“Mark McIntyre’s crazy-aero, 2JZ-packin’ time attack–specific Nissan Silvia came out of nowhere, and packs one hell of a punch”

HVAC and refrigeration technician Mark McIntyre doesn’t spend a whole lot of time in New Zealand nowadays. Working on- and offshore in the north west of Australia on oil rigs and LNG processing facilities has its drawbacks, however, it does give one time to conjure up all sorts of downright-mental project plans. Combine this restrained isolation from society with a lifelong family motor-sport heritage, and you have a catalyst for something so well thought out and consummately executed that motor-sport enthusiasts the world over will be wondering what hit them.

After helping his old man Mark Snr out with his speedway racing for what must’ve seem like an eternity, it was finally time for Mark to step up to the plate and begin his own motor-sport timeline, as he explained. “I spent a lot of time at different race tracks around the country when I was younger. I started racing speedway when I was about 15 for a couple of years in the production saloon class, then moved on to go-karts until I was about 18. I then did another year of speedway in the saloon class in dad’s car before he sold it.” The McIntyre family made the decision to sell the saloon-class racer, so Mark decided it was time to change disciplines and build a drag car. A 2JZ-GTE engine was purchased, and numerous other much-needed components. However, the build never really took off, and after the passing of Mark’s grandfather, it was abundantly clear a circuit-capable beast was where his attention needed to be spent. “After spreading my pop’s ashes at Manfeild, the hunt began for the perfect circuit-car base,” Mark told us.

Finding something road legal to build upon was not essential, as Mark was satisfied with his current road-going weapons, so something caged and without an engine would be ideal, as he explained. “From the start we were looking for a rear-wheel-drive body, and that’s when I found this Nissan Silvia S14 on Trade Me. It had been raced down south with an SR20 in it, but the motor and gearbox had been taken out and the brakes were back to factory.” Mark continued, “We went up to Manawatu and had a look at it — everything was pretty much standard in it, but it had a very nice cage. It was a great body to use as a base and only cost me around $3000.” The plan — for now — was to build the Silvia for GT2 in the local GTRNZ circuit-racing class, however, having attended several of the Yokohama World Time Attack events in Sydney over the last few years, Mark had caught the bug, and things started to get a whole lot more serious.

The 2JZ-GTE engine Mark had sitting in the shed was to be used regardless, with the initial plan to to keep it as simple as possible to maintain reliability, but after trial fitting the engine it was found the factory twin-turbo set-up was in contact with the brake booster. Off the turbo set-up came, and so started the snowball of upgrades to follow. After dummy fitting a single-turbo set-up on the 2JZ with a cheap manifold and turbo, the team began to start work on the brakes, suspension, and driveline upgrades.

The first brakes to make it onto the car were R33 GTS25T items — with four-pot calipers up front, and two-pots down the back. Tein coilovers went in, and a GT-R diff and axle set-up was installed to take the extra torque. In the meantime, the 2JZ was getting a once-over by engine specialist Ewen McMillan at Motivation Engines, but the initial report wasn’t good. “A phone call came in from Ewen saying at some stage the engine had been full of water, and only the block, crank and bare head would be any good once cleaned. It was at this point that the engine got very serious — a large order from the States was made, and the motor build began.”

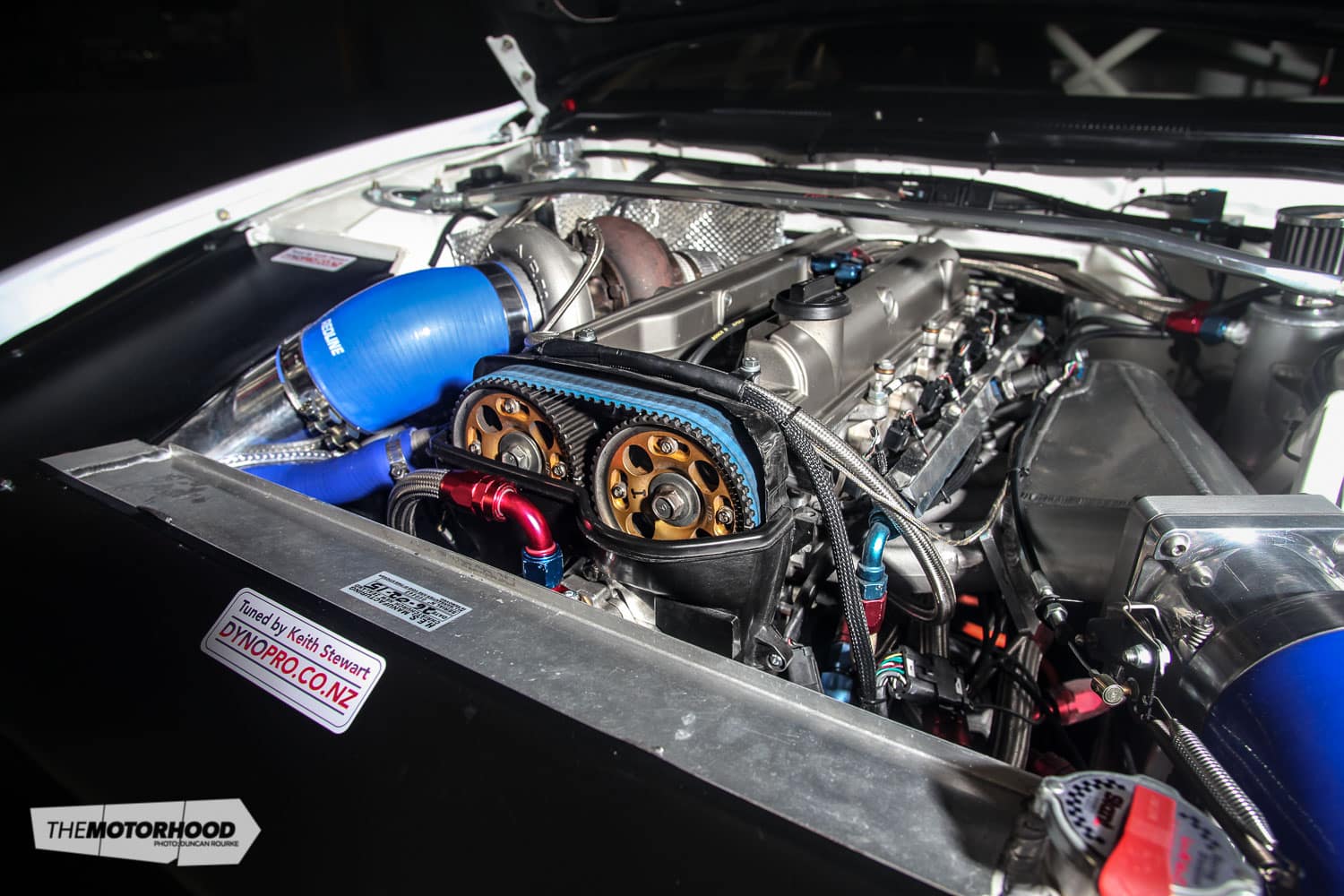

The 2JZ-GTE was built and prepared by Ewen with the upgraded components. The factory block and crank were reused, but with ACL race bearings, Wossner H-beam forged rods, and forged pistons. To further improve reliability, a Nutter Racing four-stage dry-sump oil pump was installed. While Ewen had the engine, he carried out some serious porting on the head and fitted Crow cams, Supertech valve springs and oversized valves. The manifolds were purchased locally. The exhaust side is a Sinco Customs unit, and the intake side was custom built. To give you an idea of the power goal Mark and the team had in mind, a huge Garrett T04Z turbo was installed with a 60mm TiAL external wastegate.

To supply enough fuel for the demanding conditions of circuit racing a custom fuel tank was installed in the boot, alongside an SX Performance 745kW fuel pump. Injector Dynamics ID1000 injectors were chosen to supply the 2JZ with the much-needed fuel to match the air forced into it by the T04Z turbo.

With the fuel set-up complete, it was now up to NZEFI to supply an ignition system up to the task — six NZEFI coil packs were mounted inside the cabin on a custom mount under the dashboard. Originally a Link G4 ECU was wired in, but the switch was made to a Vi-PEC unit, retaining the original Link harness which was modified to suit by NZ Wiring, which concluded the complete rewire. The engine set-up was now complete, and it was ready to be put through its paces on the dyno. After a few minor issues on its first session, Keith Stewart had the 2JZ laying down 500kW (671hp) at the wheels on 19psi of boost.

The newly confirmed power level was impressive, but unfortunately the Toyota R154 was now deemed not up to the task of handling the intense torque the 2JZ was producing. Mark said, “The R154 was sold as it wouldn’t be up to the task, and with advice from a few key people, a five-speed Tremec TKO 600 was purchased through Australia, out of the States. These Tremec boxes came factory in the supercharged Corvettes, which make a lot of torque, so with the upgraded gearset it should be more than up to the task.” Other than a custom MRP flywheel and a triple-plate clutch, the drivetrain set-up was a relatively seamless process.

Another area now deemed unusable was the braking department. The R33 four-pots were pulled off and replaced with much larger eight-pot calipers with 326mm two-piece discs, and the rear two-pots were removed, and replaced with four-pot Wilwood calipers with DBA slotted discs. “I think the only things that are Silvia in the car now are the chassis, steering rack, and cross members. Everything in the suspension has been replaced with GKTECH gear, but one of the best upgrades would have to be the GKTECH knuckles, which drop the whole car by 40mm. This helps keep all the arms inline and gives us a lot of range and adjustment with the Tein coilovers,” Mark explained. Handling, rigidity, and braking were all near completion, and it was time to get it looking presentable, gripping up, and holding on tight.

Aero is probably one of the highest priorities with any international-spec time-attack vehicle. Having downforce to get you through the corners quicker is something teams sometimes spend hundreds of thousands developing. However, as Mark wanted to first test the vehicle before full development, aero was ordered through an Australian named Freddy at Topstage, who builds aero for a living, and also competes in time attack with his own S14. “Moving forward, we will be looking to get someone involved to build on this and aim to have something in the lines of what the World Time Attack guys are running,” Mark told us.

With the initial and essential aero sorted, it was now time to get it gripping up — 18- by by 10-inch and 18- by by 12-inch Rota GTR-D wheels shod in 250/640R18 and 300/650R18 Avon slicks should see it stick like you know what to a blanket.

On its first outing at the V 4&Rotary North Island Jamboree, Mark managed a very rapid one minute, 11.8 seconds around the full Manfeild circuit, which nabbed him second place, and he was only beaten by Garth Walden in the extremely well tested and proven Hell Racing Mitsubishi Evo. “For the little testing and seat time in the car we’ve had, we were really happy with how it went. We still had a few issues with oil breathing onto the front-left tyre causing understeer, the rear brake bias not working, a bad vibration through the car at high speeds and few other things,” Mark explained.

With these minor issues resolved and some more seat time, it looks as though we may have new contender as the Superlap champion here in New Zealand and a big hitter in Australia, as Mark said. “Once I have had more seat time in the car and we have it at a level where we want it, I’ll head over to Australia. We may even build up another chassis with a few changes that we have learned from this car before we do. If you’re going all that way and spending a lot of money doing so, you want to make sure everything is up to the task. I also plan on keeping the car over there for a couple of months after, and race around Australia in it. It would be good to pit it against the Australians on their tracks while the car is over there.”

1994 Nissan Silvia S14

Engine

- Model: Toyota 2JZ-GTE, 3000cc, in-line six cylinder

- Block: ACL race bearings, ARP rod and head bolts, Ross Racing damper, Wossner forged pistons and H-beam rods

- Head: Crow cams, Supertech valve gear, oversized valves, custom porting and head work

- Intake: 3.5-inch intake pipe, Redline silicone joiners, 80mm throttle body, custom plenum, K&N pod filter

- Turbo: Garrett TO4Z

- Wastegate: TiAL 60mm V-band

- BOV: TiAL 40mm

- Fuel: JAZ 30-litre plastic fuel cell, SX Performance 745kW/1000hp fuel pump and fuel pressure regulator, Aeroflow fittings, custom fuel rail, Injector Dynamics ID1000 injectors

- Ignition: Six NZEFI inductive coil packs, custom NZEFI coil mount, Bosch spark plug leads, NGK 8 V-Power spark plugs

- Exhaust: Sinco turbo manifold, three-inch turbo downpipe with V-band into muffler, 2.5-inch wastegate pipe into muffler, 3.5-inch out of muffler to driver-side side exit

- Cooling: 600x300x100mm Redline Performance bar and plate intercooler, Custom Heatex alloy radiator, Fluidline remote oil cooler and oil filter, 10-litre dry sump tank

- ECU: Vi-PEC i88

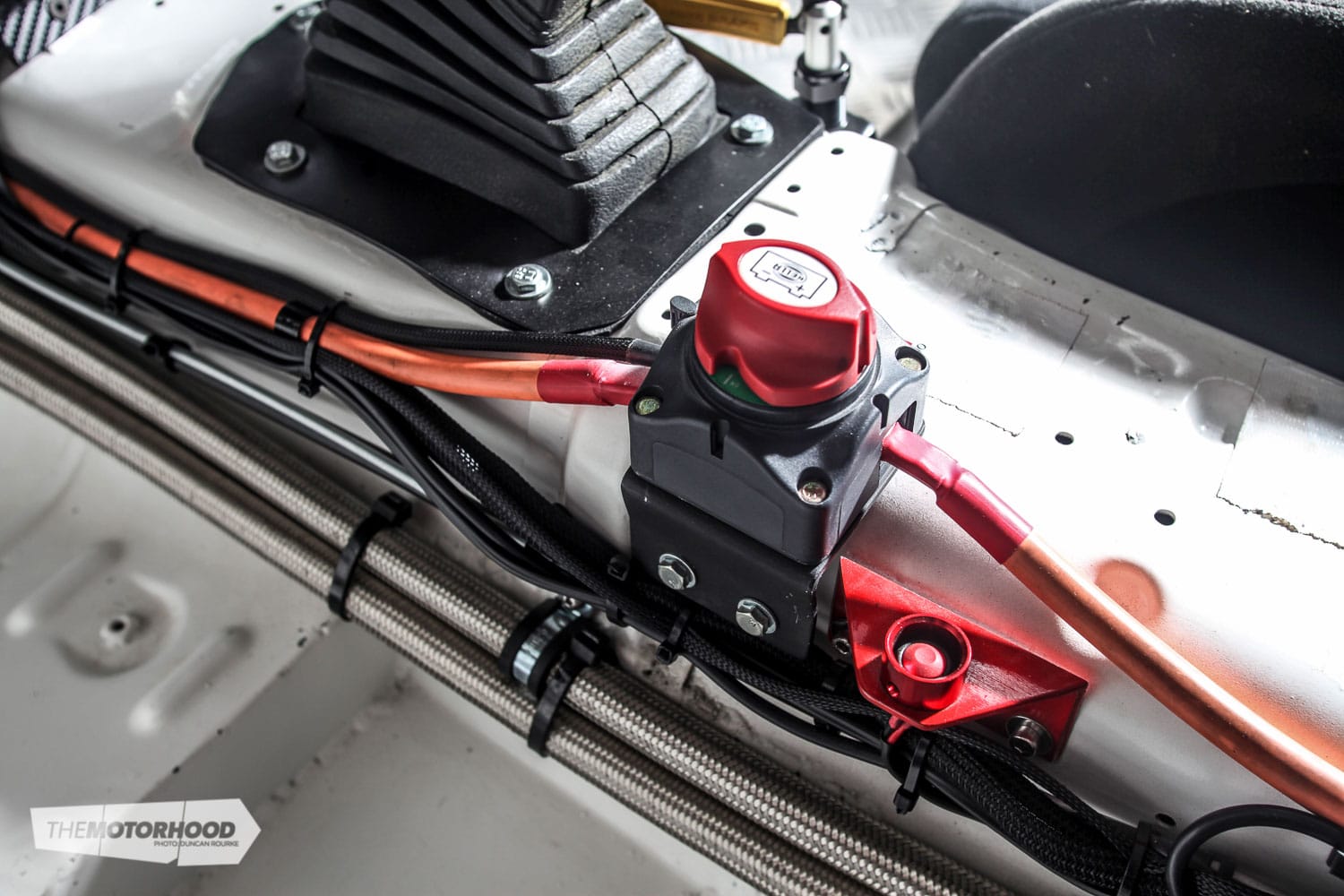

- Other: Full deloom and rewire by NZ Wiring, custom switch panel, Nutter Racing four-stage dry-sump oil pump with braided lines

Driveline

- Gearbox: Tremec TKO 600, Liberty face-plated gearset

- Clutch: Quartermaster triple plate, hydraulic release bearing

- Flywheel: MRP custom steel

- Diff: R32 GT-R, Nismo LSD

- Other: R32 GT-R axles and hubs, custom two-piece driveshaft

Support

- Struts: Tein adjustable coilovers

- Springs: Tein

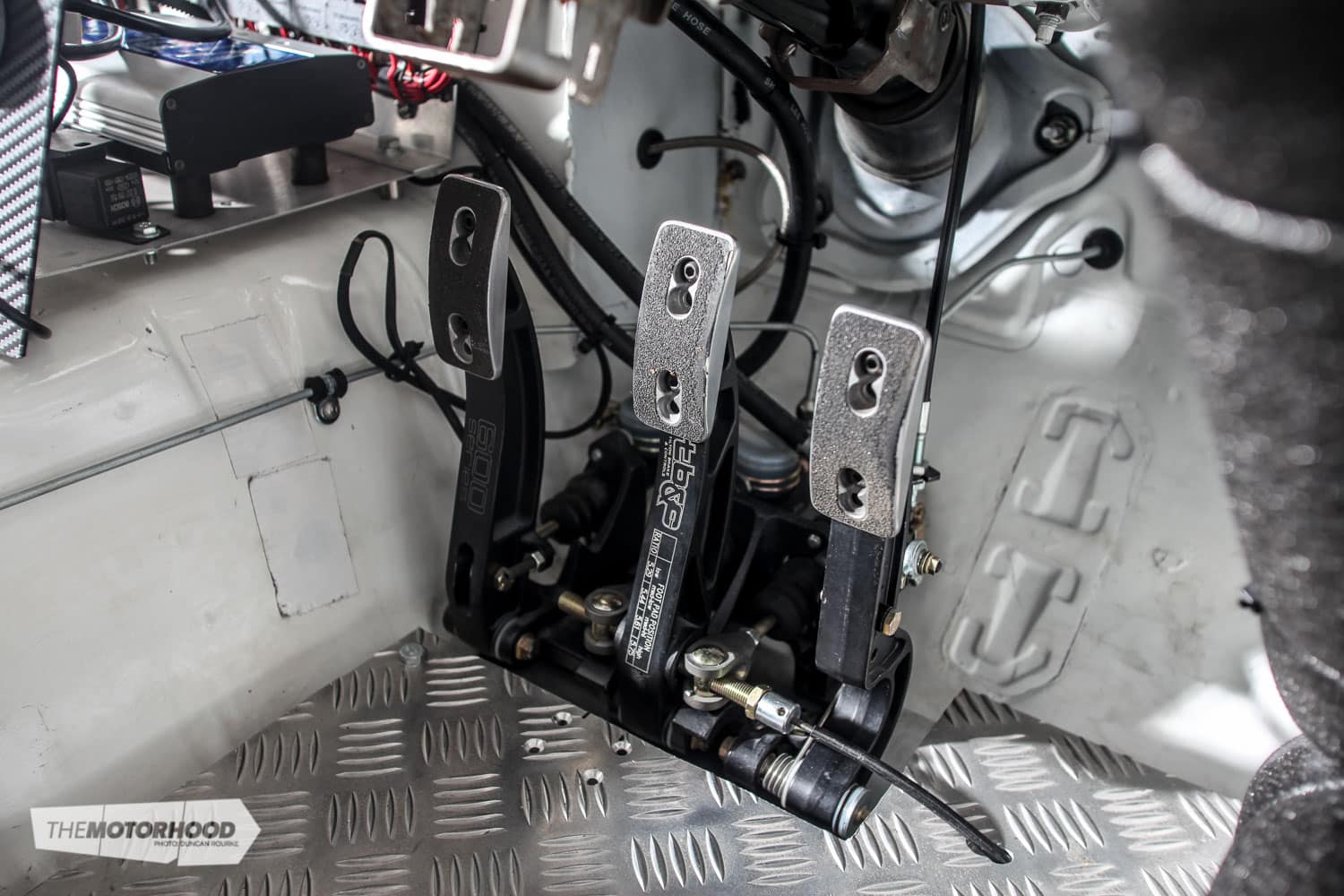

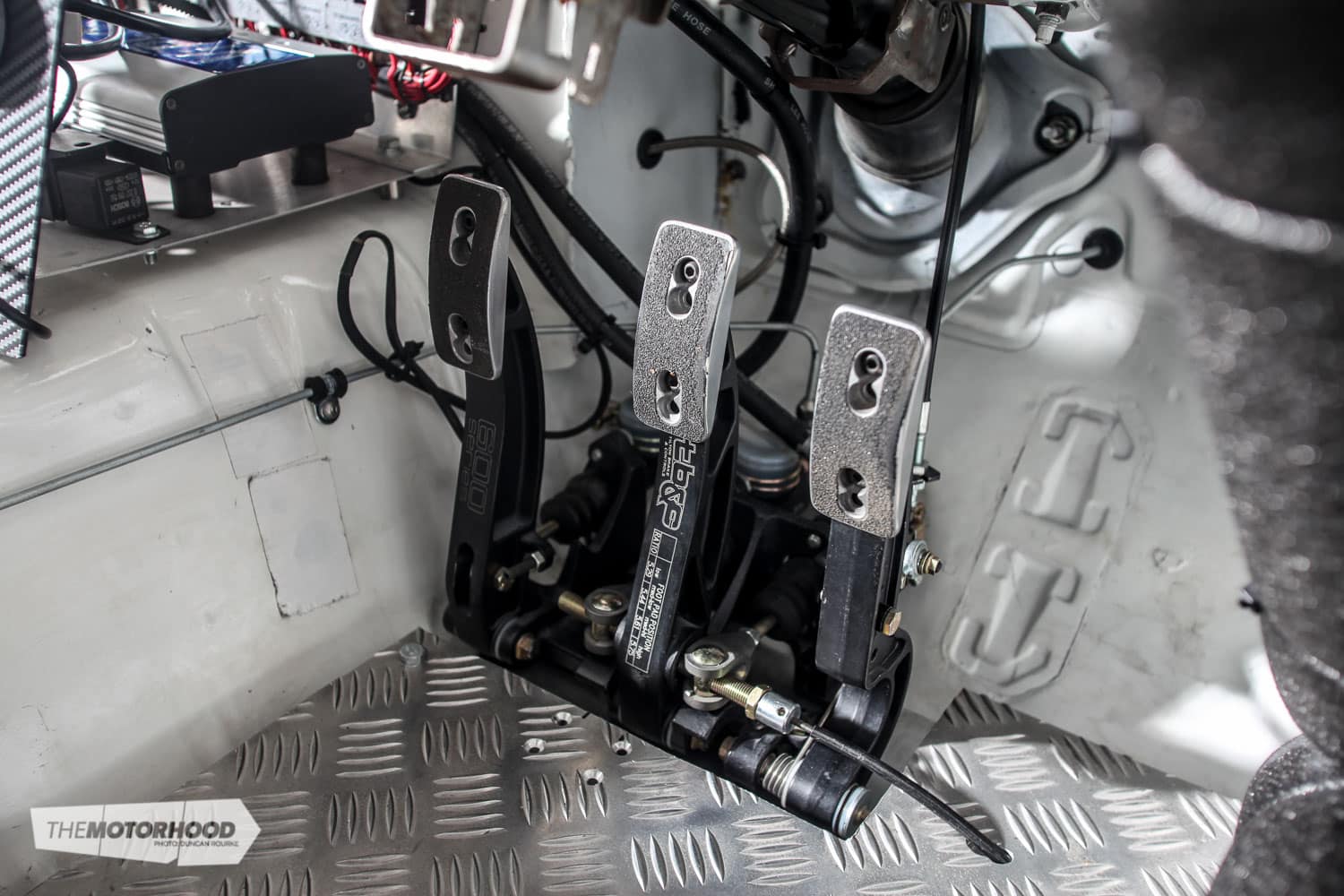

- Brakes: Tilton floor-mounted pedal box with adjustable bias, Tilton inline rear brake bias (F) Eight-pot D2 calipers, 326mm two-piece rotors (R) Four-pot Wilwood calipers, factory R33 GTS25T rotors

- Other: (F) GKTECH lower control arms, caster arms, 40mm drop-down knuckles, K frame/caster rod bar; Whiteline sway bar, Whiteline strut brace (R) GKTECH traction, toe, and camber arms; Driftworks 40mm drop knuckles, Whiteline sway bar

Shoes

- Wheels: (F) 18×10-inch Rota GTR-D (R) 18×12-inch Rota GTR-D

- Tyres: (F) 250/640R18 Dunlop/Avon slicks (R) 300/650R18 Dunlop/Avon slicks

Exterior

- Paint: 2K white prepped and painted by Matt Gaskin at Rolrich Panel and Paint

- Enhancements: Custom Topstage carbon-fibre front bumper and undertray, carbon-fibre bonnet and boot, custom fibreglass front and rear guards, side skirts and doors, Plastics 4 Performance side and rear Lexan windows

