We follow the process involved in getting a dedicated drag car legal to race. It’s a lot more interesting than your daily-driver’s WOF check!

If you’re a regular law-abiding citizen of our fine country, you will most likely be familiar with the periodic process of obtaining a warrant of fitness (WOF) for your vehicle(s). That you’re reading this magazine in the first place is a pretty good indication that you should know your way around the WOF process — essentially a safety check of your road-going vehicle to ensure that it is able to be operated without being a hazard to yourself or other road users.

It’s understandable that a similar process would be undertaken for vehicles designed specifically to get from point A to point B as quickly as possible. We’re talking drag cars, and, just as outright performance is of the utmost importance, so, too, is that vehicle’s ability to perform safely. You’ve probably heard of drag cars being ‘tech inspected’ — usually referred to as being ‘teched’. We decided to follow the process to show you just what’s involved behind the scenes before a drag car can hit the strip.

Of course, it helps when the vehicle being inspected is cooler than the average daily-driven Honda Civic. The car that we followed the inspection of is the recently completed twin-turbo Ford Falcon XY drag ute built by Jason Sellars of JSE Custom Fabrication and inspected by Dave Moyle of Pro Street Automotive, who is a recognized IHRA tech inspector.

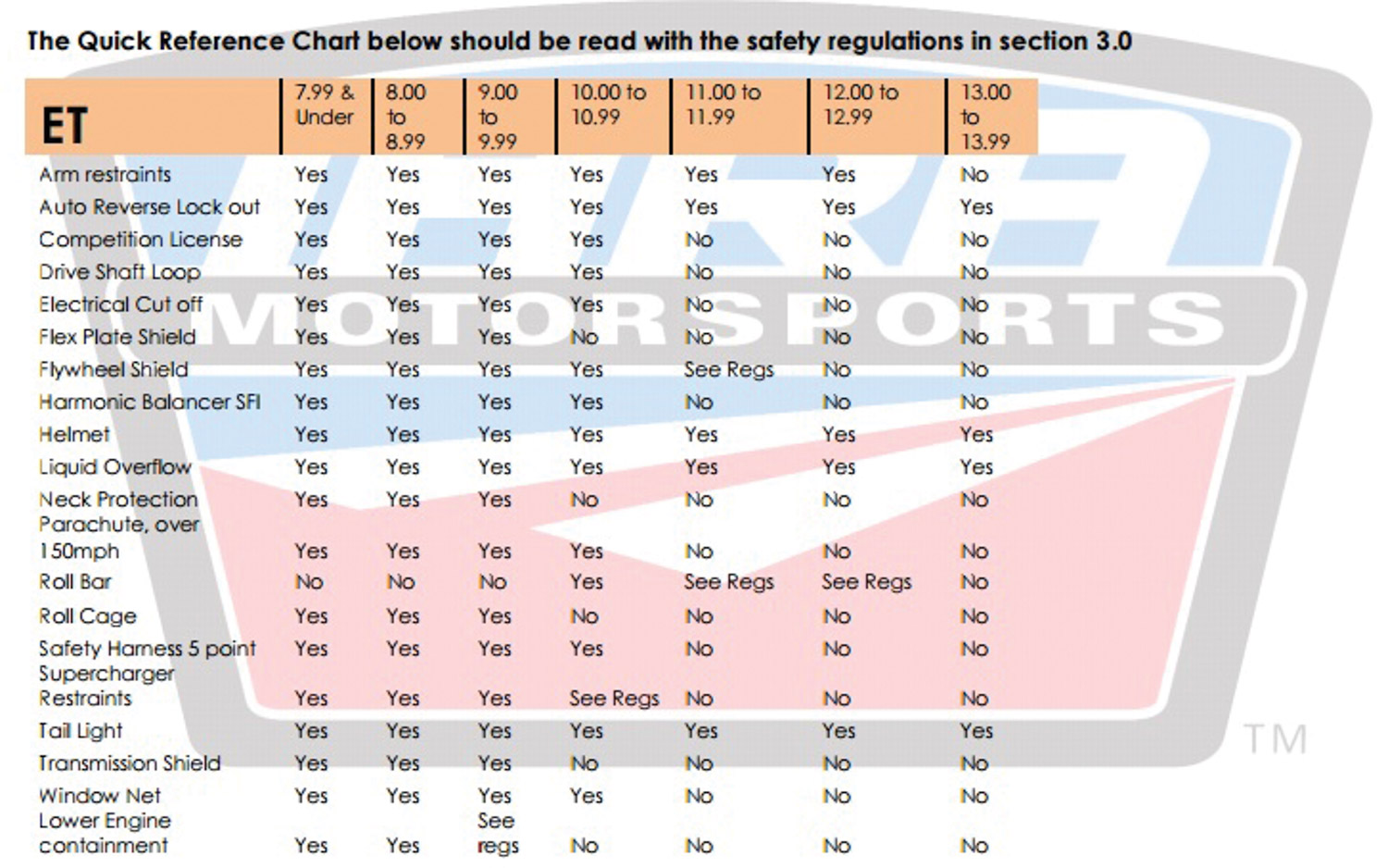

At Meremere Dragway, any car running under 11 seconds or without a WOF is required to have passed an annual IHRA/NZDRA tech inspection, consisting of a comprehensive check of all general, safety, and class regulations according to the IHRA NZ / MDI Rule Book. A valid logbook and a tech sticker must be displayed at all times during events

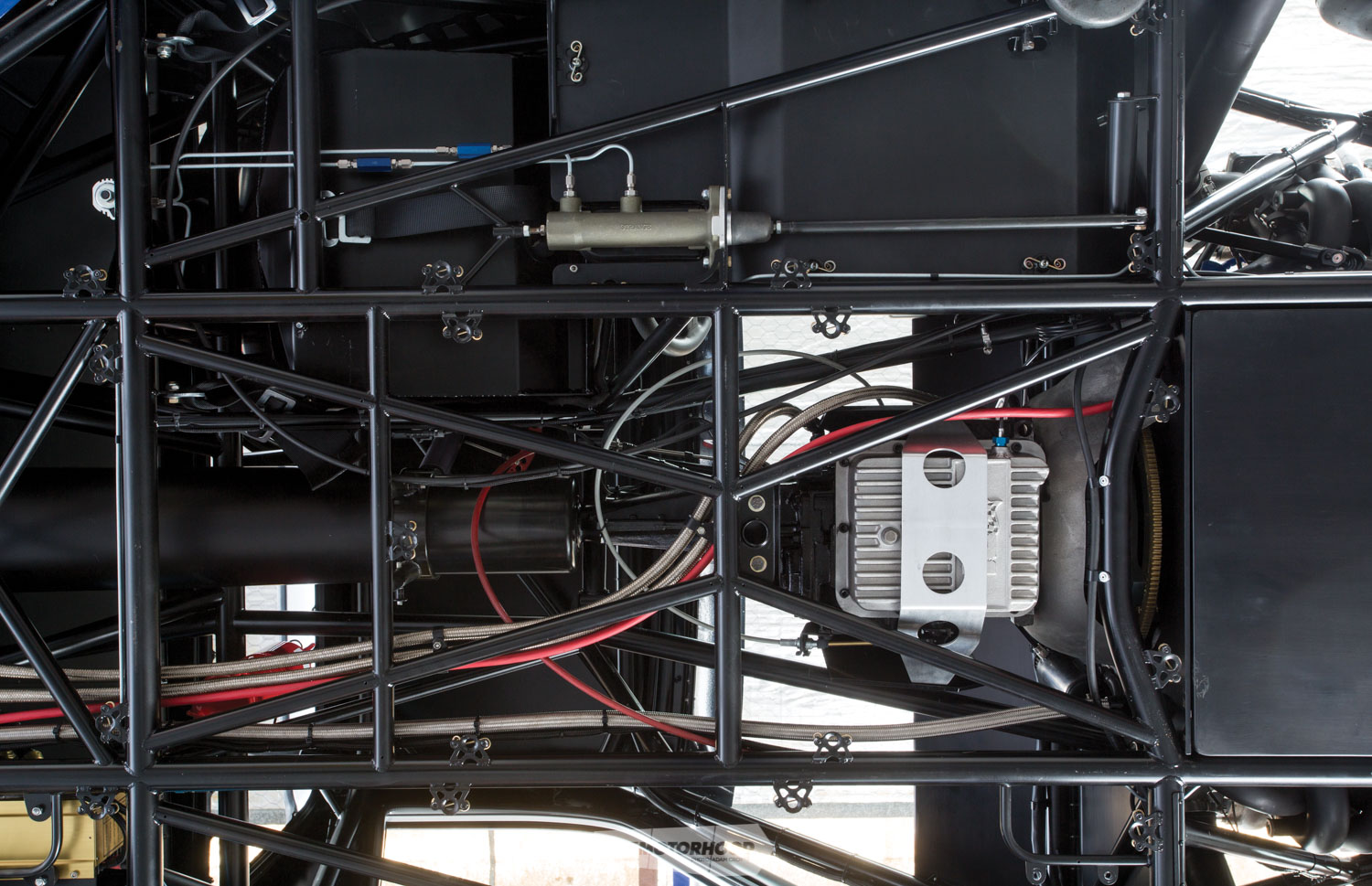

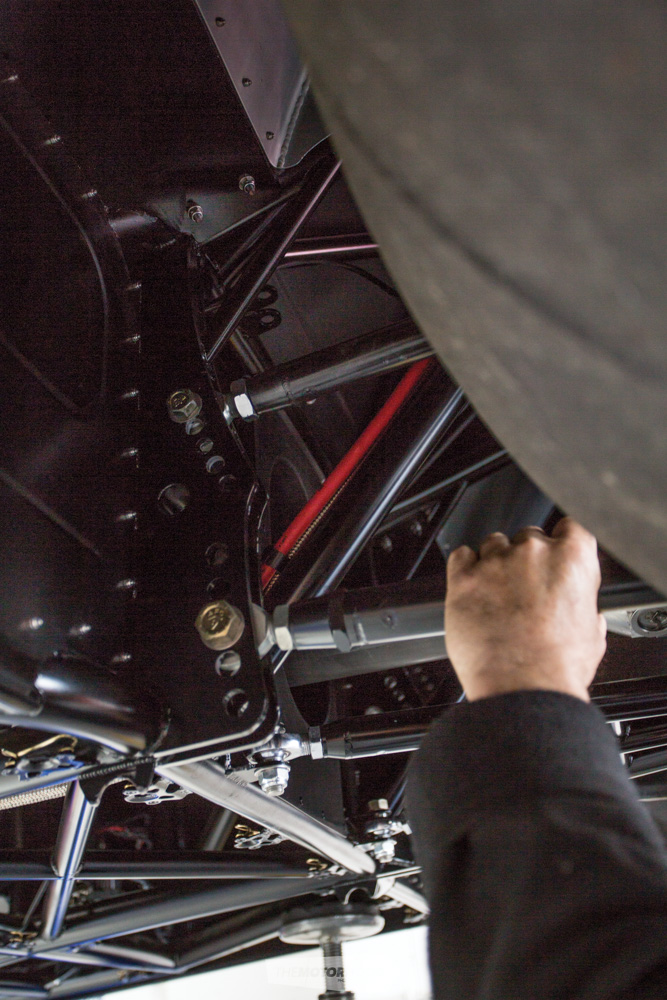

The first thing that’s done is to get the vehicle onto a hoist — in this case, we use one at Magnum Automotive — so that the inspector can check it over from all angles. He’ll spend as much time inspecting the undercarriage of a full tube–chassis car as he spends looking over everything else.

