The world is riddled with false expertise surrounding suspension setups, so we turned to the masters at MCA Suspension in order to bust a few common misconceptions

Here at the office, we like to do things properly, but, unfortunately, not everyone else shares the same approach, and that can lead to some whack information floating around the place that is outright incorrect.

Getting it right is especially important when you’re dealing with slammed cars that still want to retain some form of driveability. We can’t all be experts in every field, and some things are best left up to those that are — at the very least, we should look to their advice.

It seems that no field of expertise is more prone to misinformation than suspension set-ups.

Ask any two people, and you’re likely to get a completely different answer based on two very different experiences. There are not many specializing in suspension design left kicking around the place that you can simply ring up and spit questions at. All the big companies keep their engineers hidden away in clean rooms never to see the outside world.

However, Josh Coote of MCA Suspension has taken it upon himself to set the record straight and ensure that everyone is running the right set-up for their car. So, while we had him on the phone, we spitballed the three most common misconceptions that he’s come across to get the lowdown on exactly what people have been doing wrong all these years.

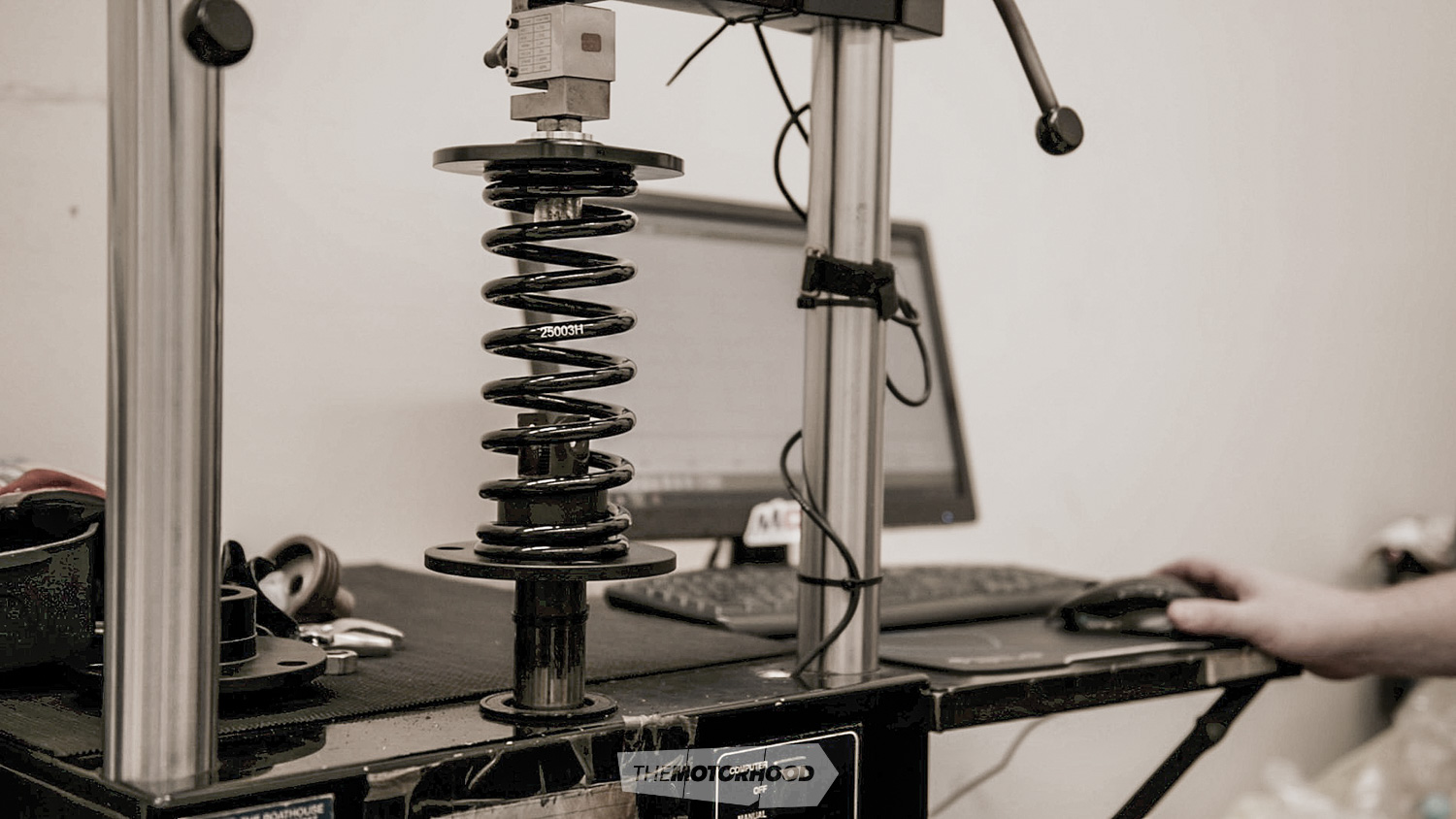

Misconception: Preloading springs

Josh said: “The belief here is that if you preload the spring, it will change the spring rate and/or the handling and ride characteristics of the car. The reality of this is that the spring rate doesn’t change. The spring rate will remain the same throughout its compression range — it’s a constant.

“Your ‘spring rate’ refers to a measurement; for example, a 5kg spring will compress 1mm for every 5kg of weight applied. Even if you preloaded it by 10mm, when a car’s weight is 250–450kg per corner, the spring is always going to compress further than you’ve preloaded it. In some cases, this may be up to 50mm and beyond. Therefore, at ride height, the spring is always exactly the same length, be it captive, non captive, or preloaded when the car is jacked up off the ground.

“As far as the vehicle is concerned, it is sitting on the same spring set-up. For the spring to change the vehicle dynamics, there must be a change of spring rate. The only exception to this is if you are jumping the car and landing — landing on a preloaded spring would make a difference. However, this would only occur when the shock is fully extended and all weight is off the wheels for a good amount of time, so 99.99 per cent of people will never experience this.”

