A lifetime love affair with utes has led to the build of the cleanest B2000 you’ll ever lay your eyes on

Flawless paint, millimetre-perfect door gaps, and a tray so clean that you’d likely be shot point blank if owner Wiremu Burkhardt ever caught you throwing anything in there: these are not the kinds of attributes you’d normally associate with the humble and often-abused utility, but the B2000 before you is much more than a simple work hack; it’s a tribute to a part of our culture central to what it is to be Kiwi.

You see, Wiremu, like many Kiwis, grew up in the tray of a ute. It served as more than just a work vehicle; it was the family car, the weekend toy, and the workhorse all rolled into one. And he’s not alone in this obsession. All you need to do is look at the top-selling vehicles in New Zealand to understand that we are a nation of ute owners. With three generations of B2000, a B1600, and a Surf for dune-bashing duties, it’s fair to say that Wiremu’s obsession goes deep, and the ’84 B2000 is the crown jewel of the fleet. Wiremu’s 10-year project has wrestled something that was never intended to be perfect into exactly that.

Having owned a long list of B2000s, when this little gem showed up in a mate’s possession, Wiremu wasted no time procuring it. He recalls: “It had been owned by an old fulla in Whangarei its entire life, and then it went to a car yard in Kaitaia, where a mate was grooming. He got it and gave me a call. By the time I got up there, he had heated the springs up to slam it out. As soon as I saw it, [I knew] it was immaculate, and I wanted it, so I swapped him the ZR4 [that] I had at the time.”

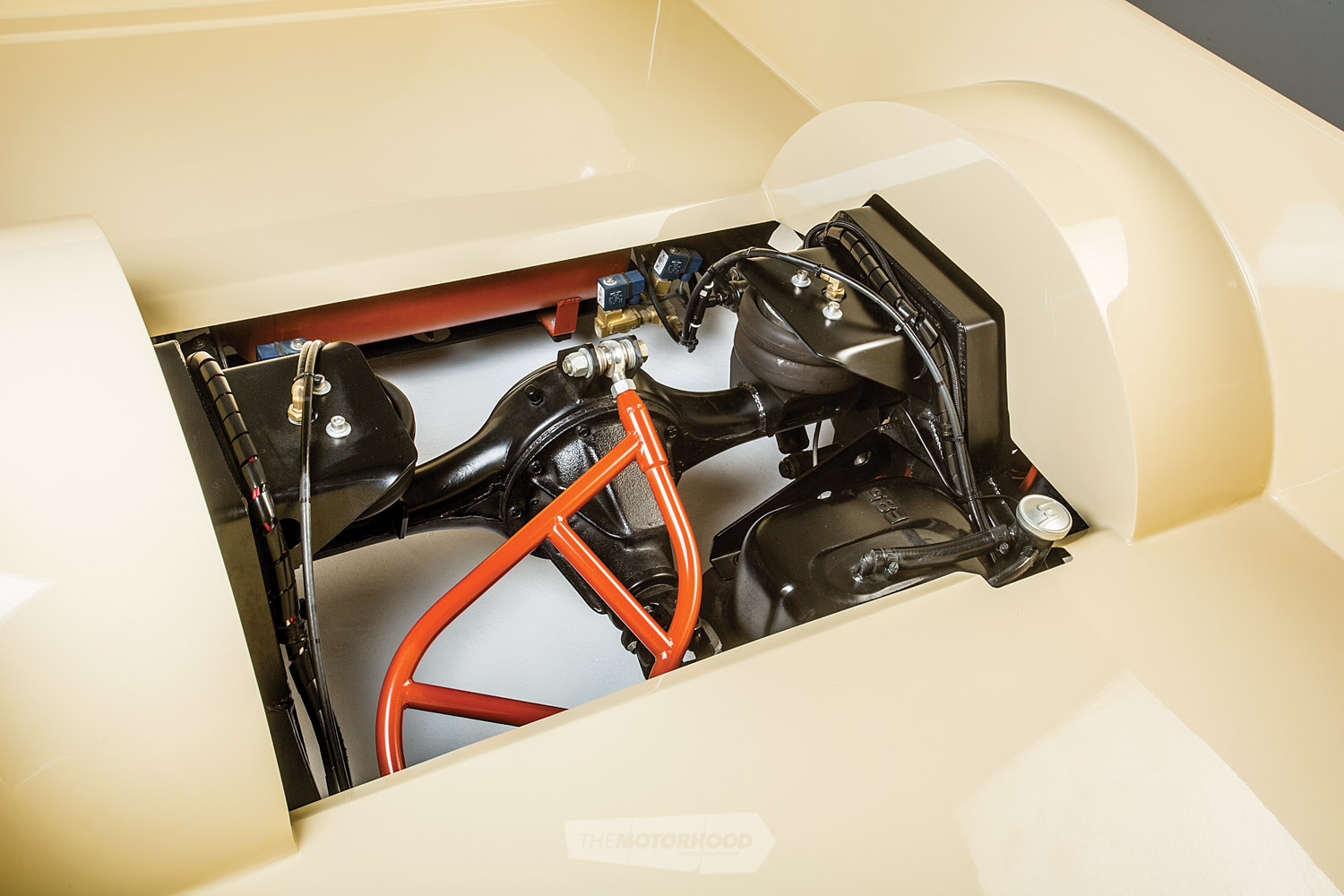

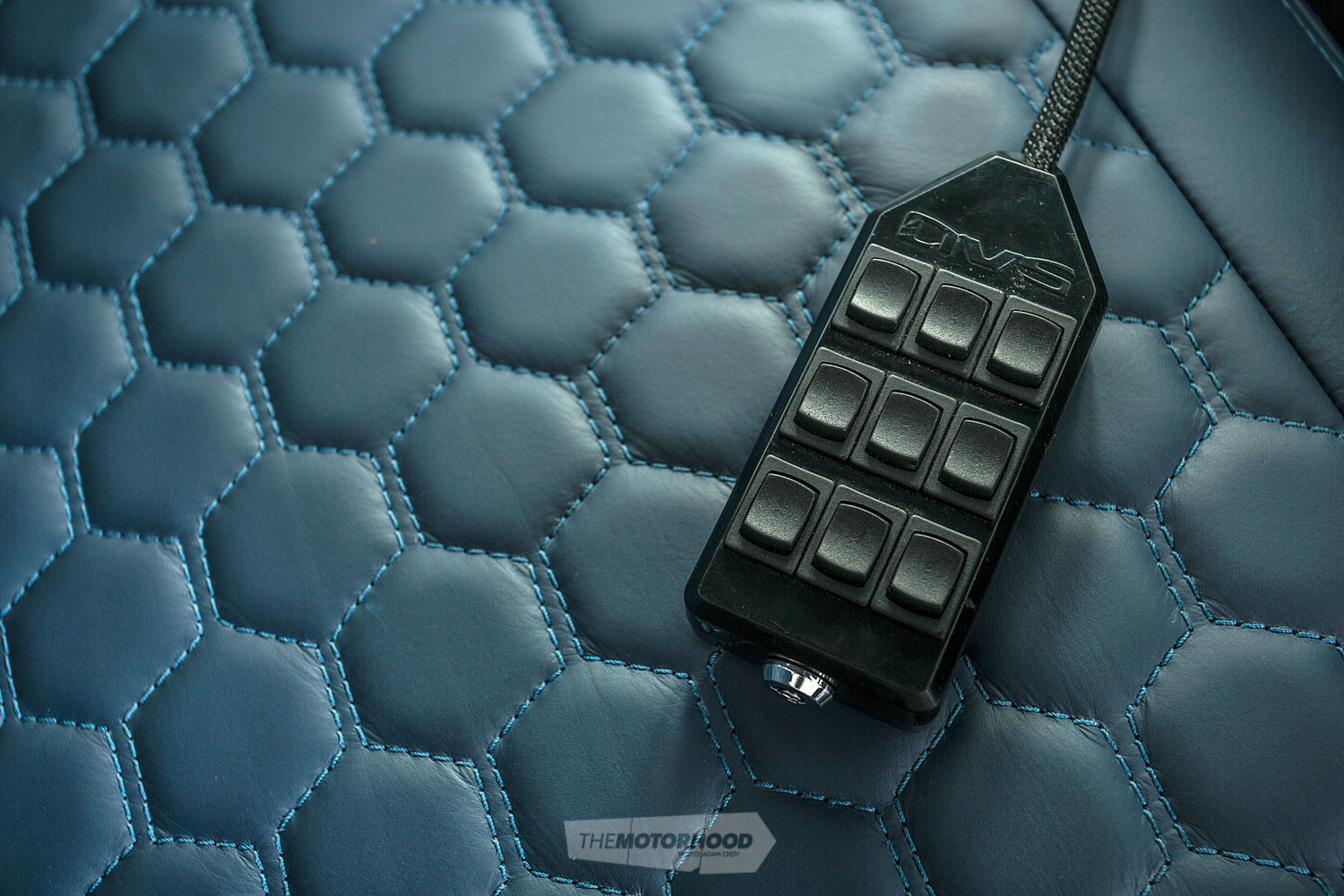

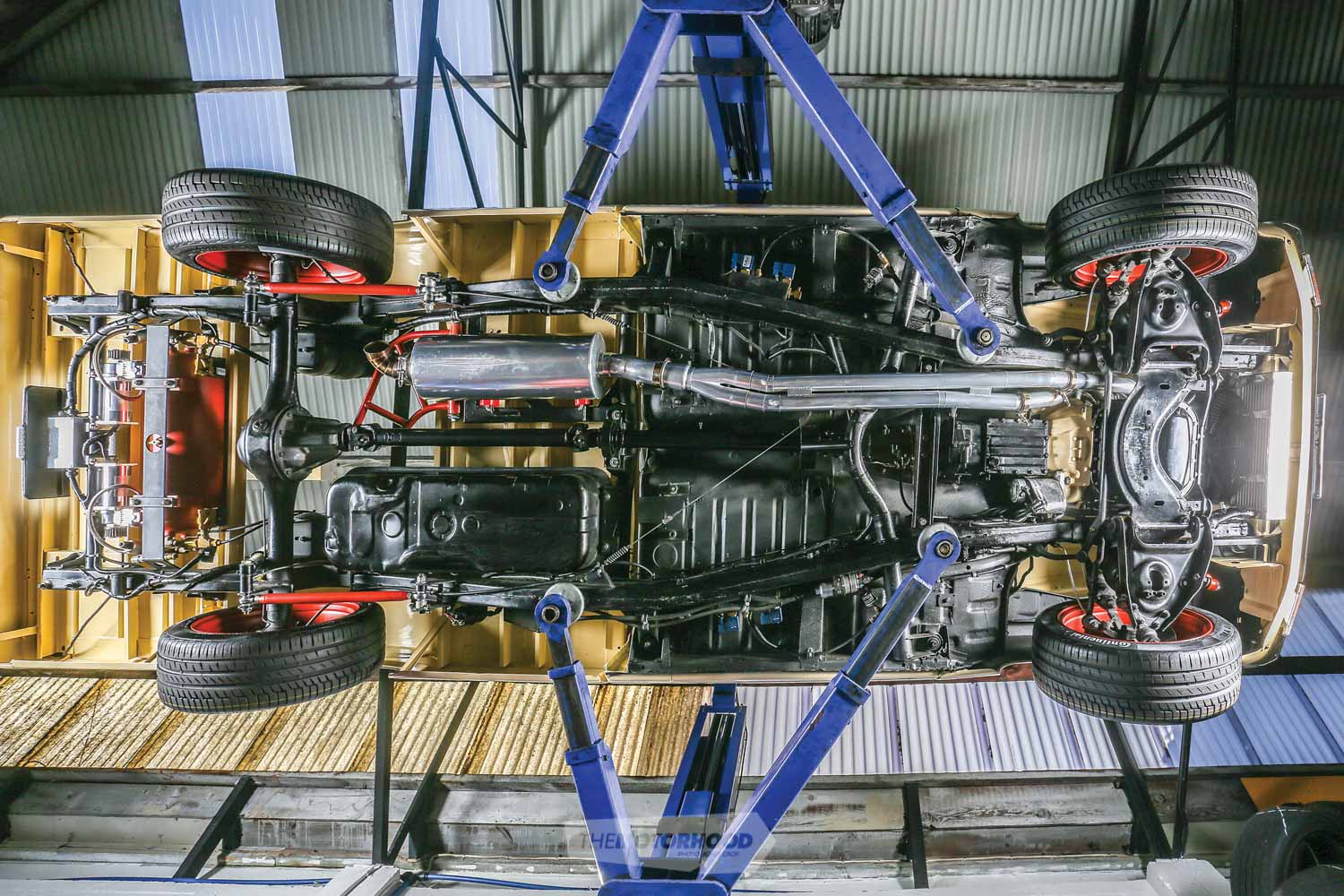

Starting with such a good base saved the hassles often associated with old tin; it also meant that going balls deep with a grinder would be disrespectful to the survivor. The original plan to body-drop it was soon ditched, as Mat from The Drop Shop just couldn’t bring himself to do it. Instead, they opted for a C-notch in the rear with a custom three-link, and the front modified to allow the all-important frame-laying characteristics once the airbag switches are hit. Under the tray lies everything carefully packaged to fit within the tight confines of the chassis rails to not intrude into the tray bed.

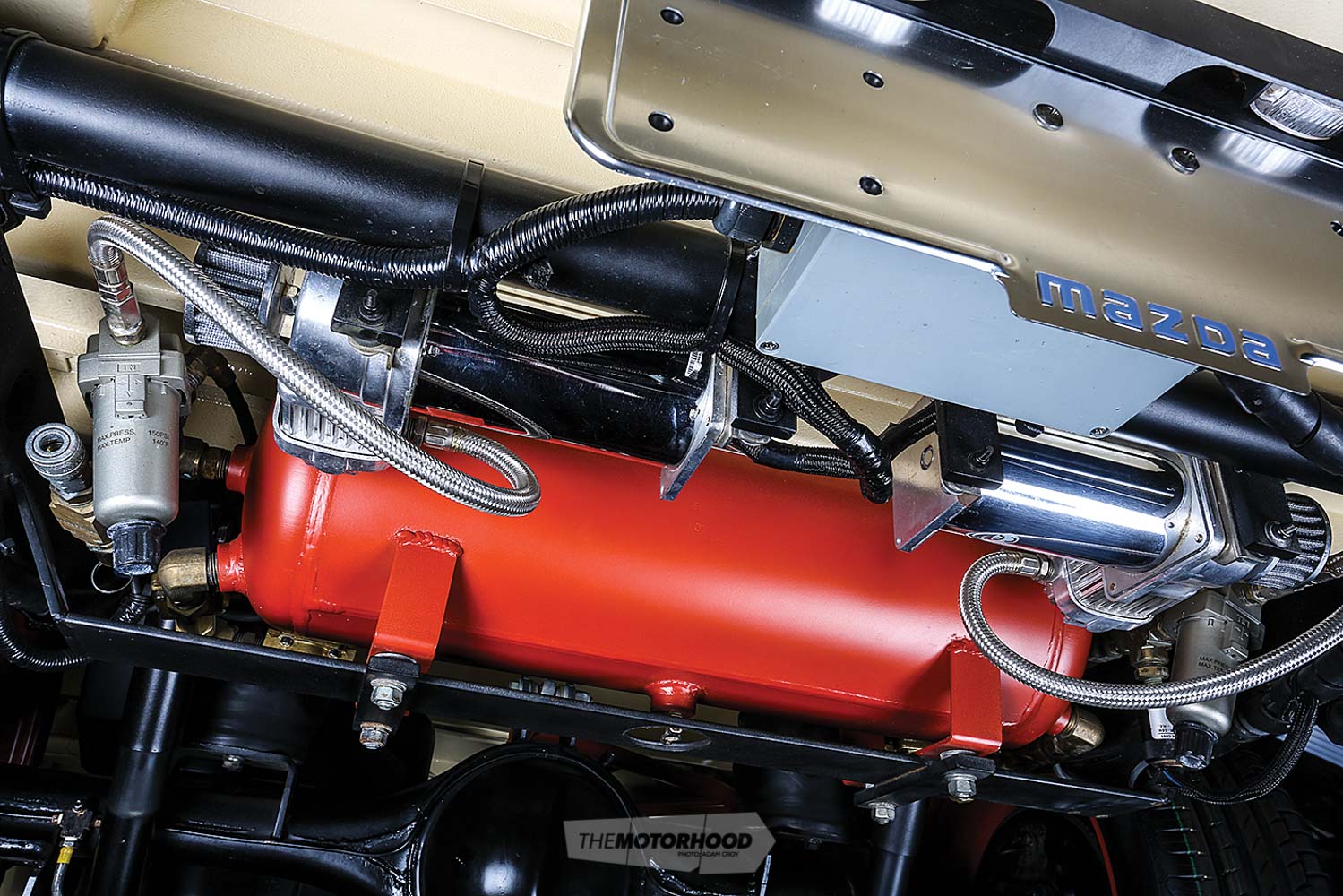

With all the added componentry tucked under the tray, it’s a busy place, housing the air tank and twin Viair compressors, the fuel system, and the custom three-link. To save space, the top centre link also acts as the locator, doing away with the need for a panhard

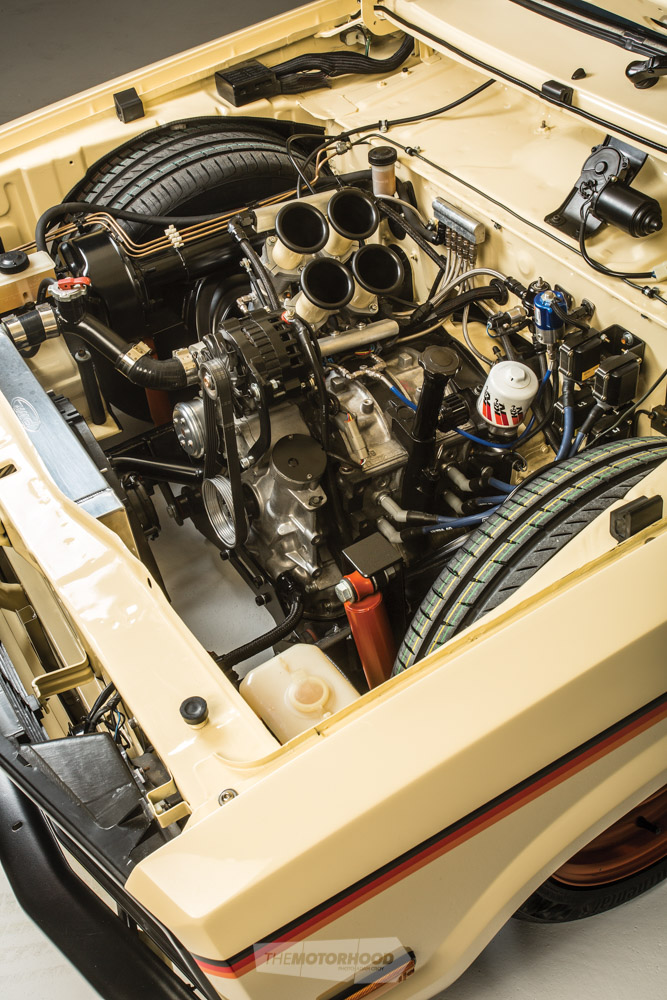

There would be a year in the chassis work alone, but that didn’t bother Wiremu, as that allowed time to focus on sorting the driveline. The decision to go 13B stems from his days racing at Meremere in his 12-second RS Legacy, where the only cars giving him trouble were of the Wankel-powered variety. One such incident is forever etched into his memory: “I was racing a silver RX-3. I blitzed it off the line as I had four-wheel drive, then, three-quarters of the way down the track, out of nowhere, it just blasted past me. The next thing I see is its tail lights directly in front of me as it crossed the centre line. I swerved and we missed each other. After that, I was sold on how insane rotaries are.”

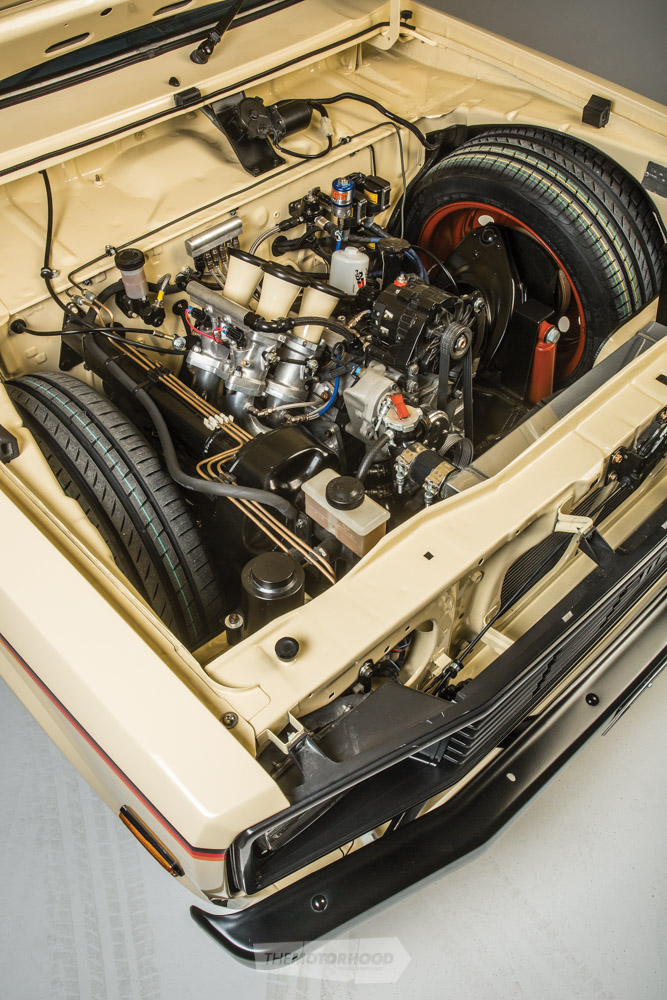

Teaming up with Brent from Curran Brothers Racing (CBR), a crazy plan was hatched to build a quad individual throttle body (ITB) set-up; something neither had experience in, but, if you know Brent Curran, you’ll know that he never shies away from doing things out of the box. Dual 50mm EFI Hardware throttle bodies now sit on a custom manifold. It’s got that old-school vibe that Wiremu was shooting for but without the hassle that he deals with regularly at work: having to tune carbs.

The block itself has all-new Mazda S6 RX-6 components, with high-comp rotors. This is following the first so-called rebuilt engine he’d already purchased that turned out to be nothing more than an assembled bunch of paper weights. The second trick up the high-compression bridgeport’s sleeve is a 200hp shot of nitrous, as Wiremu puts it, “making up for the lack of a snail hanging off the side”. This feeds into the manifold as a fogger system; when the bottle is eventually used, the lightweight ute will become a real handful, we suspect. This is something that Wiremu plans to make full use of at race tracks all over the North Island as he has been all summer long.

But this is no track hack, despite making well over four times its original power. The real charm lies in the details, half of which you’d need to roll it on its roof to admire. With the most detail of all being the custom tray — a saga that would stretch out to involve four workshops, two years, and plenty of reworking, as the first two shops just could not pull it off to the standard that Wiremu was shooting for. Eventually, it landed at Car Restorations in Matamata, which was able to turn the dream of a completely seamless inner tray with a pair of big round tubs into reality. The custom work on the tray didn’t stop there; the tail lights are now mounted via a single bolt, and the fuel filler and rear tailgate are all but distant memories. Once the metal work was complete, it then had an extended 12-month stay at Putaruru Panelbeaters, where Damien was responsible for whipping it into shape and respraying the factory cream that it’s worn since the day it left the Mazda factory. To further pay homage to its origins, the factory stripes were re-laid, giving it that quintessential ’80s vibe.

Tribute is also paid to its roots on the inside, with a retrim of factory pieces, ensuring that it’s kept timeless. Although, Wiremu admits to falling victim in those early years to a few past trends; “I’ve made some mistakes over the years,” he says. “I was in love with WRX bucket seats, so I fitted some and threw the immaculate bench seat in the bin, which you can’t get these days.” Thankfully, those buckies are long gone and in their place is a B1600 benchy that master trimmer Scotty, aka ‘Warvan’, has poured 18 hours into, hand stitching two hides of Bentley Blue Nappa together, with new foams and a powder-coated frame. That Nappa also extends to the door cards, and they’re only just getting started. As Wiremu sees it, this, coupled with the carbon-fibre moulded kick panels and sub enclosure behind the seat, is only the beginning for the interior, which will continue to undergo transformations for years to come — and he won’t stop till it’s perfect.

“I could never bring myself to sell it; it will be ongoing forever, really,” says Wiremu, who plans to continue tweaking, cleaning things up, and pushing it to the next level for the foreseeable. What we are looking at here is only stage one; we even hear that the body will soon by lifted off again to rework the wiring and plumbing. But, in the meantime, there are some track events coming up, and Wiremu’s right foot is itching to be buried. His burnout B2000 we showcased in NZPC 255 still has to be completed, or maybe he’ll continue the restoration on his earlier model B1600; both of these are stories for another day, but it’s safe to say that Wiremu’s love affair with the ute is far from burning out. He’s a lifer, folks.

Driver/Owner: Wiremu Burkhardt

Age: 32 years young

Location: West Auckland

Occupation: Pretend mechanic at Master Mechanics

Build time: 10 years

Length of ownership: 10 years

Thanks: God (at a church near you); my wife, Andrea; my kids, Waimana and Winnie; mum and dad; all of my family; Tyremax for the Continental rubber; Brent Curran for the engine; Damian Laird at Putaruru Panelbeaters; Scotty at Waikato Motor Trimmers; Tim at Procoat; Mat at The Drop Shop; Curtis and Fabien at BNT Newmarket; Sam Zolouskiy; Igor; and my team at Master Mechanics, Leo and Hamish

Heart

ENGINE: Mazda 13B, 1300cc, two-rotor

BLOCK: Lightened high-compression rotors, bridgeported s5 plates, s5 housings, balanced rotating assembly

INTAKE: Dual EFI Hardware 50mm throttle bodies, custom bellmouths, Cermakrome-coated custom intake, 200hp nitrous kit

EXHAUST: Cermakrome-coated 2.5-inch mandrel-bent headers, ceramic-coated three-inch single exhaust, stainless muffler, lobster-backed stainless tip

FUEL: Four 1000cc Bosch injectors, Bosch 044 fuel pump, custom surge tank, Aeroflow fittings, teflon line, Go Fast Bits (GFB) fuel regulator

IGNITION: Microtech ignitors, four Bosch coils, custom Moroso HT leads, NGK race plugs

ECU: MicroTech LT-10c

COOLING: PWR radiator, PWR oil cooler

EXTRA: MSD high-output alternator

Driveline

GEARBOX: Series 5 RX-7 five-speed

CLUTCH: Custom three-puck

FLYWHEEL: Chromoly

DIFF: Limited-slip

Support

STRUTS: Slam Specialties airbags, shocks

BRAKES: Factory

EXTRA: Custom C-notch, adjustable three-link, alloy air tank, two Viair compressor

Shoes

WHEELS: 17×7-inch Toyota steel wheels in oxide red

TYRES: 225/45R17 Continental Premium Contact 6

Exterior

PAINT: Resprayed in factory cream by Putaruru Panelbeaters

ENHANCEMENTS: Stripes by Sign Tint Matamata, custom sheet-metal roll pan / tailgate, custom sheet-metal tray bed with tubs, modified tail-light housings

Interior

SEATS: Retrimmed B1600 bench in Bentley Blue Nappa, powder-coated frame

STEERING WHEEL: Factory

INSTRUMENTATION: Digital air gauges

ICE: Alpine Type R speakers, custom carbon-fibre kick panels with tweeters, two Class-D amps, custom fibreglass subwoofer enclosure, 13-inch Soundstream sub

EXTRA: Custom leather door cards with polished trims, custom sheet-metal panel

Performance

POWER: 200kW

FUEL: E85

TUNER: Dynopower

This article originally appeared in NZ Performance Car issue No. 259 — to get your grubby mitts on a copy, click the cover below: