Inside the Silvia stronghold of Team Jenkins Motorsport

Tucked away deep within a semi-suburban South Auckland estate is definitely the last place you’d expect to find a race workshop stacked to the hilt with Silvias, but that’s exactly where brothers Troy and Ben Jenkins, aka Team Jenkins Motorsport (TJM) ply their drift trade. The family home is not 50m from the shed, but clearly the Jenkins parentals are supportive of their sons’ activities, allowing their property to act like some kind of drift halfway house, often hosting international drivers and their cars or travelling New Zealand teams.

Like all good race shops, it’s somewhat low-key from the exterior, with the only external clue of what lies within the converted farm buildings the mountain of destroyed Jinyus poking out from behind the shed.

The property was previously home to a prominent speedway family, who first converted the farm sheds to a race workshop — so the muffled bark of SRs and RBs would be a pleasant change of volume for the surrounding neighbours, compared with the previous sounds of roaring V8 speedway machines.

There was enough parts around the place to piece together a couple more S-chassis drifters

Once the boys took possession, they got to work making the place their own: cleaning up floors, building benches, and adding storage and a hoist. The workshop is split across two buildings. The smaller of the two is where all the mechanical grunt work goes down, and is complete with a hoist and every tool a drifter needs. The larger shop serves as storage and an assembly area. But it’s not all hard work and grease-stained hands — there’s a lounge in the corner and a well-stocked fridge — any workshop with a dual-door drinks fridge is clearly serious about its live-stream motorsport watching.

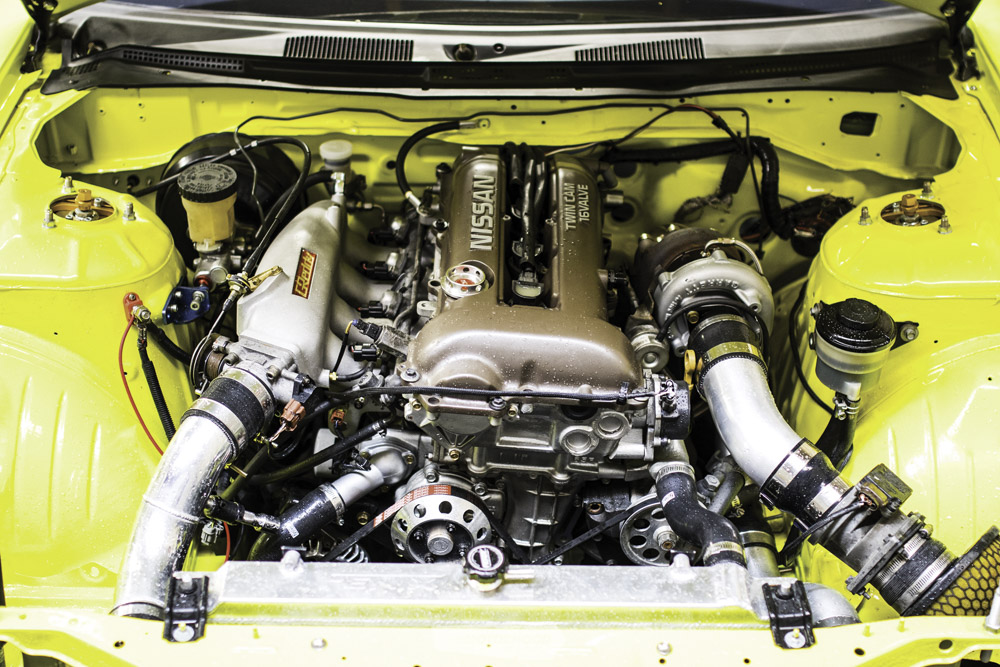

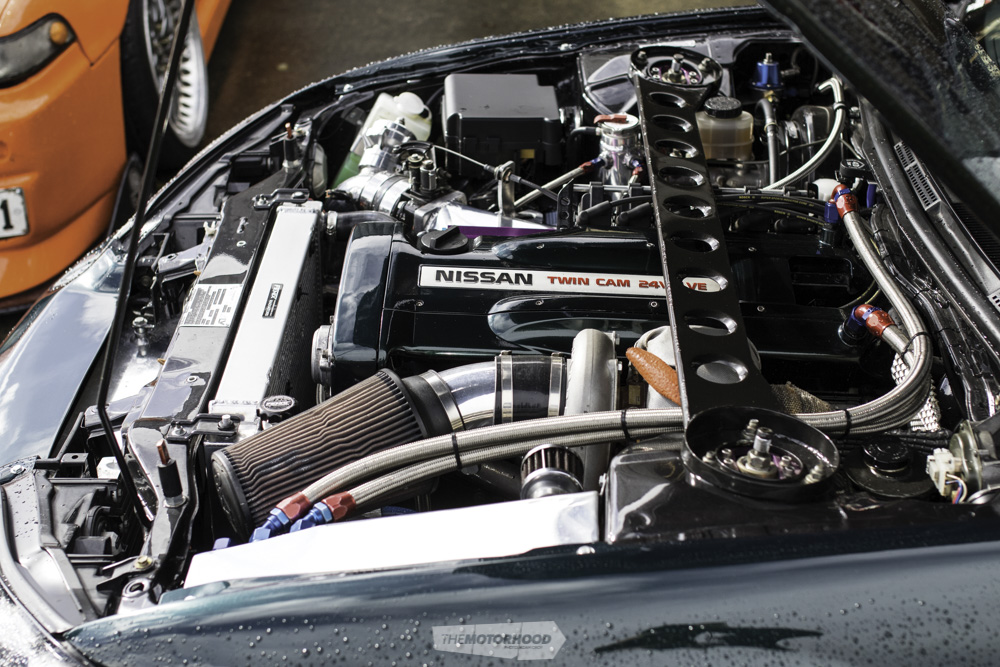

Lurking outside, we find what is one of New Zealand’s toughest street-legal Silvias. Blair Martin is no stranger to drift circles in New Zealand, having competed in the likes of D1NZ in the early days. After stepping down from competition stuff, he decided to swap his super-tough RB25 into a street-registered shell. The result is one of the cleanest we have seen. We won’t go into details on this one here, as we have it lined up for a future feature, so keep an eye out

The first thing you’ll notice is how clean and well organized the space is. It’s a proper race-shop layout and gets used like one. You can bet the boys know exactly where everything is and to which car it belongs.

Alongside the Jenkins’ own comp cars, it’s a revolving door of different projects owned by the TJM crew. There’s always something to work on, even if the comp cars are just gathering dust. But, come race season, the shop works like a well-lubricated machine.

Running a two-car team in the national championship is no easy feat. It takes many hands, many late nights, and a whole lot of determination from the entire team to make it happen. Most nights, you will find anywhere from one to 10-plus sets of hands going hard and making that dream happen. Having such a vast shop allows them to give back to their crew members, who work for nothing, by offering up the shed for them to work on their own machines.

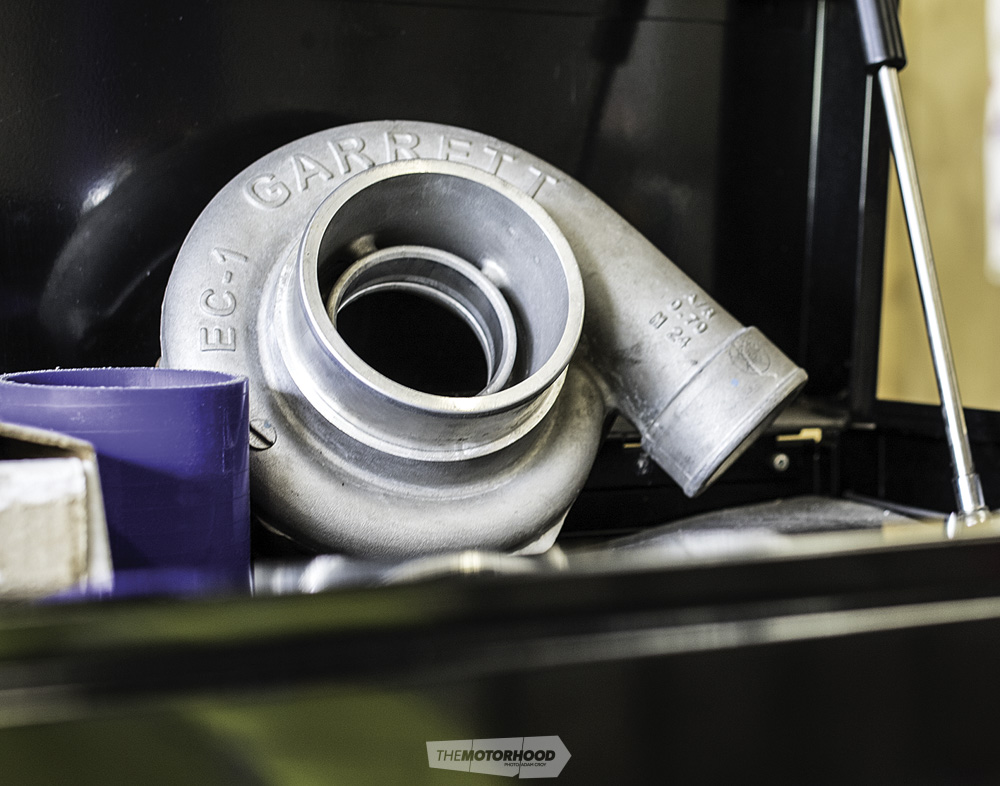

Excluding the roll cage, crew member Craig’s S14 has been built almost entirely in the Jenkins’ shop. It’s Craig’s first drifter and a simple (yet effective) package that he can learn the basics in and progress from there. But its simplicity is well and truly made up for with cleanliness. The engine is a rock-stock SR that’s been rebuilt from the ground up. It’s currently running a factory ECU and factory turbo, but, once Craig’s ready to step up, there’s a heap of killer parts ready to swap in

Current projects on the go include a clean S14, powered by an SR. It’s owned by long-time crew member Craig and is his first foray into building a drifter. It’s just recently had the key flicked for the first time. And tucked away in the back of the shop, a pair of S15 shells sit stripped bare, waiting for fabrication to commence. As it turns out, these were to be replacement shells for Ben and Troy’s current comp machines. During our visit, Ben and Troy also allude to another two-car project that has recently become their main focus, but they are yet to land one of the shells, and the other is away getting a roll cage fabricated, which is pretty much the only task other than tuning that is outsourced.

Because it is the off season when we visit, there are no international machines to be found, but the shed is often home to Aussie drivers who come across to battle in D1NZ. This is a chaotic time in the Jenkins’ house, we’re told, with a bunch of unruly Aussies to keep under control. Although, the distinct lack of burnout marks leading from the shed doors speaks of an unwritten respect that is clearly paid to the parents who allow these shenanigans to take place. It’s a dream backyard shop for many car nuts, and it’s pretty awesome to see so many boys coming together under one roof with a common love of drifting. All they need to do now is convert the surrounding paddocks into a test track, and they will have it made.