Sick of breaking parts with unreliable builds, Arthur Lee embarked on one hell of an S15 build in which not a single corner was cut — warning, if you’re a drifter this spec list will have you drooling

Some go on holiday to relax, others seek to find themselves, while a few prefer to lose themselves in some far-off location; but forget all that — the kind of holidays we’re interested in are those of the tyre-killing kind.

While many instantly think of Ebisu as the Mecca for drift R & R, New Zealand’s actually a hotbed of such activities, and for good reason. We’re a cheap country to fly to, and if you’re looking for a well-rounded drift competition, D1NZ will offer you the chance to go door-to-door with some big talents in cars that don’t require a million-dollar budget. It’s for these very reasons that Kiwi expat Arthur Lee now travels back and forth from Hong Kong during the D1NZ season. And he has arguably the highest-spec drift car in D1NZ awaiting his regular visits. What a way to spend your holidays!

Drifting for Arthur started here in New Zealand in the ’90s with his S14, but work opportunities called for a shift to Hong Kong in 2000, leaving the S14 tucked in a shed — where it still sits today. “I was a zombie from 2000 to 2009; all I did was work,” Arthur says. But a man with motorsport in his blood can only go so long before having to scratch that itch, so, in 2009, he began time-attack racing an R35 GT-R in both China and Japan.

A return to drift soon followed, which saw him contesting D1 Grand Prix (GP) China in a 447kW 2JZ S13 and drifting a 373kW 2JZ 370Z in Japan. But competing at D1GP level meant that 447kW was on the very low side, with most of his competitors running at least 597kW — a level that Arthur says he wasn’t ready for, both in terms of driver skill and car preparation. One particular trip to Japan that ended with him in hospital changed everything. “When drifting in Japan, I entered a high-speed corner and the axle broke, sending me into the wall,” he remembers. “The car was a write-off, and I went to hospital. I can still remember that feeling — that’s why we went to the level we did on this S15.”

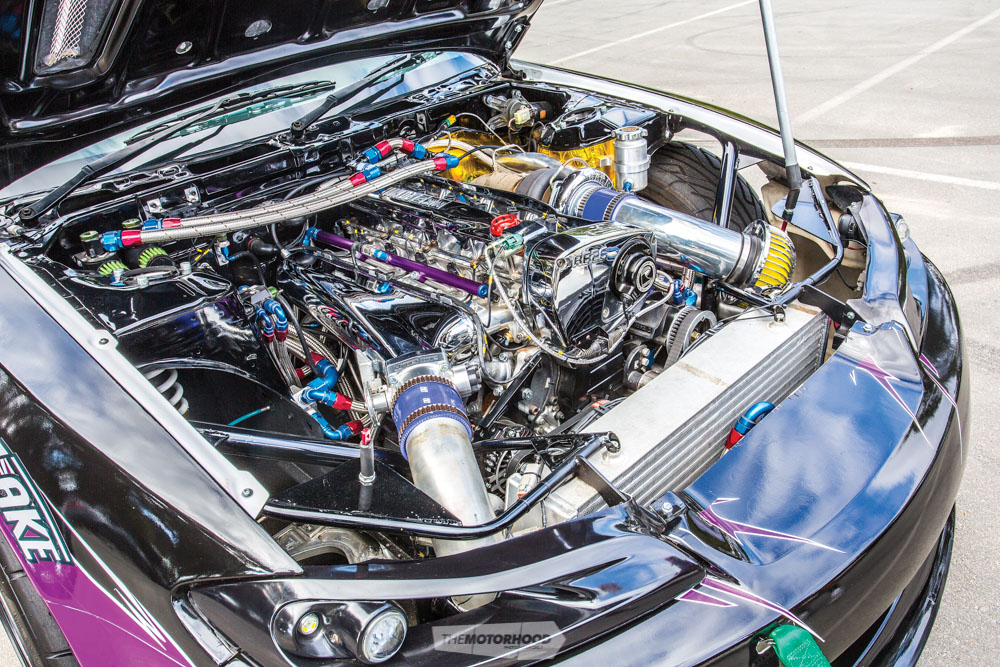

For his next build, Arthur returned home to New Zealand and started talking to workshops about building a weekend-warrior S15. Eventually, he landed at Keg’s door, at DKM Fabrication. Quickly, the build went from a simple roll cage to a full-on competition-spec car, with best-of-the-best parts that should, in theory, ensure that Arthur can fly home any time, beat on the S15, and not have to worry about anything breaking. It’s sound logic when you’re flying halfway around the world to drift.

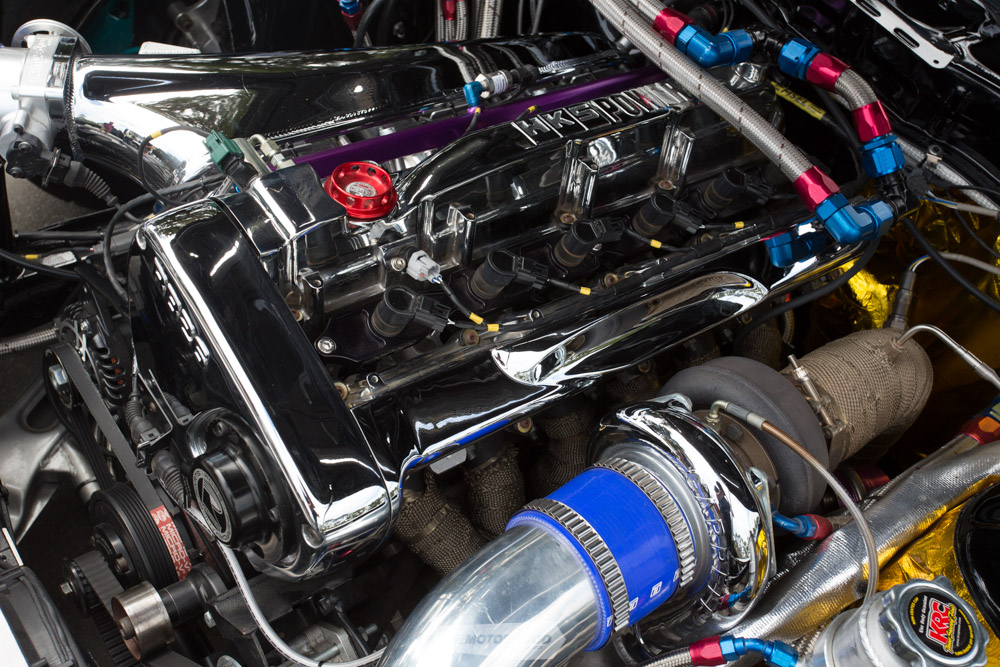

Engineered from the ground up, the S15’s spec list reads like any drift kid’s Christmas wish list, including Arthur’s all-time dream engine — a dry-sumped HKS stroked RB28. But don’t let the polish and chrome fool ya — this RB is as tough as they come. Built using an N1 block as the base, the HKS Step 2 stroker kit uses forged internals, with a compression ratio of 8.1:1 and a special molybdenum coating — which, in layman’s terms, means a dry-film lubricant is bonded to the metal. The head is a ported-and-polished RB26 unit with 264/272 HKS V Cam Step Pro system and a Tomei valve train.

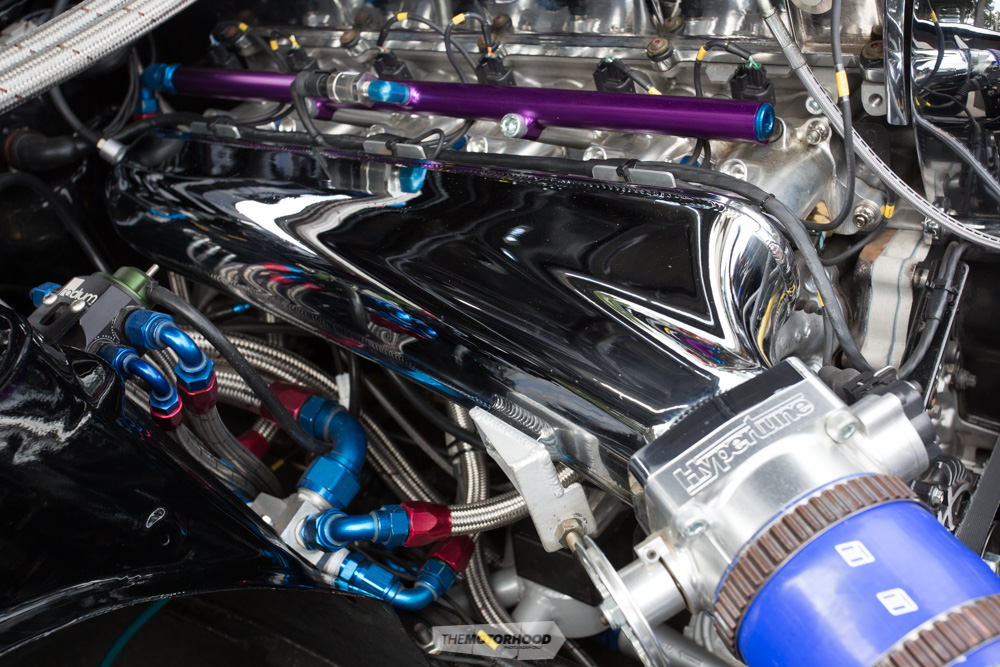

The boost brigade is led by Garrett’s latest and greatest Garrett GTX with Sinco manifold, while the charge side of the system is all Hypertune, including a large 90mm single-throttle body and giant Hypertune custom intercooler, which takes up the space where once a radiator sat.

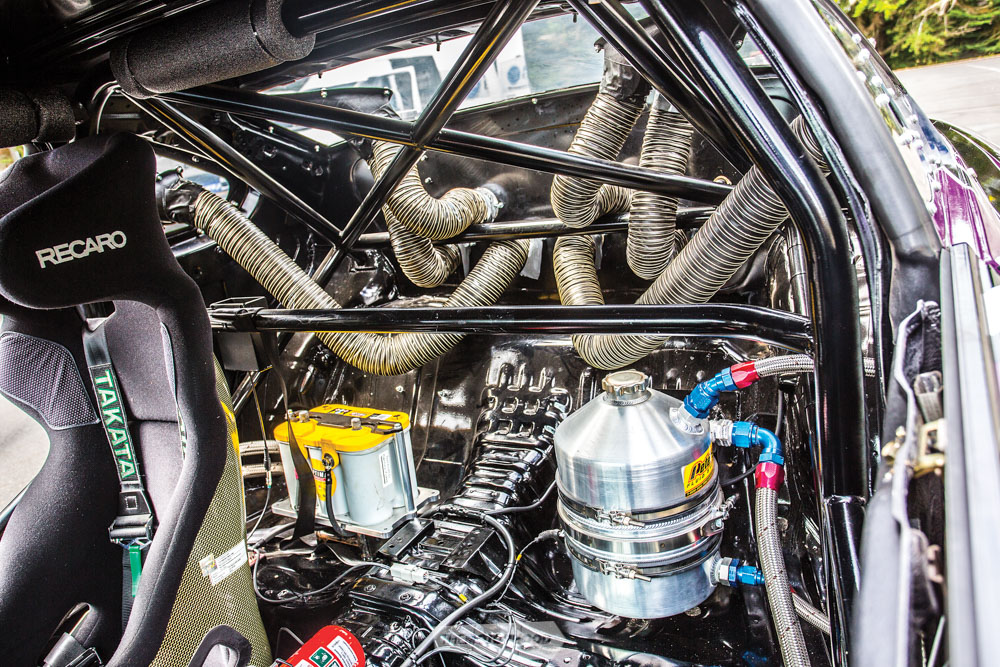

Heat plagued Arthur’s 2JZ builds in China, which is part of the reason the S15 is RB powered. Further insurance to avoid repetition of those dramas also saw the PWR radiator mounted in the boot space, fed via a myriad three-inch NACA ducts in the rear and side windows. An exit strategy was also put in place, with a large alloy duct directing the air to escape under the rear half-chopped bumper.

You’re probably starting to get the picture — no corners were cut anywhere in this build. Not a single item was under-researched, and no half measures were taken in the quest for a reliable yet competitive package. One of the areas this is most evident in is the proper motorsport–spec electronics package centred on a pair of MoTeC power-distribution modules (PDMs), an M800, C187 dash, and keypad all sealed and connected using Deutsch connectors and DR15 heat shrink. The ignition side of things is handled by a Billet Performance CDI kit. On the dyno, the package punched out a stout 500kW to the rear wheels, making it Arthur’s most powerful car to date.

Even with these figures, driveline reliability wasn’t compromised. There’s a Samsonas six-speed sequential rated to 1400Nm, a Winters 10.5-inch quick-change diff, and Driveshaft Shop axles and carbon driveshaft. From start to finish, the project took two years, with Arthur regularly flying between countries. The D1 season just gone marked the S15’s debut, and Arthur reports that the car is very easy to pedal, thanks to the combination of HKS coilovers with TDP and Parts Shop Max knuckles and arms: “It’s a very fast car and very easy to drive. I was able to jump straight in, and it felt great. I love the flat shifting.” Heading into the off season, the only small changes the car will go through are a bodykit change and a switch to electronic power steering, a testament to the car’s preparation and build programme.

Arthur did mention that the car will eventually leave our shores to compete on the world stage, but he will always have something here in New Zealand — so hold onto your hats for that next build. ome go on holiday to relax, others seek to find themselves, while a few prefer to lose themselves in some far-off location; but forget all that — the kind of holidays we’re interested in are those of the tyre-killing kind.

While many instantly think of Ebisu as the Mecca for drift R & R, New Zealand’s actually a hotbed of such activities, and for good reason. We’re a cheap country to fly to, and if you’re looking for a well-rounded drift competition, D1NZ will offer you the chance to go door-to-door with some big talents in cars that don’t require a million-dollar budget. It’s for these very reasons that Kiwi expat Arthur Lee now travels back and forth from Hong Kong during the D1NZ season. And he has arguably the highest-spec drift car in D1NZ awaiting his regular visits. What a way to spend your holidays!

Drifting for Arthur started here in New Zealand in the ’90s with his S14, but work opportunities called for a shift to Hong Kong in 2000, leaving the S14 tucked in a shed — where it still sits today. “I was a zombie from 2000 to 2009; all I did was work,” Arthur says. But a man with motorsport in his blood can only go so long before having to scratch that itch, so, in 2009, he began time-attack racing an R35 GT-R in both China and Japan.

A return to drift soon followed, which saw him contesting D1 Grand Prix (GP) China in a 447kW 2JZ S13 and drifting a 373kW 2JZ 370Z in Japan. But competing at D1GP level meant that 447kW was on the very low side, with most of his competitors running at least 597kW — a level that Arthur says he wasn’t ready for, both in terms of driver skill and car preparation. One particular trip to Japan that ended with him in hospital changed everything. “When drifting in Japan, I entered a high-speed corner and the axle broke, sending me into the wall,” he remembers. “The car was a write-off, and I went to hospital. I can still remember that feeling — that’s why we went to the level we did on this S15.”

For his next build, Arthur returned home to New Zealand and started talking to workshops about building a weekend-warrior S15. Eventually, he landed at Keg’s door, at DKM Fabrication. Quickly, the build went from a simple roll cage to a full-on competition-spec car, with best-of-the-best parts that should, in theory, ensure that Arthur can fly home any time, beat on the S15, and not have to worry about anything breaking. It’s sound logic when you’re flying halfway around the world to drift.

Engineered from the ground up, the S15’s spec list reads like any drift kid’s Christmas wish list, including Arthur’s all-time dream engine — a dry-sumped HKS stroked RB28. But don’t let the polish and chrome fool ya — this RB is as tough as they come. Built using an N1 block as the base, the HKS Step 2 stroker kit uses forged internals, with a compression ratio of 8.1:1 and a special molybdenum coating — which, in layman’s terms, means a dry-film lubricant is bonded to the metal. The head is a ported-and-polished RB26 unit with 264/272 HKS V Cam Step Pro system and a Tomei valve train.

The boost brigade is led by Garrett’s latest and greatest Garrett GTX with Sinco manifold, while the charge side of the system is all Hypertune, including a large 90mm single-throttle body and giant Hypertune custom intercooler, which takes up the space where once a radiator sat. Heat plagued Arthur’s 2JZ builds in China, which is part of the reason the S15 is RB powered. Further insurance to avoid repetition of those dramas also saw the PWR radiator mounted in the boot space, fed via a myriad three-inch NACA ducts in the rear and side windows. An exit strategy was also put in place, with a large alloy duct directing the air to escape under the rear half-chopped bumper.

You’re probably starting to get the picture — no corners were cut anywhere in this build. Not a single item was under-researched, and no half measures were taken in the quest for a reliable yet competitive package. One of the areas this is most evident in is the proper motorsport–spec electronics package centred on a pair of MoTeC power-distribution modules (PDMs), an M800, C187 dash, and keypad all sealed and connected using Deutsch connectors and DR15 heat shrink. The ignition side of things is handled by a Billet Performance CDI kit. On the dyno, the package punched out a stout 500kW to the rear wheels, making it Arthur’s most powerful car to date.

Even with these figures, driveline reliability wasn’t compromised. There’s a Samsonas six-speed sequential rated to 1400Nm, a Winters 10.5-inch quick-change diff, and Driveshaft Shop axles and carbon driveshaft.

From start to finish, the project took two years, with Arthur regularly flying between countries. The D1 season just gone marked the S15’s debut, and Arthur reports that the car is very easy to pedal, thanks to the combination of HKS coilovers with TDP and Parts Shop Max knuckles and arms: “It’s a very fast car and very easy to drive. I was able to jump straight in, and it felt great. I love the flat shifting.” Heading into the off season, the only small changes the car will go through are a bodykit change and a switch to electronic power steering, a testament to the car’s preparation and build programme.

Arthur did mention that the car will eventually leave our shores to compete on the world stage, but he will always have something here in New Zealand — so hold onto your hats for that next build.

Arthur Lee

Age: 42

Location: Auckland and China

Build time: Three years

Length of ownership: Three years

Thanks: My beautiful wife Vivian for letting me build my dream car, Keg and Jo at DKM Fabrication for building and continuing to look after and develop the car, Glenn at GDS Automotive, Ash at Hero Prints for the livery, Jerry at Big Brown for the wrap, Ross at DDT, Justin at Tyrepro, and everyone else who helped in some way with this car

Heart

ENGINE: Nissan RB28DET, 2800cc, six-cylinder

BLOCK: RB26 N1 block, HKS 2.8 Step 2 stroker kit, ACL race bearings, Aviaid billet dry-sump pan, Aviaid four-stage dry sump, ATI damper pulley kit

HEAD: Ported-and-polished RB26 head, HKS V Cam Step Pro 264/272 system, HKS adjustable cam gears, HKS 1.2mm head gasket, Tomei valve springs, 1mm oversized Tomei valves, Tomei titanium valve-spring retainers, Tomei bronze valve guides, ARP head and main studs

INTAKE: Hypertune V2 billet inlet manifold, Hypertune custom intercooler, Hypertune 90mm throttle body, Trust Airinx filter

EXHAUST: DKM 90mm stainless downpipe, stainless straight-pipe

TURBO: Garrett GTX3582R, Sinco manifold

WASTEGATE: 60mm HKS GT II

BOV: Trust Type R

FUEL: Hypertune billet fuel rail, Radium FCST (fuel cell / surge tank), Radium multi-pump fuel-pressure regulator, six Injector Dynamics ID1000 injectors

IGNITION: Billet Performance 6061 billet coil adaptors, M&W pro-16B ignition amplifier, Denso iridium plugs, CDI pencil coils

ECU: MoTeC M800

COOLING: PWR radiator, Setrab oil cooler, Davies Craig EWP

EXTRA: Advance alternator 150A, MoTeC PDM30 and PDM15

Driveline

GEARBOX: Samsonas RWDS6 sequential

CLUTCH: HKS LA carbon twin-plate

FLYWHEEL: HKS lightweight

DIFF: Sikky Winters quick-change IRS

OTHER: Driveshaft Shop axles, Driveshaft Shop carbon driveshaft

Support

STRUTS: HKS Hipermax (NOB spec), 9kg front springs, 6kg rear springs

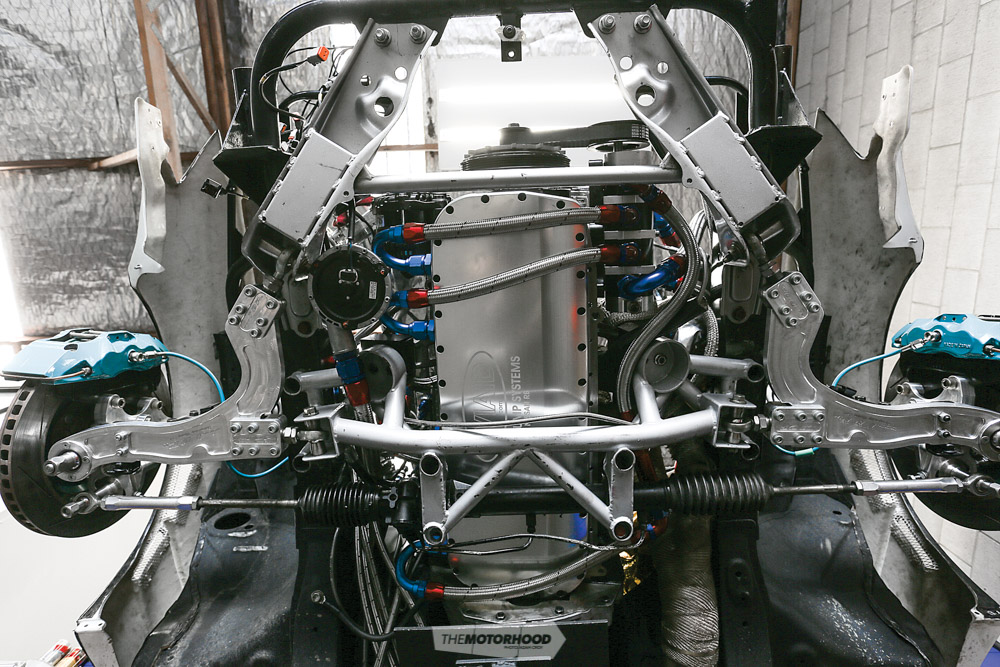

BRAKES: (F) Project MU six-pot GT calipers, 355mm Project MU rotors; (R) Project MU four-pot GT calipers, 355mm Project MU rotors, ASD hydraulic handbrake

EXTRA: TDP billet front knuckles, Parts Shop Max drop hubs, Parts Shop Max arms, Racefab front subframe, Nismo Power Brace System 2, Sikky rear subframe, DKM eight-point roll cage

Shoes

WHEELS: (F) 18×9.5-inch Rays Volk Racing CE28N RT Black Edition, (R) 18×10.5-inch Rays Volk Racing CE28N RT Black Edition

TYRES: (F) 235/40R18 Westlake Sport RS, (R) 265/35R18 Westlake Sport RS

Exterior

PAINT: Vinyl wrap by Jerry at Big Brown (designed by Hero Prints)

ENHANCEMENTS: Vertex Edge full body kit, Vertex Edge carbon bonnet, Topstage dry-carbon doors, Topstage dry-carbon boot, custom-made fibreglass headlights, SquareCraft TCA-F carbon side mirrors, HPI clear acrylic windows, Yashio Factory rear LED lights, Voltex dry-carbon GT wing

Exterior

PAINT: Vinyl wrap by Jerry at Big Brown (designed by Hero Prints)

ENHANCEMENTS: Vertex Edge full body kit, Vertex Edge carbon bonnet, Topstage dry-carbon doors, Topstage dry-carbon boot, custom-made fibreglass headlights, SquareCraft TCA-F carbon side mirrors, HPI clear acrylic windows, Yashio Factory rear LED lights, Voltex dry-carbon GT wing

Performance

POWER: 500kW

BOOST: 20psi

FUEL: BP98

TUNER: GDS Automotive

This article originally appeared in NZ Performance Car issue No. 248 — to get your grubby mitts on a print copy, click the cover below