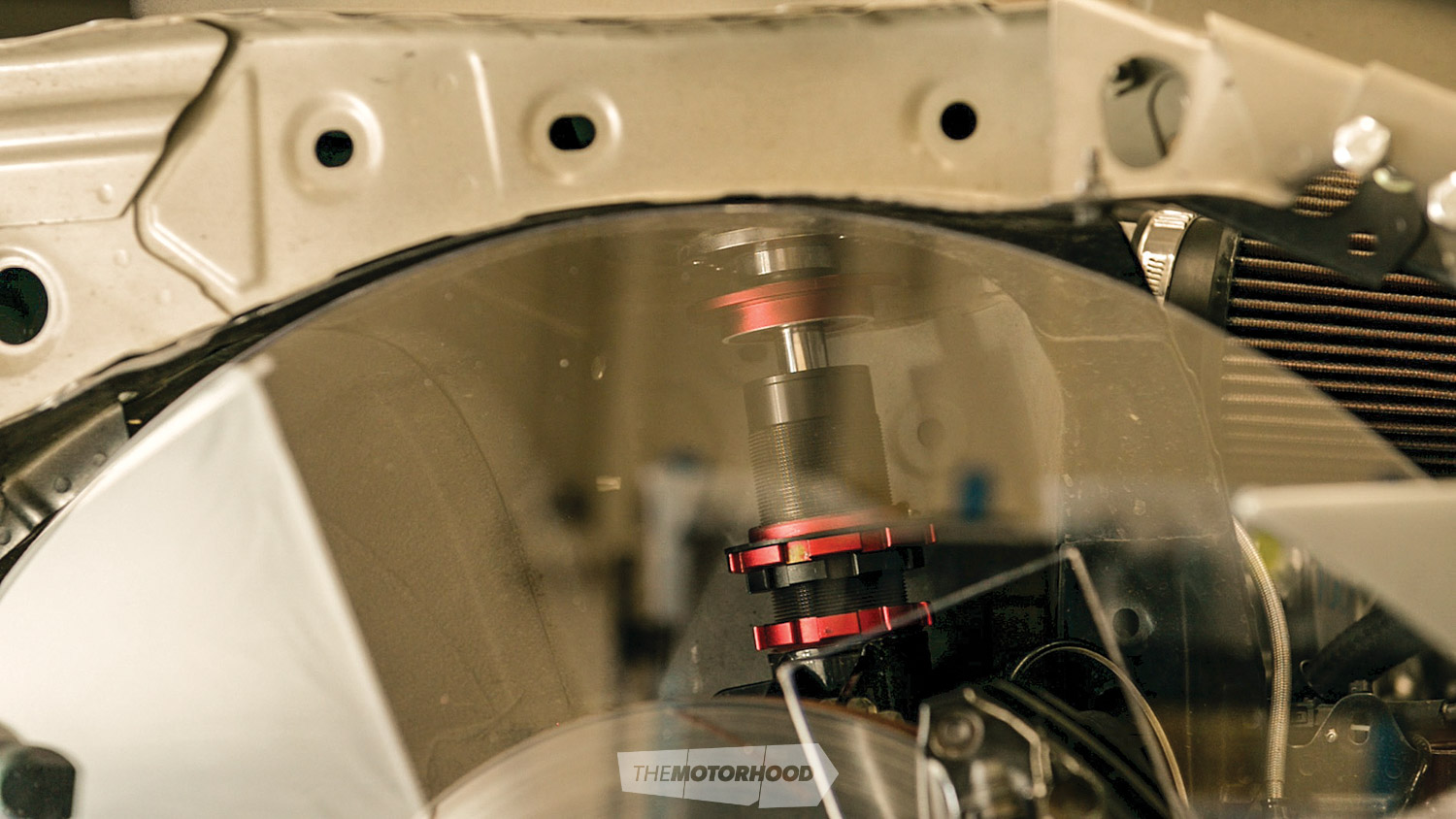

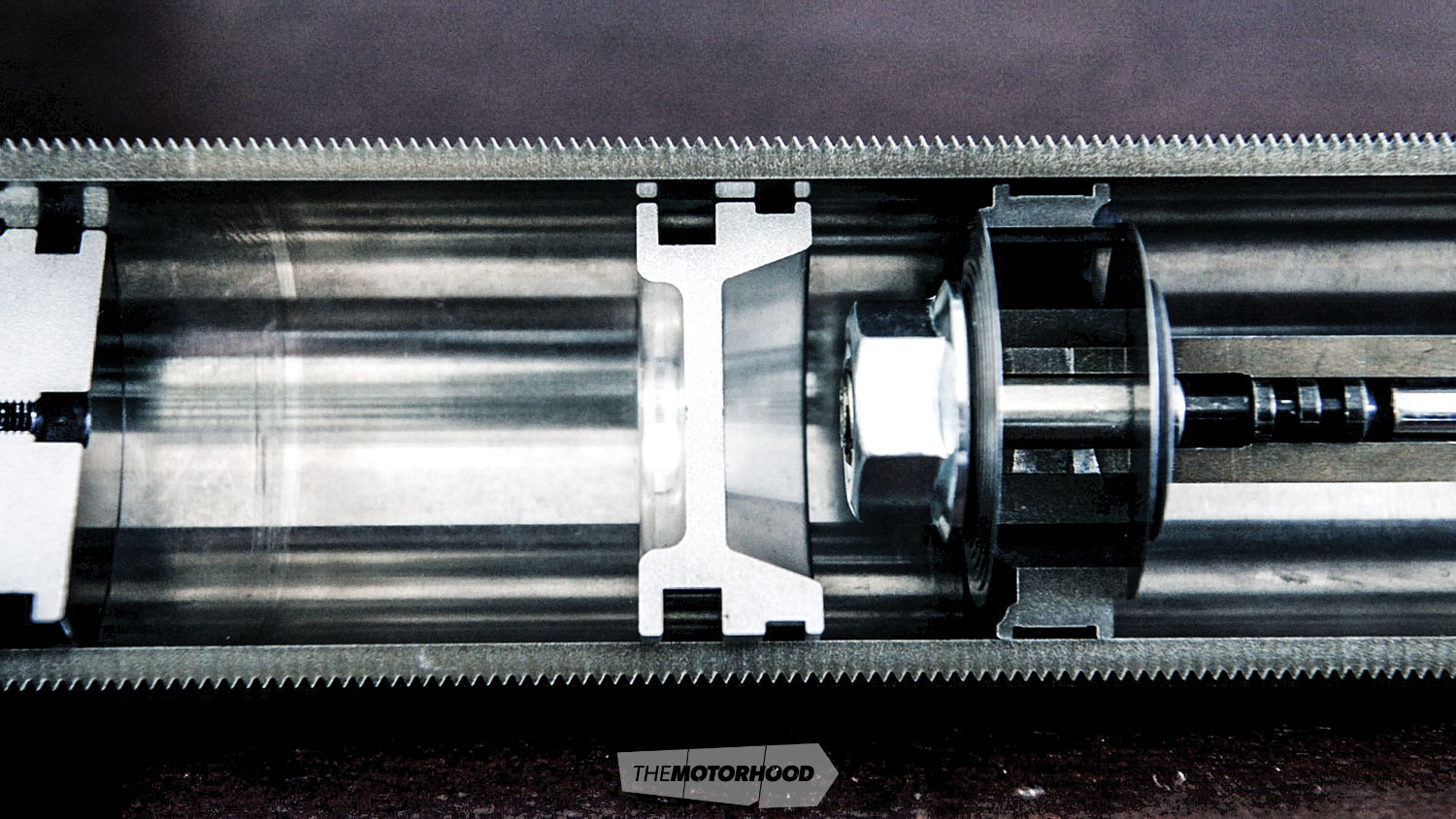

Misconception: Bottoming out

Josh told us: “Many make the assumption that dampers shouldn’t reach full compression (‘bottom out’) and believe that doing so will cause internal damage, and/or cause the vehicle to become unstable from a sudden stop in travel.

“Depending on the brand, this one can be semi-true. Due to the assembly process that the cheaper options use, it is possible to cause internal damage — however, this is a fundamental flaw in the design. It occurs because of the shaft nut hitting the floating piston at full compression.

“We [at MCA] assemble all our dampers to accommodate full shaft travel, whereas others can show another 10–15mm of travel externally while making contact. This often leads to the use of larger, excessively stiff, bump-stops to prevent damage, and, if fully engaged, these can create the potential for the vehicle to become unstable and produce a much harsher ride quality.”

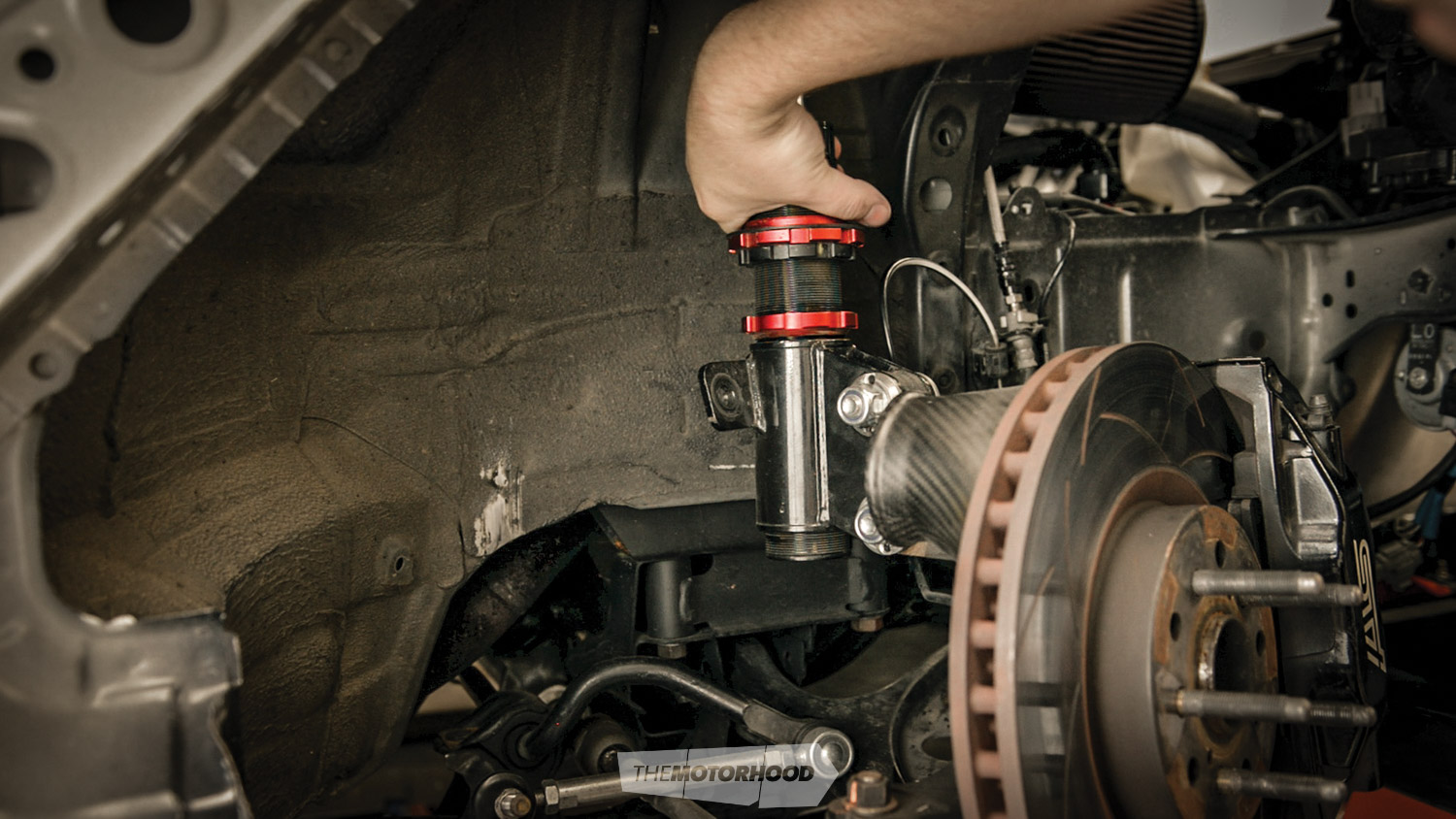

Misconception: Base height adjustment

Josh said: “The most common way to adjust height is via changing the bottom mount position. This stems from the belief that changing spring load affects vehicle dynamics — which we’ve already proven to be untrue — and that travel should not be changed.

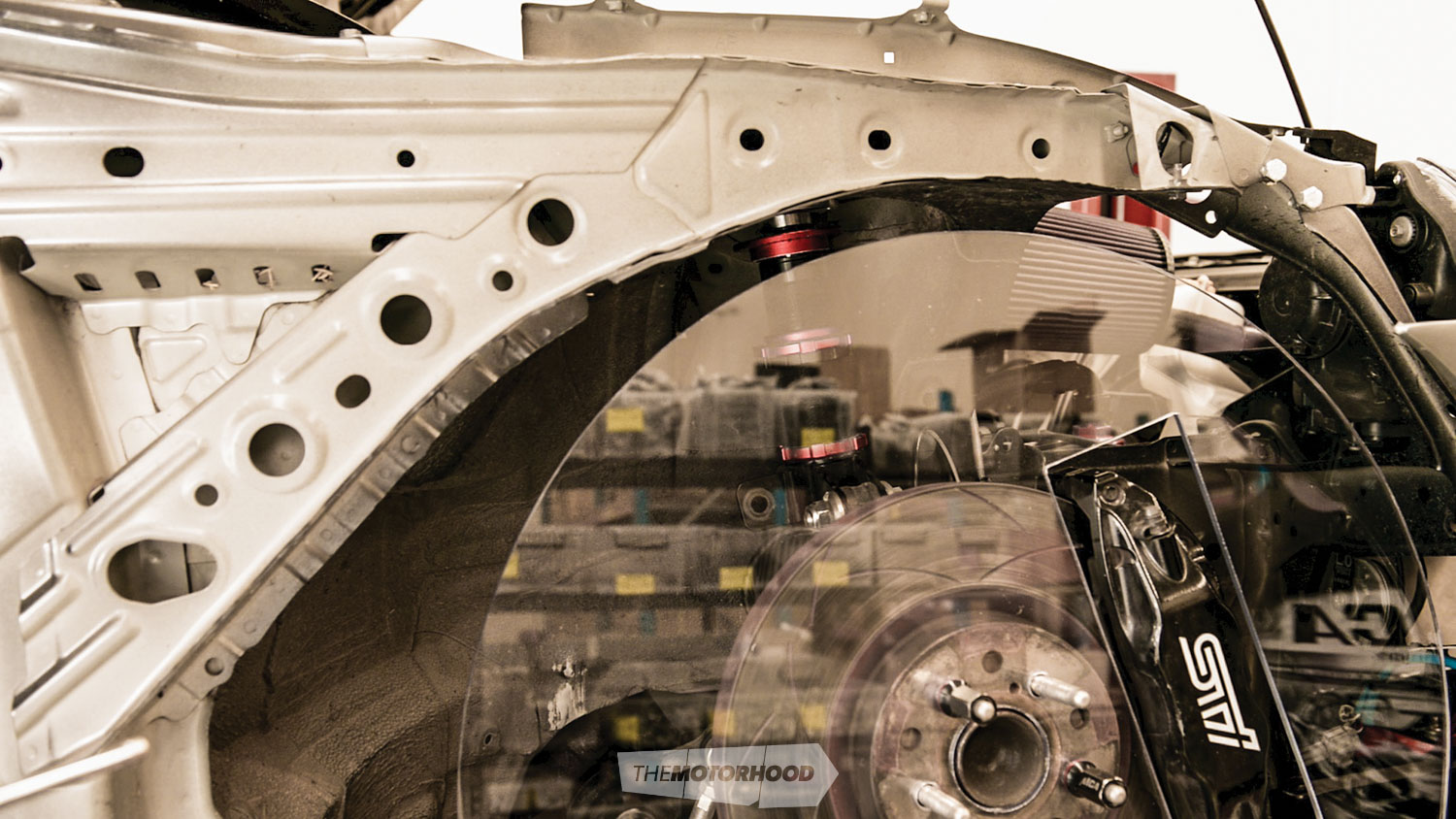

“The amount of shaft in the shock controls how much wheel travel there is — that’s how much shaft can go inside the body. What the bottom mount or length of the shock does is control where the wheel travel range is in relation to the car. When people have issues with suspension components and tyres making contact where they shouldn’t be — for example, arms hitting chassis; wheels hitting guards; or, in Silvias as an example, wearing through looms — it’s usually caused by the bottom mount adjusting the wheel travel range too high into the car.

“We set the bottom mount so that the wheel travel range is positioned so you don’t have contact issues. You want as much upward travel as you can, this is commonly referred to as ‘bump travel’. Especially for people wanting to lower their car, you want every millimetre that you can get. Bump travel helps with grip, stability, bump handling, and ride quality.

“For a car that has 50mm of tyre-to-guard clearance, and 50mm of shock travel available, when the shock bottoms out, you would have things just skimming without issue. Adjust the base height 20mm lower, and you’ll only have 30mm of tyre-to-guard clearance but still have 50mm of travel — that isn’t going to work.

“That’s why we adjust the bottom mount to where it needs to be and move spring seats to adjust the ride height and travel. You absolutely have to reduce your travel, or you’ll have contact issues.”