We delve into ethanol flex-fuel systems with Jacky Tse from Jtune to find out what’s required to run one and what to look out for

In this modern world, everyone wants flexibility — in the way we work; the way we dress; and, most important, in the circles within which we navigate, the fuel we choose to power our dyno-killers.

Can you really have your cake and eat it, too — high-octane ethanol on the weekends for racing, then traditional petroleum-based 98-octane fuel for the weekday shenanigans? That is precisely what a flex-fuel system allows, and it allows it without the need to run two separate fuel tanks. It’s a common feature on many American and Australian OEM machines, as ethanol (E85) is available from the pump at the petrol station in those countries — something that’s also starting to happen here. It’s because of this that retrofitting such systems to performance cars is a growing trend here in New Zealand.

Typically, E85 requires 30 per cent more volume to produce the same energy as 98 octane, as it contains 30 per cent less energy per litre. However, the added usage is far outweighed by the benefits, such as the higher octane rating of 105–107 for pump variants and 112 for race-blended E85s

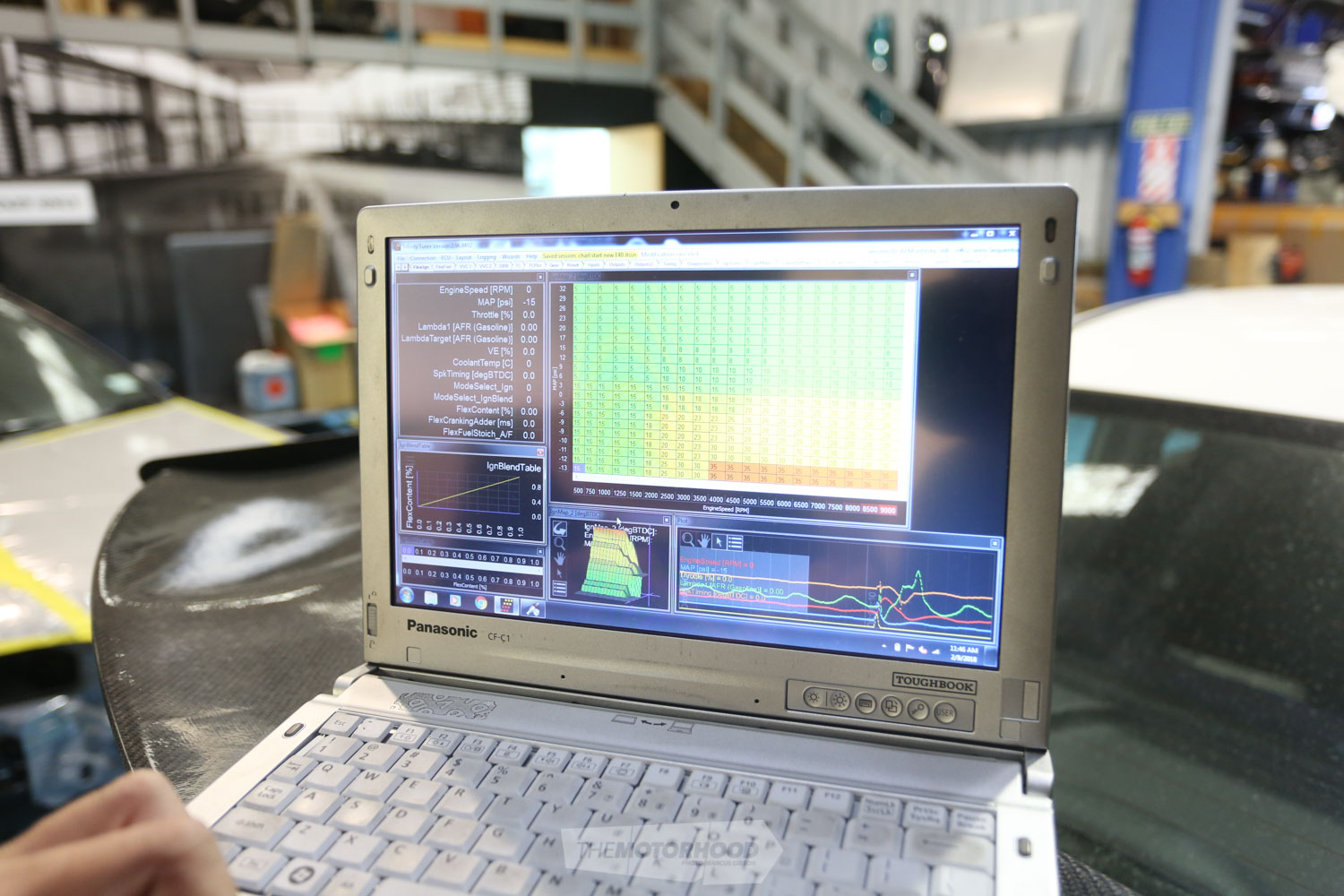

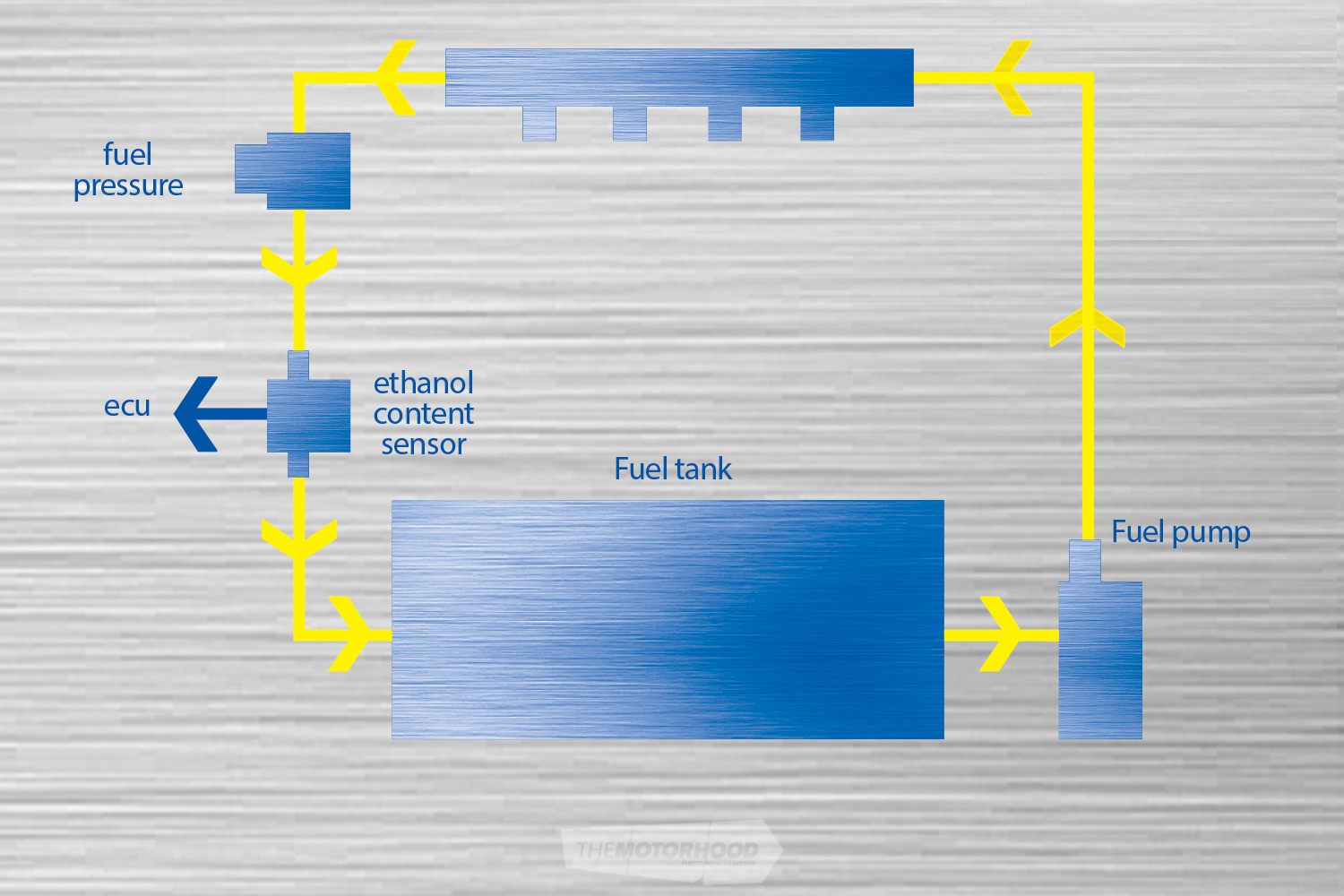

The key component to a flex-fuel system is the sensor that is plumbed into the fuel line. It detects the ethanol content in the fuel by testing the conductivity of the fuel as it passes through. Ethanol is a more efficient conductor than petrol, so the higher the conductivity, the higher the reading. This information is then sent to the ECU, as with any other digital input, so that it can adjust the fuel trim table and retard the timing; the lower the ethanol percentage it reads, the less fuel and timing.

In OEM applications, this is obviously all taken care of at the factory. However, in an aftermarket ECU, it can mean a very long, and therefore expensive, stay on the dyno, as each and every percentage would need to be configured — unless it is a high-end ECU that has a self-tuning function. Some common stand-alone ECUs don’t even have a specific input for flex fuel, so it needs to be done via a digital input, such as the fuel temp.

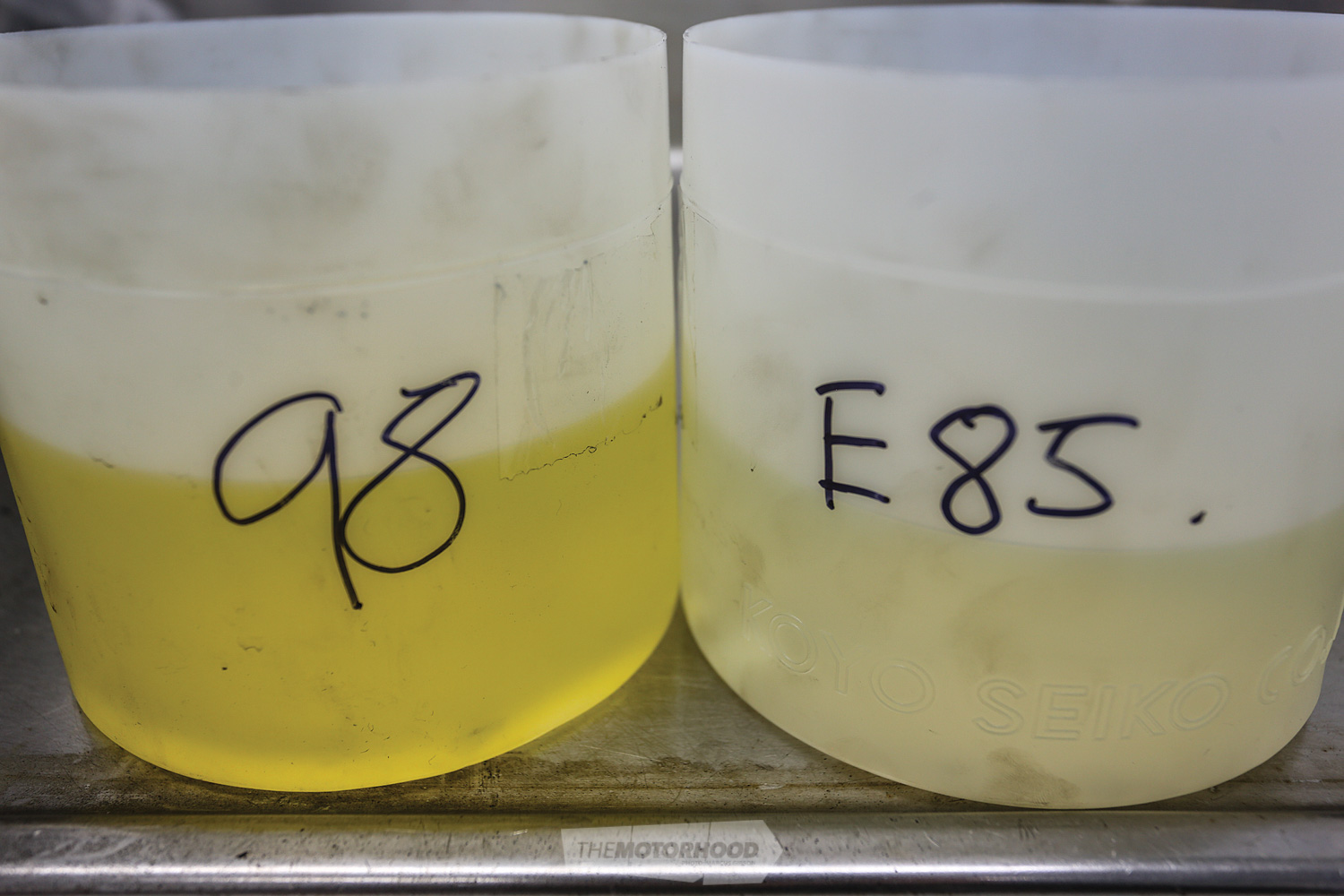

For the test, we run Gull Pro Force E85, currently the only ethanol available from the pump in New Zealand. Made from a dairy industry by-product, casein, it’s a totally renewable resource and about as Kiwi as it can get. In other countries, the ethanol is produced from corn, wheat, sugar cane, and sorghum

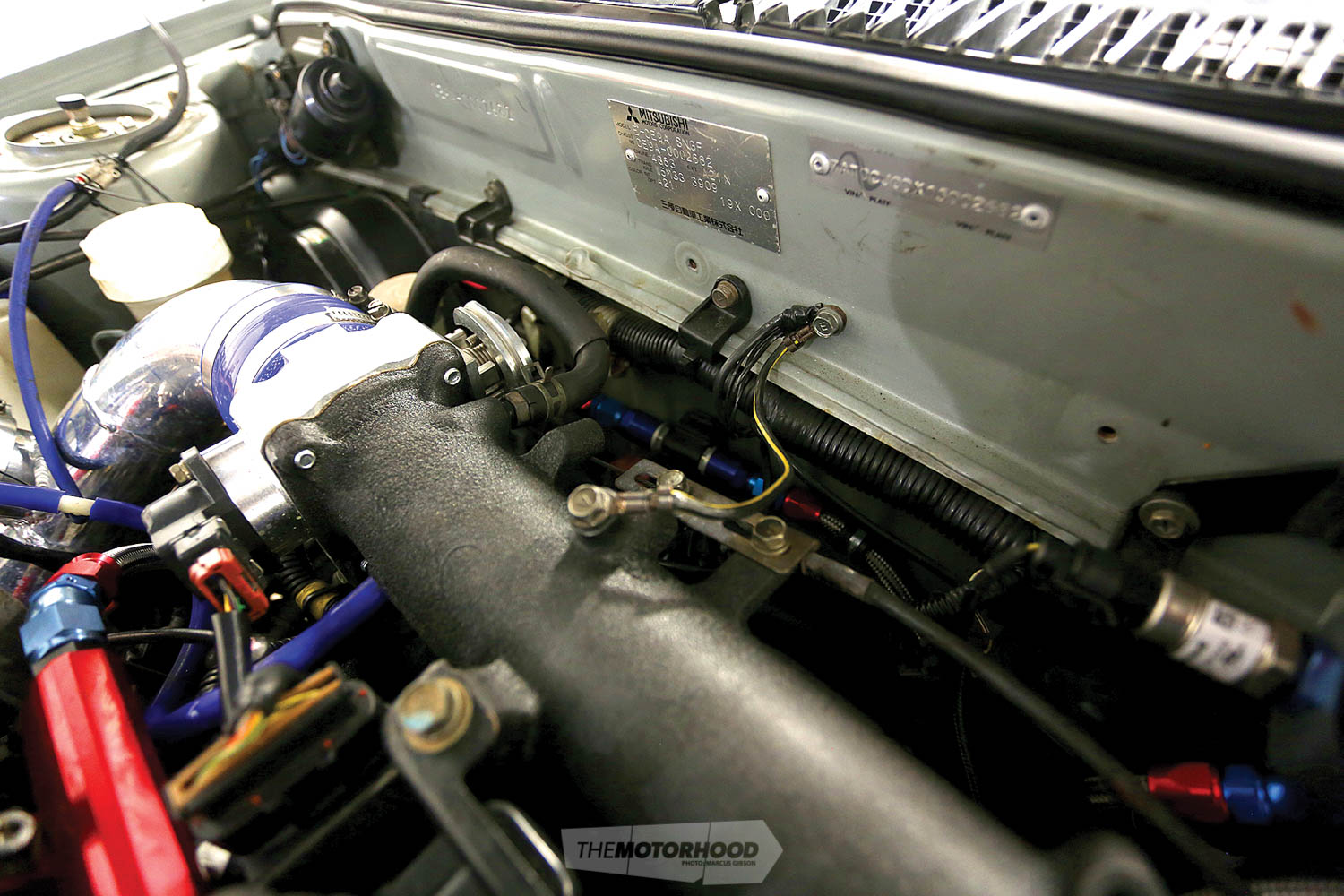

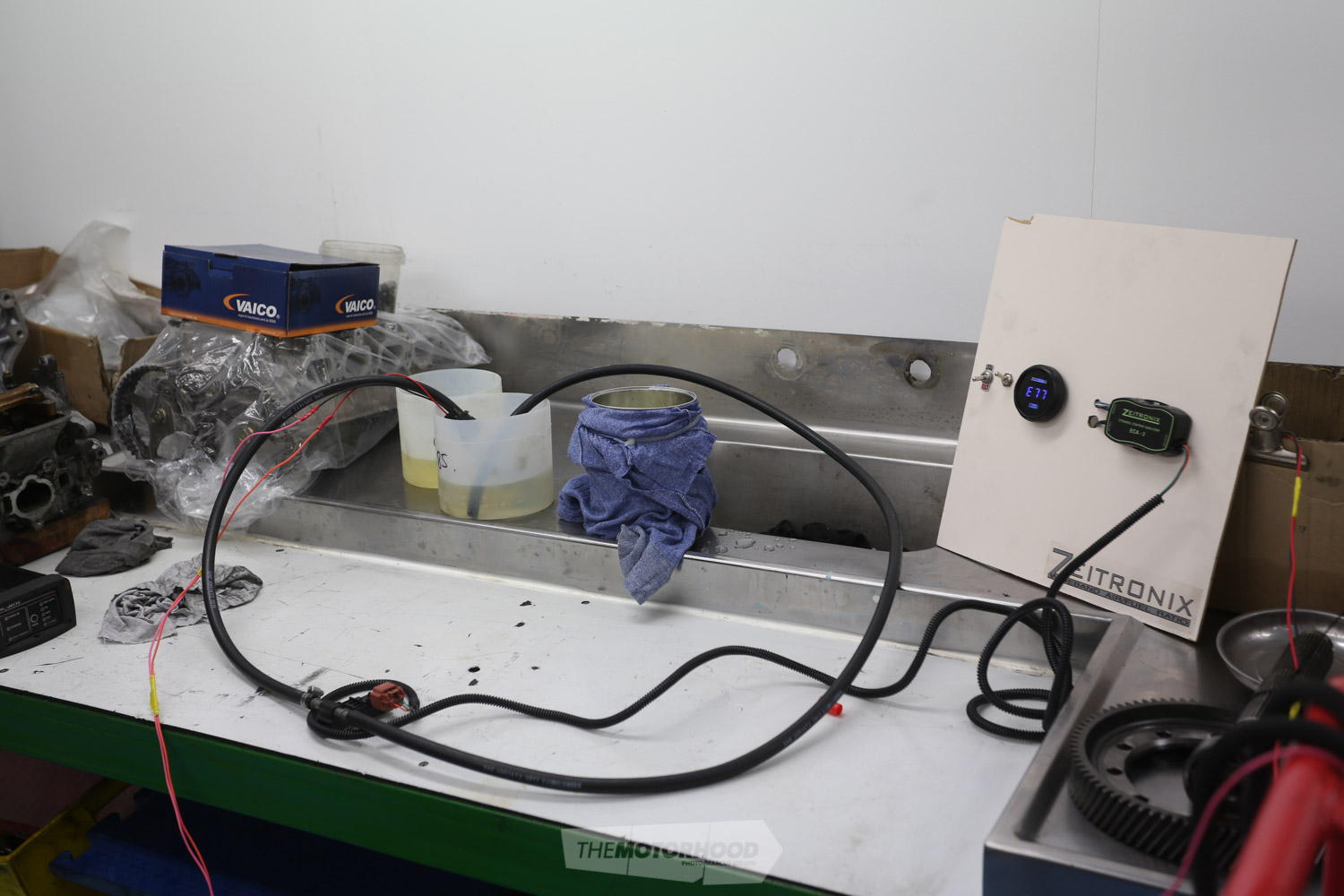

What we wanted to test was both the validity of switching fuels in the system on the fly and the accuracy of doing so. Could you simply dump your 98 on Friday night, fill up with E85, and go racing for the weekend? To showcase this, we would first set up a bench test inside the engine lab at Jtune. Jacky had set up a jury-rig consisting of a Zeitronix ethanol-content analyser (ECA) with gauge, a Walbro in-tank pump, and 10mm lines. We would later real-world test with an Evo II on the dyno.

Running a higher octane allows for more timing, more boost, and more compression, but this is where the risk comes in. If your E85 tune is running on that ragged edge and the content drops, so does the octane rating, and that could spell disaster of the engine-blown kind

Our test day begins by filling up two fuel cans at our local E85 pump — something those in the greater Auckland region are spoilt in having. Using our jury-rigged Zeitronix ECA with gauge, we set about testing the E85’s accuracy. This will typically vary a small percentage either side of 85 per cent, but this was a good batch, hitting its mark of 85-per-cent ethanol displayed on the gauge. We then drop the same rig into a tub of 98 octane, after draining it as well as possible. Jacky tells us that the gauge would typically read between three and four per cent in 98 octane, but we are sitting much higher. It takes us four rinses with fresh 98 to achieve the three–four per cent reading. Now, imagine that in your average full-size fuel system — that’s a serious amount of residue. Even if you emptied the tank via a drain bung, achieving either pure 98 or pure E85 would take a serious amount of flushing and lots of wasted fuel.

To further push the point, we switch the rig back to the E85 tub and mix in 98 in 10ml increments until we are reading E60. It takes only the smallest amount of petrol to bring the number down dramatically. That’s when things get really interesting — or, should we say, confusing. Jacky begins adding water to the blended fuel, and, as more water is added, the gauge begins reading higher and higher numbers. So, we effectively end up with a low-octane mixture that falsely tells the ECU we have 105- to 107-octane ethanol in the lines. This occurs due to water’s conductivity, and the fact that an ethanol sensor is a hygroscopic sensor testing conductivity. Confused? Yip, fair enough.

So, if you can’t rely on the sensor to read the true ethanol content of the fuel, how can you rely on it for tuning purposes?

“Letting the ECU adjust the tune entirely based on an ECA sensor when running flex fuel is very risky. A good wideband oxygen sensor should be used, and set up with closed-loop feedback, as well as a knock sensor to detect any knock. I always recommend running two wideband sensors in case of failure and giving out incorrect input to the ECU for ST tuning [short-term fuel trim],” explains Jacky.

Ethanol absorbs water, so care must be taken when storing the fuel, as the more water it absorbs, the lower the octane of the fuel, while the sensor will tell the opposite story. Petrol, on the other hand, does not absorb water. A good indication that your E85 has absorbed water is if it has turned cloudy

Our final test is a real-world example of switching a car from 98 to E85, as the owner wants to have tunes for both fuels. With the fuel tank on empty, we fill the Evo II with 40 litres of pre-tested ethanol. When we fire the Evo up, the gauge shows E15; then, as it sits idling and circulating the fuel, the figure rises and the idle becomes rough. After a quick fuel-map adjustment, it is left to idle for 10 minutes, achieving a best reading of E70.

So, you can see that a simple swap-over, even with an empty tank, is never going to achieve a true E85 mix. To achieve that, the fuel would need to be dumped, the tank and surge tank drained, the filters and pumps dried out, and all the lines and rails flushed with E85. A big exercise no doubt, and something to be considered by all the weekend warriors out there swapping fuels on the regular without an ECA set-up. If your tune is on the ragged edge, it could spell disaster as that octane rating fluctuates.