It’s all too easy to get carried away during the process of a big build, and find yourself engulfed in a series of expensive purchases that fill the engine bay and pack the supporting components with crazy pieces of kit — hell, ask the owner of any car we’ve featured and they’ll almost always tell you that’s the case. But while you’re wrapped up in all things power chasing, other important pieces of the ongoing puzzle may be decided in passing, or forgotten about completely — exhausts being one of the most frequent examples. You may even overlook it intentionally, as it all becomes too confusing: resonate what? Muffle who? Dump where? Is the meaning of any of this jargon important? In short, yes, incredibly.

Don’t fall into the trap of buying the first thing you see, and calling it a day. Not only does the muffler and resonator combo control your exhaust note and level, it can affect your power levels, too. And of course searching for the perfect exhaust note can become an obsession, and why wouldn’t it, given that everyone is partial to a different sound — whether you like a mighty rumble, a raspier growl, or virtually anything in between, the aftermarket exhaust industry has come up with every conceivable component design to get your system note-perfect, even before you consider maintaining or improving performance.

Having access to a huge pool of quality pieces is sweet, but it can get pretty hard to select the right item for your application. To do so, it’s handy to understand exactly how it all works, so we called upon Brent at Adrenalin R and Kita at Manawatu Muffler Centre for some insider knowledge.

The first question you’ll ask is, what does a muffler do in my exhaust system, and what is it made up of? That answer is pretty involved, so bear with us. A muffler works to reduce the sound that the engine produces — as part of the process of emitting the exhaust — to an appropriate level. This is achieved by cutting the sound pressure emitted. Many OEM options are made to sound OK, but are almost always restricted by efficiency concerns, ease and cost of manufacturing, and of course sound-level laws. The result is that stock items are built to be conservative, and can restrict your plan to increase power.

Depending on what style of muffler you’ve selected, it will achieve its aim in different ways, as Brent from Adrenalin R told us. “Our mufflers, which are completely made of stainless steel to avoid corrosion problems, are the baffle-packed type. They consist of a stainless steel baffle [the centre part which gas flows through] which is then wrapped in stainless steel wool, and it acts as a heat barrier. Exhaust gases travel through the baffle and are pushed through the baffle into the stainless wool, which is supported by a fibreglass packing behind it. The packing works to quieten the sound, while the steel wool absorbs heat to protect the packing from extreme temperatures”.

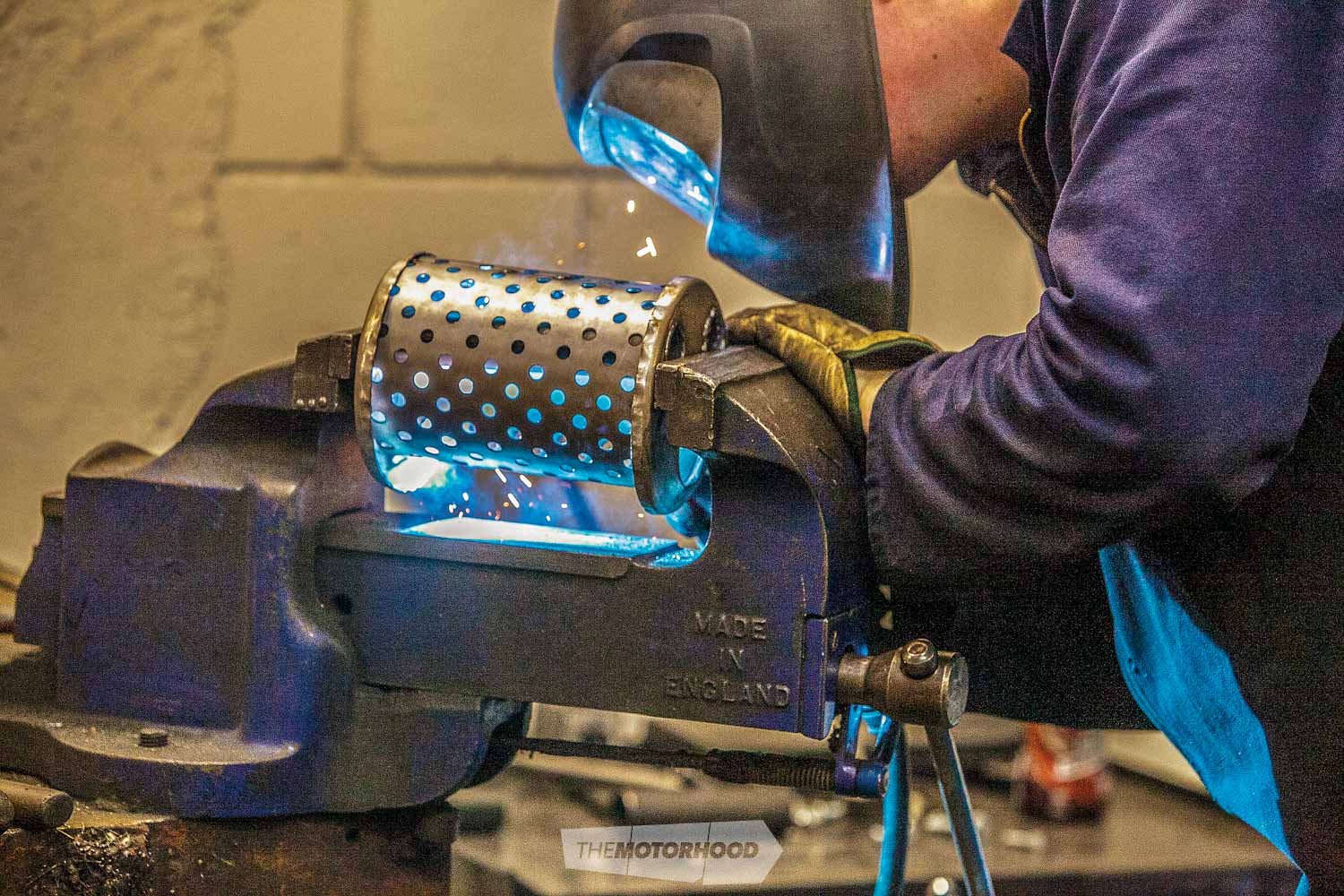

When it comes to the baffle-packed design, there are two main types of baffles, as Brent explains: “Perforated and louvred … perforated has holes in the baffle and acts as a passive gas system, meaning it relies on the pressure of the exhaust gas to push the gas through the holes into the packing. This provides less restriction and more flow for the same diameter, and is regularly used in racing, extreme performance, and high-pressure turbo applications. The perforated design is usually much louder, so considerations need to be made in terms of keeping it within legal limits.

“The second style, a louvered baffle, has a series of flutes protruding into the gas flow which scoops the gas out into the packing and acts as an active system, it actively catches the gas and forces it in the packing.” This will restrict it slightly, but is more suitable for most applications, and allows you to get away with a freeflow system for both good sound and power.

Kita from Manawatu Muffler Centre explained that when it comes to baffle-packed designs: “they will last a lot longer than fibreglass-only packed options, and they also have very little to no fibreglass in them so the muffler itself can absorb a lot of the heat. This is a bonus for removing condensation and moisture buildup from the gas, as glass-packing can act like a sponge and absorb the moisture … moisture and metal don’t go well of course and can rot out the internal structure, compromising your muffler as a whole”. Another design which can be considered is the chamber type muffler, as Kita said: “The chamber type is glass packed at either end with an empty cavity in the centre. They are normally found on older-style vehicles, things like carbureted applications, older straight sixes, V8s, single-cam engines, and those with smaller valve trains. But the design does open the muffler up and won’t restrict the flow as much, so having a chambered or straight-through glass-packed option can remove a lot of that restriction and increase exhaust gas flow — more flow means the ability to generate more power. The downside is that the fibreglass is affected by heat and isn’t ideal for higher-temp applications, such as turbo-back or rotaries.”

As for what kind of noise you can expect from the different designs, there are a number of variables in each engine that will change the sound’s character out of the muffler, and it’ll be affected by different resonators or catalytic converters. Brent said, “Some people simply prefer the sound of the perforated baffle and will put them on everything — it produces a deep, clean sound as it’s not disrupting how the gas travels … at the end of the day we always try achieve what the customer wants, while keeping it within the acceptable decibel level for a warrant. Louvered baffles produce more muffled note, and the spiral design helps to spin the gas, which disrupts the way it travels without disrupting the flow, thus reducing the noise that comes out.

Another thing to think about is the potential effects of your choice of muffler on your overall performance, and how to optimize the flow for the best possible result. Kita says, “Some form of restriction is always to be expected when it comes to mufflers, but it’s so minimal that the performance loss is negligible and doesn’t really factor into it. We’ve had custom built examples dynoed, mainly the race application ones, and there is little to no difference. By having effective internals that cut the reduction, you shouldn’t see much or any difference.”

Brent agreed, and said that when the right system is in place the difference shouldn’t be noticeable. He tells us, “It boils down to the engine in question, some will be optimal with a short pipe off the turbo, while a rotary will want a full taper system that starts off at one size and slowly tapers out — but that is always far too loud to run legally. Likewise drag cars run straight off the headers, allowing more fuel in and less restriction, but again not many places allow this. So you work to get it as close to that optimal point as possible whilst still being legal.”

So how do you go about selecting the right muffler for your application? That’s where it gets a bit trickier. There are hundreds of options available in a variety of sizes, so the first criterion is to select one that will fit the space available, as although a larger body and length may help reduce the noise level while maintaining flow, if it doesn’t fit, it doesn’t fit. After that it’s a matter of thinking hard about what you’re trying to achieve. Are you upgrading to a simple replacement for lazy street driving, or building something from scratch that aims for the best performance possible? This plays into what size pipes you’ll choose, along with the required configuration and tip sizes, etc. Brent said: “If you’re trying to get the ideal V8 muffler, you’ll be looking to use a correctly sized chamber type. Something that will go straight through to the rear chamber, cross over and then go out, which in turn helps with the back pressure that the V8s require. Likewise, a rotary muffler is looking to get the gas out as quick as you can, the less restriction the better, but as they have no valve train to chop up the noise, they can be extremely loud. It’s essentially delivering the direct combustion noise out the exhaust. Running a straight-flow system on a naturally-aspirated rotary, using two torque chamber perforated baffle resonators will produce a clean sound with the perforated baffles. When the gas goes through the chamber it has room to expand, the next pulse hits and that gas creates a small amount of back pressure without restriction, then out of there into a louvered muffler gives best of both worlds, clean sound with the most noise reduction.”

Obviously other things in the system also affect muffler selection, such as a catalytic convertor on newer vehicles. While most people opt to delete these where possible, some may not be able to be deleted without a lot more hassle, so will remain in place. In this instance you have a few choices, and as Kita explained: “Cars are very restrictive by themselves, so they are often deleted and replaced by a resonator to keep noise down. In some instances they are fitted with a second oxygen sensor which is fed to the ECU, and the only way to delete the cat is to turn the sensor off, which isn’t always easy — here we’d recommend upgrading to a high-flow cat instead. It acts similar to a muffler and we’ll treat it as such, knowing that the cat will reduce noise, and the type of muffler used can be based around that. It’s important to decide on what course of action you’ll take with the car before installing a muffler, as the muffler recommendation is going to be different.”

So to wrap up the whirlwind of information, a lot more consideration needs to be paid to your muffler and related componentry than most people realize. The answer on what type, where, how large, and how many all lies within your specific application and how much you’re looking to spend. All in all, consult the people in the know and seek the correct advice when making your selection — you’ll end up with a better result, and even save yourself a bit of coin, too.