It may not be the simple daily driver Michael Kim set out to build, but here’s how you piece together a 440kW ‘Evo’ wagon worth writing home about

“I only wanted to build something which I could drive to work and back,” admits Wellingtonian native Michael Kim. These would become famous last words for Mike, as what he now sits behind the wheel of is far from anything that resembles a ‘just a drive to work’ car — unless you’re accustomed to pedalling 440kW on the daily, that is.

Mike was once a self-confessed Honda boy through and through, and recalls that it was close mate Peka Pietkiewicz who brought him over to the so-called dark side that is Mitsubishi: “It was how raw the Mitsis feel. They are real aggressive, I can’t explain it,” Mike says, “The feeling is a lot different to the Hondas I used to drive.”

He credits Peka as being the catalyst behind the build, and says, “You could say he’s the real mastermind of the car, helping me pull together the right combination.” Although this may be true, Mike was equally humble when it came to crediting himself for the copious hours he has poured into transforming this once derelict 4G93-powered Libero into a fire-spitting animal that now seeks to claim the title of the country’s fastest for its kind.

“I got it back when everyone was into swapping cars, and this [Libero] was passed around half of Wellington before heading north and coming back down,” Mike says. “It was going too cheap so I grabbed it, but every time I pulled something out to fix what had been neglected, I would find something else needing to be done, too”. It wasn’t long until every component possible had been stripped and laid out on the garage floor, and all that remained was the shell and a lot of work to be done.

“I thought to myself at that point, why not put it back together using new bolts and bits, something simple just to make sure it was reliable. But here we are now …”

He doesn’t quite recall where it all went so wrong — or so right, depending on what side of the money fence you are sitting on — but does remember it being somewhere around the time that a research mission into Google’s depths of knowledge returned an old NZ Performance Car article originating from issue No. 104 that featured an orange Libero owned by Saul Patterson. “There wasn’t much info out there on Liberos in New Zealand, and what had been done with them besides the orange one. It was from there that I started spitballing the concept of going for the fastest example in New Zealand.”

To keep those 1750cc injectors fed with fresh E85, the factory tank and spare wheel were ripped out in favor of a custom-built 54-litre fuel cell

But records like that aren’t built on whatever you have kicking around in the back shed, and slapping them together. Nope, you’re going to need a bulletproof motor and an even more bulletproof driveline. Mike looked to Peka for where to start, and he told Mike to get his hands on one of the strongest Mitsubishi blocks available, a VR-4 six-bolt 4G63. With a bit of further research to confirm it, he was convinced this would help hold things down in the bottom end, and quickly sourced one to get things rolling. It wasn’t until the block was sitting on the workshop bench that he learned it was also one of the hardest to source parts for locally.

“There are no parts for them here, so I wasn’t sure what to do until a little more research revealed that the US-market Eclipses were still using them long after their Japanese counterparts had dropped the configuration,” Mike explains. “That’s where I managed to find the Eagle stroker crank, along with suitable Eagle rods and CP pistons.”

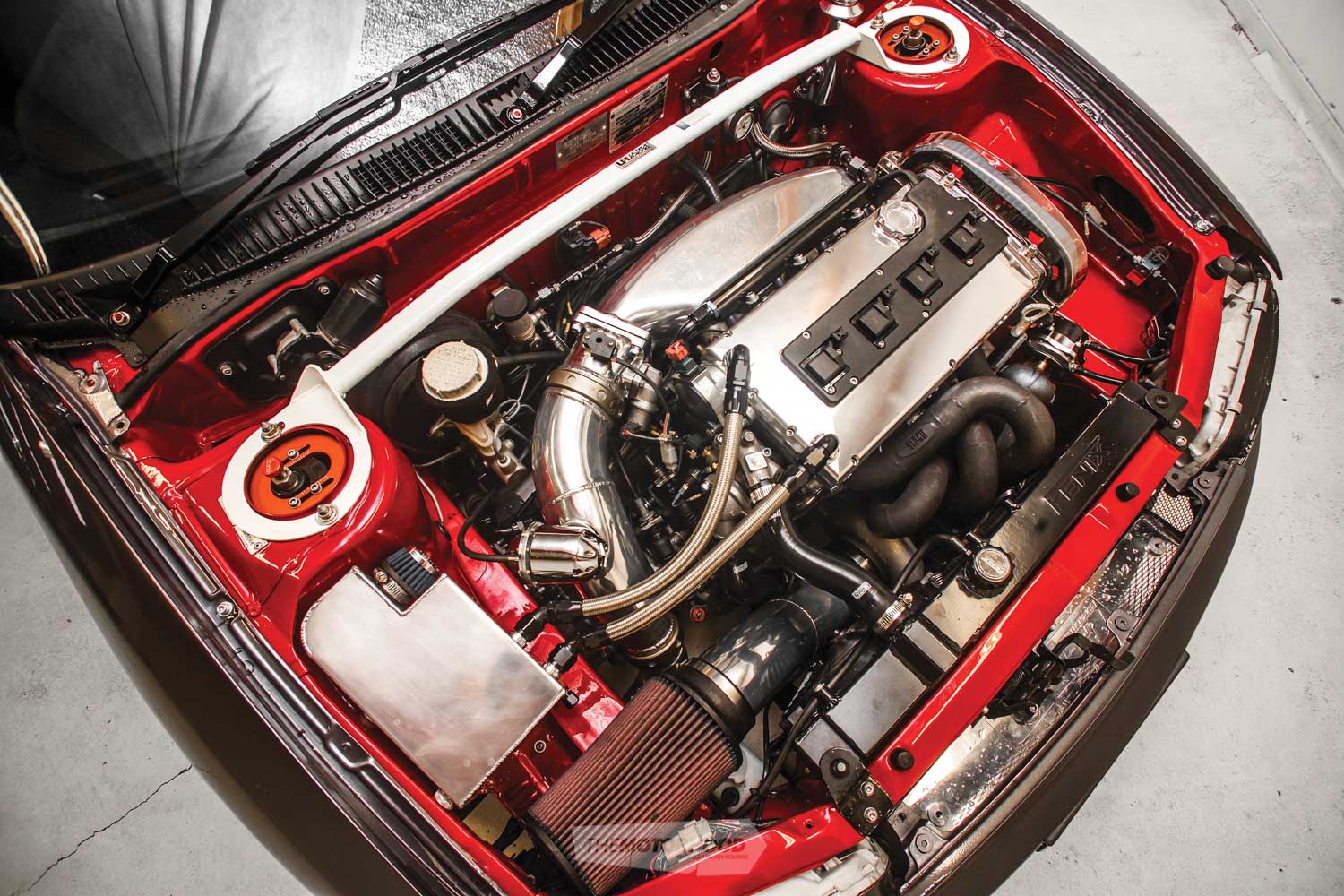

That crankshaft increased capacity to 2.3 litres, and the pair installed a Kiggly Racing main griddle to tie the bottom end together, along with fresh ARP fasteners. Meanwhile up top the intention had been to retain the factory VR-4 head for a cohesive OEM look, however, an exhausting search revealed there were no intakes up to par with what Mike had envisioned in his head. Back to square one, and contemplating what to do next, Peka once again came through with the solution: grab an Evo II example and machine it to suit the six-bolt block. This lead to Hartley Engines and Motorsport being called in to undertake the machining, including a dose of CNC machine porting before vast catalogues of available go-fast bits were called upon to pack it with Ferrea Competition Plus valves and a pair of Kelford 272/278-degree cams. A Sinco sheet metal plenum paired with an Accufab 80mm throttle body now accepts forced induction by way of a Holset HRC40RS that sits atop another Sinco piece.

It wasn’t just the motor which received a rework, either. While all that power was being sought under the bonnet, the five-speed which would later back it was rebuilt using a Competition Clutch forged release fork, and the set-up was fitted with a mechanical-plated LSD and Evo III axles, along with an Exedy five-puck clutch. Macbilt was tasked with whipping up a new fuel cell to fill the spare-tyre well above the factory tank, which increased capacity from 35 litres to 54 — a necessary upgrade to house all that precious E85 being slurped up by the twin Bosch 044 fuel pumps and Injector Dynamics 1750cc injectors. Macbilt was also responsible for piecing together the 3.5-inch straight-pipe exhaust and whipping up the custom rose-jointed arms. Mike maintains though that this outsourcing was due to time constraints, and the car would not be going by now if he hadn’t taken that route. “Everything else — bar the paintwork — was done in-house, in-house literally meaning in the garage at my house. But I was running out of time with work and life, so I took some of the extra jobs to Macbilt to get taken care of.”

As for the exterior, Mike was set on paying homage to the golden era of Mitsubishi through a very specific combination of the best Evo bits, while maintaining an aesthetic that could be excused for being mistaken as factory. Finding genuine pieces ain’t no small feat, and the quest saw him travel deep into rural New Zealand to source the smallest of pieces. These missions resulted in an Evo III bonnet being fitted for the second time in the car’s life (it is not pictured, we thought you’d prefer to see that glorious engine bay instead) — it had run one before Mike’s ownership, along with Evo III side skirts and end caps.

“I didn’t want to put the Evo III bumper on though,” he explains, “as it didn’t look factory,” so an earlier Evo II example was fitted instead. Naturally second-hand panels can look the worse for wear, and so the combo was tied together via a decent amount of panel work, before a fresh lick of gunmetal grey was laid down courtesy of a few mates.

To continue that ‘factory’ theme there’s a set of 17×7-inch Enkei Tarmac wrapped in 205/40 Dunlop Direzza rubber. Those of you already shouting at the pages that they are far from factory wheels can hold your tongue, as Mike explains in his own words: “Enkei Tarmacs just look original, they look like a factory wheel — an original rally wheel, which I like. They were on so many Evos over the years that people think of them as more of a factory wheel than the genuine examples now.”

Sticking with a factory look inside and out was important to Mike, and he went to great lengths to source genuine Evo pieces to complete it — this would see a combination of parts used that spans from the II to VI

It only takes a quick glance at the specs scattered throughout this article to understand that Mike has achieved his desired effect with precision, and formed a very unassuming-looking road-goer with so much more going on under its skin than one would expect, while ensuring it’s capable of blowing the pants off many of those that dare challenge it at a red light. As it’s only recently been finished, he hasn’t been able to make the most out of its full potential yet, but he looks forward to making the most of it as we head into the sunny months, and the upcoming show season.

Next time you pull up next to an eerily clean-looking gunmetal Libero, take a second glance to make sure it’s not Mike, just waiting to set that 2.3 litres of pure evil on you.

1994 Mitsubishi Libero GT

Heart

ENGINE: Mitsubishi 4G63, 2300cc, four-cylinder

BLOCK: VR-4 six-bolt 4G63 block, Eagle 2300cc stroker crank, Eagle rods, CP pistons, Kiggly Racing main griddle, Fluidampr harmonic balancer, STM balance shaft delete kit, ARP fasteners

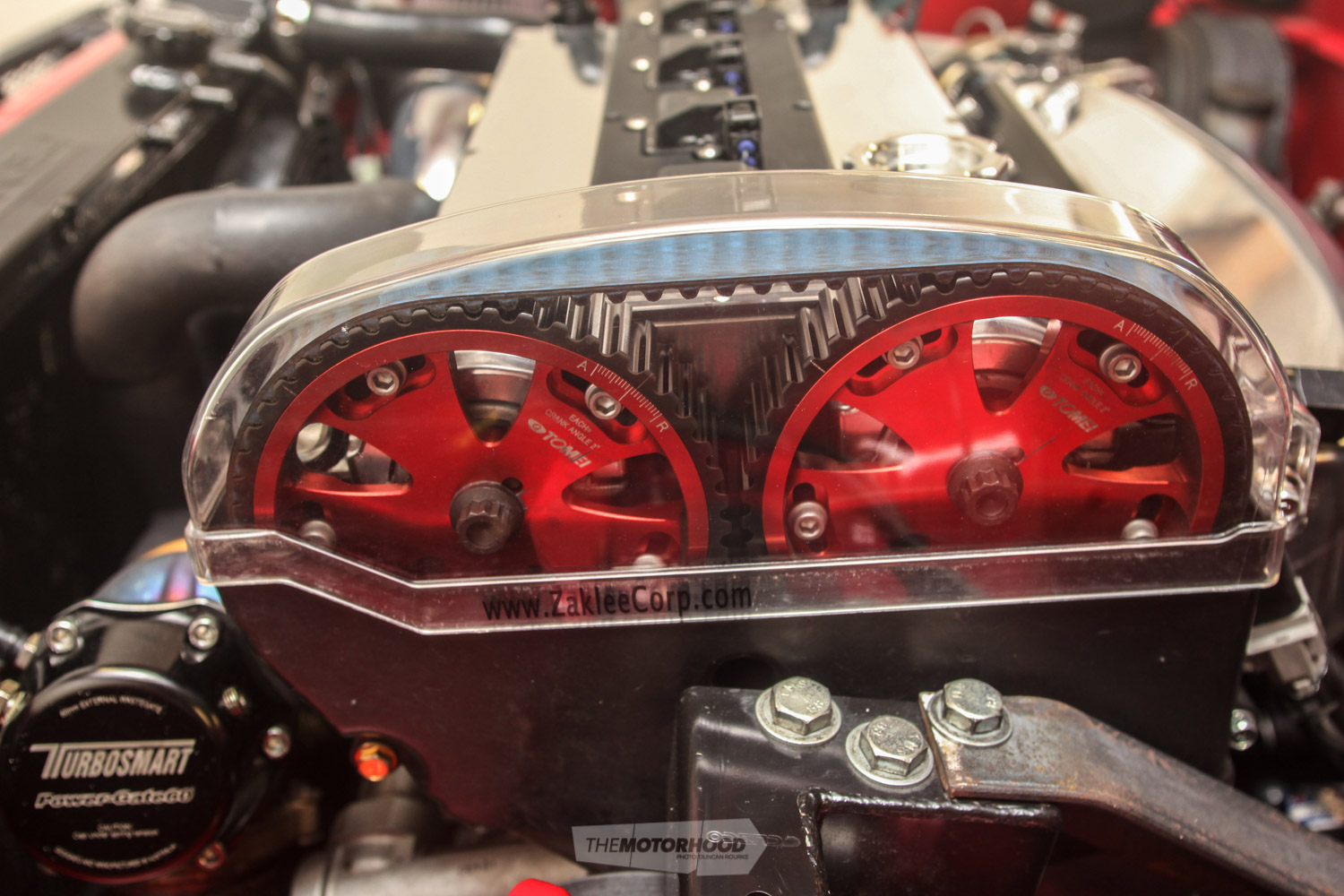

HEAD: Evo II head, CNC ported by Hartley Engines and Motorsport, Kelford TX278 camshafts, Kelford valve springs and titanium retainers, Ferrea valve guides, Ferrea Competition Plus valves, Ferrea valve stem seals, Ferrea valve locks, 3SX Performance lifters, Tomei cam gears, Kiggly Racing HLA pressure regulator, ARP fasteners

INTAKE: Sinco plenum, Accufab 80mm throttle body, K&N pod filter, Macbilt four-inch piping

EXHAUST: 3.5-inch stainless steel system by Macbilt, AdrenalinR muffler

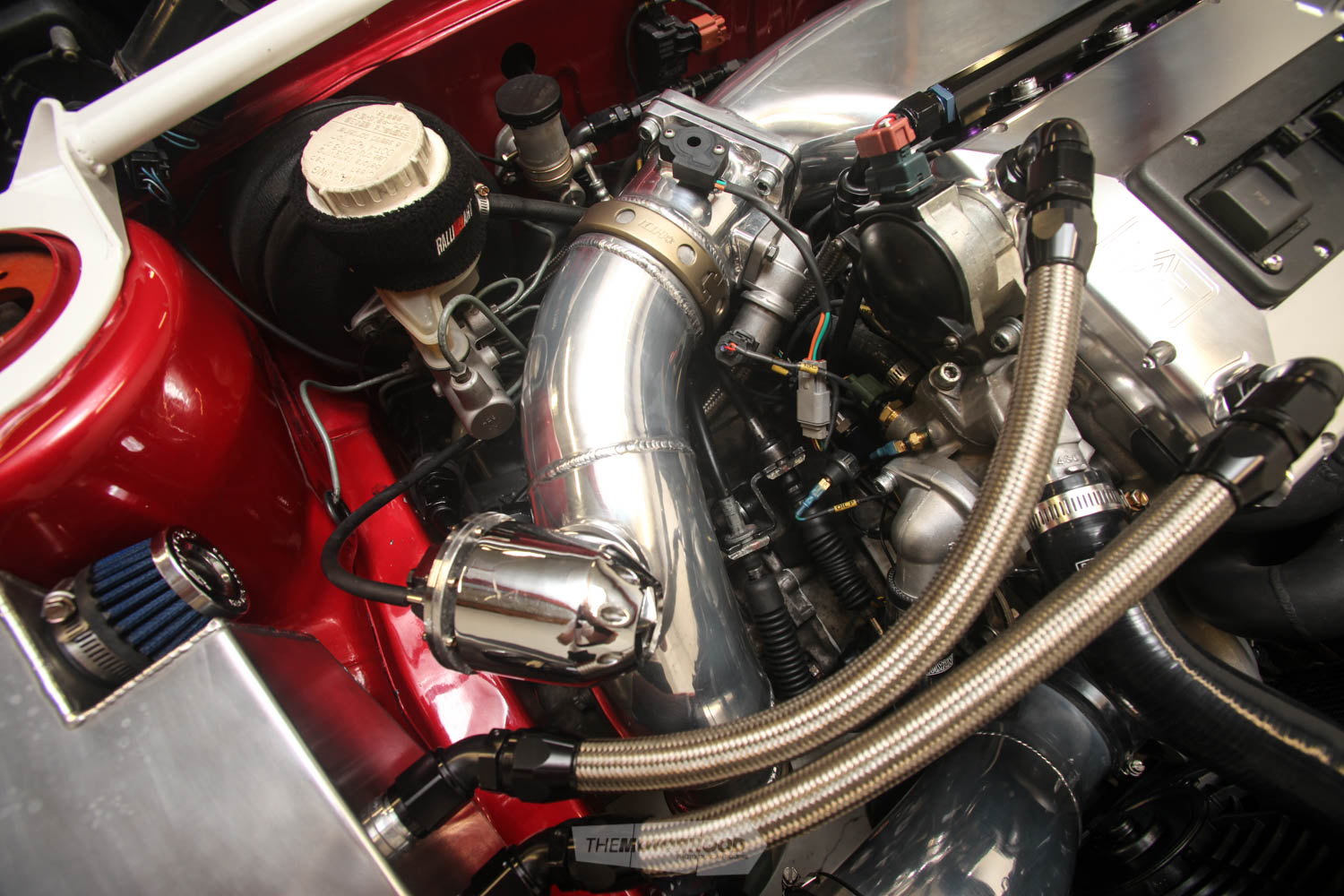

TURBO: Holset HRC40RS, Sinco twin-scroll exhaust manifold

WASTEGATE: Turbosmart Power-Gate60

BOV: HKS SSQV

FUEL: Custom fuel tank by Macbilt, Aeromotive 340 lift pump, Aeroflow surge tank, twin Bosch 044 main pumps, twin Aeroflow filters, Aeromotive A1000 fuel-pressure regulator, Aeroflow billet fuel rail, Injector Dynamics ID1750 injectors

IGNITION: Sparktech Ignitions Pro CDI coil-on-plug, NGK spark plugs

ECU: Link G4+ Storm

COOLING: Aeroflow oil cooler, HDI GT2-spec intercooler, HDI GT clamps, aftermarket alloy radiator, alloy intercooler piping

EXTRA: Link ethanol content sensor, custom catch can, Frontline Fabrication billet rocker cover, relocated fuse box, electric power steering pump, custom steering reservoir, Cusco engine mounts, Jay Racing alternator relocation kit, wiring by Geoff at NZ Wiring and Performance, engine bay resprayed Velocity Red

Driveline

GEARBOX: Five-speed

CLUTCH: Exedy five-puck clutch

FLYWHEEL: Competition Clutch lightweight

DIFF: Front and rear mechanical plated LSD

EXTRA: Torque Solutions solid mounts, Competition Clutch forged release fork, Torque Solutions gear shifter bushing, custom stainless steel braided clutch line, Evo III axles

Support

STRUTS: DGR coilovers

BRAKES: (F) Wilwood Dynapro four-pot calipers, slotted rotors, (R) factory calipers, slotted rotors: Evo V brake booster, stainless steel braided lines

EXTRA: Custom Macbilt rose joint arms, custom adjustable Panhard bar, front subframe stiffening rings, Ultra Racing front strut brace, Nolathane bushes, J Speed fender braces

Shoes

WHEELS: 17×7-inch Enkei Tarmac

TYRES: 205/40R17 Dunlop Direzza (street), 235/40R17 Toyo R888 (track)

Exterior

PAINT: Resprayed gunmetal grey

ENHANCEMENTS: Evo III bonnet, Evo II front bumper, Evo III side skirts and end caps, shaved rear bumper, shaved door handles, shaved antenna

Performance

POWER: 440kW

TORQUE: 621Nm

BOOST: 30psi

FUEL: E85

TUNER: Ross Honnor at DDT

Michael Kim

AGE: 27

LOCATION: Wellington City

OCCUPATION: Parts advisor

BUILD TIME: 4.5 years

LENGTH OF OWNERSHIP: 4.5 years

THANKS: The biggest thanks goes straight out to Peka Pietkiewicz, the mastermind behind the build, who devoted all his time from day one — I couldn’t have done it without him and his knowledge. Special thanks to my partner Alicia Colledge for helping me pick up parts all over New Zealand, for the time I’ve spent working in the garage, and allowing me to finish what I’ve started: my parents for coping with all the late-night noises and the use of the garage, Alistair and his team at Macbilt Engineering and Racecars, Isaac and Jason at Wellington Mitsubishi, Nelson at Hartley Engines and Motorsport, Hayden at Custom Works Automotive, Steve Murch at Motor Sport Engineering, Noel at Motorworx, Reuben Bemrose at R’s Garage, Jason at NZKW, Hayden at Streetsoundz, Steve at Bridgestone Miramar Tyres, Chris Wall at Prestige Tuning and Motorsport, Ross Honnor at DDT for the Tuning, the boys at Fortress Fasteners, Paul at NZ Performance, Jared at Unleashed Automotive, Aaron and Joe at BNT Wellington, Mike at Sinco, Umesh at Page European, Jake Clennick, Sean O’Driscol, Ryan Vermeulen and Brandon Roberts for the panel and paint work, my manager Cameron McElroy for wiring up the dash swap, sourcing genuine Mitsubishi parts, and all the time off work, and lastly to all my friends and family who have helped me over the past few years: Vibol Duch, John Filipo, Andrew Young, Kevin Young, Damien Brehaut, Ryan Brenton, Elliot Uilao, Cameron Turchie, Gopi and Bogen Ramakrishnan, Sunny Patel, Scott Barriball, Duong Nguyen, Viane Leo, Phillip Horan; and Duncan Rourke for the photos

This article originally appeared in NZ Performance Car issue No. 253 — to get your grubby mitts on a copy click the cover below