Despite the summer holiday season, things have been ramping up at Paddon Rallysport Group (PRG) as our May deadline for the roll-out of our EV rally car quickly approaches. The project has now been split into two main components of the construction.

Part one is the continuation of the chassis construction, which is expected to be completed within the next few weeks. Fabricators Mike and Ben have spent more than 500 hours on it. Unlike your normal rally car chassis build, everything for this project has required custom fabrication, including a floorpan to work with the floor-mounted battery system. The unique mounting of the front and rear transmissions requires changes to the firewall, chassis rails, and rear floorpan. The wheel arches and top mounts have all been designed for maximum suspension travel.

While the fabrication continues, the engineering team of Matt Barham, Rory Callaway, and Jack Williamson continue with component design and prototyping. As we are designing and building 90 per cent of this car in-house, everything needs to be reworked — the cooling system, auxiliary power system, charging systems, brakes, and suspension. The unique characteristics of the lower centre of gravity and extra weight mean all components need to be fully analyzed for strength whilst weight must be reduced wherever possible. Many hours have been spent performing FEA (finite element analysis) on both our self-designed and our inherited components. Working with our suspension partner EXT in Italy, we will have new and previously unseen suspension technology that will first be used in our prototype and then developed for future projects. While the actual battery is still being constructed, a mock-up battery is being built, which will assist the final part of the puzzle of the chassis build to ensure fitment and quick fit when required.

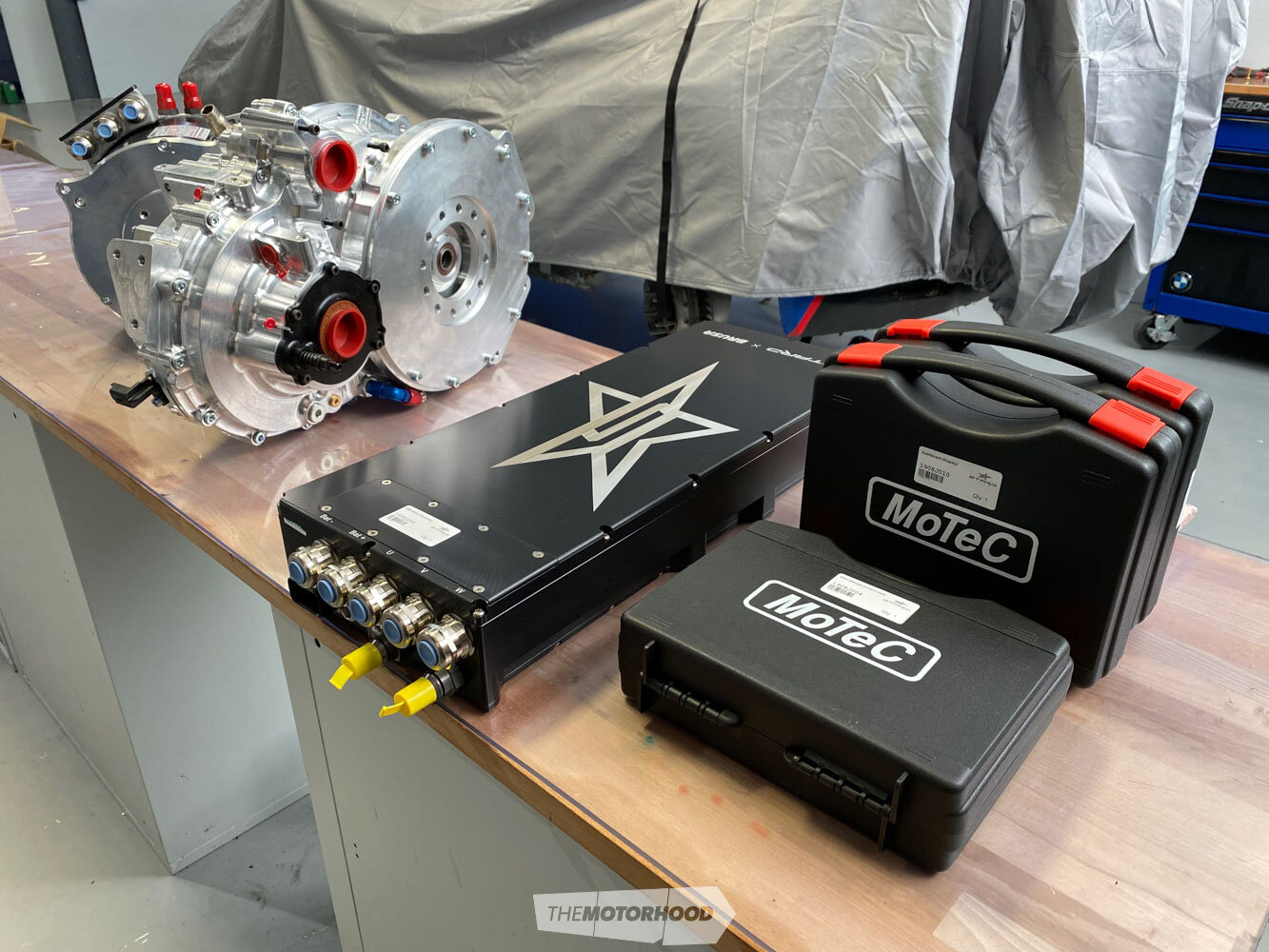

Just after Christmas we received a nice gift from our technology partner, STARD. A large pallet of the main components, comprising the transmissions, motors, inverters, and MoTeC electronics, has arrived. These are all bespoke motorsport components, which we have worked closely with STARD to adapt to our rally project. This technology is already used in European Rallycross, but stage rally brings with it a whole new challenge. This will include our own software to control energy output and how we manage that over the longer durations that we will encounter in rallies.

While this project has been under way for almost 12 months already, these last 4 to 5 months will be the busiest. It seems like there is still a mountain to climb, but everyone is working hard to ensure we meet all our targets. Some busy times lie ahead.