Glenn Hodges is known for operating outside the box, and after the first incarnation of his rear-mounted V6 twin-turbo Nissan March met an untimely demise, he’s back with a 2.0 — bigger and nastier than before

The pages of history tell us the story of a practice so brutal that it now sits firmly amongst the most serious of war crimes. It was a practice used to brutalize, weaken, demoralize, and even destroy enemies during wartime, a practice which quickly become known as the ‘death march’. However, while neither this particular March nor its owner/driver, Glenn Hodges, plan to end up on an international war criminal list, the car itself is the physical embodiment of what a death march aims to achieve — striking unprecedented fear into the hearts of any being that may cross its path — and Glenn intends to use it to destroy the competition at the local time-attack series.

Regular readers may recall seeing the car’s first incarnation back in NZ Performance Car issue No. 241, in which we detailed the build of the twin-turbo VQ35DE-powered track killer. Back then we talked about how safety became an important factor for Glenn, after he encountered a dicey high-speed late-braking situation into turn one at Hampton Downs before completing his last season of NZ Superlap.

He put aside his then 300ZX track car in favour of a build fit for a madman, and the base for this project became a Nissan March. Although that would not be the first choice for most, it was the result of years of back and forth between Glenn and a friend overseas, who enjoyed discussing the intricacies of rear-engined all-wheel drive cars from the Group B era. These discussions quickly turned to creating a modern equivalent, and focus was directed at taking a series of components which were never intended to come into proximity with one another, and not only making them work, but making them work incredibly well, with a hefty amount of safety equipment fitted to compensate in case things ended up pear shaped.

That decision would turn out to be a very smart one — a lifesaver in fact — when after an extensive build and last-minute rush to get it to the first round of NZ Superlap at Hampton Downs for its maiden shakedown, a combination of seemingly harmless events saw the March play tag with the pit entrance wall at speeds we cringe at even thinking about. Thanks to his insistence on solid safety gear, and his own capability with a welder, Glenn walked away from the crash in (relatively) one piece. Unluckily, the same couldn’t be said for the car.

He was left with an unsalvageable shell, so opted to strip out all the components and make piles for the saveable, the maybe saveable, and the absolutely cooked. The latter ended up being a much bigger pile than the others, but with enough left in the saveable piles and a few kind acts — including the supply of a new three-door shell — from a group of local racers, he was convinced that a second, more refined version of his car was on the cards.

That new shell was a little banged up and would require twice the amount of work to repair and then modify, than expected. However, it didn’t go to waste, as a replacement five-door hatch was sourced and the three-door shell was unstiched to convert the five-door to the lesser. While it was all apart, it only made sense to make a few weight saving decisions and the biggest came by way of the roof — the factory steel example now hangs in Glenn’s garage, weighing at an estimated eight or more kilograms, while a custom carbon-fibre example of Glenn’s own creation now seals the cabin with an estimated weight of just 800 grams.

“Although not the first choice for most, it was the result of years of back and forth between Glenn and a friend overseas who enjoyed discussing the intricacies of rear-engined all-wheel drive cars from the Group B era”

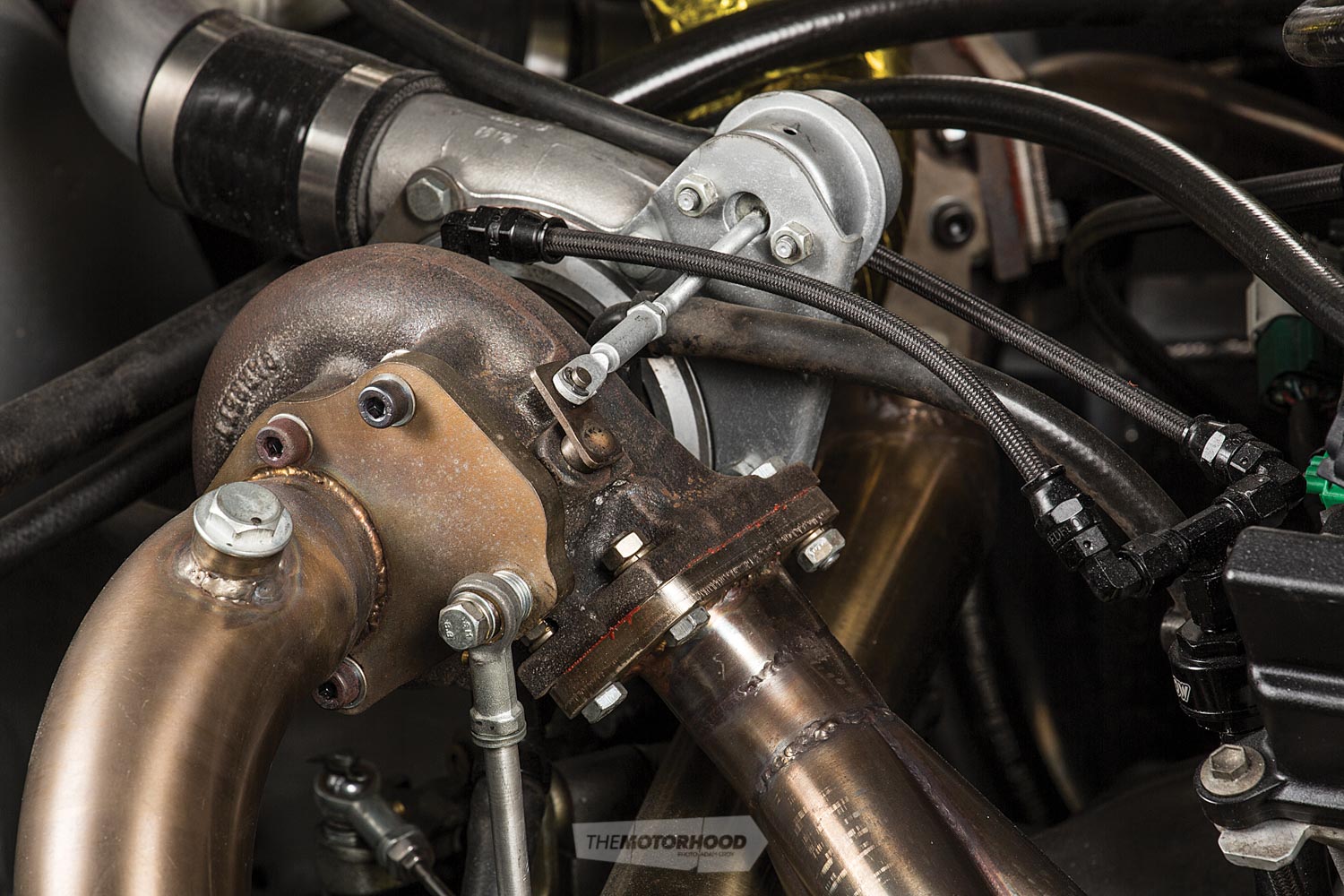

Glenn also jumped back on the welder to replicate the extensive eight-point roll cage, with an MSNZ-approved multi-level harness bar to suit the difference in height between driver- and passenger-seat height. A fully enclosed rear firewall prevents heat and other nasties from entering the cabin from the motor’s living quarters. Version 2.0 retains the same rear-mounted hybrid heart that consists of a Maxima VQ35DE block fitted with Wiseco 11:1 forged pistons and Eagle forged rods. Bolted atop are still a pair of 350Z heads which utilize the factory valvetrain and intake manifold, while the crown jewel(s) of the powerplant remain as the two Garrett GT2860RS snails. Glenn described these back then as being “just for fun”, however, with the package now pumping out 400kW at the wheels on the dyno, and weighing in at under 1000kg, it’s quite clear that it’s far from just a game.

The main difference between the new shell and the old is that most components have progressed beyond the prototype stage. Glenn had originally lopped off a big chunk of the rear, including the chassis rails, to create his own replacement that would suit the motor’s new mounting position. Rear shock towers were recreated to suit a set of RSR coilovers, along with a custom subframe designed to drop the engine and gearbox low in the body for the desired weight distribution. Power was delivered to the rear wheels by way of a six-speed box that fed through Maxima front axles and J31 knuckles — a pretty slick conversion for the previously front-wheel-drive car.

Much of this initial concept was retained, but given it had now been tested in the car — which he hadn’t achieved the first time around — a number of suspension components were rejigged for more cohesive geometry. The rails are a similar design as before, although now slightly higher up, and the rear subframe was altered to allow the engine’s mounting position to rise, so the whole car could sit lower without having a terrible CV angle.

“The original car had a lot of modified factory components only intended to be used long enough to check geometry and basic handling,” Glenn tells us. “Some of it was not very aesthetically pleasing, but the intention was always there to upgrade to what we have now, once we had confirmation of geometry.

“Even after having built a prototype of those systems, and tested them, and then built the ‘final’ version, there are still improvements to be made.”

While that’s still a work in progress — as no race car is truly finished, right? — Glenn has poured considerable hours into piecing together the aero package that the first car never got to see. It consists of WRC-inspired box flares with a front air dam to channel airflow towards the rear, where you’ll find a larger-than-life wing of Glenn’s own design to provide the required downforce onto those rear wheels. He has also developed his own blown rear diffuser: “Air that is travelling faster will have a lower pressure than the air around it, so given the exhaust gasses coming out of the tail pipes are getting a bit of a wriggle on, they create a large low-pressure area around them. This in turn drags air towards the low pressure area, sucking the car down.”

Glenn’s got some serious talent behind a welder, and has created almost every out-of-the-box component himself, most of which was binned and remade a handful of times before making the final cut

And while the small car now looks much wider, most would be shocked to hear that the wheelbase is actually the same as the 300ZX he used to race. With a 45/55 weight distribution, sub 1000kg dry weight, and 400kW on tap to play with, it’s still just as much of a death March as when we initially laid eyes on it — only it now sports a serious amount more development.

Glenn plans to debut the new car at the upcoming season of NZ Superlap, and is currently getting as much testing in ready to brutalize, weaken, demoralize, and inevitably destroy its enemies of war.

2004 Nissan March K12

Heart

ENGINE: Nissan VQ35DETT, 3500cc, V6

BLOCK: J31 Maxima VQ35DE, Wiseco 11:1 pistons, Eagle rods, J31 Maxima main sump plate, modified Z1 Motorsports sump sandwich plates, ACL Race Series bearings

HEAD: Nissan 350Z heads, factory valvetrain

INTAKE: Factory intake manifold, custom piping, twin three-inch pod filters

EXHAUST: Custom stainless twin 2.5-inch system, The Lab resonators

TURBOS: Twin Garrett GT2860RS, The Lab stainless turbo manifolds

WASTEGATES: Internal

BOV: HKS

FUEL: JAZ 35-litre fuel cell, twin Bosch 044 fuel pumps, Speedflow twin primary and secondary filters, aftermarket fuel rail, Injector Dynamics 1300cc fuel injectors, Aeromotive fuel-pressure regulator, Link fuel-pressure sensor

IGNITION: Factory

ECU: Link G4+ 350Z plug-in

COOLING: Water-to-air intercooler, Mocal 28-row oil cooler, Nissan Maxima radiator, Nissan Maxima fans

EXTRA: The Lab oil catch can, modified wiring harness

Driveline

GEARBOX: Nissan Sentra six-speed, Maxima bellhousing

CLUTCH: Heavy-duty pressure plate, brass button friction plate

FLYWHEEL: JWT alloy

EXTRA: J32 Maxima half shafts

Support

STRUTS: RSR coilovers, King Springs springs, custom mounts and camber plates

BRAKES: (F) Nissan four-pot calipers, Z1 two-piece 370Z rotors, (R) Nissan twin-pot calipers, Z1 two-piece rotors, Hawk race pads, hydraulic handbrake

EXTRA: J31 Maxima knuckles, The Lab custom arms, 10-point roll cage, custom rear chassis rails, custom front and rear subframes, custom rear firewall, custom front strut tower support frame

Shoes

WHEELS: (F) 18×9-inch DTM Gravity, (R) 18×10-inch DTM Gravity

TYRES: (F) 235/40R18 Nexen, (R) 265/35R18 Nexen N’Fura SUV 4

Exterior

PAINT: March Silver, The Lab livery

ENHANCEMENTS: Custom alloy flares, FRP- front splitter splitter, custom rear wing, custom rear blown-diffuser, custom carbon-fibre roof, custom fibreglass roof scoop, modified factory bonnet

Interior

SEATS: OMP HTE-R, OMP TRS-E, Sabelt six-point harnesses

STEERING WHEEL: OMP

INSTRUMENTATION: Link Dash2 Pro

EXTRA: Woodward steering column

Performance

POWER: 400kW

TORQUE: 700Nm

BOOST: 13psi

FUEL TYPE: E85

A Maxima radiator and Jaz 30-litre fuel cell now fill the barren engine bay up front, with relevant pipework running back through the empty tunnel — keeping the fuel away from Glenn, and possible ignition sources too

Glenn Hodges

AGE: Old enough to know better

LOCATION: Hamilton

OCCUPATION: Owner at The Lab Limited

BUILD TIME: Nine months

THANKS: My wife, Christine, Nissin King Izuzu Partsworld, Autoparts Partsworld, Z1 Motorsports, Link ECU, DTM Wheels, Mike Shaw Fibreglass, Race Products, GSS Performance, Race Cars In Sheds, Hamilton Windscreens, Automint, Jim Wright Nissan

This article originally appeared in NZ Performance Car issue No. 253 — to get you grubby mitts on a copy, click the cover below