The IHRA tech guidelines are laid out in the 2015–2016 IHRA NZ / MDI [Meremere Dragway Incorporated] Rule Book, which can be downloaded from Meremere Dragway’s website (dragway.co.nz). That said, every car is evaluated slightly differently, as every car is different. “It’s about 90 per cent in the book, 10 per cent in here [taps head],” Dave says, suggesting that he must still take the initiative and apply his own knowledge to each tech inspection.

Straightaway, he’s underneath the Falcon, checking all fasteners for their SAE grades and for tightness. One of the nuts in the four-link is found to be slightly loose, which Dave points out to Jason. “He did tell me beforehand that they were working on the car up until the inspection, so I can understand that, but it’s important to have your car completely ready for inspection,” Dave says. This check of fasteners extends to things like the grub screws in the steering shaft — thoroughness is key, as the failure of any one component can lead to total catastrophe on the drag strip.

There is no hard and fast way to conduct an inspection — you’ve just got to be meticulous, and know what you’re looking for. As Dave checks the car over, he’s looking out for a large number of things at any given time. While he’s underneath, the driveshaft is also subjected to a closer look. The universal joints are Mark Williams non-greasable units, which are sufficient in this case, and the custom-fabricated driveshaft enclosure is given a thorough once-over to ensure it meets the minimum requirements.

As Dave moves from the rear to the front of the Falcon, he seems impressed with the car’s build quality, but doesn’t fail to notice the things he’s there to notice — the brake pedal pivot bolt is SAE grade 5, but the minimum required is a grade 8.

Further forward, he notes that the steering-rack boots are missing cable ties to fasten them to the rack ends. While this may seem trivial, Dave points out exactly why something like this can’t be overlooked, saying, “There’s grease in there, and it’s gotta be contained. If that grease were to come out on a pass — for whatever reason — and the rear tyres touch it, it’s all over.”

The fuel system is checked over carefully, including all fuel lines. While Dave’s doing this, he’s also closely looking for any leaks, be they oil, water, or fuel. Keeping the fluids topped up is the concern of the owner, but any leaks have the potential to cause a crash. As you probably expect, there are no concerns when it comes to leaks on the XY. The brake master cylinder reservoir is also inspected to ensure there is sufficient fluid for the hydraulic system to operate properly — the reasons for this should be obvious.

“All nuts, bolts, and component parts on each car’s suspension system, system, chassis and running gear must be secured with lock nuts, lock washers or cotter keys, and must have at least one full thread showing through nuts” — IHRA NZ / MDI Rule Book

Then there are the components that must meet a specific SFI rating. The harmonic balancer is one of them; it must meet SFI 18.1, be manufactured of forged steel or aluminium, or have a suitable scatter shield (containment device) beneath. In the case of Jason’s ute, the harmonic balancer is an SFI-approved unit as manufactured by ATI Performance Products. Another area that is checked in this regard is the transmission bell housing, which again is found to meet the appropriate SFI rating. If a driveline failure results in a shattered flexplate, it’s in everyone’s best interests to have a safety device in place that will deflect the bulk of the shrapnel away from the driver.

“All vehicles quicker than 11.00 seconds require a battery isolation switch, capable of cutting off current flow and operable from the exterior of [the] vehicle. It must be installed on the rear of vehicle and marked ON/OFF or Push Off” — IHRA NZ / MDI Rule Book

The SFI rating check extends even to Jason’s protective gear. As well as looking over the XY’s fire-suppression system, Dave inspects Jason’s helmet and race suit to ensure they are correct for the class in which he’ll be racing. Super Sedan class requires a race suit to have a minimum of two layers, which Jason’s does. The parachute is also looked over, with Dave requesting it to be released. It is inspected for condition — namely, ripping or fraying in the shroud lines and canopy. Being a brand-new Simpson unit, Jason’s parachute passes with flying colours.

“A braking parachute produced by a recognized drag racing parachute manufacturer is required on all cars exceeding 150 mph (130mph if only two-wheel braked). All cars exceeding 200 mph must have two parachutes, both operational … Chutes will be inspected for worn or frayed shroud lines, ripped or dirty canopies and worn or ragged pilot chutes.” — IHRA NZ / MDI Rule Book

While Dave is at the rear of the car, the battery is checked to ensure it’s properly secured — it is, as you’d expect — and the battery cut-off switch is appropriately fitted and marked. Dave also gives the wheelie bars — which aren’t currently fitted to the ute — a closer look to ensure they meet the requirements set out in the rule book.

The interior of the car is also subject to an in-depth inspection. The parachute release lever is checked over, and Dave also makes sure nothing is hanging down, such as wiring. He looks at the construction of the roll cage. The window safety net — which is a requirement for this car — is checked to ensure it is fitted correctly. All the while, Dave is also inspecting the myriad other small things that can’t be overlooked.

“All cars running under 11.0 seconds having doors and a roll cage must be fitted with an accepted window net attached to the inside of the side bar and the inside of the top bar of the roll cage at driver’s window. Net must be permanently attached at the bottom” — IHRA NZ / MDI Rule Book

The presence of an inhibitor switch — which prevents the engine from being started when the [automatic] transmission is in gear — is a key concern for Dave.

“You wouldn’t believe how many people try to run their cars without one. It’s something that I’ll usually check last. The inspection usually goes well, car’s ready to go, and I’ll ask them to fire it up — it’ll be in ‘park’, and it’ll start. Then I’ll ask them to stick it in ‘neutral’, and start it up. Then I’ll get them to do the same in ‘drive’, and that’s when they realize. If you don’t have a switch, you don’t pass inspection.”

“All RWD vehicles exceeding 140mph or 10.0 are RECOMMENDED from July 1 2015 to have a front tyre specifically built for drag racing use (e.g. Hoosier, M/T, Firestone or Goodyear Front Runners). Use of a front tyre specifically built for drag racing will be MANDATORY from July 1, 2016” — IHRA NZ / MDI Rule Book 1, 2016.

Once Dave’s satisfied that he’s checked everything that needs to be checked, he lets Jason know the result. Throughout the inspection, he has pointed out the areas of concern to Jason, so he knows exactly what Dave’s talking about and what will need attention. Given the top-tier quality of the ute’s build, the list of things needing to be rectified is very short — replacing the SAE grade 5 bolts with grade 8 items and installing cable ties on the steering-rack ends.

“All other [than Top Alcohol and Top Doorslammer] rear wheel drive vehicles quicker than 10.0 seconds, must have a totally enclosing 360-degree bell housing, the bell housing must be formed or fabricated entirely from 6.25mm (1/4’’) steel plate and attached directly to the rear of the engine. Shields meeting SFI 6.1, 6.2, or 6.3 are highly recommended” — IHRA NZ / MDI Rule Book

As mentioned earlier, though, there is no hard and fast way of doing such an inspection. It comes down to the individual car in question, the class in which it is racing, and the inspector.

“It’s sort of like a WOF check,” Dave says. “Each class has different rules and regulations, but the main concern is always safety.”

“Wheelie bars … may be adjustable, but must be fixed during run. Any movement or adjustment during run [is] prohibited. Wheelie-bar wheels must spin freely on start line. Preloading [is] prohibited. No metallic wheels are allowed” — IHRA NZ / MDI Rule Book

That’s probably the best way to put it — be it a routine WOF check or a drag racing tech inspection, faulty components are replaceable but a life isn’t.

This article originally appeared in NZV8 magazine issue No. 127 — you can get your grubby mitts on a print copy by clicking on the cover below: