There is one moment in any project that stands out as a make-or-break situation, and for Darren Kelly and his R35 project, that moment was somewhere in the early hours of July 15, when TTT Auto Engineering was broken into and some very key parts, including the Ross dry-sump system, Jerico four-speed, and Work Meisters vanished into thin air. Obviously having something like this happen mid build is terrible, but Darren wasn’t about to let it ruin the dream, and the team have pressed on.

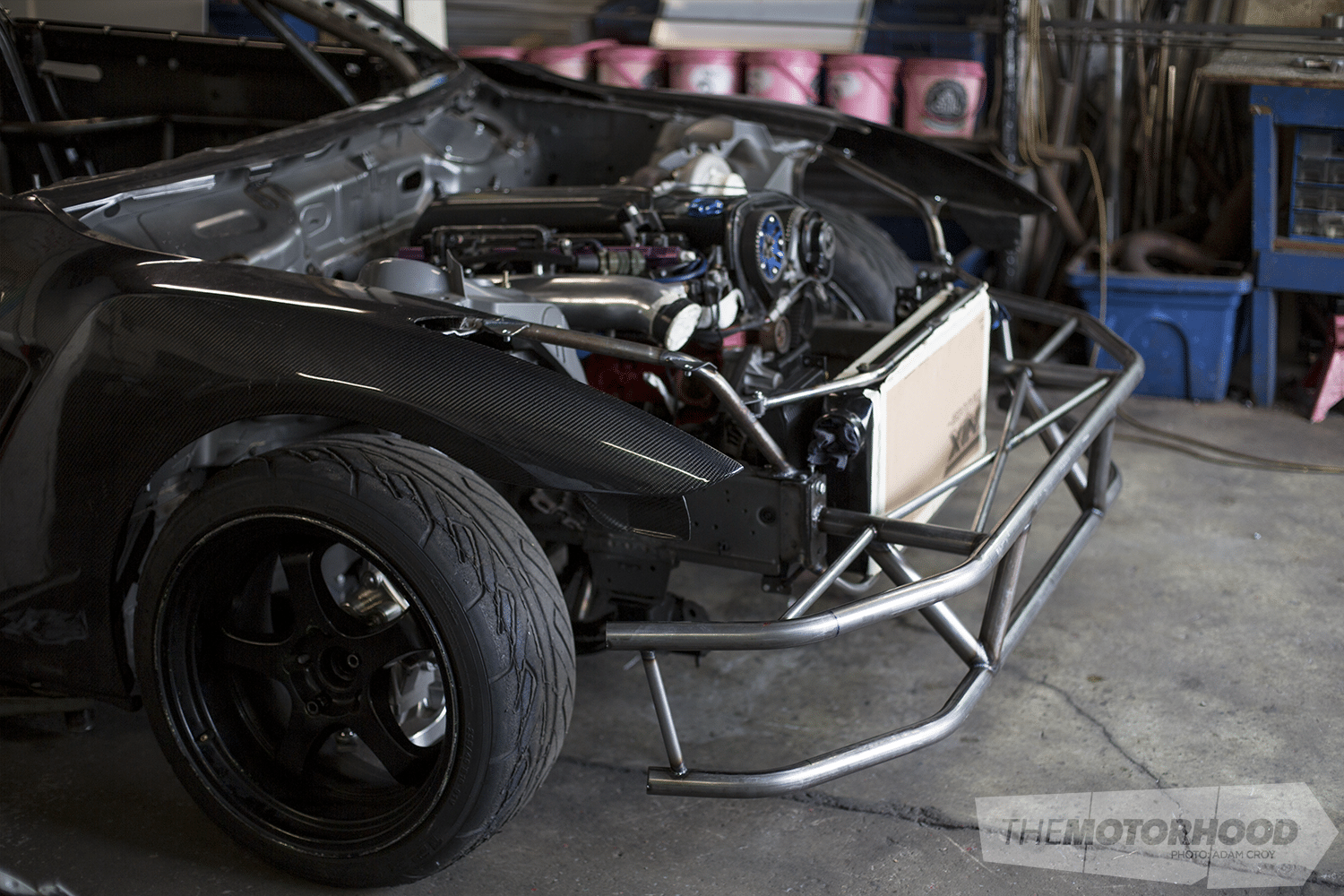

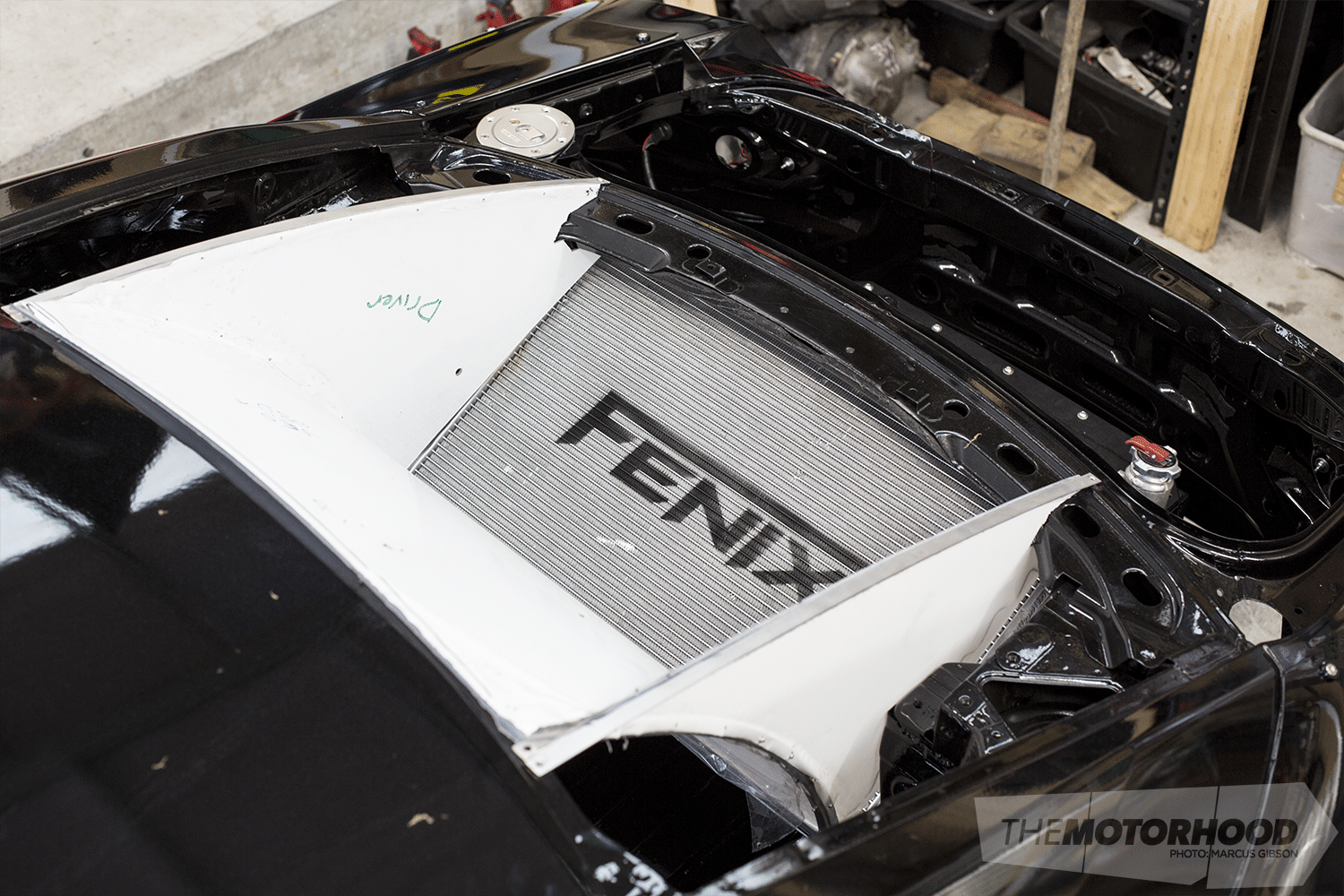

Ninety-nine per cent of the fabrication is now completed, the RB30/26 engine and new gearbox are in, and all the surrounded mounts are sorted. The front tubular bumper support structure, which bolts directly to the chassis rails, should withstand some punishment, but is easily replaceable via four bolts if needed. There is also a tubular front section that mounts the Fenix Performance intercooler, oil cooler, and headlights. The structure has been designed so that everything is hidden behind the factory panels once bolted on.

Tim has built a set of lobster-backed alloy pipes for the cooler that snake around the tubular structure and feed the large plenum. Like in his R34, the RB26 head will be fed via the factory six ITBs, rather than a large single, to aid in throttle response.

If Darren was to come up with one silver lining from the theft, it would be that his ideal gearbox choice is now in place — a TTi sequential. The clutch package will be as found in the R34, a Quatermaster triple plate with a lightweight flywheel.

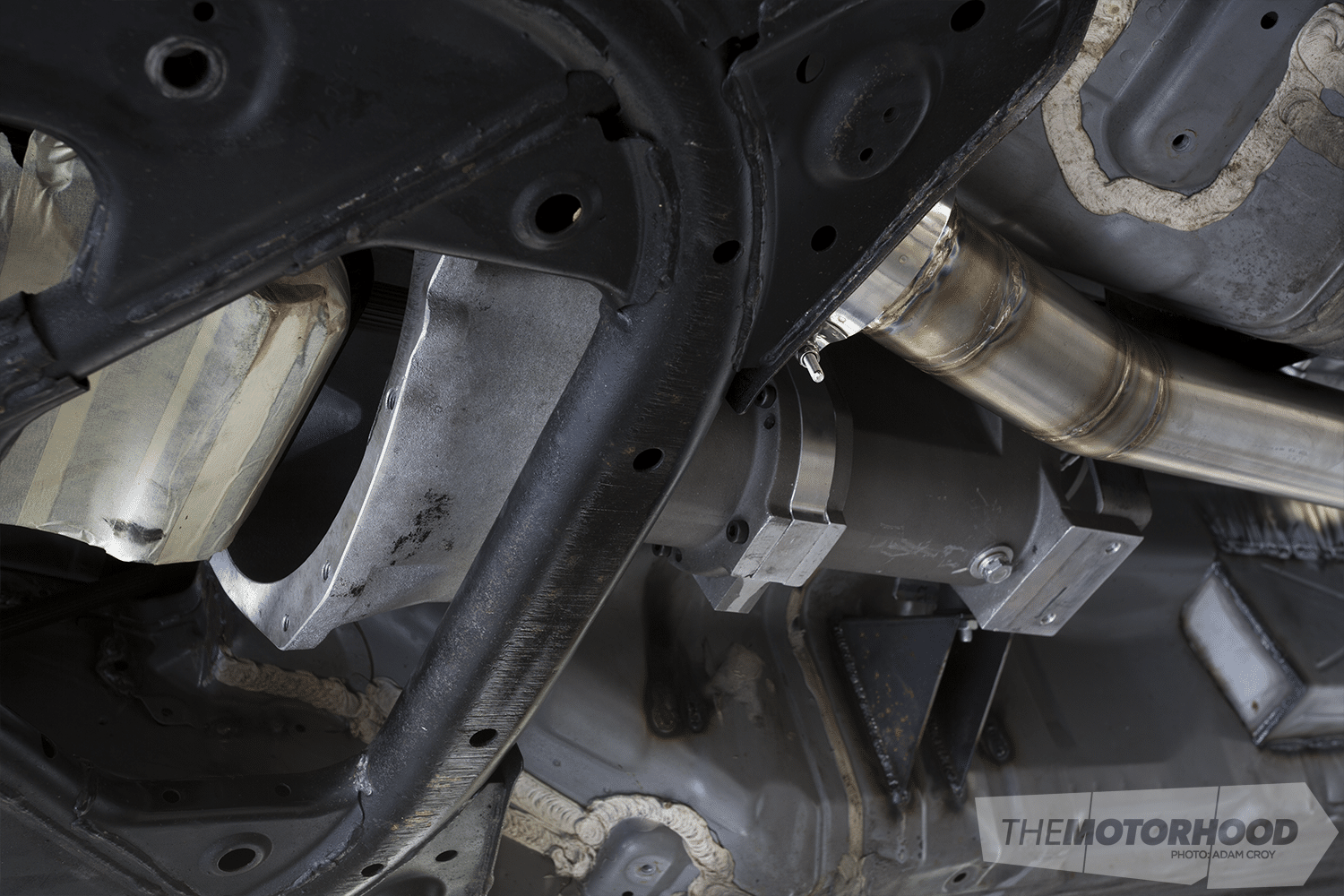

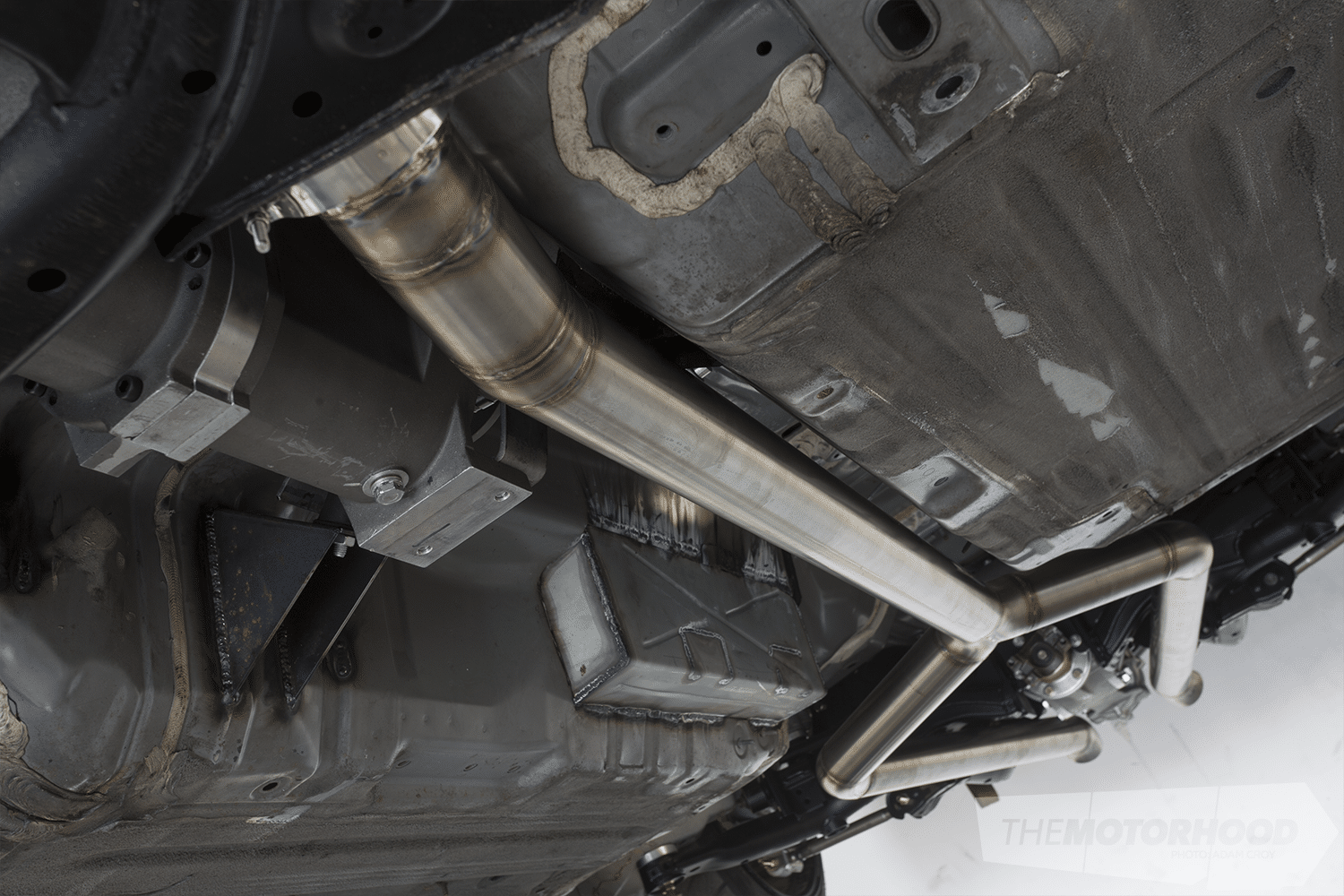

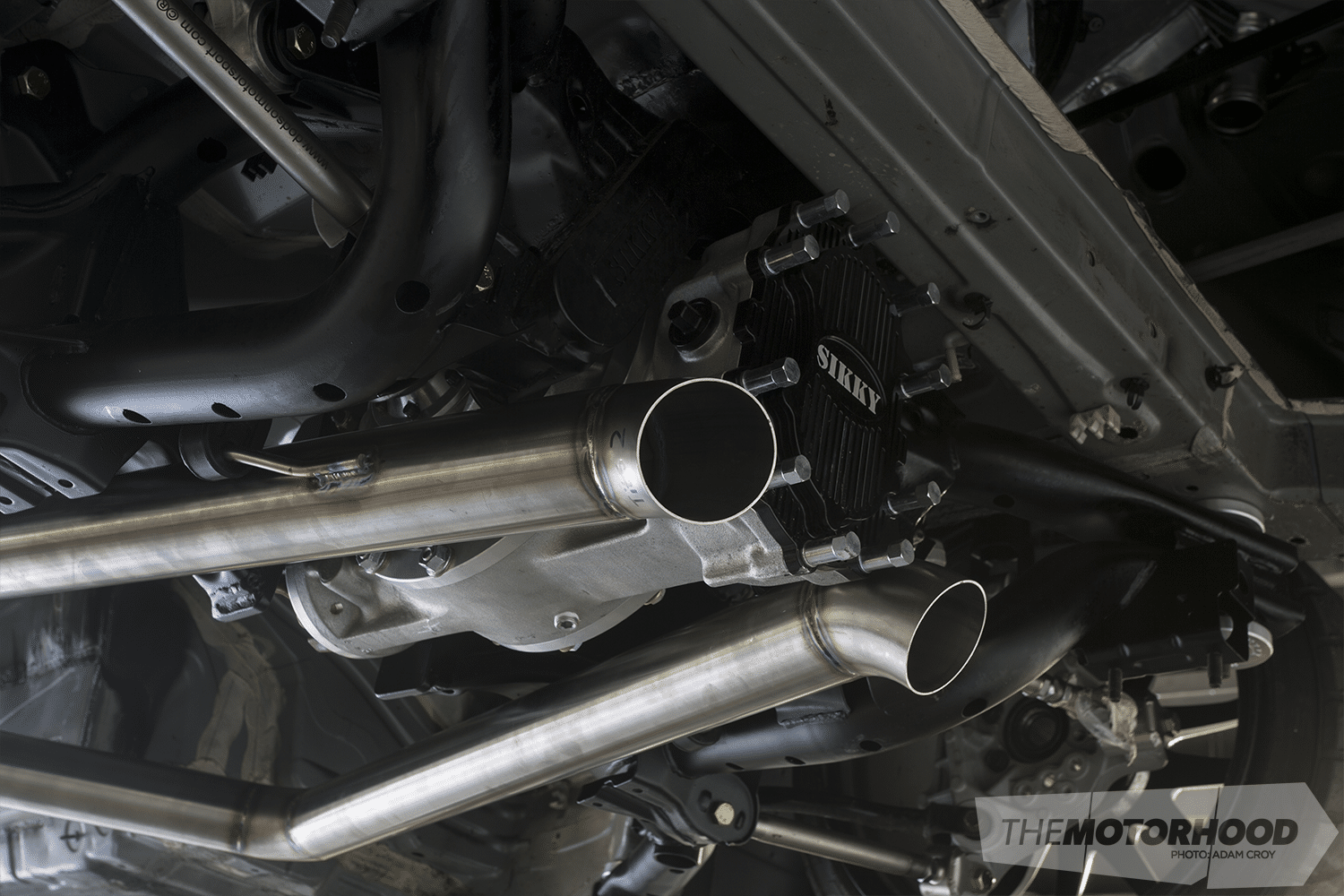

The boys at TTT have whipped up a four-inch stainless straight pipe from the back of the Garrett GT35/82R.

That splits and dumps each side of the Winters quick-change. No mufflers here, people, this is going to growl.

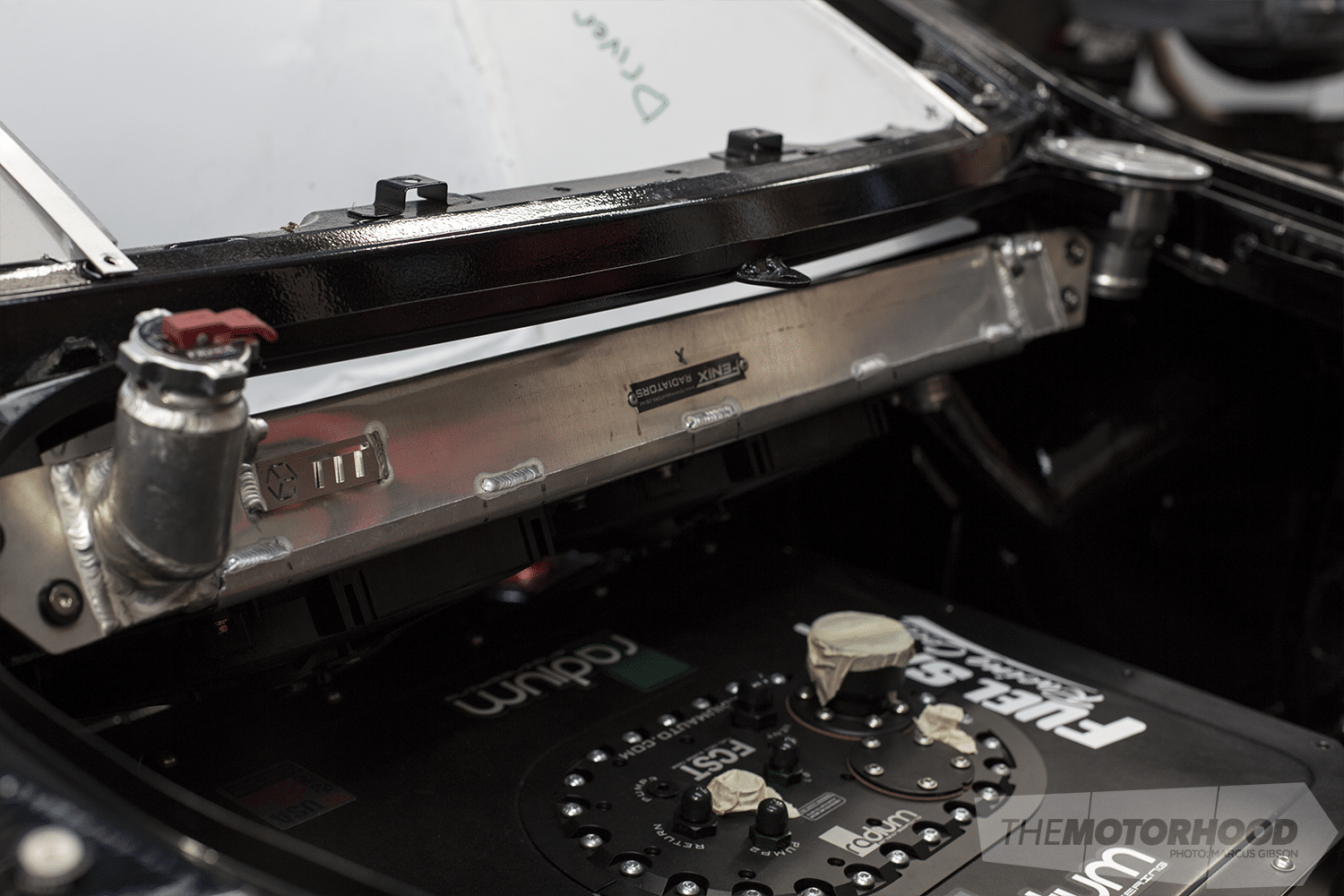

The rear tube work has also been completed, which mounts the Radium fuel cell and houses a handing jacking point underneath the bumper. These Radium fuel cells make life easy with everything enclosed into the tank, you simply have to plumb and wire it.

The ducting for the rear-mounted Fenix Radiator is nearing completion. Tim has formed a curved alloy frame for the Lexan pieces to sit in, with the two side bits yet to be added. There is also a rear scoop to go on that will ensure the dual 14-inch fans are fed with air. One of the last jobs on Darren’s list will be plumbing the entire car using braided lines and AN fittings.

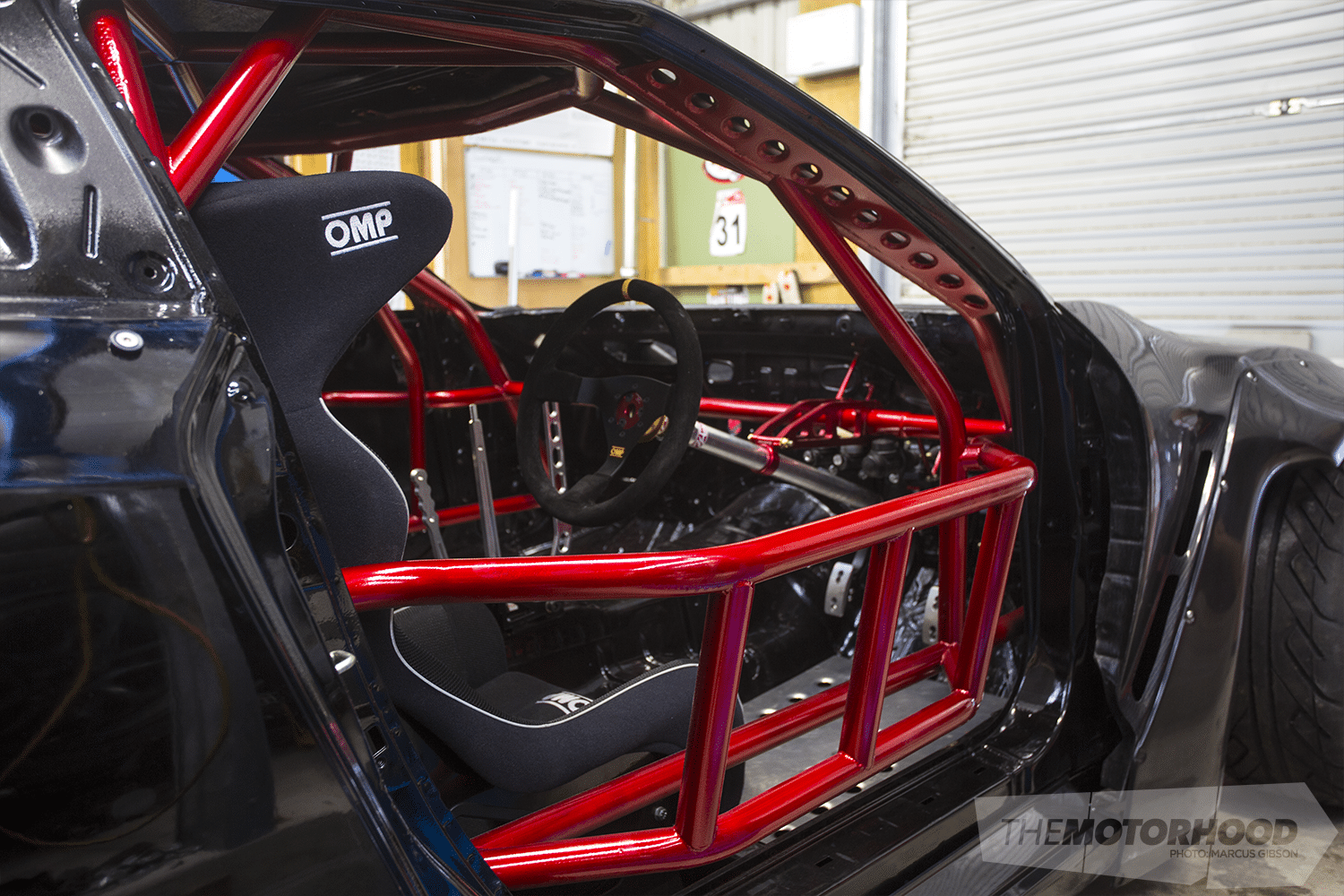

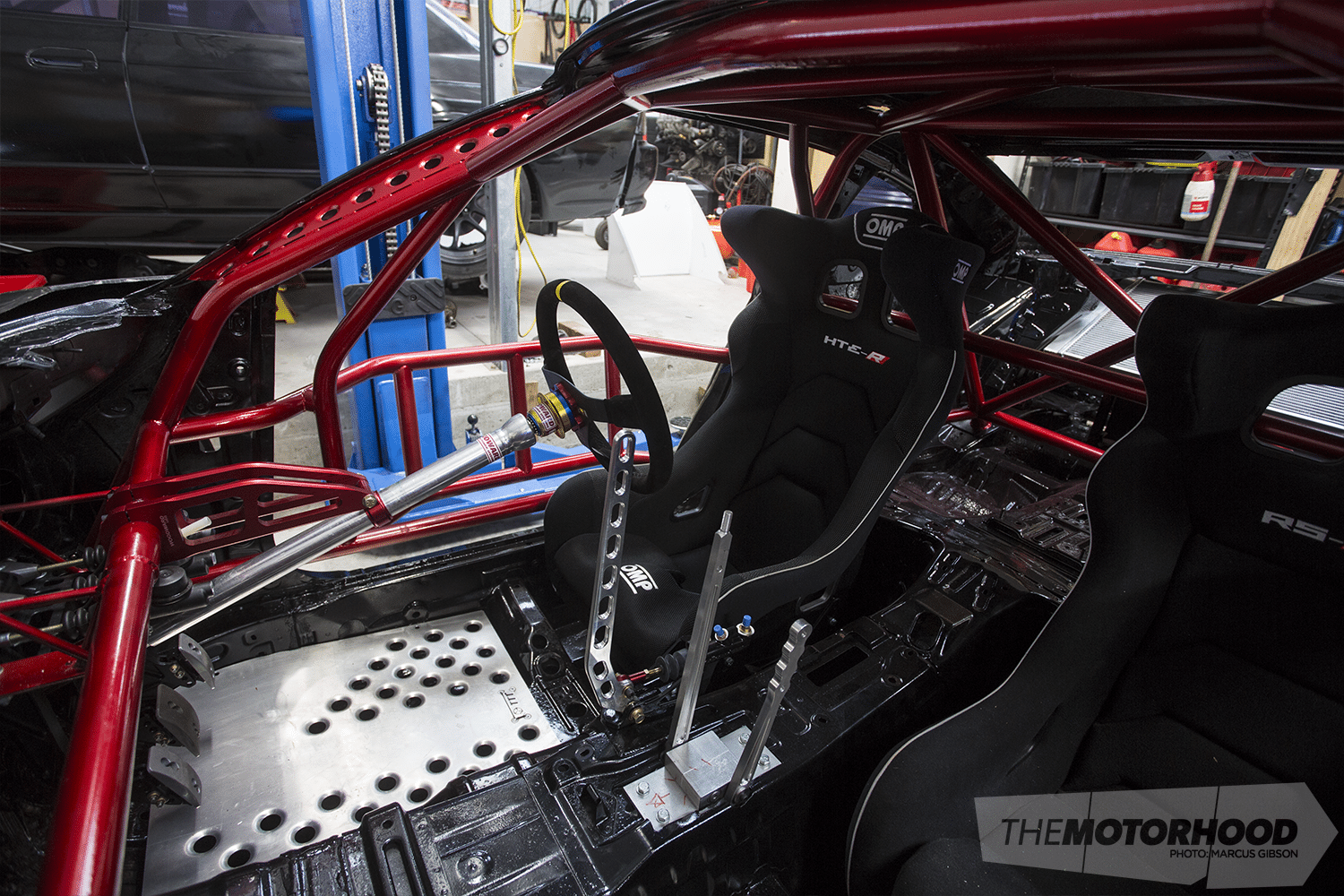

The best part about finishing up all the fab work, meant that color could finally be added to the car. The shell itself has been painted black inside and out to give a good base for the vinyl to be laid over — but more on that in a few weeks. All the tube work has been coated in a candy red.

Darren’s office is really starting to take shape with the TTi levers and alloy handbrake all aligned with the OMP wheel. The Wilwood reverse-mount pedal box, with adjustable pedals, is also hung off the cage. Over the next few weeks the cabin will be filled with all the plumbing and wiring ahead of the tune and shakedown. The deadline for the car is approaching fast, so expect things to move very fast over the coming weeks as it all comes together.