1300cc of historic rally car fury

There was a time in the not so distant past when the likes of the humble Toyota 4K 1300cc with a pair of side-draught carbs, plenty of compression, and a ‘hot’ cam was a formidable weapon for anyone who mashed the right pedal to the metal and danced on gravel, swapping lock to lock. But, as any motorsport stalwarts, rally folk were not perturbed by advancements in technology, and the quest for victory soon saw the likes of the humble 4K superseded by bigger capacity engines and, of course, boost!

Some 30 years later, and here we are, blasting up a wet and winding road as the Lampola five-speed screams away under the floorpan, the Stack tacho licks 9000rpm, and the trees and Armco are but a blur through the side window. The lack of technology, capacity, and boost, for that matter — all of those quibbles simply melt away as the nimble little Starlet dances on the Alcon brakes, and proves just how well these little terrors would have gone in their day.

But what we are riding in and what you see before you is no 30-year-old survivor. It is the culmination of 27 months of hard graft headed by the team at West Auckland’s F40 Motorsport.

The front suspension components are a mix of AE86, T3, and custom F40 parts, which take orders from the 200mm travel MCA coilovers

That work saw the transformation of a 1983 Toyota Starlet Sprint into a historic gravel-basher, one compliant with the most stringent historic rally regs set by the likes of MotorSport New Zealand (MSNZ) and the FIA. It’s the machine in which F40’s Steve Cox will make his return to the gravel following a 20-plus-year break from the sport that he got his start in, as he recalls: “I rallied as a young man, from 21, through to my early 30s. I started in a Datsun 120Y, which didn’t last long, and then a MkI Escort that we did two or three seasons with, followed by a Group N Daihatsu Charade, and, finally, an early Ralliart Evo I. We binned the Evo in a pretty big way. We fixed it, but it was never the same — the car was, but I wasn’t, and the general feeling toward rally in the family had cooled, so we took up circuit racing. But I never retired from it, I always intended to go back to rallying. I guess when Hayden Paddon lifted the profile of rallying again, I started watching again, thought a little harder about it, got itchy feet, and decided I would find a car.”

It was decided that historic rally would be his chosen class, and he’d run in the likes of the Silver Fern Rally and as many hill climbs and rallies as possible. The exacting regulations of historic rally are based around upholding the way it was done when sex was safe and motorsport dangerous, with every modification coming under stringent scrutiny to ensure it is period correct and just the way it was back in the ’70s and ’80s. So, with a little more than just MSNZ Schedule A to worry about, Steve had MSNZ technical advisor Andy Culpin involved from the project’s inception, overseeing each component to ensure that it would be valid under the rules, everything from the configuration of the rear suspension to the way the engine was pieced together.

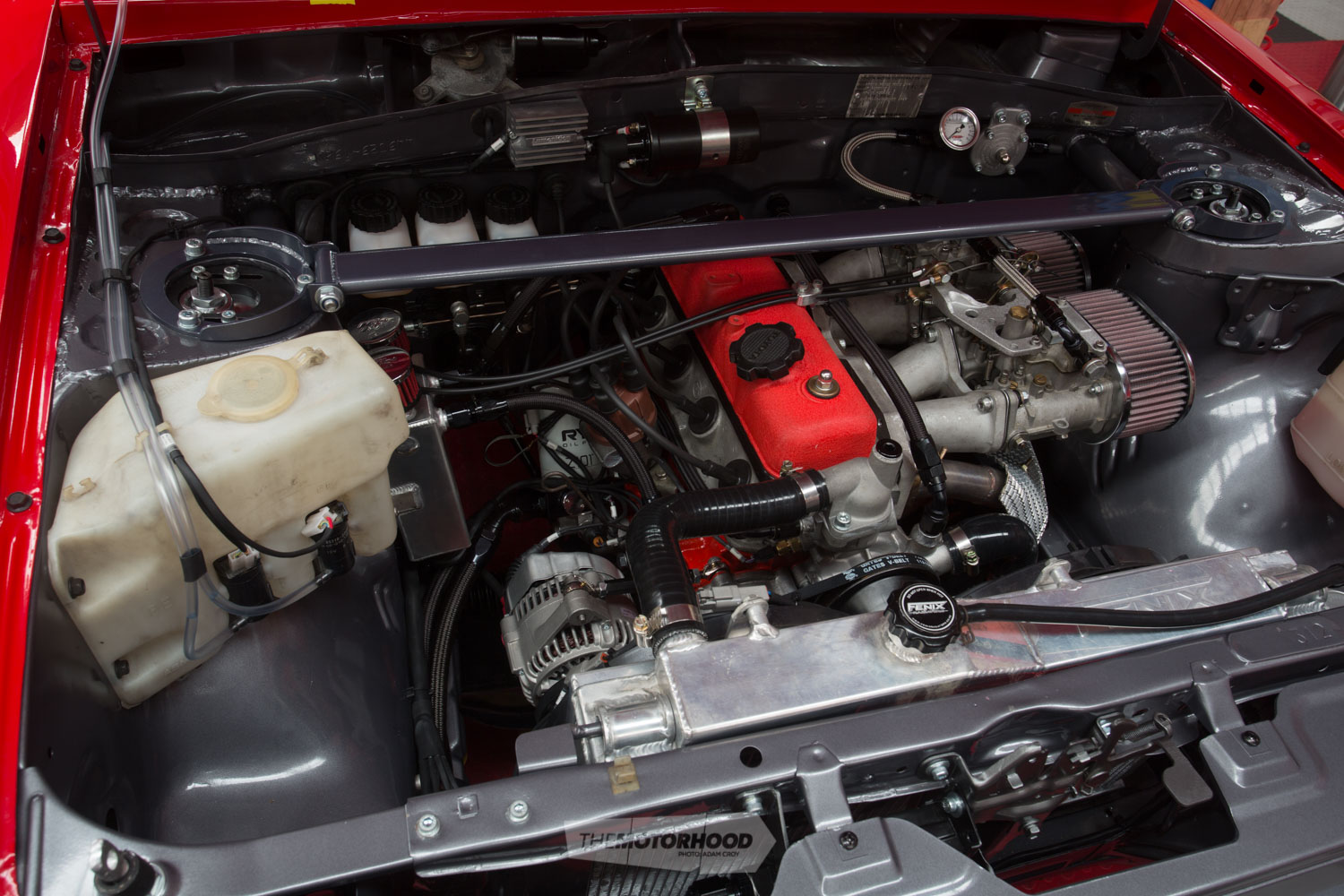

Starlet trainspotters will note that the engine is not sitting as you would have found it straight from the Thames Toyota plant; it’s been uprighted to allow a better intake design when fitting twin 45mm Dellorto side-draughts

But having these limitations placed around the build did not mean that some modern technology could not be put to use working smarter, rather than harder, before any steel was cut or welded — as Steve explains. “The rear trailing-arm suspension was all designed using a computer suspension-analysis programme. So we know [that] it’s right as long as the points are put in the correct place by the welder, so there was no guesswork.” The housing itself is a Ford Escort item with inboard brakes, a period mod popular to avoid the twig-like axles of a Starlet. The other bonus was opening up the possibility of off-the-shelf components like the Quaife Automatic Torque Biasing (ATB) limited-slip differential (LSD) with a 5.1-ratio crown and pinion.

It’s one of the benefits with building an ever-popular Escort — as long as the cheque book is fat enough, you can build a complete rally car from the catalogue, which is far cry from the availability of aftermarket parts for Starlets, for which the majority of the components need to be custom made. Mind you, when you own a business like F40 Motorsport, which specializes in CNC components, nothing is out of the question. Everything from the strut tops to the brake kit, hubs, and rear arms has been designed and machined in-house to the way it was done in the ’80s, but utilizing modern machining techniques, which, much like anything else found on the Starlet, is worlds above the quality that would have been achieved if it had been built in period.

This is most evident (not that you can see inside) when it comes to squeezing the maximum 112kW or so from the 4K. When you’re dealing with only 1300cc, two valves per cylinder, and no forced induction, pressing out power requires some serious work. Hartley Engines and Motorsport in Palmerston North tackled the job to 1980 specs with, you guessed it, plenty of compression, a ton of porting, and all new internals, although the quality of the metal found on the likes of the Denco forged pistons is of a much higher calibre than you’d have found in 1980. But not all parts are new; the block and head castings, for example, are 35 years old, and simply finding a head that was not porous proved difficult.

Built to regularly see 9000rpm, the 4K head was CNC ported before a lightened valve train found it’s way up top, including roller rockers. Usually, with an engine like this, you’d dry sump, but rallying generates less oil surge so a custom baffled sump was the next-best option. Starlet trainspotters will note that the engine is not sitting as you would have found it straight from the Thames Toyota plant; it’s been uprighted to allow a better intake design when fitting twin 45mm Dellorto side-draughts, considered the better option for rally given the regular throttle work required to keep a car on a thin sliver of gravel.

The chassis has been strengthened throughout, with Escort rear turrets welded in and extensive gusseting supporting the towers. The roll cage is far safer than those of period

All this work has resulted in a humble 112kW, and Steve is under no illusions that the car will actually be competitive against the likes of the Escort BDAs, but that won’t stop him giving it a red-hot go: “The key with rallying is to keep tyres under the thing, and because I’m at the stage in life where budget is less of a concern, we will be throwing tyres at it. We are doing a pretty serious attempt at it. But, in saying that, it’s a 1300; we have no hope in the outright 2WD or even the historic 2WD championship — it would be reliability that would get us there. It’s a class car; it’s a car that I should be faster than it, so we should hopefully not get into too much difficulty arriving at a corner way too fast than I can cope with. I don’t want to blame age; [it’s] more the lack of experience in gravel for the past 20 years [that] means I don’t want to get a car like an AP4, in which you’d arrive at a corner with 40 to 50kph more speed and going, holy hell, how do we get around this corner? We are going back for some fun rather than being stressed about winning, to reminisce about old times, and have some fun with the bigger team [that] you need for rally, the co-driver, and all the cool bits you get with rallying.”

From our small stint in the passenger seat in not-ideal conditions, we suspect this little Starlet will do just what its counterparts did in the early ’80s, proving that even a 4K can be a formidable weapon in the right hands.

Steve Cox

Age: Older than the car by 20 years

Location: Auckland

Occupation: Owner Prodoc and F40 Motorsport

Build time: 27 months

Length of ownership: 27 months

Thanks: Tracy, Brodie, and Bailey for putting up with my absences in the workshop; Rob and Pete at F40 Motorsport; Alan at Dunkworks; Stephen at SD Performance; Steve at Moselle Panel and Paint; Brian and Nelson at Hartley Engines and Motorsport; Paul and Richard at Plastics Construction; Chris at Racer Products; Phil at Key West Bolt and Supply; Richard at Neil Allport Motorsports; Clark at Hella New Zealand; Russell Cole, for wiring; Jeff at Havana Print; Dave at Racetech, Chris Wilmouth, for the roll cage; Paul Dunkley, for the suspension design; Andy Culpin, for keeping the build on the right path to ensure eligibility for historic racing

1983 Toyota Starlet (KP61)

Heart

ENGINE: Toyota 4K, 1300cc, four-cylinder

BLOCK: Forged Denco pistons, Carrillo rods, custom ground cam

HEAD: Hartley CNC-ported head, lightened valves, lightened push rods, roller rockers

INTAKE: Twin Dellorto side-draught carburettors, custom intake manifold, K&N filters

EXHAUST: Dunkworks stainless four-into-one headers, two-inch stainless exhaust

FUEL: FIA GT tank in custom drop enclosure, intake pump

IGNITION: Period Lumenition ignition on original Toyota distributor

COOLING: Modified Fenix AE86 alloy radiator

EXTRA: Custom breather tank, period accelerator linkage, Dunkworks engine mounts

Driveline

GEARBOX: Lampola dogbox, five-speed

CLUTCH: Tilton single-plate, Tilton release bearing

FLYWHEEL: Custom lightweight

DIFF: Ford Escort housing, Quaife ATB LSD (5.1-ratio)

Support

STRUTS: Custom MCA coilovers (200mm travel), King Springs, F40 Motorsport adjustable strut tops

BRAKES: Wilwood pedal box, hydraulic handbrake; (F) Alcon four-pot calipers, 10.5-inch vented rotors, Ferodo pads; (R) Alcon two-pot calipers, 10.5-inch solid rotors, Ferodo pads

EXTRA: Trailing-arm conversion, Watt’s link, Techno Toy lower control arms (LCAs), Techno Toy leading links, AE86 stub axles, F40 Motorsport hubs, F40 Motorsport adjustable arms, strut brace, seam-welded chassis, eight-point roll cage, turreted rear suspension with trailing link boxes, strengthened front towers

Shoes

WHEELS: (Gravel) 13×6-inch Revolution replica Minilite, (tarmac) 15×6-inch Revolution replica Minilite

TYRES: (Gravel) (F) Dunlop SP85 165/80R13, (R) Kumho R800 175/70R13, (tarmac) Bridgestone R888R 205/40R15

Exterior

PAINT: Sting Red by Moselle Panel and Paint

ENHANCEMENTS: Mike Shaw fibreglass flares, polycarbonate windows by Plastics Construction

Interior

SEATS: OMP

STEERING WHEEL: OMP, OMP quick release hub

INSTRUMENTATION: Stack Pro oil-pressure, oil-temperature, water-temperature, voltage, and fuel-level gauges; Monit rally tripmeter; modified tacho to show 10,000rpm

EXTRA: Stilo intercom earmuffs with Bluetooth (for sounds), custom door cards, flocked dash, metallic silver paint by Moselle Panel and Paint

Performance

POWER: 112kW

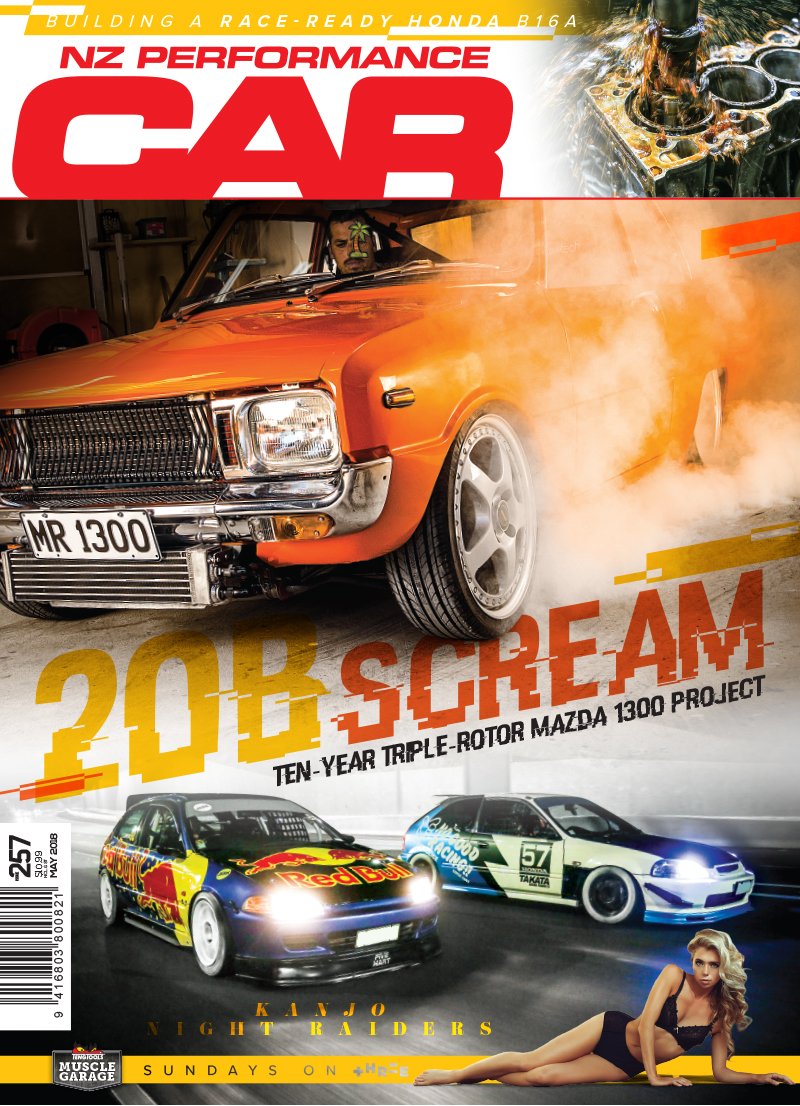

This article originally appeared in NZ Performance Car issue No. 257 — you can get your grubby mitts on a copy by clicking the cover below