Five years of hard work took this once-rusted Beetle to show-stopping dragster hell-bent on the New Zealand import H-pattern record

While we tend to blow our own trumpets here in New Zealand about how crafty we are, a proud nation of do-it-yourselfers, brought up on a diet of number-eight wire and just making do, the truth is that we are not the only nation on this planet that breeds such crafty buggers. We share this DIY ingenuity with South Africa, so it should come as no surprise that the Beetle before you was built almost entirely in the small Bay of Plenty garage of South African–expat David Du Toit and his family. Unlike the case with a lot of DIY work, though, there is very little on this drag car to indicate that its birthplace was the backyard. You might even have been fooled into thinking it was built by pros, as rumours of it being imported have been floating around.

The only steel panels left on the body are the roof and rear quarters. Every other panel has been produced in fibreglass by David during a painstaking three-year process in search of perfection

A keen racer back in South Africa, where he pedalled and built a vast array of 10-second streeters, David made a shift down under to start a new life and family — a move that put a stop to his racing while they settled in and made New Zealand home. Once accustomed to the ways of life here, he decided that it was time for him to get a taste of the local drag racing scene. Having raced rotaries back in his homeland, David’s first choice was an RX-3 — although the price of these is, well, astronomical.

“I started searching Trade Me for an RX-3 coupe, but found they were out of my price range. I had owned a Beetle back home, and they were in my price range, so I decided to build one,” David explains.

What David was about to embark on was a race car project well above anything he had built before — a build that would span nearly six years. He decided to go full tube chassis, with a front engine–rear drive combination, but the quotes for a chassis had him choking on his morning cereal. Acquiring a dilapidated VW shell, one very determined David purchased the tools required to bend and notch some tubing, and set about learning the art of chassis building — which is no mean feat, we might add.

David recounts his experience: “No one is keen to give away their secrets, so you have to look at what everyone is doing, do a lot of Googling, and just figure it out as you go. I have probably used enough tube to build two chassis. It took the most time, but was the cheapest part of the whole build. It took me so long as I was learning the hard way about how to do it right.”

Before David went too far, the shell needed attention. With so much rust in every panel, it was decided that making fibreglass panels would be faster and easier, and achieve a better (lighter) outcome. Over the next year, each panel was whipped into shape and moulds taken — work that included constructing a one-piece front clip. The moulds were then set aside.

As David puts it, “After I made the moulds, they sat for two years, so [that] they could stretch and pull and do their thing. After that, I spent another six months prepping, sanding, and filler priming them. It was a lot of work, but, once they came out of the mould, the panels were pretty tick-tock.”

“Tick-tock” is an understatement. David, who is a spray painter, laid down DNA special-mix Fuchsia Candy, achieving a finish we rarely see on fibreglass, and one that looks better than that on 90 per cent of the show cars out there.

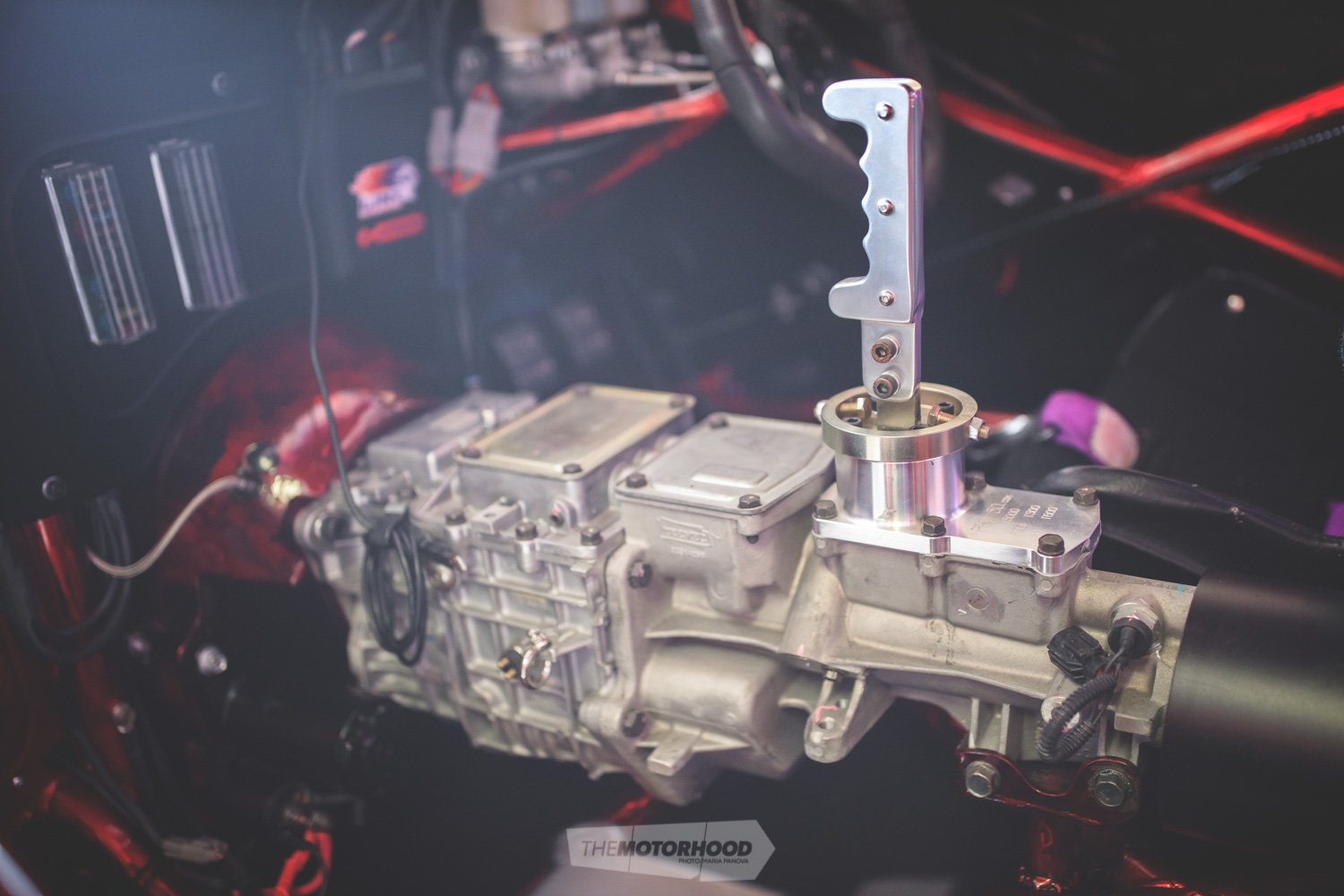

“With the H-pattern record in mind, a dog-geared Tremec TKO 600 has the job of swapping gears and sending power to the ladder-barred Moser nine-inch”

Make no mistake, though; this Beetle is no show pony. It was built for a different purpose: to run numbers — more specifically, to run the fastest H-pattern pass by an import in New Zealand, a title currently held by Brad Jonson’s RX-7 at 8.59s at 260kph. To do this, David called on Green Brothers Racing for a Tremec TKO 600 equipped with dog-engagement gear set and a Moser nine-inch diff with chromoly full-spool and 35-spline axles.

You can bet this has been a family affair, with David’s two girls lending a hand wherever they could throughout the build. They even picked the colour long before seeing the car

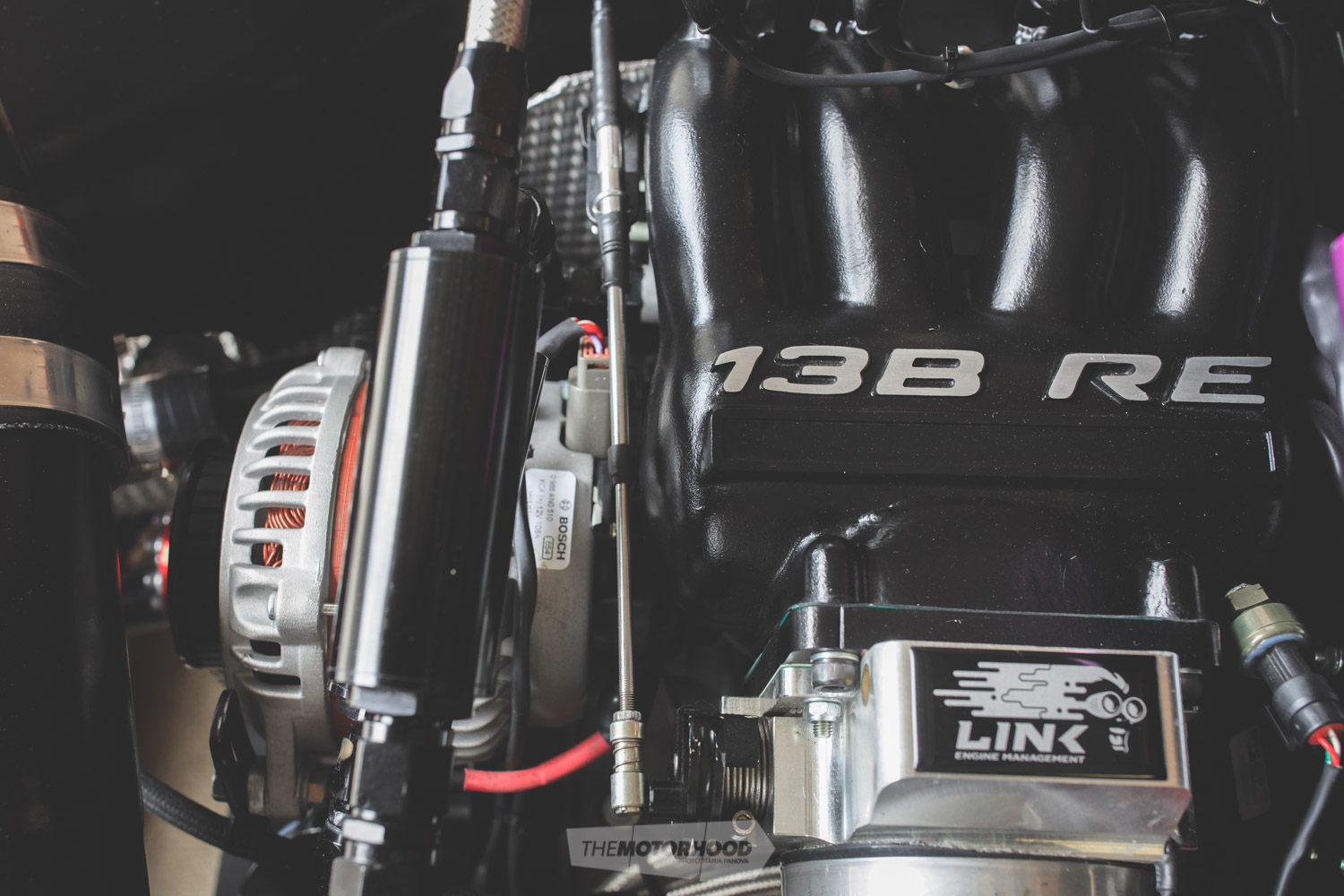

A trip further down the road in Tauranga to Dyno Power saw the build of a stout little 13B capable of big revs, big boost, and plenty of methanol. An 83mm BorgWarner S400 that once called the Abbotts’ FD home currently has boost sitting conservatively at 21psi while David shakes the car down, but, with all the supporting mods in place, 50psi is a real possibility.

As everyone knows, drag racing can be a fickle beast, so simply throwing in lots of power before getting the car to hook up and run straight is the first hurdle to overcome. The front Strange Engineering lightweight spindles and shocks are joined by a ladder-bar rear with QA double adjustable shocks — a change from the first set, as the first few meetings saw the car not wanting to hook up and bouncing during the launch. However, after chassis guru Terry Bowden looked over the car, some new rear shocks with softer springs found their way onto the ladder bar. At the time of writing, the rain is playing havoc with seat time, but hopefully, by the time you read this, David will have managed to get in some full track passes.

“It’s so cool being finally able to get some seat time after jumping in and out of it probably 500 times during the build. It’s been a bit scary, especially not knowing what’s going to happen each time we change something. You just don’t know what to expect,” David tells us.

For the relatively inexperienced team of family and friends, it will be a learning curve, but once it does hook up, and run some full-power, full passes, this bright pink Beetle will cause more of a stir than it already has.

David Du Toit

AGE: 35

LOCATION: Tauranga

OCCUPATION: Spray painter

BUILD TIME: Six years

LENGTH OF OWNERSHIP: Six years

THANKS: My wife, Lindie; Link ECU, GlassArt NZ, Popeye Pics, Linkup Paints Tauranga , Vulcan Steel Tauranga

2017 tube-frame VW Beetle

Heart

ENGINE: Mazda JC Cosmo 13B, 1300cc, two-rotor

BLOCK: Series 4 lightened, balanced, and clearanced rotors; stage-two ported plates; dowelled

INTAKE: Ported JC Cosmo intake, single 100mm throttle body, five-inch K&N filter

EXHAUST: Four-inch stainless side-exit

TURBO: Custom BorgWarner S400 (83mm)

WASTEGATE: 60mm TiAL

FUEL: 8x2400cc Siemens Deka injectors, Aeromotive fuel-pressure regulator (FPR), Aeromotive mechanical pump, 15-litre fuel cell

IGNITION: 16V CDI

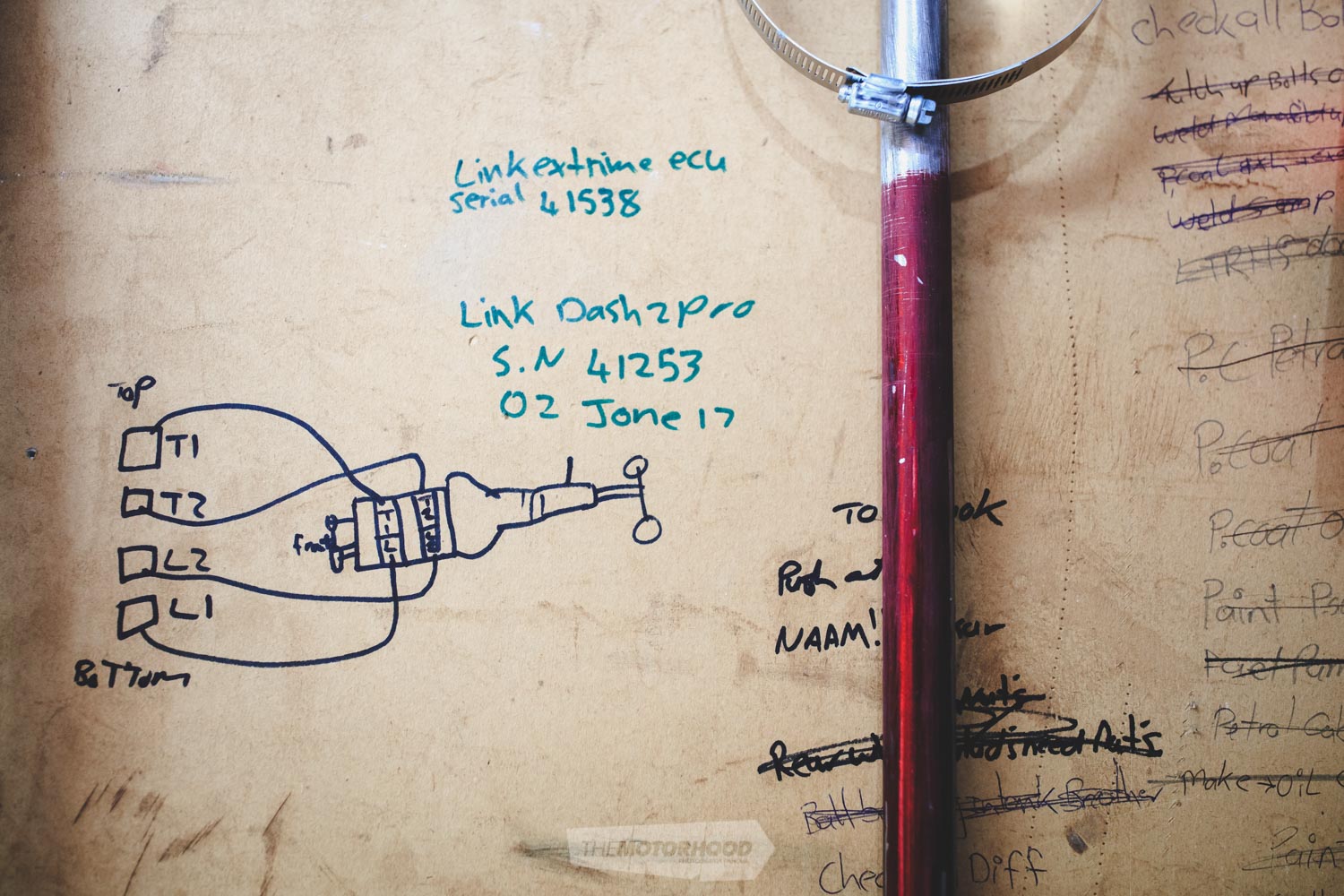

ECU: Link G4+ Xtreme

COOLING: Alloy radiator

EXTRA: Remote oil-filter mount, Link five-bar boost controller, 10-litre catch-can

Driveline

GEARBOX: Green Brothers–built TKO 600, dog-engagement gear set, Green Brothers steel bellhousing

CLUTCH: McLeod eight-inch twin-plate

FLYWHEEL: Custom chromoly

DIFF: Green Brothers–built nine-inch, Moser head, chromoly full spool, 35-spline axles

EXTRA: Custom chromoly driveshaft with billet yokes

Support

STRUTS: (F) Strange single adjustable, (R) double adjustable QA1 coilovers

BRAKES: (F) Strange lightweight rotors and calipers, (R) Nissan Bluebird calipers and rotors, DJ Safety parachute

EXTRA: Strange front control arms, Strange steering rack, ladder-bar rear end, spring-loaded wheelie bars

Exterior

PAINT: (Body) DNA special-mix Fuchsia Candy, (chassis) red candy clear

ENHANCEMENTS: Fibreglass nose cone, doors, guards, and boot lid; polycarbonate windows

Interior

SEATS: Powder-coated Kirkey, RJS five-point harness

STEERING WHEEL: Momo

INSTRUMENTATION: Link Dash2 Pro

EXTRA: Special-effect black powder-coated tin work

Performance

POWER: 536kW (720hp)

BOOST: 21psi

FUEL: Methanol

TUNER: Brent at Dyno Power

This article originally appeared in NZ Performance Car issue No. 256 — you can get your hands on a copy by clicking the cover below: