Photos: Glen McNamara

What inspired you to choose a Chaser for your build, and what condition was it in when you first got it?

I went for a test drive with a friend that was buying another one and I was hooked on them straight away. The Chaser was purchased in basically stock form with wheels and coilovers, aero not on the car and needing some TLC.

How long have owned it for, and what’s your favourite thing about it?

I’ve owned the car for seven years now. I would have to say the engine work done by Rapid Performance; the car’s run flawlessly for the last six years since they did their job!

We see you’re the man behind DS Customworx! Tell us how owning your own automotive body shop has helped you with your build.

The car has been through four different colour styles and wheel setups over the years, so having the ability to carry it out myself has definitely been a massive perk. I think I’m finally happy with how it looks now.

What was the process behind creating the steel widebody and how long did that take you? The rear doors and inner tubs needed to be cut and rebuilt to a high radius for full clearance and an OEM look. Once that work was carried out, the ride height was set and the vehicle aligned. The steel guards start life as a flat sheet of panel steel, and using various methods on the English wheel, bead roller, shrinker stretcher, and hand hammer work, you end up with some flares ready to be welded on. New rear door gaps were made as the flare is built into the door as well. I then sourced a Series 2 front end for the car, chopped the ends off the bumper and lip, made new plastic extensions to suit the widebody, and plastic welded them on, along with doing a number plate delete to the bumper to achieve a sleek look. All up, the metal and plastic work took me around 60 hours.

You’ve been granted unlimited funds! What wheels are you running on your Chaser?

It’s a hard choice, probably a common one too, but it’s difficult to go past a set of Blitz 03s if I’m not paying.

Is there anything you’re itching to do next?

I’d love to add more power, but with how reliable this setup has been, it’s hard to change it.

Give us the lowdown on what it’s like behind the wheel of your Chaser …

I don’t use it as often as I’d like to or used to, but when I do, it quickly reminds me why I’ve still got it. It’s really hard to beat these Japanese cars.

If you could go back in time and do one thing on the car over again, what would it be?

There are a couple of things I would have done differently, mainly related to supporting mods that I could have done at the time of the engine work to make more power easily achievable. But all in all, I am pretty content with the car; there’s not much I’d change.

1997 Toyota Chaser Tourer V (JZX100)

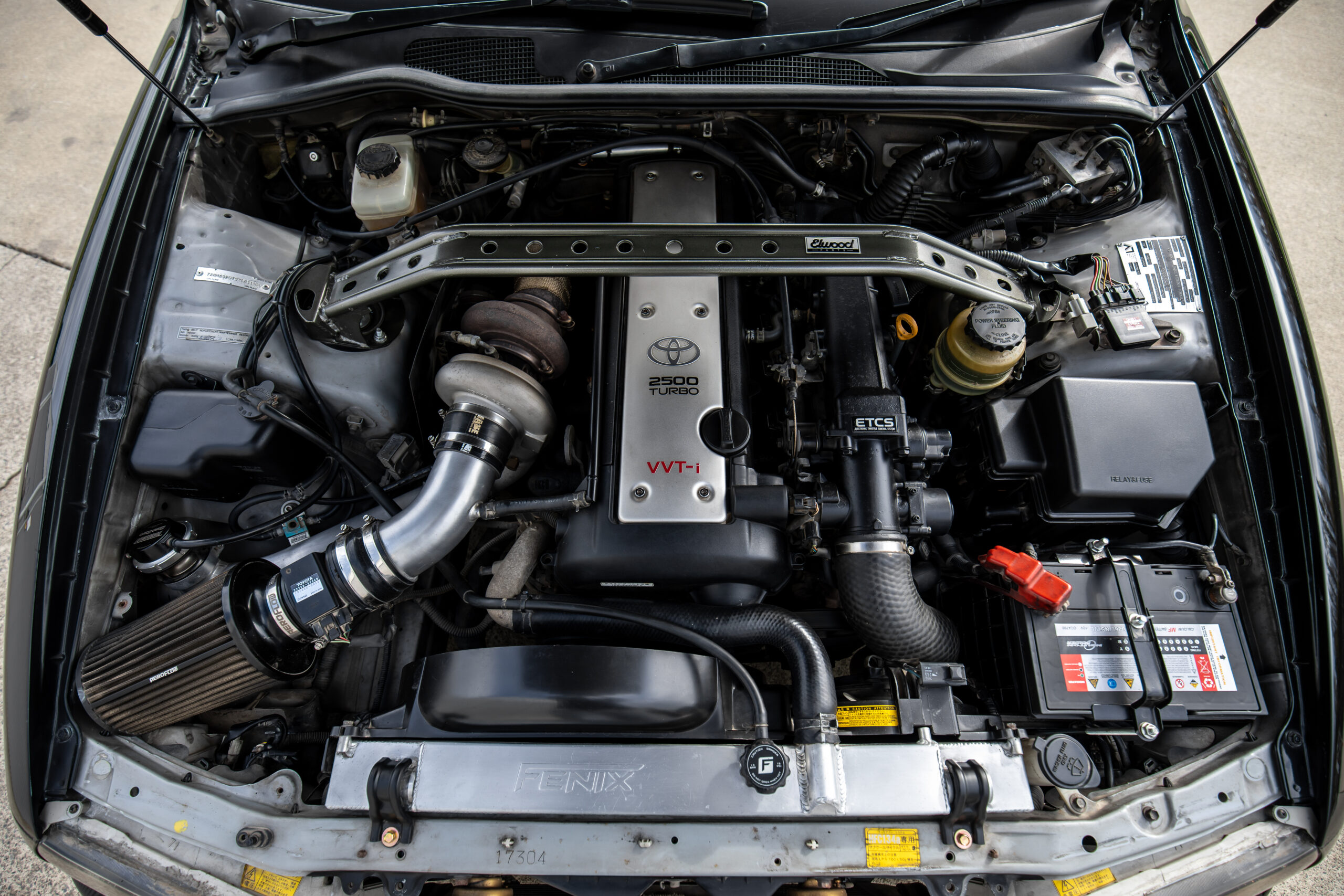

Engine: 1JZ-GTE, 2500cc six-cylinder, TD06 turbo, Sinco turbo manifold, stainless exhaust, HKS muffler, Siemens 880cc injectors, AEM 320LPH fuel pump, Turbosmart 45mm HyperGate, Turbosmart RacePort BOV, Turbosmart electronic boost controller, APEXi Power FC ECU

Driveline: Factory five-speed R154, Kaaz two-way diff

Interior: Recaro SR6 seats, Nardi steering wheel, TRD shift knob, custom floor panels

Exterior: Custom steel widebody, carbon-fibre Aero Twenty Three Power Aero mirrors, Nissan Phantom Black pearl paint

Wheels/tyres: (F) 19×9.5-inch (+11) (R) 19×10.5-inch (+11) SSR Type 6 Reiner, (F) 225/35R19 (R) 245/35R19 Nankang NS20

Suspension: Hakon adjustable coilovers, Rapid Performance billet NRCAs, complete Kazama Auto adjustable rear end

Brakes: Wilwood Superlite calipers, Znoelli rotors

Power: 347kW

Fuel type: 98 octane

Tuner: Reuben at Rapid Performance

Name: Doyle Harris-Lynch

Age: 26

Location: Christchurch

Occupation: Panel beater

Build time: Seven years

Length of ownership: Seven years

Thanks: I have to say thanks to an old boss of mine, Dave Archer at Automotive Concepts, and the boys there — Michael Bainbridge and Tom Edgar — for lending a hand with the preparation to get it across the line for paint. Big thanks to my mate Josh Grant for helping run everything in and out of the paint booth and for his general assistance; it all helped a lot.

The team at Rapid Performance also deserve a huge thank you. The car is a testament to their workmanship and knowledge of how to build a 100-per-cent–reliable street car. The car was left in their hands to make the upgrade choices, and it’s definitely proven itself.

Thanks to Aero Twenty Three for the made-to-order carbon fibre mirrors — the quality is second to none. I can’t forget Luke Baker for all his detailing and ceramic coating services, which have made the car a breeze to maintain.

Lastly, a big thanks to Jason Parker and the team at Way 2 Go Heliservices for providing the perfect location for the shoot!

_________________________________________________________________________________________________

This article originally appeared in New Zealand Performance Car issue 311