So you’re thinking about filling up with ethanol? Stop: there are a few things to consider first

We have all undoubtedly heard about the big gains that can be had when running an ethanol-blend fuel like E85, and you have probably been tempted to make the switch. But we don’t need to tell you that it’s not as simple as just filling up with an ethanol blend, and hey presto, your car will make more power. There are quite a few things to consider when switching, but before we delve into those, here is a little backstory on ethanol-blend fuels, and how are they produced.

Ethanol is derived from ethyl alcohol, aka moonshine, and takes the chemical compound C2H5OH — the ‘O’ denotes oxygen. It is produced in the same way as any member of the alcohol family, through fermentation of organic matter containing sugar. The actual source depends on what country you get the fuel from. Our neighbours in Australia produce it from wheat, or sugar cane, in the USA it’s produced from corn, and in parts of Europe and here in New Zealand it’s connected to our biggest industry, dairy.

The casein precipitated when making skim milk is a vital part of many products — including adhesives, plastics and, primarily, various processed foods — and now it is also used in the production of four million litres of ethanol each year from Fonterra’s Reporoa-based Anchor ethanol plant. The vital component is lactose, which is a by-product of Fonterra’s casein production. The leftover lactose is fermented with yeast, resulting in a low-concentration ethanol (around two to four per cent). The low-concentration ethanol is distilled to a 96-per-cent ethanol, which is suitable for printing, antiseptics, food service, etc. Fuel-grade ethanol, the stuff we want, is put through a further drying process that removes all water, taking it to 99.9-per-cent purity. There are a few outlets also selling imported ethanol here on the New Zealand market.

Darren Kelly made the switch to E85 with his RB30, and to a larger exhaust housing (.82 from a .63). On pump fuel, the RB30 peaked at 424kW on 17psi, so by just making these few key changes the RB30 made 479kW on the same boost, picking up 55kW at the wheels alongside a huge amount more torque and reliability. Even more impressive is an increase of 3psi saw 527kW

Why is it blended with petrol? The most common form of ethanol-blend fuel we deal with at NZPC is known as E85, which is 85-per-cent ethanol and 15-per-cent petrol. With an octane rating of 105 to 108, it will rival any of the expensive race fuels. You can efficiently run any blend percentage you want, with lesser blends like E10 very popular for daily motoring — think Gull Force 10. We Kiwis have been a little slow to catch on, with ethanol blends first making an appearance in the ’30s on American soil, and ethanol now part of 97 per cent of its fuel supply, while countries like Brazil run E100. That is not a very cost-effective option due to the quality required to match the petroleum’s energy output. Cold start is also a big reason why a blend is most commonly used.

Won’t it kill my fuel system?

Under New Zealand legislation all ethanol fuels are required to contain an anti-corrosive additive. Both of New Zealand’s largest suppliers use what is known as DCI-11. So little goes in that it’s not even included on the MSDS (material safety data sheet) — there’s around one litre of DCI-11 to 15,500 litres of ethanol.

Why is it needed? Ethanol is hygroscopic, meaning that it absorbs moisture — such as water (H2O). When stored in tanks that vent to the atmosphere, ethanol will absorb water present in the air, and therefore the oxygen compounds that are present in it. The oxygen content, although good for making power, is also known to cause corrosion in metals such as zinc, magnesium, aluminium, and steel.

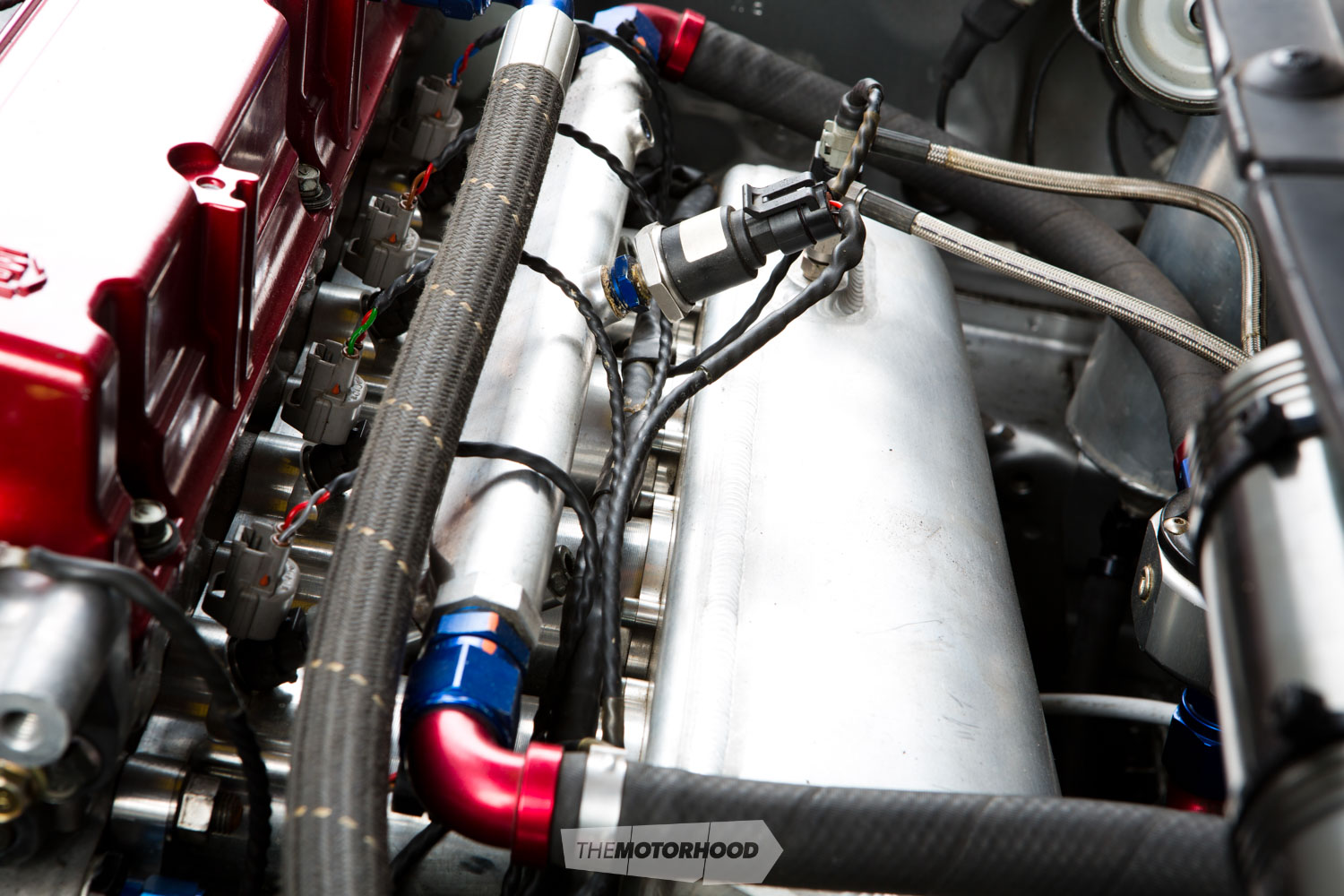

Most aftermarket companies that produce fuel-system components will offer ethanol-specific variants like items with anodized fittings, and alcohol-rated lines. Ethanol’s taste for non-metals can become a problem if your fuel lines and tank foam are not rated for ethanol, as what commonly occurs is the rubber or foam degrades, with small particles breaking off and finding their way into the fuel filter, blocking it, or worse, getting into the injectors or carb jets and doing the same. This can be very costly.

Even when running an ethanol-rated system many racers choose to drain and flush the fuel system with the likes of 98 after an event. This can help with the life of rubber seals. If you are doing this you need to ensure that the system is properly drained of the petrol before refilling with your ethanol blend, as any petrol left in the tank will dilute your blend. If you’re not running a flex-fuel system and your high-compression engine is tuned specifically to E85, and you begin running E70, E60 or E50, then you could end up leaning out and destroying your engine.

Setting up a flex fuel system

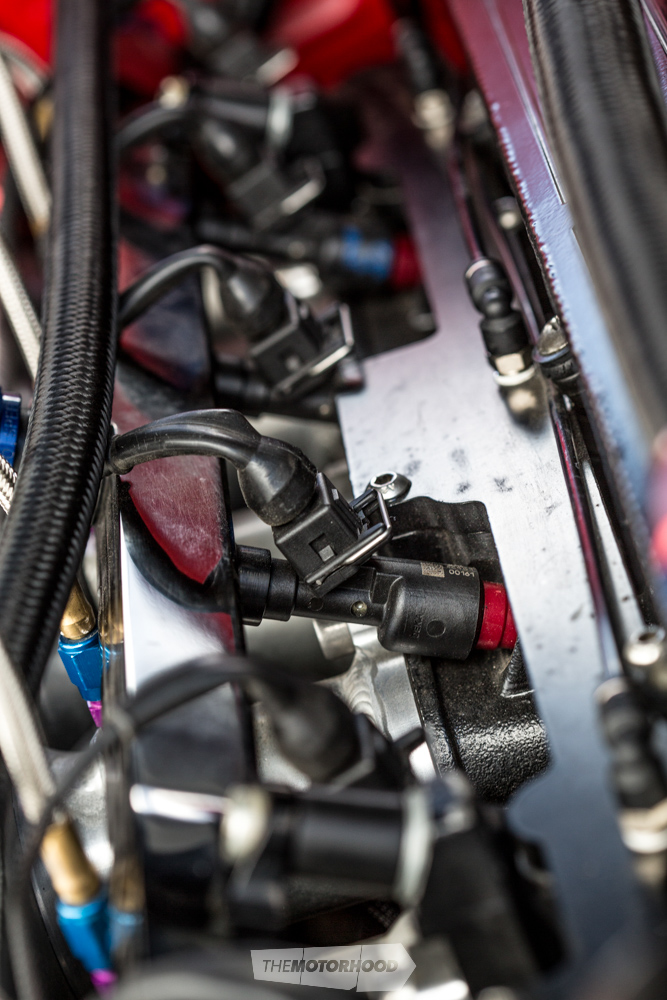

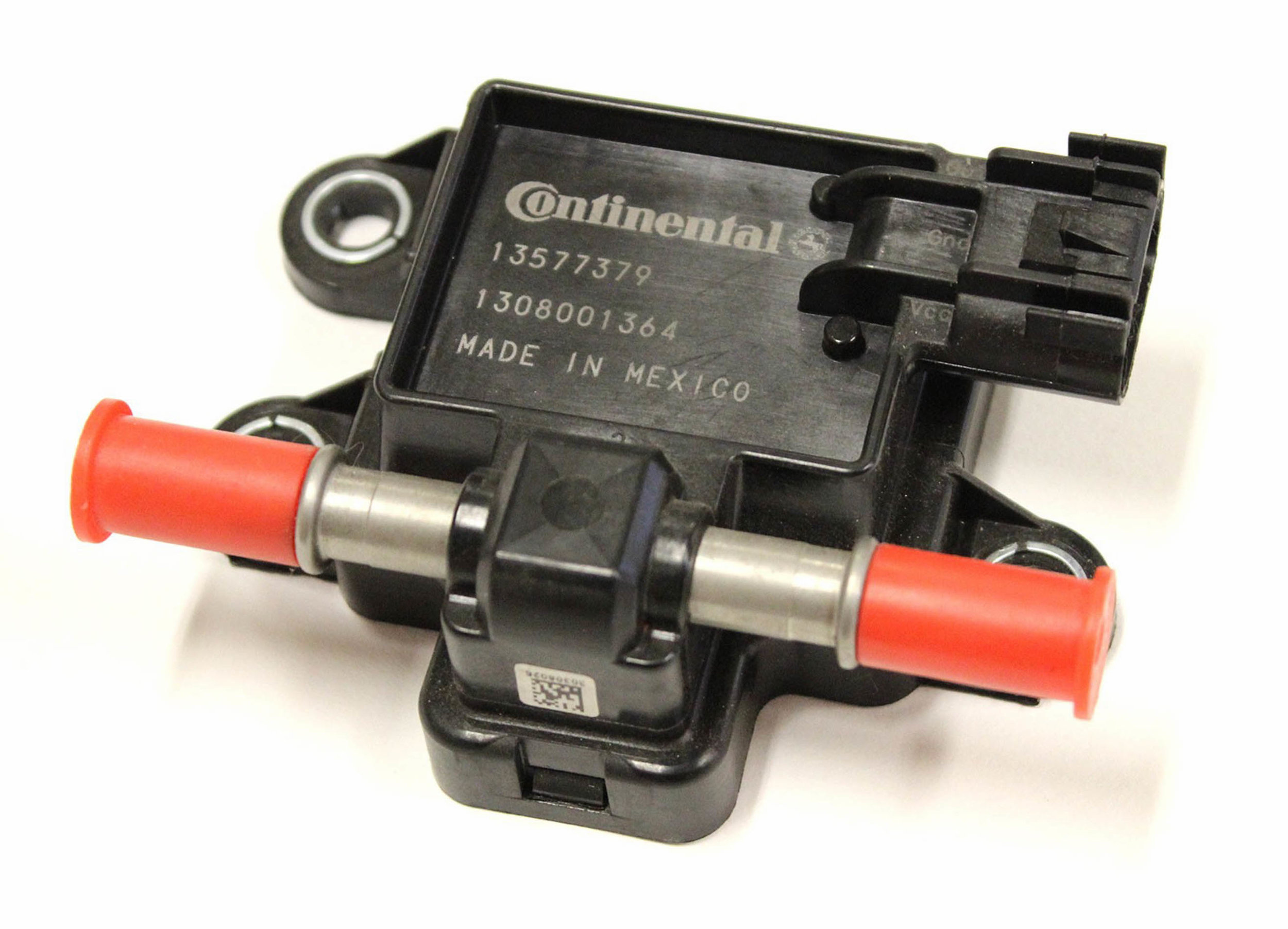

Modern cars are increasingly produced with flex-fuel capabilities, thus meaning you can run any blend of ethanol safely, and your ECU will make those changes to the tune on the fly. The most common of all the flex-fuel sensors is a GM product, generally found here in late-model Commodores. Many of the big ECU companies offer their own branded sensors, and it’s becoming a very popular addition to any ethanol fuel system. These sensors read the oxygen content and temperature of the fuel and relay it to the ECU. There are also control modules that allow you to run a flex-fuel set-up with many of the simpler ECUs including piggybacks, such as those from the likes of Nistune. You can also get a gauge that displays the percentage from a control module.

The sensor is pumped in-line on the return line of the fuel system. Commonly these sensors are -6, so if you’re running a larger return line, you can plumb in parallel in order to not reduce the flow of the system.

If you plan to run a specific blend all the time, rather than chopping and changing, it’s not necessary to fit the sensor. We are lucky down here in New Zealand, as our pump blends are far more accurate than those in America. And if you’re blending your own, then it’s on you.

Tuning for Ethanol If you plan to switch to E85 then you’ll need to change a few things in your system and your tune. The energy output of most fuels is measured in British thermal units (BTU). One litre of gasoline has an energy content of approximately 3698 BTU, while one litre of ethanol has an energy content of approximately 2110 BTU. What this means is that an internal combustion engine will need to burn more ethanol-blend fuel than gasoline to produce the same energy. Typically you will need to use at least 30-per-cent more volume of fuel to achieve a similar energy, so why would you switch?

When making the switch to E85, you will need to move between 30- and 50-per-cent more fuel through the system. This means THAT each component in the supply chain will need suitable changes, from filters to lines, injectors and rails, especially if they are already close to capacity. When upgrading, make sure you select ethanol-safe components

The octane rating of E85 sits between 105 and 108 octane, the higher the octane reading, the slower the combustion burn is. This means that you can run more advanced timing, with higher compression and higher boost pressure at the same AFR, and avoid detonation. Basically that gives you upwards of 30-per-cent more power for the same ‘safe’ range of the engine. But you can also go further than that tune and see even more gains, if the engine is built to take the boost.

The cooling properties are also a huge benefit to consider. The fact that you’re running more volume of liquid to transfer heat to is one side of it, plus the latent heat of ethanol means the amount of energy (heat) absorbed as the liquid transforms into a gas results in a cooler intake temp and overall engine temp, and that poor hard-working turbo will last a little longer due to reduced heat.

So E85 ‘wonder fuel’ has pros and cons, but overall we say it gets the big tick. While running it in your factory NA street car won’t see massive gains, the higher compression that you can run in your weekend warrior will see a decent power boost from making the switch, even if you don’t increase boost. Talk to your tuner early on, and make sure you’re setting up the fuel system correctly. You will need to flow between 30- and 50-per-cent more fuel than on pump gas, and so that cost along with the added cost of the blend needs to be taken into account.

We hope this has given you some insight into ethanol blend, and perhaps dispelled a few of the myths associated with it, as there is no doubt that it will only become more and more prominent both when racing, and at

the pump.

TIPS FOR STORING FUEL

If you have an older car that is only taken out only every so often, these few pointers will help preserve your fuel and the integrity of your fuel system.

Use premium pump gas. Higher-octane gasoline tends to be more stable, and lasts longer than lower-octane fuel.

If your car is in storage, keep the fuel tank or cell as full as possible. Store the vehicle in an environment with minimal temperature swings. This will help to prevent ‘breathing’, which leads to the ingress of moisture into the fuel tank or cell.

Sunlight can damage fuel. If you’re storing fuel in a jerry can, or have an exposed fuel tank on your vehicle, make sure it’s stored where it has minimal exposure to sunlight. Sunlight can cause containers to ‘breathe’, leading to the ingress of moisture, and speeding up oxidization. Opaque fuel containers, such as those made of steel, are preferable.

This article originally appeared in NZ Performance Car issue No. 228. Grab yourself a print copy of the mag at the link below: