“Sublime, slammed, and unsurpassed, this 1969 Crown is a lesson in building the perfect retro cruiser at home”

Built not bought. Have a think about that somewhat overused cliché that runs rampant among the automotive modifying community, particularly within those subgroups that concern themselves with the building of older cars and hot rods. It’s a simple turn of phrase which, at face value, quite literally exclaims to the world, “I built my car, in a shed, with a bunch of tools and my own two hands.” Here in Aotearoa, hand in hand with the ‘number eight wire’ mentality, we share a special kind of relationship with this idiom as a means of validation, a concise method of defining oneself as a Kiwi creator of automotive bliss.

But delve a little deeper into this expression. Beyond the surface it represents so much more than what can be gleaned at face value. It represents hours of laborious toil, countless bloody knuckles, untold greasy fingernails, and perhaps above all, a dogged determination to make it work, and get it right. Call it what you will, it’s solidly entrenched in the romantic notion that as Kiwis, we’ll have a crack at it and we’ll damn well do a fine job.

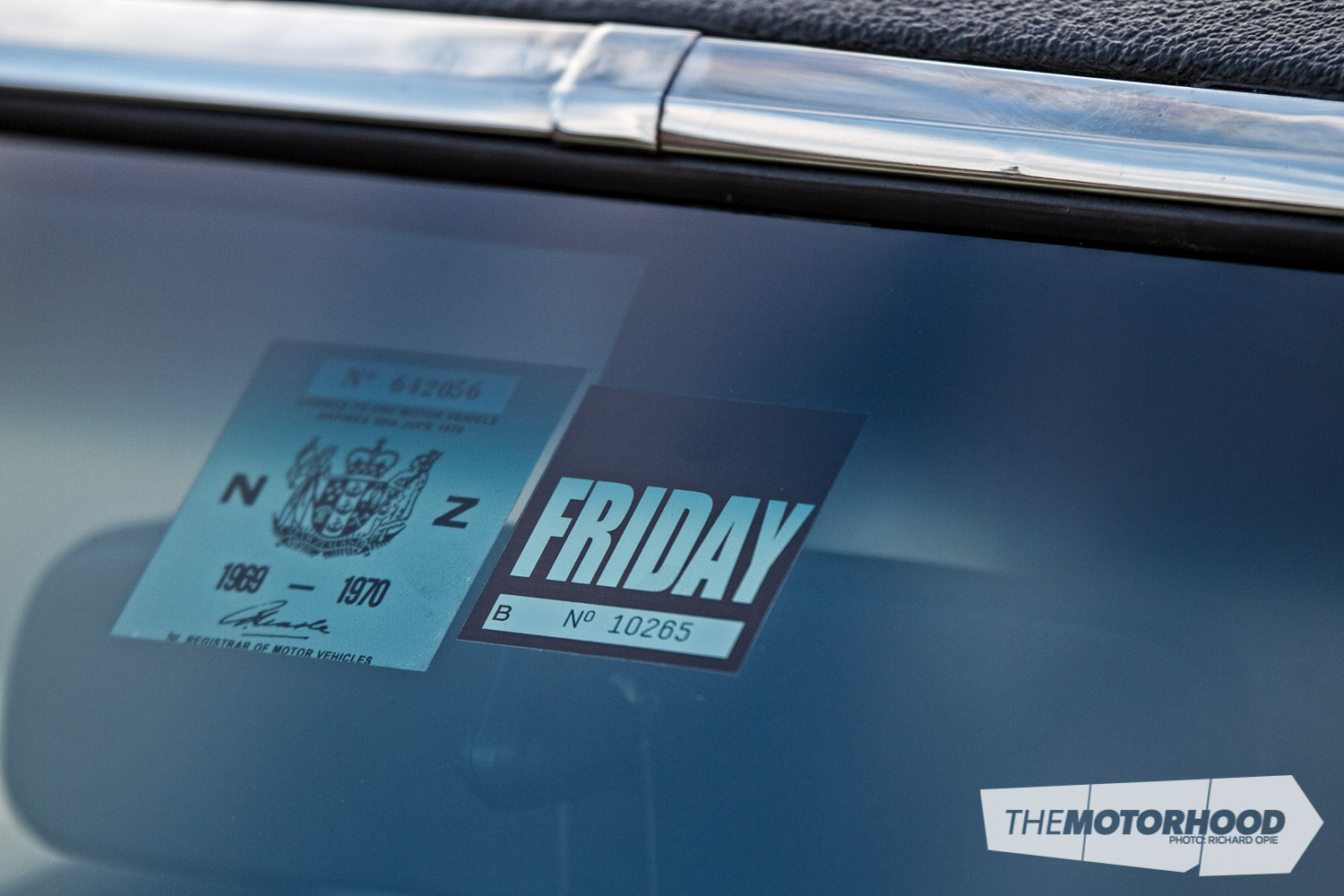

Beneath the flickering fluorescent light fittings of a suburban Auckland garage, serial Toyota-fiddler David Arthur spent two years of hard labour honing his craft — thinking, planning, and learning as his 1969 Toyota Crown hardtop coupe took shape, before finally rolling (well, scraping!) out into the sunlight under its own power during the summer of 2014.

Resplendent in its unique shade of green, and sporting the 1970s luxury touch of a vinyl roof, the Crown represented one man’s expression of the perfect shed-built retro Japanese cruiser.

David’s a self-confessed retro Toyota maniac and, perhaps even more noteworthy, possesses an enthusiasm for Toyota’s perennial ‘big-body’ sedan of their product range — the Crown. Although now becoming increasingly desirable with the rising acceptance of older Japanese cars as classics in their own right, David’s torrid love (and hate!) affair with the big Toyotas began almost by accident — after becoming smitten with an H230 Nissan Cedric (Datsun 260C) coupe sometime in the 1990s and failing to locate one. Coming up scarce, the call was made to investigate one of the comparatively common Crowns for sale in the Trade & Exchange (that’s right — actual classifieds on paper). Shortly after, David was driving home in an MS65 Crown sedan, beginning years of recidivist offending as this soon blossomed into cyclic Crown ownership, including no less than six MS75 hardtop coupe versions, the first of which really kicked off the love for the pillarless hardtop alternative to the comparatively staid four door option.

Fast forward a few years, and following a period where not one Crown was gracing the shed or the lawn, David came across an MS51 Crown hardtop for sale — “I had no idea the MS51 even existed until years after owning the MS75. Then I saw one for sale in New Zealand, and I had to have it.” As a base, the car was the perfect blank canvas — think original dull white paint, straight panels, and extremely minimal levels of rust, owing to the South Island life the car had lived. A full complement of original trim was enough to seal the deal. Wheeled from transporter to shed, the build began.

The striking aesthetics of the Crown owe much in part to the fact that the car had many of the requisite parts to enable a body resurrection rivalling that of cars traditionally restored to factory-spec as classics. With skills honed on previous builds, hours have been put into the sheetmetal of the MS51, ensuring arrow straight panels, panel gaps with the regularity of the six o’clock news, and the feature David’s most proud of creating — the front and rear flared arches.

With no prior experience, and only an experienced panel beater friend to call on for guidance, both front and rear flares have been created purely by stretching the existing sheet metal — no material has been added, simply time honoured metalworking techniques to hammer the previously inward sloping arches (as was the style at the time) into curvaceous spans across the wheels. Achieving an aim of minimal filler, the entirely shed-fettled bodywork was transferred to the spray booth and coated in a factory ‘Spring Green’ Toyota hue, in keeping with the car’s period body lines. A unique cherry atop the hardtop silhouette is the ‘unobtanium’ JDM front clip, featuring unusual-for-period rectangular lamps and trim bespoke to Japanese market only models.

Contributing to the Crown’s neck breaking presence is, of course, that ride height — or, rather, the lack thereof. David explains the ethos behind bringing the Crown closer to the asphalt, “I realized that I had a massive amount of work to get it as low as it needed to be on the 15x10s. Compromise was not an option — it was on the ground or nothing. So, I got the grinder out and started cutting!”

Beneath the sparkling bodywork, the Crown achieves the road grading ride height courtesy of a Ridetech air ride system, complete with self-levelling sensors. Another product of shed-borne tinkering, careful consideration was required to ensure the front geometry remained acceptable throughout the ride height of the car, with shock mounting, wishbone, and tie rod angles all requiring trial and error to get exactly right to ensure the car’s form was graced with function. Out the back, the chassis has been pinched and C-notched to allow room for the rear wheels to rotate, in conjunction with a narrowed F-series LSD disc brake diff and very mildly tubbed rear inner guards.

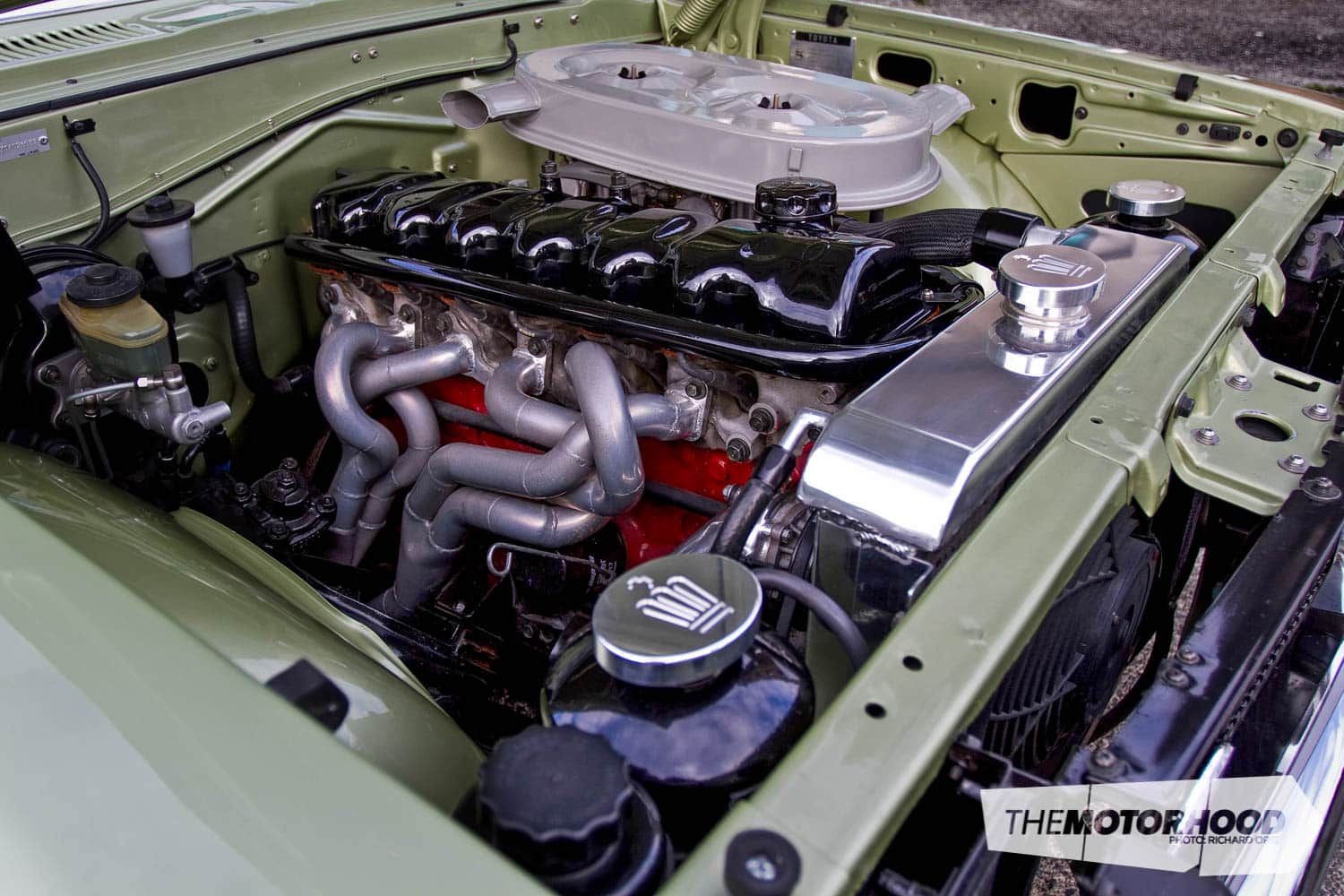

And those aforementioned wheels? A conscious decision was made early in the build that double-digit width was going to grace the rear arches no matter what, so a set of 15×8- and 15×10-inch Weld RT-S forged wheels were duly ordered from the USA, providing a distinctly American-inspired visual to complement the pseudo-American styling so favoured by 1960s Japan. Mopar-sourced wing mirrors atop custom billet machined pedestals and lowrider-inspired twin telescopic aerials off the rear deck tie together a subtle, tasteful exterior package that would slip seamlessly into a Mooneyes Japan show, although not without raising an eyebrow or two of approval.Not merely striking from the exterior, the silky-smooth theme continues once the bonnet is popped. Although the car had been butchered with the addition of a 265 Hemi ‘slant six’ and a suitably hacked up firewall to accommodate it, order was soon restored with the reinstatement of Toyota motivation in the form of a 2.6-litre 4M inline six, more commonly found between the arches of the later MS65 Crown. Amidst the fluid lines of the smoothed engine bay, although stock internally, the 4M benefits from a pair of refurbished factory twin carbs hiding beneath a factory airbox. Snaking from the exhaust side of the head is a set of custom equal length headers, leading into a cackly 2.25-inch straight through exhaust.

Inside, much of the period character of the Crown has been retained. As one of the few jobs outsourced, upholstery wizards Waikumete Upholstery created an immaculately 1960s space with a new headlining, reupholstered and bolstered factory front and rear seats, and plush carpet updating the tactile experience of the Crown somewhat. A further nod to neo-American Japanese style is found in the form of a Mooneyes gear knob, while the immortal style of a Nardi Classic wheel in stark black directs the Crown to the nearest sunset, along the most scenic of routes.

This then brings us to a final point — regardless of the absolute OCD levels of attention to detail of the Crown’s build, it has been constructed in a shed for one reason above all, to be driven. Since construction, the car has been driven extensively throughout the country (including a mammoth South Island roadie), performing faultlessly, riding comfortably, and providing conversation at each and every stop. Testament to the quality that can be produced from within four comparatively small walls, this definitely isn’t the last eye-opener you’ll find slipping from beneath David’s garage door. With his two past NZ Performance Car featured Celicas in constant development, the thirst to create simply does not subside — rather, it serves to stimulate, motivate, and inspire future builds.

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

1969 Toyota Crown HT (MS51)

Engine

- Model: Toyota 4M, 2600cc, six cylinder

- Block: Stock

- Head: Stock

- Intake: Rebuilt factory option twin carbs

- Exhaust: Custom extractors, custom 2.25-inch straight exhaust

- Fuel: Stock

- Ignition: Hidden leads, electronic ignition

- Cooling: Aluminium multi-core radiator and electric fan

- Extra: Deloomed, no visible hose clamps, smoothed panel work, hidden power steering pump, custom windscreen washer bottle, custom radiator overflow bottle, custom power steer reservoir, billet CNC machined caps

Support

- Struts: Custom-valved Bilstein yellow shocks, Ridetech airbags

- Brakes: (F) Peugeot 505 turbo rotors, LN106 Hilux calipers (R), MS112 Toyota Crown discs and calipers

- Other: Ridetech Air Ride system with electronic level controller, single compressor, boot mounted tank, custom front A-arms, custom front shock mounts, relocated sway bar mounts, rear half of chassis pinched, rear chassis C-notch, custom rear bag mounts in chassis and on the diff

Drive

- Gearbox: Toyota W50, four-speed

- Clutch: Stock

- Flywheel: Stock

- Diff: Cut and narrowed Toyota F-series housing, 3.9:1 Toyota LSD

Interior

- Seats: Reconditioned factory seats

- Steering wheel: Nardi Classic wheel

- Instrumentation: Factory gauges, Ridetech auto level airbag controller

- ICE: Alpine head unit, Alpine amplifiers, DLS front components, Fusion rear speakers

- Other: Mooneyes gearknob, full interior retrim including carpets and headlining

Exterior

- Paint: Resprayed in Toyota ‘Spring Green’ paint

- Enhancements: Hand-beaten front and rear steel flared arches

- Other: Vinyl roof, handmade chrome roof trims, CNC machined billet mirror pedestals, Mopar wing mirrors, rechromed bumpers, refurbished and polished chrome and stainless trim

Shoes

- Wheels: (F) 15×8-inch custom made Weld RT-S wheels, (R) 15×10-inch custom made Weld RT-S wheels

- Tyres: (F) 205/50R15 GT Champiro, (R) 225/50R15 GT Champiro

Power

- Unable to spin rollers

- 0-400m: Mid-1:13s

This article was originally featured in NZ Performance Car Issue No. 224. Pick up a print copy or a digital copy of the edition here: