At Paddon Rallysport Group (PRG), the past month has been full on with various motorsport projects on the go at our Highlands Motorsport Park facility. Our core project — New Zealand Electric Vehicle Rally Car 1 (NZEVRC1 ) — has been making steady progress, particularly as we now focus on the construction of the chassis.

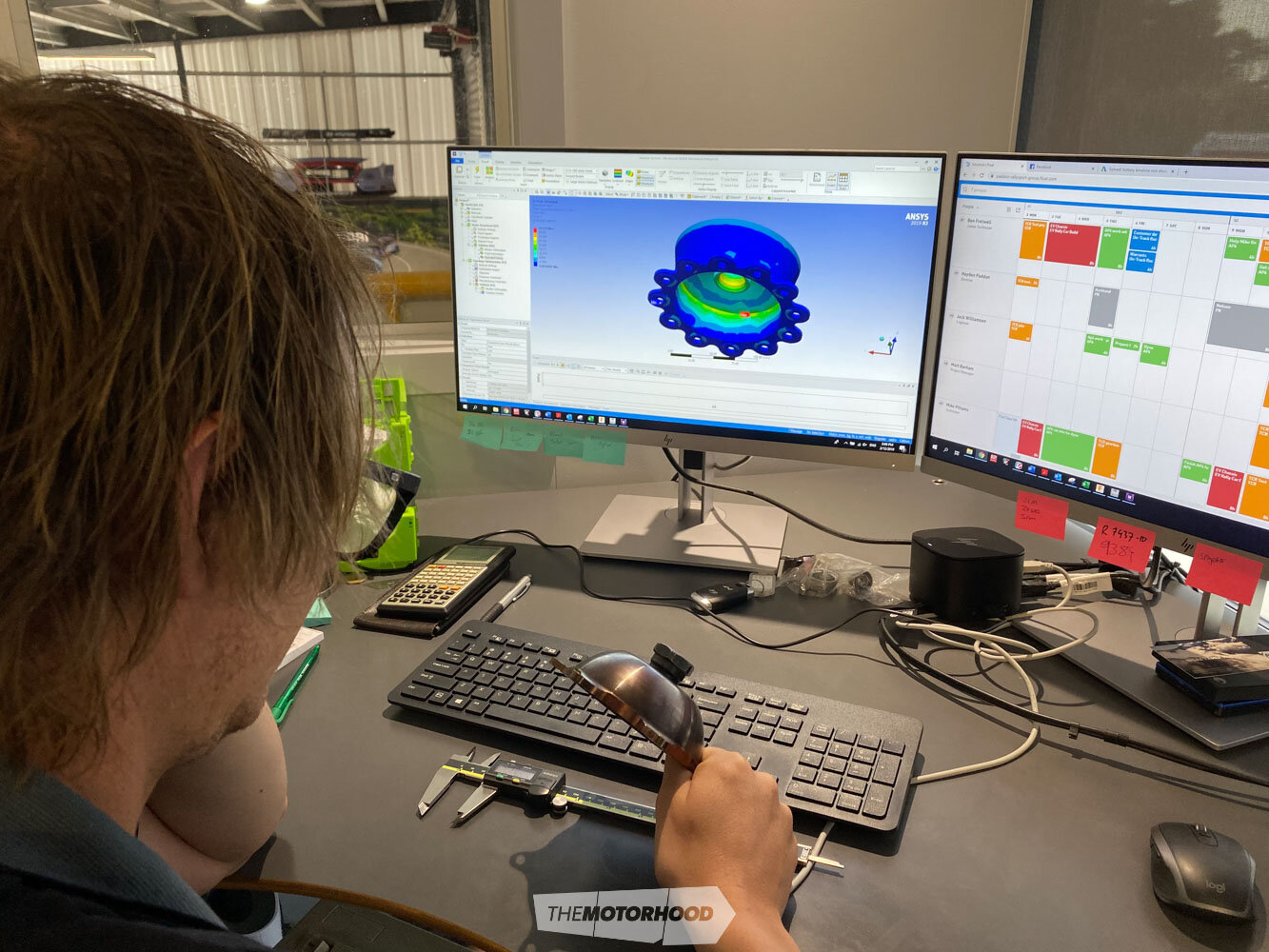

Confirming the design of the chassis has been a long process: taking the geometry data from a WRC and AP4 car, and factoring in the completely different weight distribution of an EV car — heavier and all the weight centralized. Using CAD and our new Ansys software we have been able to simulate all scenarios and finalize a design that we are very happy with and excited about.

Once the engineers, Matt Barham, Jack Williamson, and Rory Callaway had confirmed and frozen the design of the chassis and geometry, the next step was getting the car on the chassis jig to start inputting the suspension points and top mounts. The chassis construction is planned to take about 500 man-hours, starting with a brand-new Hyundai Kona bodyshell, which has been completely stripped and then given a heavy diet to try and get the base weight down. The specially made laser cut jig is accurate to within 0.1mm, which is crucial to ensure not only fitment but also performance. Mike is now mostly through inserting the new top mounts. These allow for the larger competition dampers and the longer stroke for increased travel, which equals more traction. The summer break puts the brakes on a little but the chassis fabrication should be mostly complete by the end of January.

Meanwhile, our team of engineers, led by Matt Barham, have been going through other design concepts relating to the car, including battery and transmission mounting, and work has begun on the wiring loom. There is a lot of integration involved as the driveline/motors use a completely separate power source to the auxiliary items such as lights, fans, and normal road-going items. With much of the major electronics componentry that was outsourced having now departed from Europe, the new year will see us beginning to dummy fit the major components in the car. That will allow us to design everything around it.

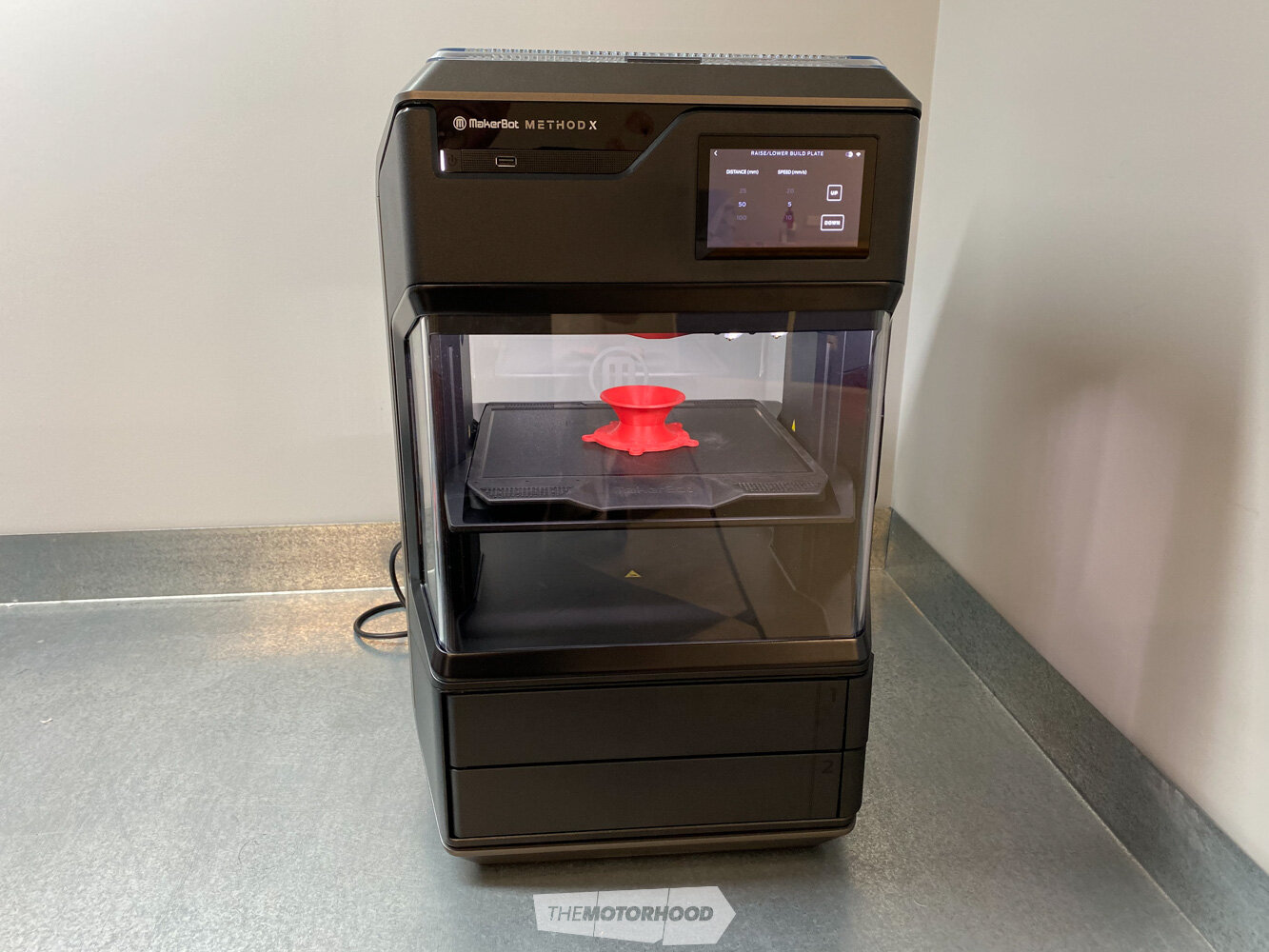

Design and prototype testing has been continuing on some unique technology that we are looking to introduce to the market, based around both the EV car and general motorsport use. While our focus is on technology in motorsport and our new project, which is at the leading edge of this, it gives us a platform to try and push the boundaries in many forms of new concepts and ideas. We have been able to use our existing IC Hyundai AP4 for this testing — it has been acting as a test mule around the race circuit here as we try out new parts and collect data.

Other projects keeping us busy at PRG at present, are the preparation of our TCR car for the upcoming inaugural NZ TCR circuit race championship and our first taste of circuit racing as a team. Our AP4 rally car is also getting a makeover, with a new 700bhp engine being built to tackle Leadfoot Festival and the new Ben Nevis Station Golden 1200 Hillclimb that we are hosting in March. Then it’s straight into the rally season in April.

So, busy times in more ways than one. The deadline is getting ever closer, and the next five months will disappear very quickly, but it’s great to have such a dedicated and motivated team working on this and I am confident we will see success come mid 2020.