger that percentage, the faster the lap. To help that along, every associated aspect has been covered. A six-speed Modena sequential has been selected to keep the 13B screaming and right in its power band. To assist the handling, much of the suspension was replaced, with the set-up now including custom rose-jointed chromoly arms, adjustable blade–type sway bars, and two-way adjustable external-reservoir Fortune Auto coilovers. Add to this the big 380mm rotors, six-pot AP racing brakes, and a 275-wide slick, and the combo starts to sound very promising indeed.

All the speculation about how fast the FD will be is about to be put to the side, though, as the car is ready for actual testing. As we go to print, it is poised to hit the dyno to check everything is perfect, before getting a shakedown ahead of the season opener. “At the moment, it’s just a matter of getting it to the track and seeing what happens,” Graeme said. “There is bound to be stuff. I just hope we get to the track and there isn’t any vibration, etc. But I’m pretty confident that everything we have done as far as what we have built — cooling and suspension — is going to work; it’s just a matter of hoping nothing falls off, [there are] no weird vibrations, and the brakes all work, etc. It will be good to just get out and do a few laps, then come in and check over everything.”

It’ll only be then that the driver in Graeme can take over from the car builder, and we will really get to see what the FD can do. After a few seasons running in GTs, it will be a big change jumping back into an SS car, but, having used the knowledge gained to build the FD, he will also be able to use that knowledge to better pedal the aero-equipped SS racer, which will undoubtedly be one of the best-prepared cars on the grid. Are we looking at a championship winner in the making? Only time will tell.

Tuning Menu

MAKE AND MODEL: 1996 Mazda FD RX-7

Heart

ENGINE: Mazda 13B

BLOCK: Xtreme Rotaries–built, 13B bridge port

INTAKE: Quad throttle bodies, Xtreme Rotaries cast aluminium intake manifold, carbon trumpets, custom aluminium airbox, VE Commodore intake duct

EXHAUST: Custom two-inch stainless system, AdrenalinR rear muffler

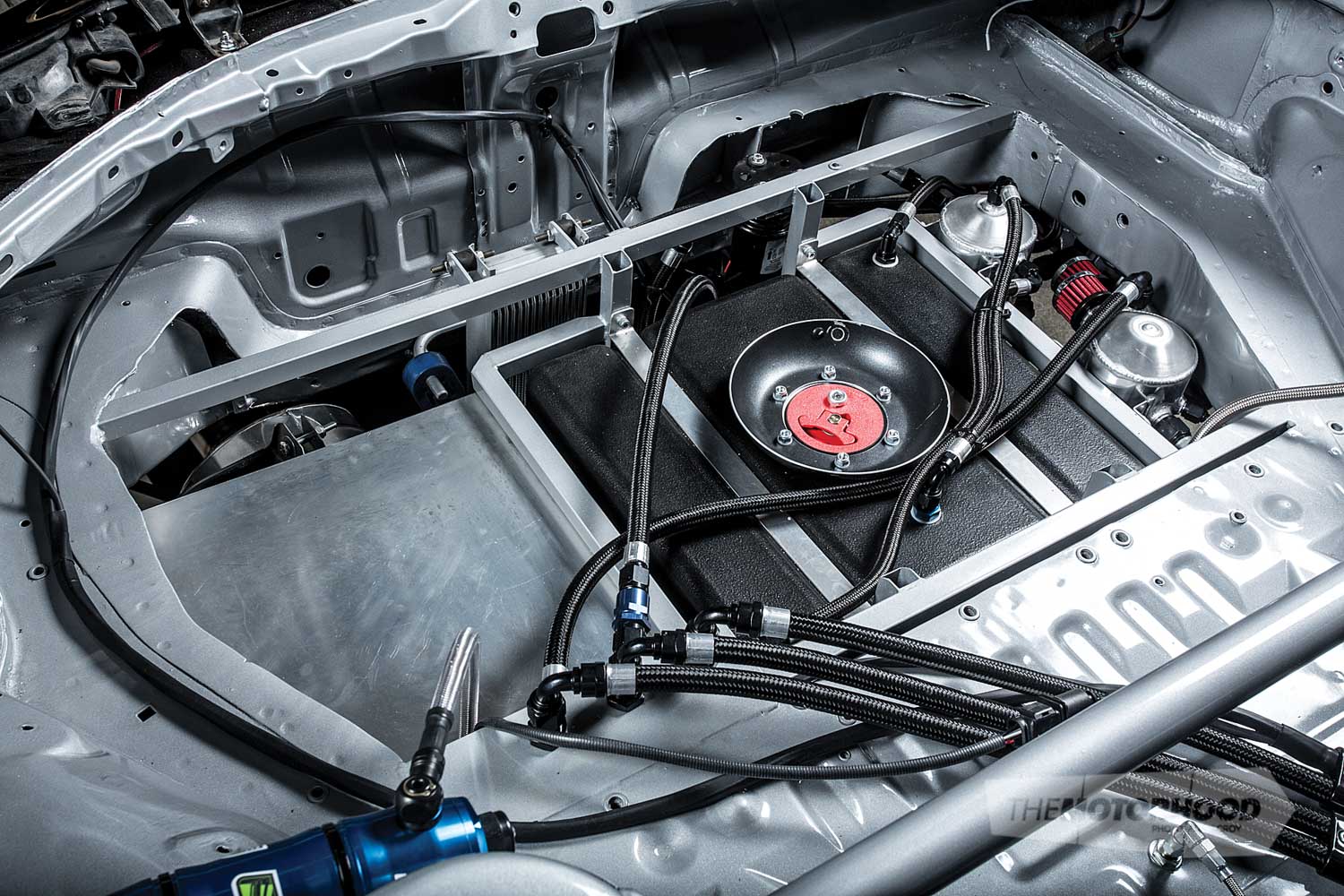

FUEL: Jaz fuel cell, custom surge tank, Carter lift pump, Bosch 044 main pump, 750cc injectors

IGNITION: AEM coils, MSD leads, NGK plugs

ECU: MotTeC M84

COOLING: Custom aluminium radiator, twin custom oil coolers, Setrab gearbox oil cooler, Setrab diff cooler, custom aluminium ducting, Davies Craig electric water pump, Tilton diff oil pump

EXTRA: Custom motor-sport wiring loom, Xtreme Rotaries dry-sump front cover, custom coolant swirl pot, custom power-steering reservoir, Mechman alternator, Xtreme Rotaries oil block, Xtreme Rotaries coolant outlets

Drive

GEARBOX: Modena six-speed sequential

CLUTCH: Quartermaster twin-plate

FLYWHEEL: Chromoly

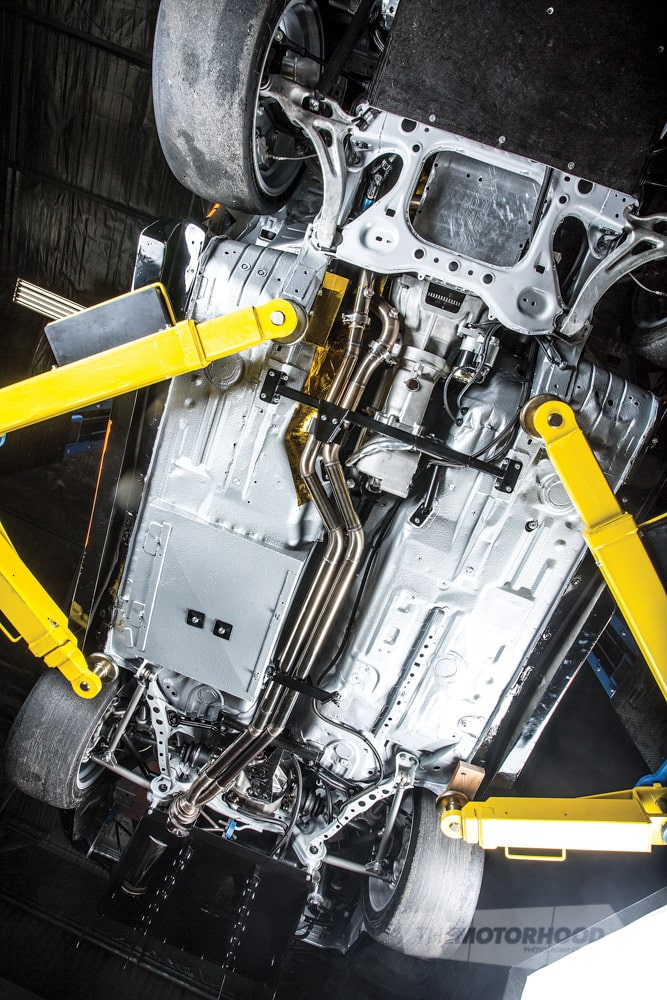

DIFF: Custom fabricated nine-inch IRS housing, Strange aluminium 9-inch diff (4.7 ratio)

EXTRA: Custom chromoly axles, GT-R Skyline CVs, custom chromoly hubs

Support

STRUTS: (F) Fortune Auto two-way adjustable coilovers, 12kg Swift springs, (R) Fortune Auto two-way adjustable coilovers, 14kg Swift springs

BRAKES: Brake bias valve, (F) AP Racing six-pot calipers, 380mm rotors, custom aluminium cooling ducts, Endless pads, (R) Factory calipers, slotted rotors, Endless pads

EXTRA: Custom chromoly front upper control arms, custom chromoly rear lower control arms, custom chromoly rear toe arms, rose joints throughout, custom blade in-cabin adjustable sway bars, eight-point chromoly roll cage, fabricated gearbox tunnel, fabricated floor for driver seat, fabricated rear fuel-cell enclosure, fabricated engine and gearbox crossmember pick-ups, fabricated pedal-box mounts

Shoes

WHEELS: 18×10-inch Enkei RPF1

TYRES: (F) 270/650-18 Michelin slicks, (R) 270/680-18 Michelin slicks

Exterior

PAINT: Complete rotisserie respray inside, outside and underneath by Allmotive Panel & Paint, gloss-black exterior, silver interior and underneath, livery designed by Pixelsaurus and applied by The Wrap Shop

ENHANCEMENTS: C-West front bumper, modified RE Amemiya bonnet, modified BN front guards, modified Vanquish side skirts, Final Konnexion rear guards, fibreglass doors, fibreglass hatch, carbon-fibre rear wing, fibreglass front splitter, carbon-fibre splitter end plates, custom rear diffuser, heated front windscreen, moulded Lexan side windows, moulded rear Lexan hatch, LED headlights

Interior

SEATS: (F) Racetech seat

STEERING WHEEL: Sparco, custom switch panel

INSTRUMENTATION: MoTeC CDL3 dash

EXTRA: Floor-mount pedal box, custom false floor, aluminium oil tank, custom chromoly steering column, carbon-fibre dash, carbon-fibre roll-cage cover, custom pressed door cards

POWER: 268kW/360hp at the flywheel

DRIVER PROFILE

Driver/owner: Graeme Smyth / Kerry Smyth

Age: 25/undisclosed

Location: West Auckland

Occupation: Fabricator/ diesel mechanic

Build time: Ninety per cent of the build was done over one year, and the other 10 per cent was spread over three years

Length of ownership: 3.5 years

Thanks: Rowan and Chris at Xtreme Rotaries, Frank at Modena Engineering, Barry at Allmotive Panel & Paint, Matt at Redline Auto Electrical, Barry at MRP, Dave at The Wrap Shop, Don at Enzed, Jason Booth, Andy Duffin, Dillon Grant, and anyone else who I’ve forgotten who has helped out in some way.