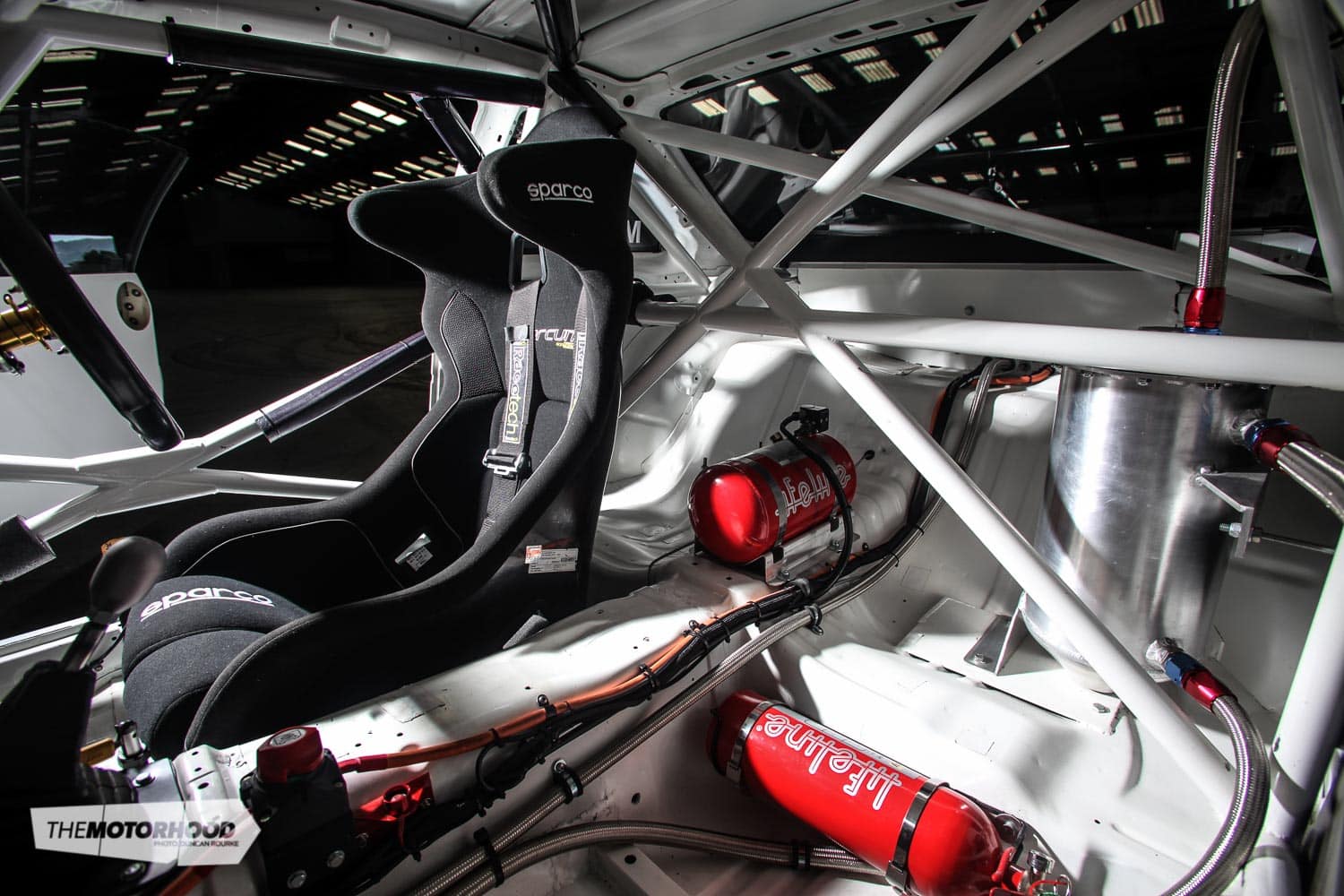

Interior

- Seats: Sparco Circuit 2, Racetech five-point harness

- Steering wheel: Sparco

- Instrumentation: Auto Meter 2⅝ oil pressure, water temperature, fuel pressure, and boost gauges, air/fuel ratio gauge, Auto Meter five-inch tachometer with shift light

- Other: Lifeline on-board fire extinguisher system, 3.5kg hand-held fire extinguisher

Performance

- Power: 500kW (671hp) at the wheels on 19psi of boost with Avgas (745Nm)

Circuit times: Manfeild 1:11.8

Driver profile

- Driver/owner: Mark McIntyre

- Age: 27

- Location: Wellington/Australia

- Occupation: HVAC technician

- Build time: 3.5 years

- Length of ownership: 3.5 years

- Thanks: Thanks to dad who has built most of the car, Macbilt Engineering, Keith Stewart for the dyno work, Ewen McMillan at Motivation Engines, Autolign Petone, Freddy at Topstage, Geoff at NZ Wiring, GKTECH, Aztech Engineering, Rolrich Panel and Paint, friends and family that have helped, Plastics 4 Performance, Burt at Powder Surfaces, Bruce at Turnbull Engineering, Macca Industries, JB Hughes

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

This article was originally published in NZ Performance Car Issue No. 224, and you can pick up a print copy or a digital copy of the magazine below: