“We speak to those in the know to resolve the LS V8 versus force-fed Japanese feud once and for all”

You’ve all seen the banter on social media when a drifter makes the swap to an LS-series V8 engine. People worldwide are so passionately against the conversions that they start fighting each other from behind their keyboards. Many argue V8 conversions are ruining the heart and soul of drifting, that Japanese cars should not be bastardized with American muscle. On the other hand, many people who have done the conversion wouldn’t go back to a smaller-capacity turbocharged Japanese engine.

But why are people jumping on the V8 bandwagon, or going to the ‘dark side’, as some people call it. What do they know that we don’t about our big American eight-cylinder brothers? We talked to the experts, and race-car drivers who have gone through the V8 conversion process, and find out everything you need to know before you make up your mind between turboed Japanese engines or American muscle.

Even if you do decide to go down Route 66, it seems there are a limitless number of combinations of this GM ‘super engine’, so we’ve gone for a rundown on the world’s most popular V8 swap into the world’s most popular Japanese chassis — the Nissan Silvia. But that’s not to say it can’t make it into RX-7s, 350Zs, BMWs and other popular drift chassis …

Weighing it up

In theory, an eight-cylinder engine should be heavy, so let’s compare the most common Japanese inline fours, sixes and V8s with the aluminum- and iron-block LS engines. Allow +/- 10–15kg depending on engine accessories.

The much-loved aluminum SR20DET engine comes in the lightest, and Nissan’s highly technical quad-cam V8 is the heaviest. The 1UZ-FE packs a competitive weight given its technology, yet the RB25DET is a heavyweight compared to the iron-block LQ9 V8. You still can’t beat the 2JZ-GTE in terms of how much outright power it can deliver with stock internals for its weight, but the torque and tunability from the factory makes the LS a clear winner in this category.

- RB25DET=250kg

- SR20DET=149kg

- 2JZ-GTE=233kg

- VH41DE=260kg

- 1UZ-FE=215kg

- LS1=217kg

- LQ9=254kg

Common LS-Converted Chassis in New Zealand

S-chassis

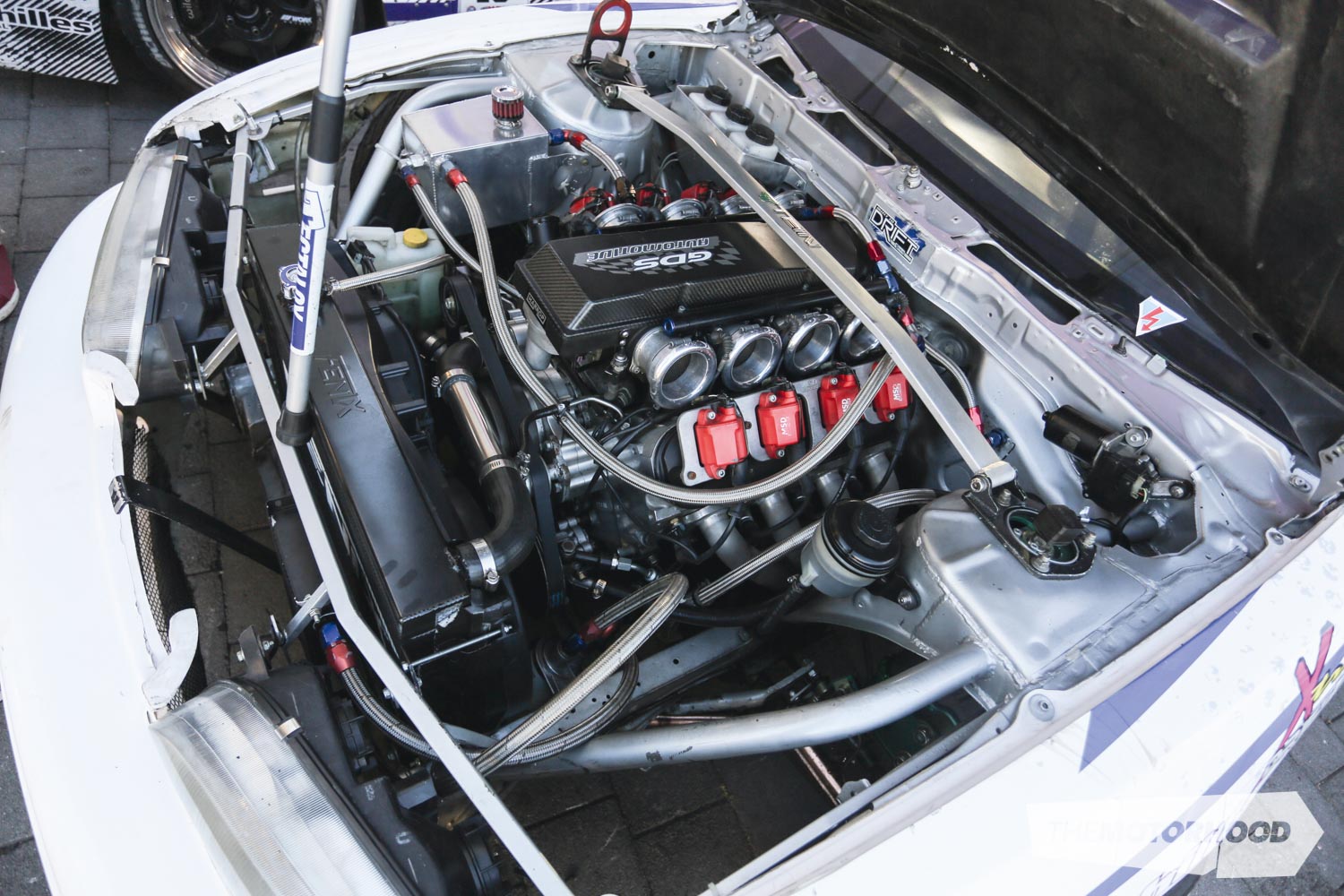

The most commonly converted chassis in the world would hands down have to be the Nissan Silvia platform. The S13, S14, and S15 have all been converted successfully locally, but where do they get their gear from? Drivers like Drew Donovan are pretty handy in the shed, so for him it was easy enough to fabricate the required engine mounts, notch out the rocker cover and do all the other necessary fabrication jobs required to get the conversion sorted.

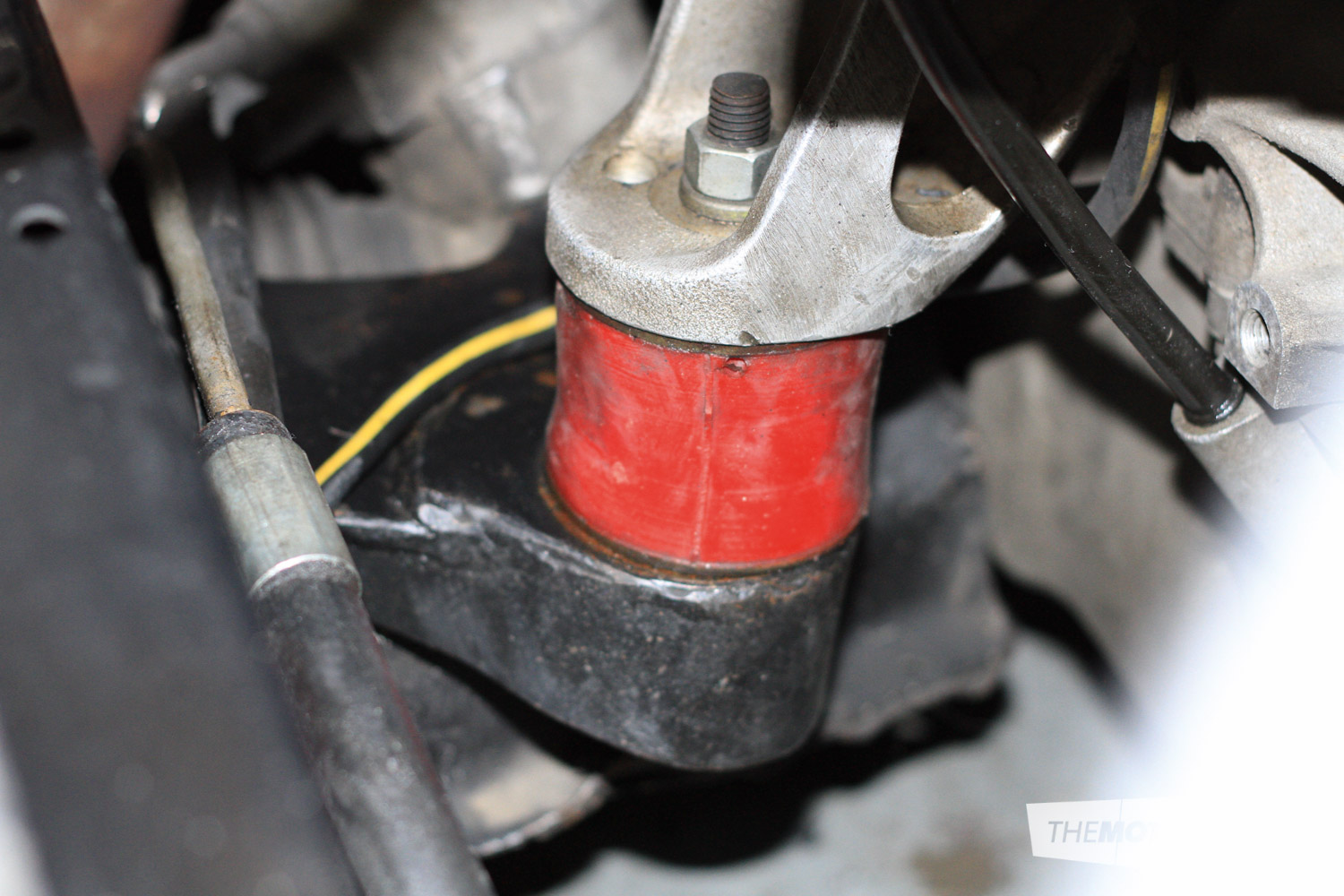

There are very comprehensive kits available off the shelf in America designed specifically for the conversion, covering every possible outcome including retaining the air conditioning for summer cruising. The stand-out off-the-shelf kits for the popular Nissan platform come from the well-known American brand, Sikky. There are two kits available, the basic and the complete. The complete mount kit is the one you’re after if you want an absolutely trouble-free conversion. The kit is designed for use with the LS-series motors (LS1 to LS9) and the T56 transmission commonly backing them, although other transmission-mount kits are available upon request. This kit requires no modification to the factory cross member or subframe, and does not hang below the cross member when installed.

The complete mount kit includes an aluminum race oil pan with a 6.6-litre capacity, a remote-mount filter kit, engine mounts and transmission mounts which are CNC machined from solid 6061 T6 aluminum, with custom urethane bushing and a steel one-piece driveshaft with high-strength U-joints, all designed for use with the T56 transmission. You also have the choice of upgrading to an aluminum driveshaft for an extra $250 on top of the total kit price of $3406. This may seem like a lot, but Sikky has a complete how-to DVD which gives you the know-how to complete this conversion in your garage at home, saving you plenty of money in labour costs. It doesn’t get any easier than this. The only items that don’t work with this kit are the LHD headers, so suitable items have to be sourced locally.

A common problem encountered with the conversion is the wiring, so Sikky made it a goal to sort out this problem too. They work with a wiring company which builds completely plug-and-play looms that work with RHD Silvias.

We asked Sikky what problems people encounter when doing the swap, and they replied, “Installing the LS engine without a kit is about as easy as doing an SR20 swap into the S-chassis. The problems one will encounter depend a lot on mechanical ability, or not following our very in-depth instructions.” Sikky does not at all recommend using the factory Nissan gearboxes behind the LS motors due to the amount of torque they produce, instead they recommend using the T56, as it was designed to support the torque with ease.

Four-time DK Gaz Whiter

Four years ago Gaz Whiter’s team was at their wits’ end, having suffered numerous SR20 engine failures that cost placings, sleepless nights between rounds and plenty of the folding stuff, so the decision was made to switch to an LS engine.

“The conversion was really easy, we imported a full kit from Fueled Racing. It came with engine mounts, a gearbox mount, sump, and extractors. It bolted in really easily without any hassles. Guys like Fanga have had problems with the GM power steering, so we went with the SR one and made a bracket. We also stayed with an SR alternator.”

The first motor was an LS2, but the car now runs a stroked 7.2-litre LS7 with forged rods, crank, individual throttle bodies, a cam and valve springs. The combination makes a very reliable 400kW only revving to 6500rpm.

“It’s so easy to drive compared to an import motor, it has such a linear power curve you always know there will be power there. It allows you to concentrate less on keeping the engine in its power band, and more on the car you are chasing. I can now left-foot brake a lot better, and basically leave it in one gear for the entire section,” he says. “It was great learning with an SR, as you learn to react quickly, but it would just be too hard to go back to an import motor. It’s the torque that smokes the tyres, not power. When I drove the RB25DET Laurel at round one of the Demon Energy D1NZ, which is 340kW, we had to run huge tyre pressures in the Achilles 123 tyres just to spin them. Look at a car like Andrew’s [Redward], it makes similar power [300kW] and smokes them up easily.”

The package has proved extremely reliable for the team, with only a few rod issues that are common with the titanium rods found in the LS7. These have now been replaced with steel rods. It’s this reliability that has let the four-time New Zealand champion continue competing, and winning.

“If we were still running the SR I wouldn’t be able to compete, we would have blown it up again and that would have been it. There are a lot of people who hate the LS, but don’t knock it till you try it, there is just nothing as good in bang-for-buck terms in a competitive drift car.”

We caught up with Drew Donovan to ask him about his LS conversion:

NZ Performance Car: Hey Drew, when did you first hear about the possibility of doing an LS conversion into your S15, and what prompted you to finally make the move?

Drew Donovan: Chatting with Andrew Redward and Fanga Dan was what helped me decide to go down the LS path. Fanga especially couldn’t say a bad thing about them, so that gave me confidence to go ahead with the conversion. I was running an RB26, which melted a couple of pistons due to a faulty wastegate, so a change was looking imminent, however, it was actually more to stand out from the rest of the field that I really made the change to a V8.

Was the conversion very difficult?

Because I had my own ideas in mind on positioning the engine, and I needed to cut whatever costs I could, I decided to install it myself. As a result there were some really tight clearances to deal with, but all in all it helped me build a car that is more competitive.

How affordable was the conversion initially?

To set the car up is a significant outlay, because it’s not just an engine you have to purchase, you need the gearbox, clutch, headers, loom and ECU, plus any other small items. Even a simple set-up can be over $20,000 in parts alone. The costs are on a par with what it would cost to set up a smaller turbocharged engine capable of the same results.

What has the affordability been like for maintenance on the LS?

Oil is vital in any engine, but because of the heat that’s dissipated into the oil in an LS engine it is vital you use a really good synthetic oil. If you have a well-built engine, get a good tune and use a top-grade oil, it really is just a matter of servicing them often.

What do you think the advantages are of the smaller-capacity turbocharged Japanese motors?

Turbos are a great piece of engineering that help create oodles of torque and plenty of extra free power, however, with pressure comes heat, and that’s where I lost interest. There are different fuels which will help drop engine temperatures, and so long as vital components like wastegates are operating correctly there is no reason why a turbocharged set-up shouldn’t operate just as reliably.

View fullsize

View fullsize

View fullsize

Complete guide to the LS engine

“There seems to be no shortage of variations for GM’s LS engines — we check out the differences”

LS1

The LS1 was the first of General Motors’ Gen 3 engines to meet worldwide acclaim, and is possibly the most recognized and acknowledged model in the LS line-up. Displacing 5.7 litres thanks to a 99mm bore and a 92mm stroke, it produces anywhere from 220kW through to 285kW depending on the specific model and year of manufacture. A special Callaway-modified variant known as the C4B was also produced in limited numbers, which produced 300kW. The LS1 is fitted with cathedral-port cylinder heads, and has a compression ratio of 10.25:1.

Produced: 1997–2007

Found in: VT–VZ Holden/HSV, Camaro, Corvette, Pontiac GTO, Pontiac Firebird

Power: 220–285kW (300kW for Callaway C4B variant)

Torque: 446–520Nm

LS2

In 2005 GM replaced the Gen 3 engine series with the new Gen 4 series. The LS2 is closely related to the architecture of the LS1, but enjoys a larger 6.0-litre displacement. The LS2 gained an extra 300cc of capacity via an increased bore (now 101.6mm). The compression ratio also lifted, to 10.9:1.

On this side of the world the LS2 is most commonly found in the HSV VZ to VE models, while in the US the engine was fitted to a wide range of chassis including the Chevy Trailblazer, Cadillac CTS-V and the Pontiac GTO.

Produced: 2005–2008

Found in: HSV VZ–VE, Pontiac GTO, Cadillac CTS-V

Power: 300–307kW

Torque: 542–550Nm

LS3

The LS3 is a further refinement of the LS2 engine package, taking engine capacity to 6.2 litres thanks to a 103mm bore. One of the biggest improvements on the LS3 was the move to the rectangular-port cylinder heads shared with the L76/L98 engine. These offer improved flow over the early cathedral-port LS1/LS2 heads. Compression ratio in the LS3 is 10.7:1.

Produced: 2008–2013

Found in: Corvette, Pontiac G8, VE HSV, Camaro SS

Power: 317–325kW

Torque: 570–580Nm

LS6

The LS6 was a higher-performance variant of the LS1 introduced for the C5 Corvette Z06 from 2002 to 2004. The LS6 retains the same basic architecture as the LS1, as well as the LS1’s capacity of 5.7 litres. The increased performance came from a more-aggressive camshaft design with greater lift and duration, as well as a higher compression ratio of 10.5:1 and a higher-flowing MAF sensor.

Produced: 2002–2004

Found in: C5 Corvette Z06

Power: 302kW

Torque: 540Nm

L76

The L76 is a variation of the LS2 made specifically for Holden Australia’s requirements. The L76 engine retains the 6.0-litre capacity and adds Displacement On Demand (DOD), which is also known as Active Fuel Management (AFM). This technology allows four cylinders to be shut down by the ECU during cruise situations to improve fuel economy, achieved via a special set of hydraulic lifters.

The L76 is a mixed bag, as it benefits from the same high-flowing rectangular-port cylinder heads fitted to the LS3 and L98, but suffers from a conservative camshaft design that was required to work with the AFM. The result is the L76 produces 10kW less power than the almost identical L98.

The AFM system is a pain if you intend to fit a performance camshaft, as you will need to replace the special AFM lifters with a conventional set, adding significant expense to the job.

Produced: 2006–2010

Found in: Holden VZ, VE Commodore, Pontiac G8

Power: 260kW

Torque: 510Nm

L98

The L98 is a modified version of the L76 with the AFM hardware removed. It retains a capacity of 6.0 litres, as well as the high-flowing rectangular-port cylinder heads from the LS3/L76.

Thanks to a slightly more aggressive cam profile than the L76, the L98 produces 270kW.

In stock form the L98 produces less power than the similar LS2 engine due to the more conservative camshaft design. With equal cam profiles, the L98 outperforms the LS2 due to its superior head flow. These engines are what you will find in most VE Holden Commodores.

Produced: 2006–2010

Found in: Holden VZ, VE Commodore

Power: 270kW

Torque: 530Nm

LS7

The LS7 engine takes the Gen 4 LS block architecture to the limit, working on the principle that bigger is better. The LS7 achieves a capacity of 7.0 litres thanks to an increased stroke of 101.6mm and a bore of 104.8mm. The LS7 block uses pressed-in sleeves to achieve sufficient block strength with the larger bore.

The crankshaft is a forged steel item, as are the main bearing caps. To reduce reciprocating weight, the connecting rods are made of titanium. Despite the engine’s capacity and long stroke, it offers a high factory redline of 7000rpm, and in its native Corvette Z06 chassis it is also equipped with a dry-sump lubrication system. The LS7 is the same engine as that chosen by the V8 SuperTourer class.

Produced: 2006–2014

Found in: Corvette Z06, Camaro

Power: 377kW

Torque: 640Nm

LS9

The LS9 was built for the Corvette ZR1 and was designed from the ground up with supercharging in mind. The basis for the LS9 is the 6.2-litre LS3 block with 103mm bore. Compression ratio was dropped to 9.1:1 to handle the forced induction, which was supplied by a 2300cc Eaton positive displacement supercharger.

Produced: 2009–2013

Found in: Corvette ZR1, Hennessey Venom

Power: 476kW

Torque: 819Nm

LSA

The LSA is a 6.2-litre variant with close similarities to the LS9 engine. Notable differences include the use of a smaller 1900cc supercharger, and a slightly reduced compression ratio of 9.0:1. The LSA is the engine chosen by HSV to power the range-topping VF GTS with a power output of 430kW and 754Nm.

Produced: 2009–2013

Found in: HSV VF GTS, Cadillac CTS-V

Power: 415–430kW

Torque: 747–754Nm

LQ9

While not as common on our side of the world, the LQ9 is achieving some impressive results in the US, where it is both more plentiful and considerably cheaper than its alloy-block cousins. Designed as a truck engine (Chev Silverado etc), the LQ9 shares many similarities with the LS series, but uses a cast-iron block. In a truck application the extra weight of cast iron isn’t an issue, while it offers a significant strength advantage over the alloy LS block in the performance aftermarket world. Think of it like a budget-spec LSX block and you will be close to the mark.

While its output in stock form is nothing to write home about, it really comes into its own once you add turbos, a supercharger or a large shot of nitrous. The LQ9 shares the same bore and stroke as the LS2, and uses a 10:1 compression ratio.

Produced: 2002–2007

Found in: Cadillac Escalade, Chevy Silverado, GMC Sierra

Power: 257kW

Torque: 515Nm

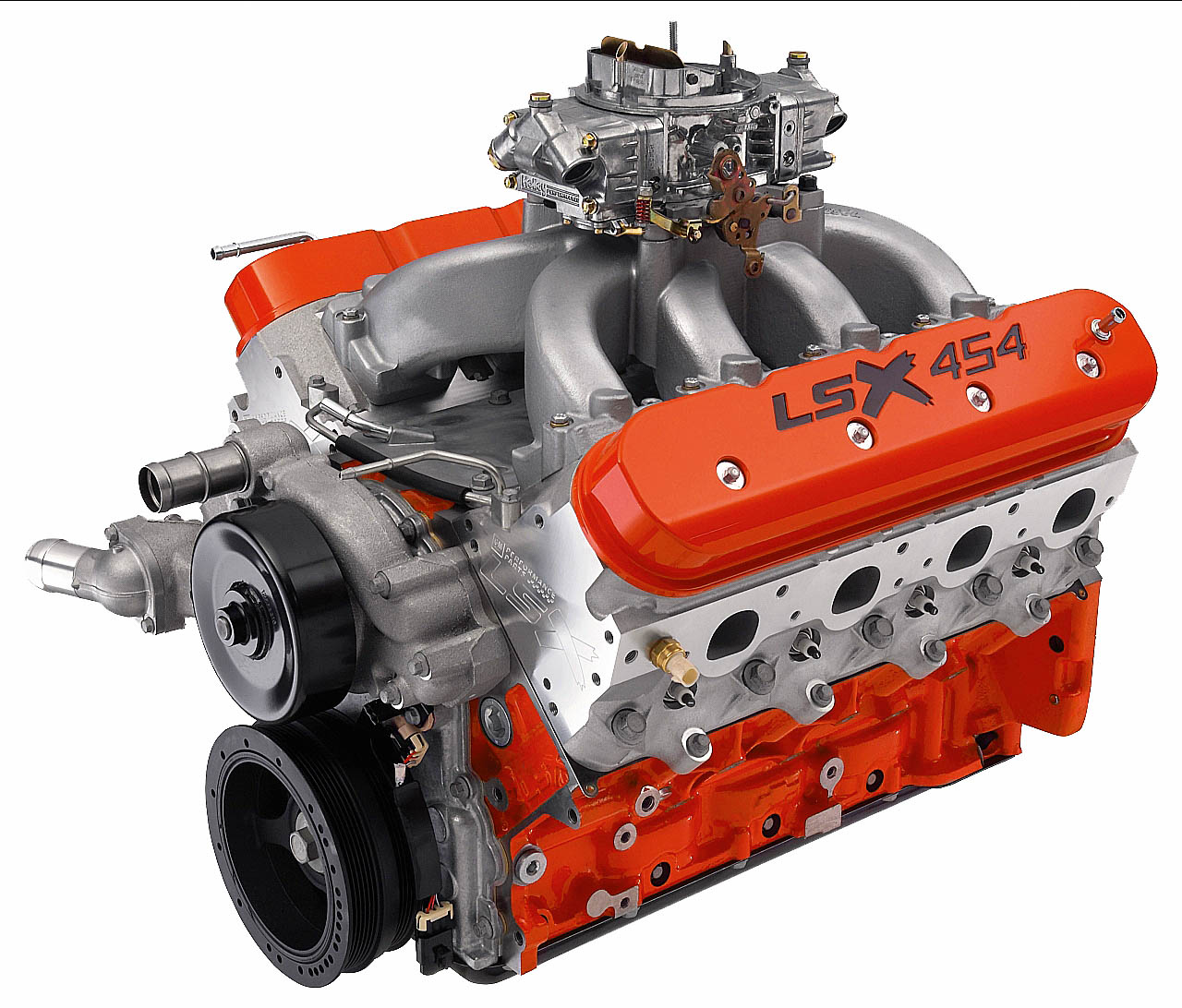

LSX

With the popularity of the LS range of engines and their universal adoption for just about any performance application, from street rods to purpose-built drag vehicles, the limits of the alloy LS block can become a problem. While its light weight is one of the engine’s advantages, it can also be its downfall. Aluminium just doesn’t have the strength and reliability when you start bolting on serious superchargers, big turbos or a large shot of nitrous.

Conventional aftermarket fixes for this are available in the form of ductile iron sleeves, but buying and fitting them is an expensive exercise, and some sleeved blocks continue to give trouble with the liners or sleeves dropping and affecting the head-gasket seal. GM Performance Parts addressed the problem by releasing the LSX block in 2006.

The LSX block follows the same bore spacing and bolt pattern as a conventional LS alloy block, but uses cast-iron material for improved strength. Performance-oriented features include extra-thick cylinder walls to allow a bore of up to 106mm, a thick deck surface and an extra head-stud per cylinder for improved head clamping, priority oiling for the main bearings and billet six-bolt main caps located by dowels.

GM Performance Parts offers the LSX as a block only, or it can be purchased as a complete crate engine. The LSX block is rated as being capable of supporting 1864kW (2500hp).

Images: Adam Croy and Jorgi Jansen