Meet the wildest import drag car to come out of New Zealand in recent years — and it’s about to set Meremere on fire!

Right off the bat, you’re probably thinking that we should have named this article ‘Godzilla’, right? That nickname has stuck to the GT-R like glue since its older brother, the R32 GT-R, was dubbed with it on arrival on Australian soil in the Group A days of the early ’90s. It’s a term that stuck around for the generations of GT-R to come. However, what we have here is technically not a Skyline, not an R35, not a GT-R, or even a Nissan, so it’s most definitely not a Godzilla. So, what is it? Well, my friends, what we have here is a ‘King Kong’, hand built here in New Zealand to serve any Godzilla a death blow. Confused yet? Well, read on and all will be revealed.

At first glance, one might be forgiven for thinking this is a Nissan R35 in drag-spec trim, but look a little closer and its real form starts to unravel at about the same time as your mind starts to unravel as you come to grips with the intensity of this build. Draped in a complete carbon-fibre body, which is hung from a hand-built 4130 chromoly tube chassis, which was both designed and constructed here in New Zealand by Dodson Motorsport (DMS). It takes all the running gear from the famed Nissan R35, and drops an impressive 500kg of kerb weight straight away, while also improving rigidity and safety. Dropping that much weight while retaining all the wizardry of the R35 in stock form would make a formidable race car by most people’s standards, but for Iain Clegg and the team from ST hi-tec a stock power train would never do.

Those names will be familiar to you — or, at the very least, you’ll recall the latest two of Iain’s GT-Rs that we had on the cover, in particular, his last R35, which boasted 969kW from a 4.1 stroker VR38. With that car, Iain dominated the 2016–’17 Pro Street class in Superlap, ran a 10.056s at 147mph (236.5kph) on the quarter-mile, setting the New Zealand R35 record, and ran a top speed of 315kph during a Landspeed New Zealand Association event. All of that was in full street trim and with every one of the 1780kg that the R35 GT-R came with from the factory.

So, when Iain wanted to take a serious step up with his circuit racing, the logical choice was to give up the streetability and build a proper race car. Enter the idea to build up a DMS GT1 chassis kit, which, at the time, was the prototype and first of its kind in the world. Devoid of anything not necessary in order to go fast, it was deemed the perfect base from which to jump to the pointy end of New Zealand’s fastest tin-top race class, GTRNZ.

Before that step to circuit racing was taken, the idea was floated to have a crack at the Sport Compact GT-R world record, which was in the mid-seven-second zone at that stage. With Dodson’s Glenn Cupit the long-time tuner of Kiwi racer Rod Harvey, it didn’t take long for Iain to twist his arm on the drag idea. What the two workshops would build over the next four years is one of the most serious import drag cars ever to be constructed in New Zealand. It’s no half step into drag racing, but, during the four-year build process, that GT-R record continually dropped, with top teams in the US throwing serious quantities of resources at it, in the process lowering the record to 6.56s at 225mph (410kph). It’s not something that will be chased easily from here in New Zealand, with the limited budget and track time, but running in the sevens remains the goal, and, in the process, they hope to smash the current Australasia R35 record and, of course, the New Zealand record.

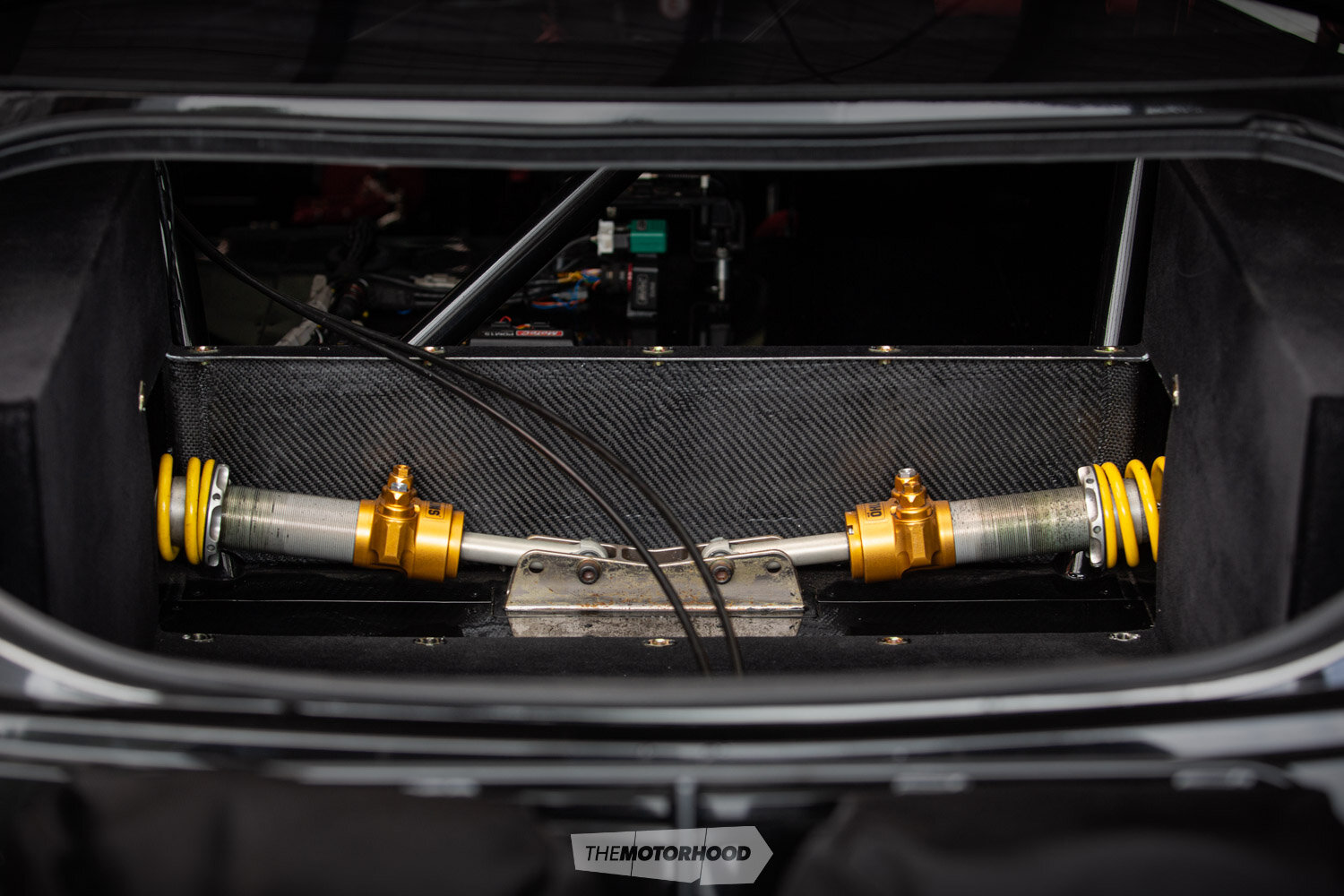

Record aspirations aside, what this project will really do is showcase some amazing Kiwi engineering and componentry; it truly is a world-class piece of drag gear. The chassis itself remains unchanged from the DMS GT1 spec, which is dimensionally an R35, although suspension geometry and weight balance have been optimized. Dodson’s head fabricator, Duane Huxtable, who spends 10 weeks per frame hand building each chassis, explains the design as the best compromise between strength, rigidity, and weight. Up front, the geometry remains as Nissan designed it, while, out back, the Ohlins TTX twin-tube dampers are mounted horizontally and act off custom bell cranks. The Ohlins are serious dampers: the very same ones you’ll find in the Nismo GT3 R35s, although the spring rates are currently much lower to achieve the squat needed in drag racing. A lightweight brake kit with solid rotors and five-stud hubs replace the big brakes and centrelock hubs that it will wear in circuit spec. It should go without saying that the wheel package is also drag specific, with Belak beadlocks, complete with titanium hardware measuring 17×10 inches up front and 15×10-inches on the rear.

Where things really ramp up for drag racing, though, is under the carbon bonnet. The exact power output remains simply an educated guess, as the final tuning will take place at the track. The parts list (which includes a billet crank; Diamond pistons; billet alloy rods; CNC ported heads with custom cams with an undisclosed duration north of 300 degrees; and custom billet block, designed by Dodson and carved from a solid chunk of billet alloy) should give you an indication of the car’s potential if the gigantic Garrett Gen II 106mm huffer hanging off the front fails to.

The block is devoid of any water galleries; instead, an electric water pump (EWP) sends water to the heads only and cools them via a small radiator tucked under the side of the bumper. The bulk share of responsibility for cooling the engine will fall to the tonnes of methanol passing through the custom billet fuel rails with 1700cc and 5750cc injectors, yes that is 5750cc injectors, mounted in the custom billet and carbon-fibre inlet manifold.

To give an indication of the drag package’s potential: during early development, the engine hit the dyno on E85, and, with low boost, it made significantly more power than the old R35 ever did. Now running strictly on methanol, and with plenty more boost to be dialled in as the team comes to grips with the car and putting it down the drag strip here in New Zealand, the true potential should soon be realized. The key to this all comes via the all-controlling MoTeC M150 ECU. If the team were simply to feed high boost off the start line, the torque delivered would smash the driveline to pieces, so a complex boost-control system using wheel speed as the reference point is employed to limit the amount of boost the engine sees. To achieve this, four wheel-speed sensors can be found, one at each corner. These sensors also feed information to the custom DMS front diff controller, which controls the front diff’s electromagnet. The electromagnet engages the clutch packs, applying more torque to the front wheels as soon it senses that the rear wheels are starting to lose traction.

It’s this sort of thinking that has long seen DMS as a world leader on the R35 GT-R world stage. Its Heavy Duty GR6 gearboxes and 13-plate Extreme Duty clutches, both of which are employed here, are world-leading components that have long been used by record-holding teams around the world, with guys putting upwards of 3000whp (2237kW) to the ground through them.

Any project of this magnitude takes time to get ready to run. With the build now complete, the team is working hard to get it dialled and Iain in the driver’s seat ready to send it — understandably, Iain is chomping at the bit to mash the billet loud pedal. The first shakedown a few months back saw a few small teething issues that resulted in some wild rear-wheel-drive-only passes, but these issues have been ironed out by the software writers at MoTeC, and a second private test day will have taken place before you read this.

You may be wondering when you can come trackside to witness this beast run. Well, we’ve been told that, all going to plan, it will be hitting some of the biggest drag events this summer to make use of the track surface but that it will not be seen in public until the team is confident that it can put the car on kill and show the world what the package is truly capable of — that will be a sight well worth the admission.

For all that it’ll be exciting to see what the team can achieve over the coming year while in drag trim, let’s not forget that there is a whole other race programme planned, including a complete new engine package and carbon aero package, which will take place once the team is satisfied it has achieved all it can on the strip. But that’s a whole other story for a whole other day — one that will be well worth reading about if the current guise is anything to go off!

Driver/Owner: ST Hitec

Thanks: ST Hitec, Dodson Motorsport, Glen Cupit, Duane Huxtable, Michael Dalton, Ultimate big boy collaboration; NZ vs the world; the late Arnie Ngyen RIP always riding by my side

Heart

ENGINE: Billet VR38DET, 3800cc, V6

BLOCK: Custom DMS billet block, Bill Miller Engineering (BME) forged alloy drag rods, Diamond pistons, heavy-duty diamond-coated wrist pins, Bryant billet crankshaft

HEAD: DMS drag package, CNC ported heads, custom camshafts, oversized Super alloy valves, heavy-duty valve springs, titanium retainers

INTAKE: DMS custom alloy intercooler piping, custom billet / carbon intake manifold,

EXHAUST: Custom stainless side-exit

TURBO: Garrett GTX5544R Gen II (106mm), DMS stainless exhaust manifold

WASTEGATE: Twin 44mm TiAL

BOV: Twin Turbosmart Race Port

FUEL: Twin MagnaFuel 675 fuel pumps, Walbro 255 pump, custom billet fuel rail, 1700cc primary injectors, 5750cc secondary injectors

IGNITION: M&W capacitor-discharge, M&W coils, MSD leads

ELECTRONICS: MoTeC M150, twin MoTeC PDM, custom race harness

COOLING: Custom small radiator, Davies Craig EWP150

EXTRA: Peterson dry-sump pump, Peterson oil tank

Driveline

GEARBOX: DMS Heavy Duty GR6, DMS Extreme Duty gear set, billet front diff housing, billet mid-plate, billet shift forks

CLUTCH: DMS 13-plate Extreme Duty, DMS front-wheel-drive clutch

DIFF: Wavetrac front, Wavetrac rear

EXTRA: Carbon driveshafts, trans brace

Support

STRUTS: Ohlins TTX dampers, Eibach springs

BRAKES: GT1R drag package

EXTRA: DMS chromoly chassis, DMS billet suspension arms, custom rear suspension rockers

Shoes

WHEELS: (F) 17-inch Belak beadlock, titanium hardware; (R) 15×10-inch Belak beadlock, titanium hardware

TYRES: (F) Hoosier front runner, (R) 28.0 x 10-inch Mickey Thompson ET Drag

Exterior

PAINT: Smithy Signs wrap

ENHANCEMENTS: Full DMS carbon body, carbon doors, carbon drag wing, carbon bumpers, polycarbonate windows

Interior

SEATS: Head-restraint Racetech

STEERING WHEEL: Sportsline

INSTRUMENTATION: MoTeC C127, MoTeC C187

Performance

POWER: Plenty