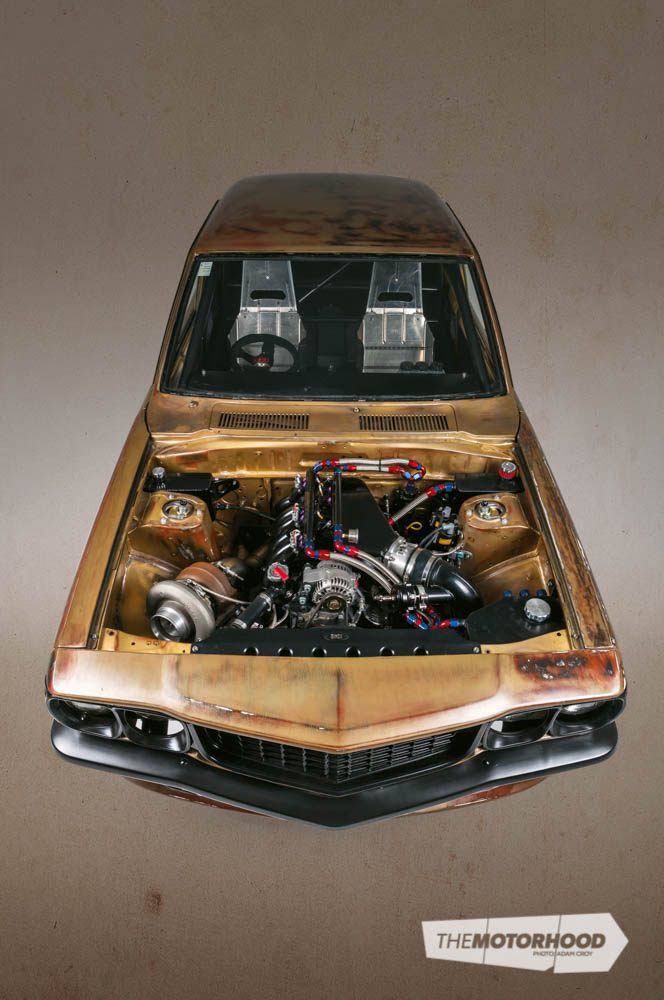

“Aaron Keach played the stance game, and now he is searching for the perfect balance between form and function with the killer 20B under the hood of this street and strip 808”

Cast your mind back around four years, and the stance movement was really just starting to find its feet both here in New Zealand, and on a world stage. Tyre stretch, demon camber, rims that poked out of the guards, and wheels wider than eight inches were all on the rise. One of the most insane New Zealand builds — and one which gained plenty of overseas notoriety — was Aaron Keach’s 520kW 20B-powered FC RX-7.

But there was a problem — although it looked awesome, all that 20B power up front was going to waste, as Aaron explained. “Any time you put your foot down it just spun the rears. I got sick of not be able to plant it. You couldn’t use the power, it would just go all over the road. I decided to make the most of the 20B by putting it into something which could handle the jandal. I wanted something that would hook up, something with slicks.”

At around the same time, Brent Curran from CBR had a seemingly OK-condition piston-powered Mazda 808 which was the perfect base for the build. Aaron was sold, and over the next two years it was transformed into a tough street/strip small-tyre 808.

The FC RX-7 was stripped of all the necessary components, and the rolling shell was passed on. The only problem was, as Aaron soon found out, his simple plan of swapping it all over to the new chassis ready to go racing quickly spiralled out of control. “I was originally just going to put in a Series 4 [RX-7] gearbox and Hilux diff behind the 20B, but then Brent got in my ear and suggested that I put a decent diff in it, and just run it on factory leaf springs. So I got a good diff [an alloy Strange nine-inch], then he said, ‘if you have the diff you may as well three-link it’, so I did that, then he said, ‘oh well since you have all that shit you may as well get a decent gearbox’. So it just went from there.It’s pretty much Brent’s fault that it got to where it is.”

Early on in the build the 808 was dropped to GT Refinishers, where the seemingly OK-condition shell soon revealed its true condition — with rusty quarters and a rusted out and poorly-repaired floorpan.

“We ended up cutting off the entire rear end, and I purchased a rear cut for $100, which Grant stitched on,” Aaron explains. One of the bigger tasks for GT was the extensive interior tin-work covering the adjustable three-link nine-inch diff and 28- by nine-inch Mickey Thompson ET Streets. This is where the build diverted from your traditional 28-by-nine-tyred drag car, which would retain the factory chassis rails, but given the rest of the 808’s chassis that would have left it sitting much higher than Aaron wanted.

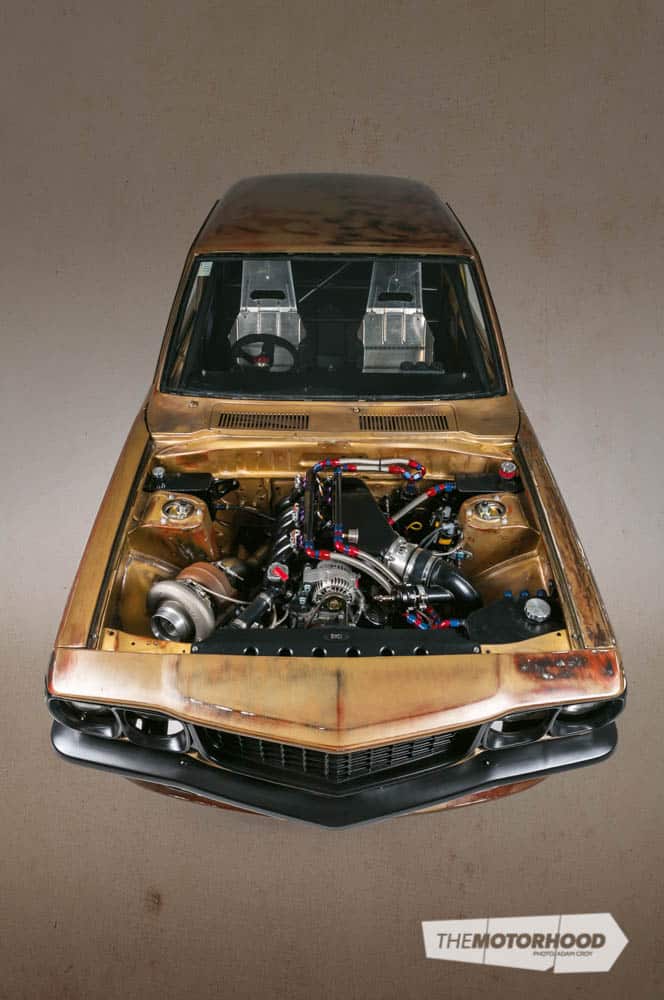

Once the chassis and tin work was sorted it was handed over to Sinco Customs in Hamilton, to have the 20B mounted and a few other pieces of fabrication done. That was the idea anyway, but it soon spiralled into refabricating everything, as nothing swapped over from the FC’s engine bay would play ball when it came to fitting it into the tighter confines of the 808’s engine bay, and that meant new manifolds, catch can, plenum, cooling system, and exhaust. Basically the only remaining bolt-on parts carried over from the FC were some of the injectors, the ECU and the engine block.

The goal was to run on both street and strip, so when it came to gearbox selection a compromise had to be made, as a full drag box wouldn’t suit those trips to the dairy or beach, and a synchro gearbox wouldn’t last very long at the track with big launches and high-rev changes. The result was a Tremec TKO600 with a Liberty dog-engagement gear set.

Aaron collected the car from Sinco just a few weeks ahead of Christmas 2014, and with the unveil date set for the 2015 V 4&Rotary Nationals just over a month and a half out, he had only six weeks to build a complete car — including two weeks for paint.

So while everyone was at the beach or bach over summer, Aaron was furiously piecing the car together. “I basically built it in just over a month from a bare shell,” he explained. And by build we mean everything, including wiring in the MicroTech himself: “I had someone wire the FC for me and he butchered it, which killed a 20K motor. I then had a shop try and fix it, but they butchered it too. I basically rewired that entire car myself, and made it work. That’s why I went with the MicroTech in this car, as I knew what I was doing with it. I have wired everything on its own circuit so that it’s easy to trace problems down the track. If I have an issue with, say, a gauge, a coil, or a fuel pump, it’s only that circuit I need to look at. It makes it much easier to problem-solve.”

A few weeks before the Nationals the car was handed over to GT Refinishers so the team could get a coat of paint on. Thankfully no panel work was needed, as things got a little crazy. “I like to do things a little different. At the end of the day everyone does nice, shiny paint. It just wouldn’t have stood out. This way it stands out, and I don’t have to worry about scratching or denting it, as it’s already got dents,” Aaron explained.

Many will remember his FC, which had a full satin balck steel widebody and bright green Work Wheels — and this time they decided to go one step wilder, with a faux patina. Many people believe it’s a vinyl wrap, but it’s actually the result of hours of painting and sanding before a final, base clear coat to seal it all in. The finishing touch is the Alejandro’s Mower Repairs shop signs on each door, as a little tongue-in-cheek poked at the rotary engine that lies beneath the car’s skin.

The week leading up to the show it was all hands on deck to get the project completed and fired for the first time so it could be driven into the ASB Showgrounds, where it featured as one of the main unveil cars. But now all of that is done, it’s time to get the little jobs sorted so it can be made road legal, and Aaron can get some seat time and learn the art of pedalling a big-power small-tyre drag car.

First up he will retune the MicroTech with the entire new engine set-up, he’s hoping it will make close to 600kW on E85 at the wheels. His FC managed a best ET of 11.4 on mega-camber street rubber with 520kW and a ton more weight. All signs point to the fact that this will be a fast street car, whichever way you look at it.

If you ask us, Aaron has managed to build it to look equally — or more — tough than the FC it’s replacing, and this time around he will actually be able to put that power to the ground in what we hope will result in some wheels-up antics — the perfect balance of form and function.

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

1977 Mazda 808 (STC)

Engine

- Model: Mazda 20B, 2000cc, triple rotor

- Block: CBR bridge-port plates, 2mm apex seals, lightened and balanced rotating assembly, custom alloy sump.

- Intake: Sinco intake manifold, Accufab 105mm throttle body, custom Sinco intercooler, four-inch intercooler piping

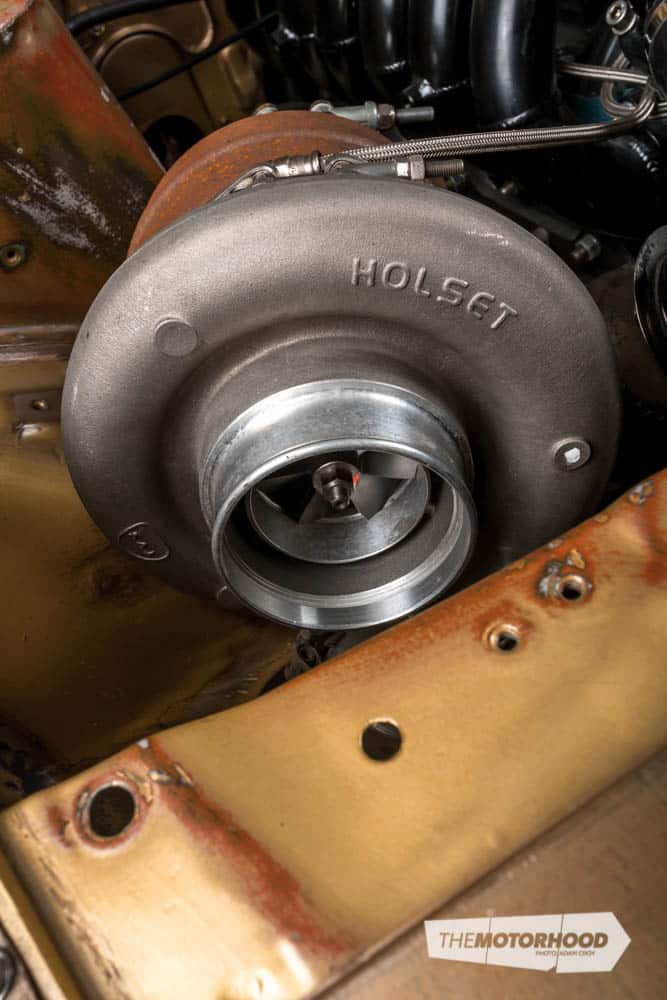

- Turbo: Holset Pro55

- Wastegate: TiAL 60mm

- BOV: TiAL 50mm

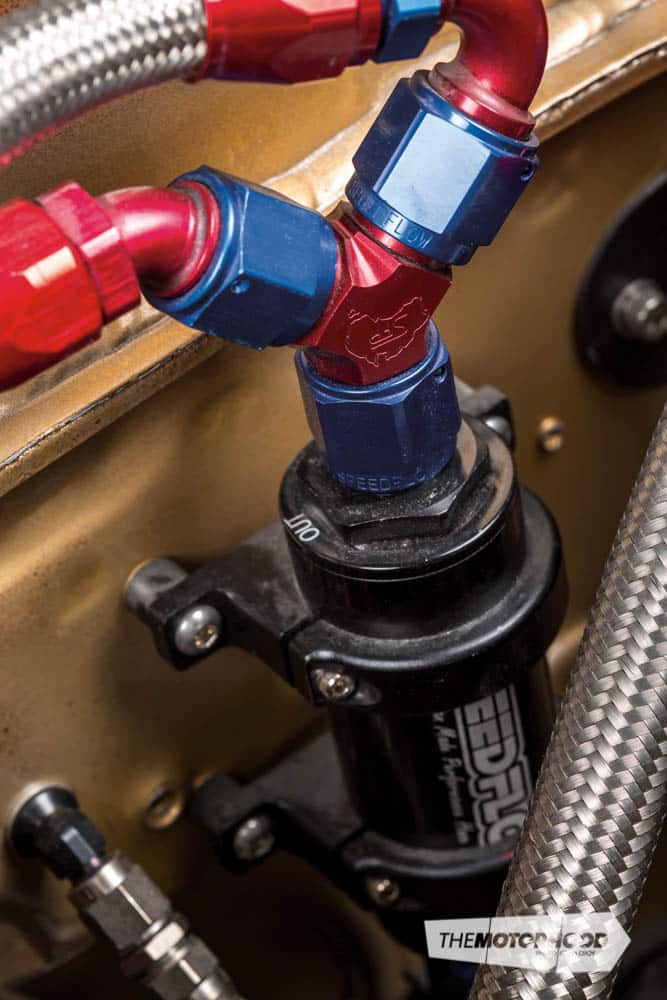

- Fuel: Aeromotive mechanical fuel pump, Aeromotive fuel-pressure regulator, three ID1000cc injectors, six ID2000cc injectors, Sinco 10-litre fuel tank, Speedflow inline filter

- Ignition: MSD leads, NGK plugs, Bosch coils

- Exhaust: Sinco stainless exhaust manifold, four-inch stainless side-exit exhaust

- Cooling: Griffin radiator, AN fittings

- ECU: MicroTech LT-16C

- Other: Turbosmart e-Boost2, Sinco oil tank, Sinco radiator overflow tank, Speedflow fittings throughout

Driveline

- Gearbox: Tremec TKO600, Liberty face-plated gearset

- Clutch: Tilton twin-plate

- Flywheel: Custom flywheel

- Diff: Alloy Strange full spool

- Other: Currie axles, custom driveshaft, adjustable three-link, adjustable Panhard

Support

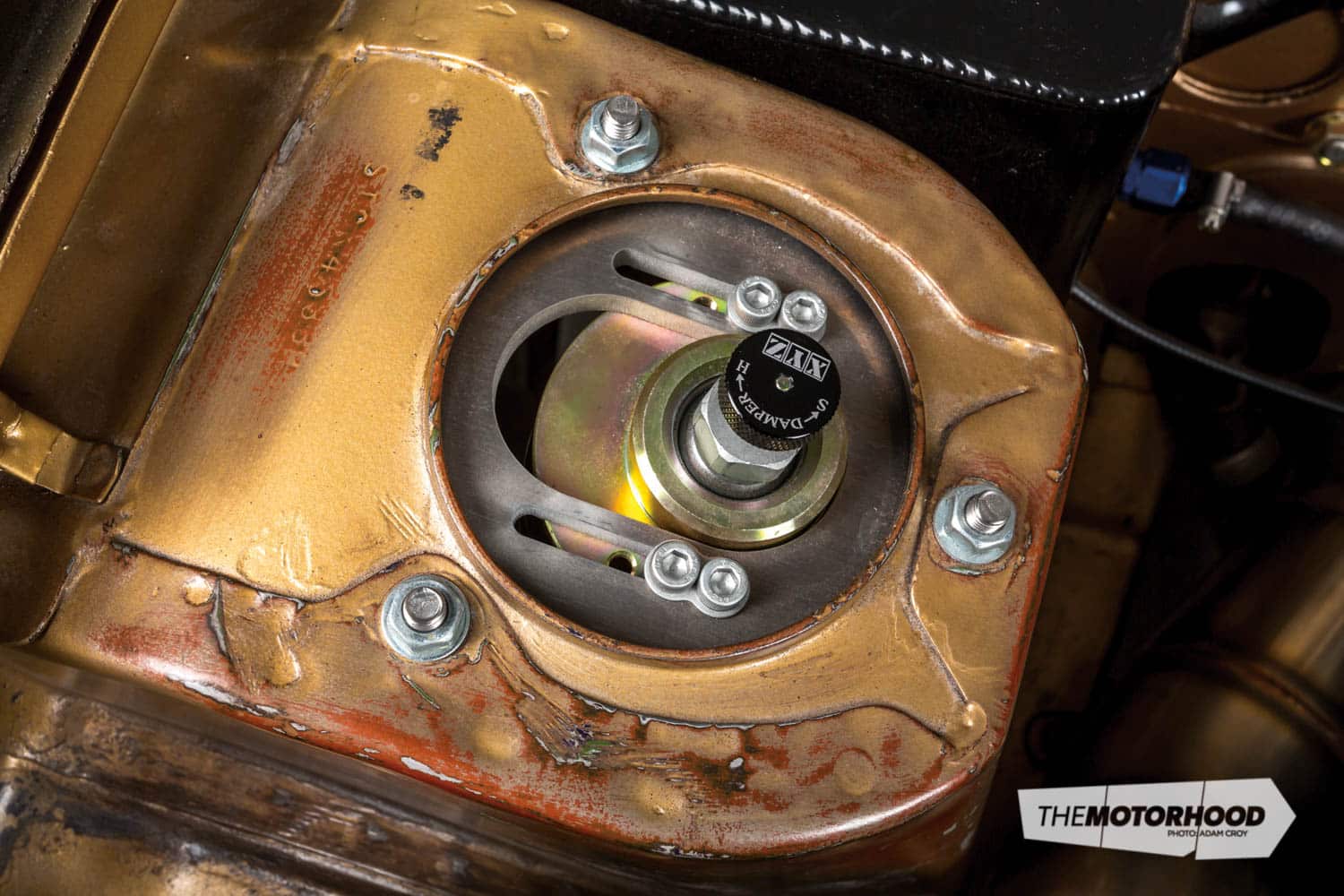

- Struts: (F) Custom XYZ coilovers (R) QA1 coilovers

- Springs: Custom

- Other: Steering rack conversion

- Brakes: (F&R) Wilwood 330mm rotors, Wilwood calipers, line lock, Wilwood brake-bias controller, hydraulic handbrake

Shoes

- Wheels: (F) 15×4-inch Billet Specialties (R) 15×8-inch Billet Specialties

- Tyres: (F) 145/40R15 Hankook (R) 28×9 Mickey Thompson ET Streets

Interior

- Seats: Kirkey alloy race seats

- Steering wheel: Sparco

- Instrumentation: Auto Meter gauges

- Other: Hurst shifter, alloy dash, Woodward steering column, Wilwood pedal box, six-point roll cage

Performance

- Power: Untested (old set-up 520kW at the wheels)

Exterior

- Paint: Custom faux patina

- Enhancements: Fibreglass front guards, fibreglass bonnet, fibreglass 12A nose cose, 10A Savanna teacup tail lights