data-animation-override>

“The Abbott Racing FD RX-7 is not only one of the best-looking import drag cars in New Zealand; it is also the fastest 13B drag car to ever come out of Australasia”

Brothers Jeremy and Cory Abbott achieved a feat in their 13B-powered FD RX-7 last season that no teams across the ditch have been able to do, even after chasing it like a pack of rabid dogs: we are, of course, talking about a six-second pass with a 13B – 6.96@196mph to be exact. It’s a feat that, only a few seasons ago, seemed too far-fetched to most, even the Abbotts. It’s not something they ever imagined when building the car, and they certainly never set out to be number one; they simply wanted to be competitive bracket racers, but, by keeping their heads down, working hard at perfecting their set-up, and with the help of some of New Zealand’s best, the brothers now find themselves with their names inked permanently into the record books.

Running sixes in one of the country’s best-presented drag cars is a far cry from their early days in the late ’90s, racing at the Mazda Rotary Enthusiasts Club (MREC) drag days when naturally aspirated (NA) motors ruled the roost, and events like the nationals were yet to exist. The import drag scene in New Zealand was about to blow up big time, and the boys would be right there, soon upgrading to turbo 13Bs and then slicks; competition cars; and, eventually, nine-second passes, as Cory recalled: “They were just street cars, and then they progressed to slicks and bigger turbos. We were putting Supra boxes and diffs in my car like they were going out of fashion.” But it wasn’t just broken drivelines that prompted the decision, as Jeremy explained: “When Pro Import kicked off, we had to race with a personal index system that handicapped the slower cars really badly. We were racing the Glen Sucklings and the Ronnie Lims, and all of those people, so we couldn’t really compete. We decided to build new cars. Originally, we were building two — Cory bought this RX-7 and I bought an RX-3 — but, in the end, we decided it would be better to pool our resources, so I sold the RX-3.” Neither brother has regretted joining forces. The investment in both time and money to run a car of this calibre is huge, with both brothers agreeing that it’s the only way they would have got to this point, so this move would have happened sooner or later.

Although they have carried out a lot of the build themselves with the help of mates, Terry Bowden of Terry’s Chassis Shoppe has been an integral part of the process.

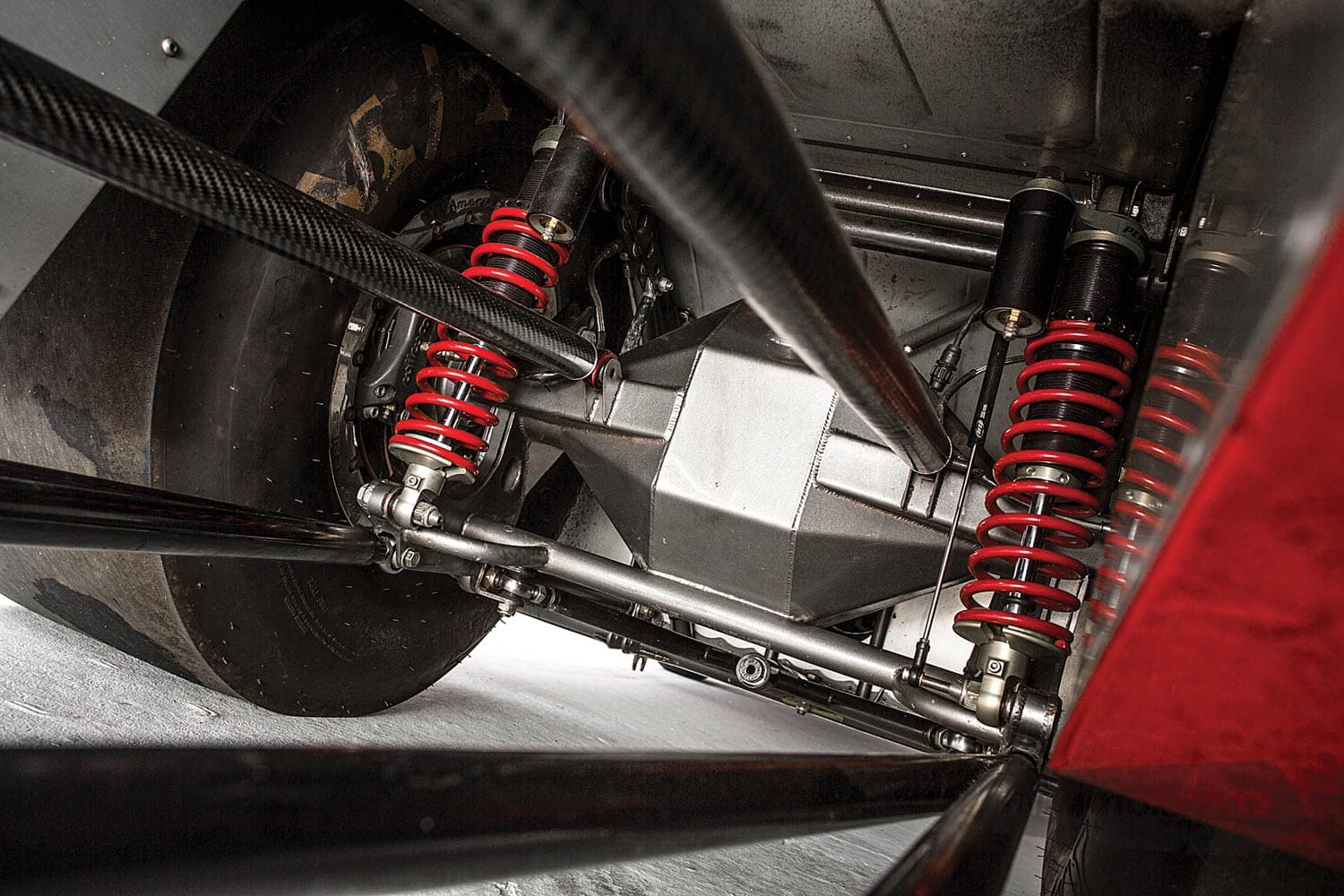

It was 2004 when Cory picked up the FD as a 70,000km uncompliable import. At the time, Rod Harvey and Terry Bowden had just completed the infamous Rayglass Datsun, so the boys paid a visit to Terry. They formulated a plan and jumped on the waiting list. A year later, the FD was dropped in to Terry as a stripped shell with a pair of 15x15s. The plan was to build a decent back-halved car, but as plans do, it soon blew out to the three-quarter chassis. Essentially, it’s a tube-frame car from the firewall back. The problem was, the goal posts were moving fast. The longer the project continued, the quicker the competition was running: “To be a top car, you had to be running an eight. When we booked it in at Terry’s, it was an 8.9; by the end of that season, it was down to an 8.2; by the time the car was completed, we were looking at a high seven. I thought that running a seven would be unbelievable,” Jeremy said.

But just because the boys wanted to run at the pointy end of the field, didn’t mean they wanted to be doing so in a spaceship, compromising the look and feel of the car, even if that meant making things harder for themselves in the long run. From the outset, it was to remain on its stock 95-inch wheelbase, and it was also very important to both brothers that the car remain right-hand drive, even when all the chassis literature available (we are talking thousands of bits of information) are focused on setting up a left-hand-heavy car. Setting up a car with the driver and turbo on the right meant a learning curve for the boys. It is something that has taken a very long time to get correct, and they feel as if they are only now getting on top of it. Having someone like Terry in their corner has helped immensely, teaching them as much as possible, but he has also been open to trying some seemingly out-there stuff — it’s the only way you learn and move forward.

The engine side of things has always been Jeremy’s department, this has been the first methanol engine. Another learning curve, for sure, but one that thankfully hasn’t seen too many destroyed parts — touch wood. “Obviously, it’s been apart a few times. We had a rock go in the motor and stuff a rotor and a housing (good ol’ Meremere gravel) and, obviously, the odd set of apex seals. I put a billet crank in it a few seasons back. But we have been really lucky, and I have managed to not have too many accidents with the tune-up — because it cost me, so I’m really careful. Any little harmonics from any little misfire — you have to have a good tune in it, otherwise you are going to cost yourself bits.”

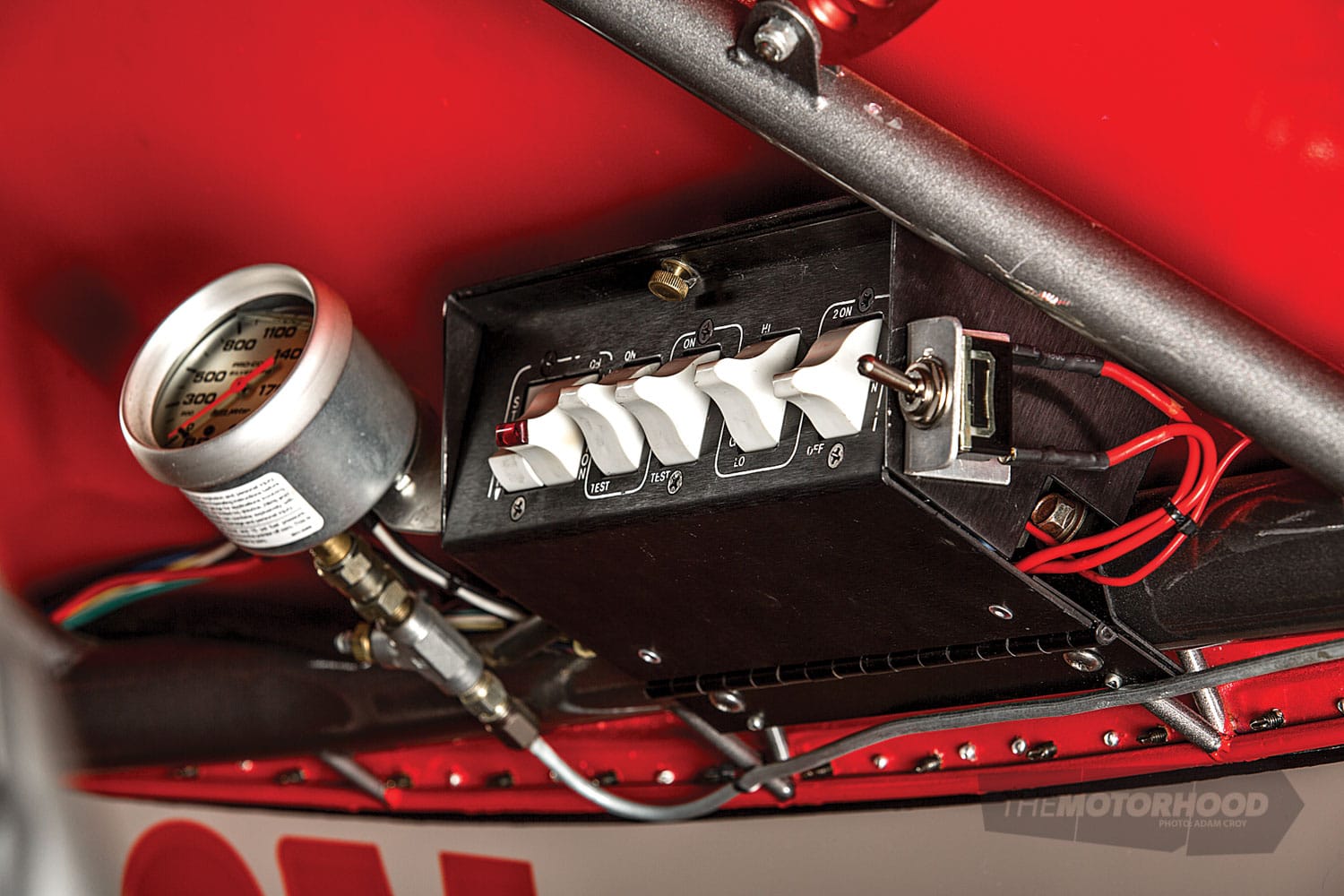

At the moment, boost is at 48psi, and Jeremy is keen to push it into the 50s, although they will do it slowly and at a pace that ensures they are learning what the chassis and tune need to make that kind of psi work. Part of this tuning involves coming to grips with the addition of a RAM slider clutch, which, in itself, is a huge tuning tool. But, as far as upgrades and changes to the set-up go, the clutch has been one of the few made since first building the car.

Although they ran into the sevens right out of the gate, it hasn’t all been smooth sailing, and many will remember the 2013 V 4&Rotary Nationals at which Cory put the car into the left-hand wall, damaging it pretty badly. He recalled, “It was a huge kick in the guts for everyone involved. We had done really well, then we struggled through the middle of that season tune-up–wise, and then we got on top of that and the car went 7.40s ending the season. But then we crashed [during] the second meeting into the following [one].” The entire right-hand side of the RX-7 was damaged, and it would be three seasons before anyone saw the FD return to the track.

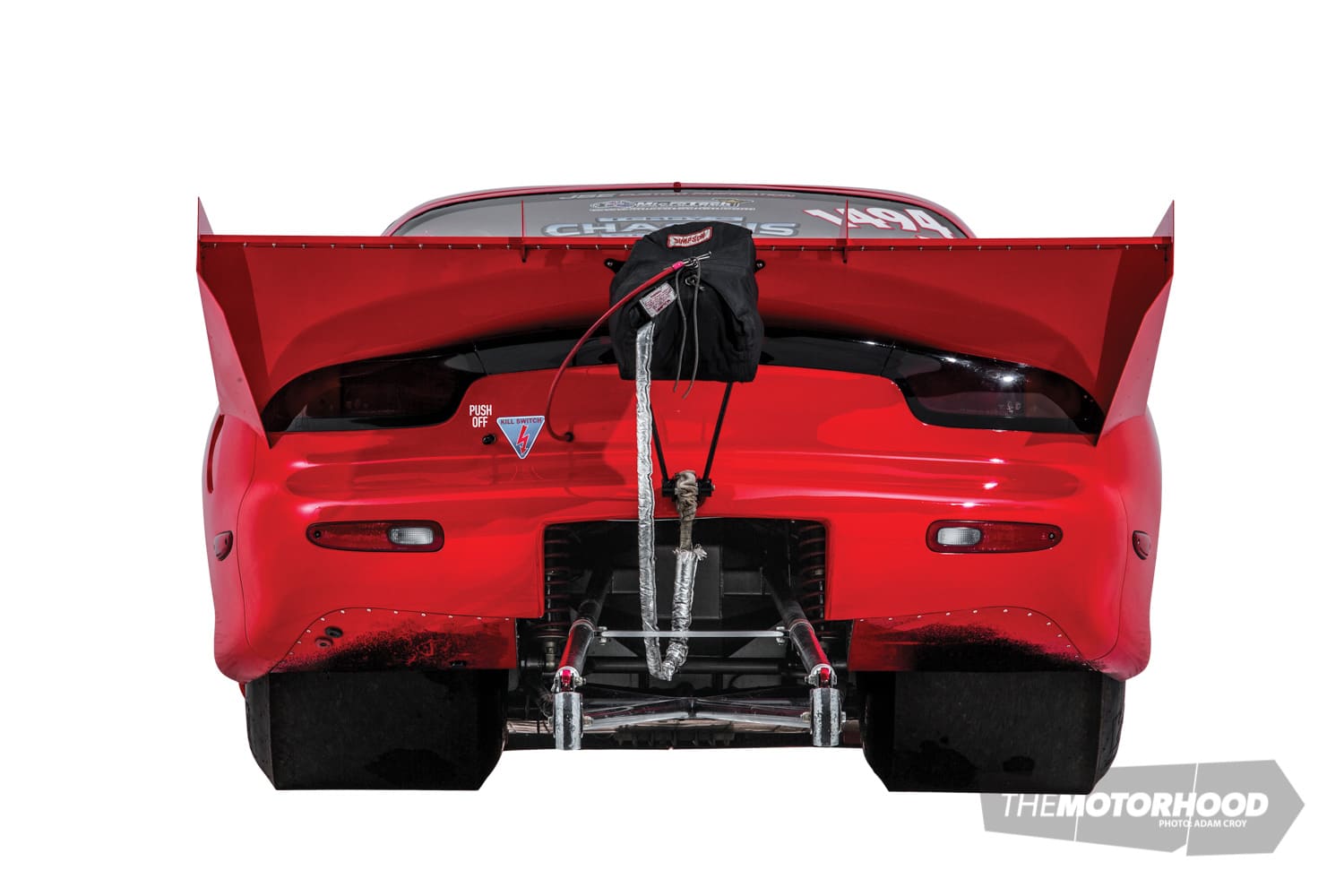

The silver lining was the chance to redo a ton of work, and ending up with a much better car for it. Taking what they had learned since their debut, a lot of weight was shifted around the chassis and also dropped. Over the course of many weekends at Terry’s shop, the boys moulded a one-piece carbon front clip. The rear bumper was also reproduced in carbon, and a set of carbon doors were modified to take the factory rubbers and handles. But, even as they upgraded the body to carbon, they were careful not to take it away from the original aesthetics. All the factory lines remain, as do the cowl panel, park lights, and rear lights. It’s this level of detail, which the boys have put into every aspect of the build, that makes it such a standout car. Doing it their way, using the best parts they could afford, and with help from the likes of Terry, the two brothers have turned the 7.5-bracket racer into the fastest 13B car in Australasia.

As for the future? They will continue doing what they do, chipping away at the set-up and running hard at Meremere. They would like to make it back over to Willowbank — as Cory said, “That place reeks of speed.” And maybe a 200mph pass is in the future, as only 76 people in New Zealand have ever done it, and only two or three 13Bs have managed it worldwide. But this is drag racing — nothing is for certain, and nothing is promised.

Tuning Menu

MAKE AND MODEL: 1993 Mazda FD RX-7

Heart

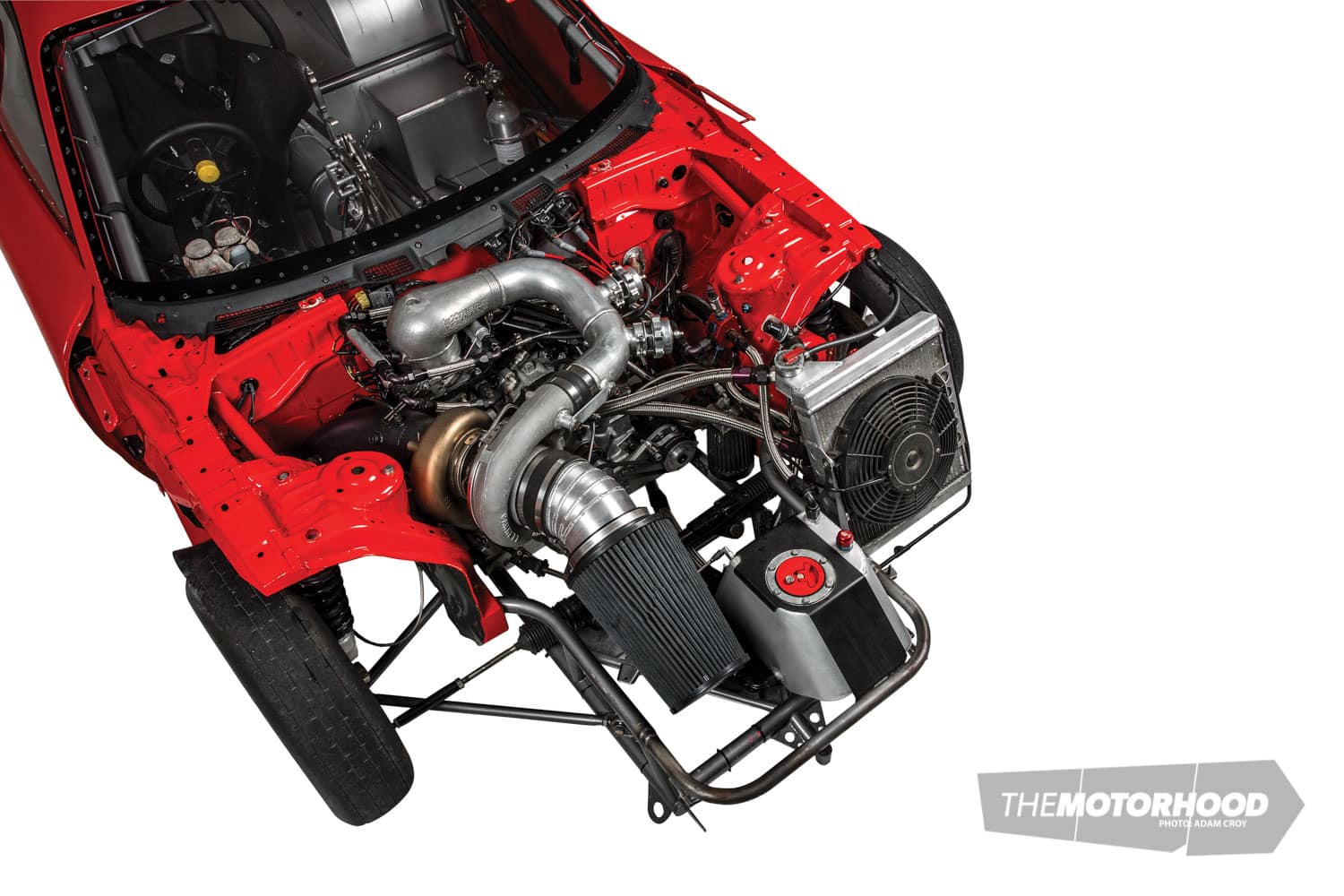

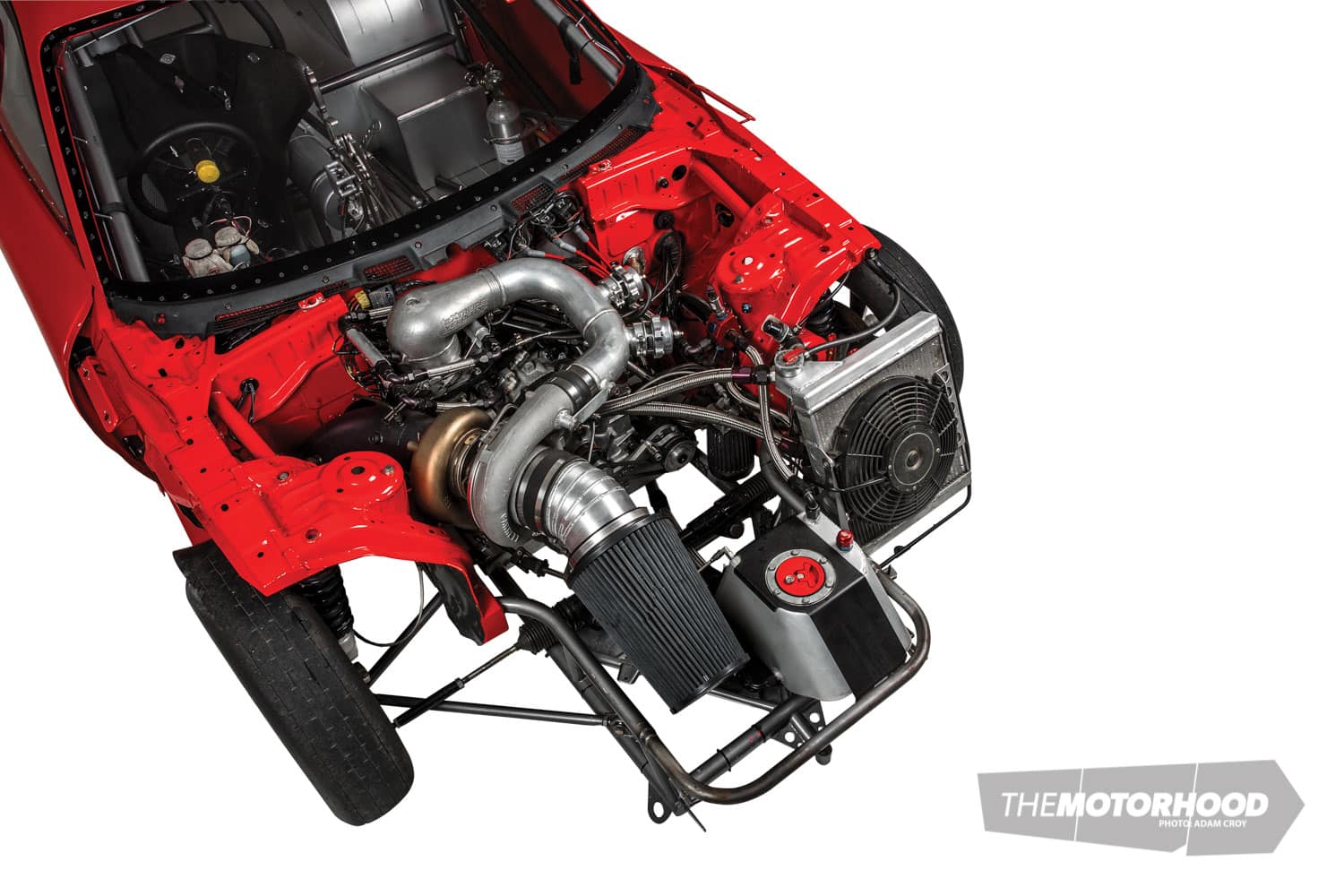

ENGINE: Mazda Cosmo 13B

BLOCK: Bridge-ported plates, semi PP housings, S4 RX-7 rotors, billet eccentric shaft, aftermarket apex seals

INTAKE: Semi PP manifold, four-barrel throttle body, Extreme Velocity alloy intake, large screen filter

EXHAUST: Five-inch stainless dump pipe

TURBO: Garrett GT

WASTEGATE: TiAL

BOV: Dual TiAL

FUEL: 10x 2000cc injectors, Aeromotive mechanical fuel pump, Aeromotive regulator, Bosch 044 lift pump, Speedflow in-line filter

IGNITION: M+W CDI, M&W coils, MSD leads, NGK plugs

ECU: MicroTech LT16C

COOLING: Alloy radiator, electric water pump

EXTRA: Custom alloy sump, custom fuel tank, custom catch tank, remote oil filter, AMS boost controller

Drive

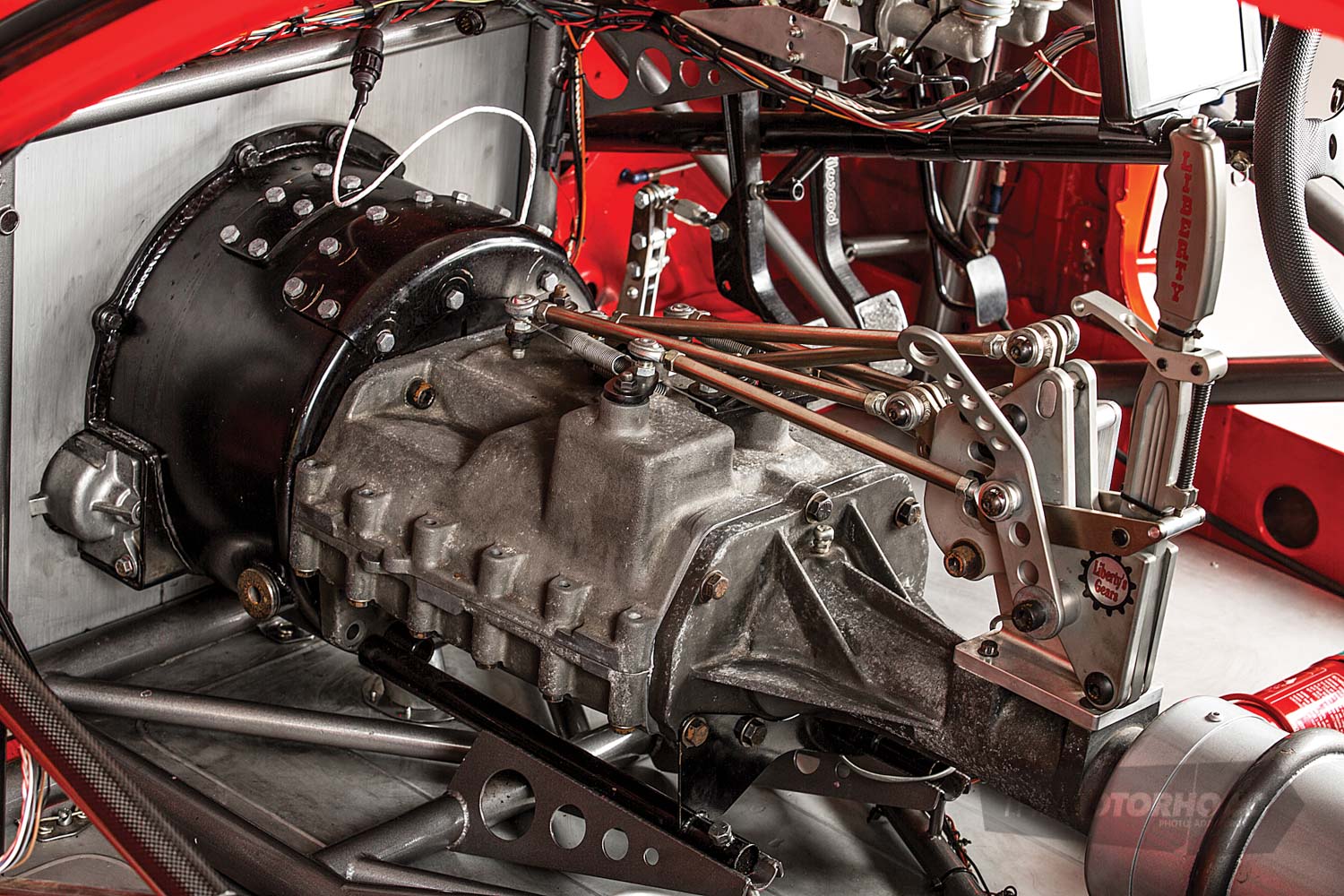

GEARBOX: Liberty five-speed clutchless, custom catch can

CLUTCH: RAM adjustable

FLYWHEEL: Custom

DIFF: Terry’s Chassis Shoppe sheet metal housing, Strange nine-inch diff head (5.19 ratio), Strange chromoly driveshaft

Support

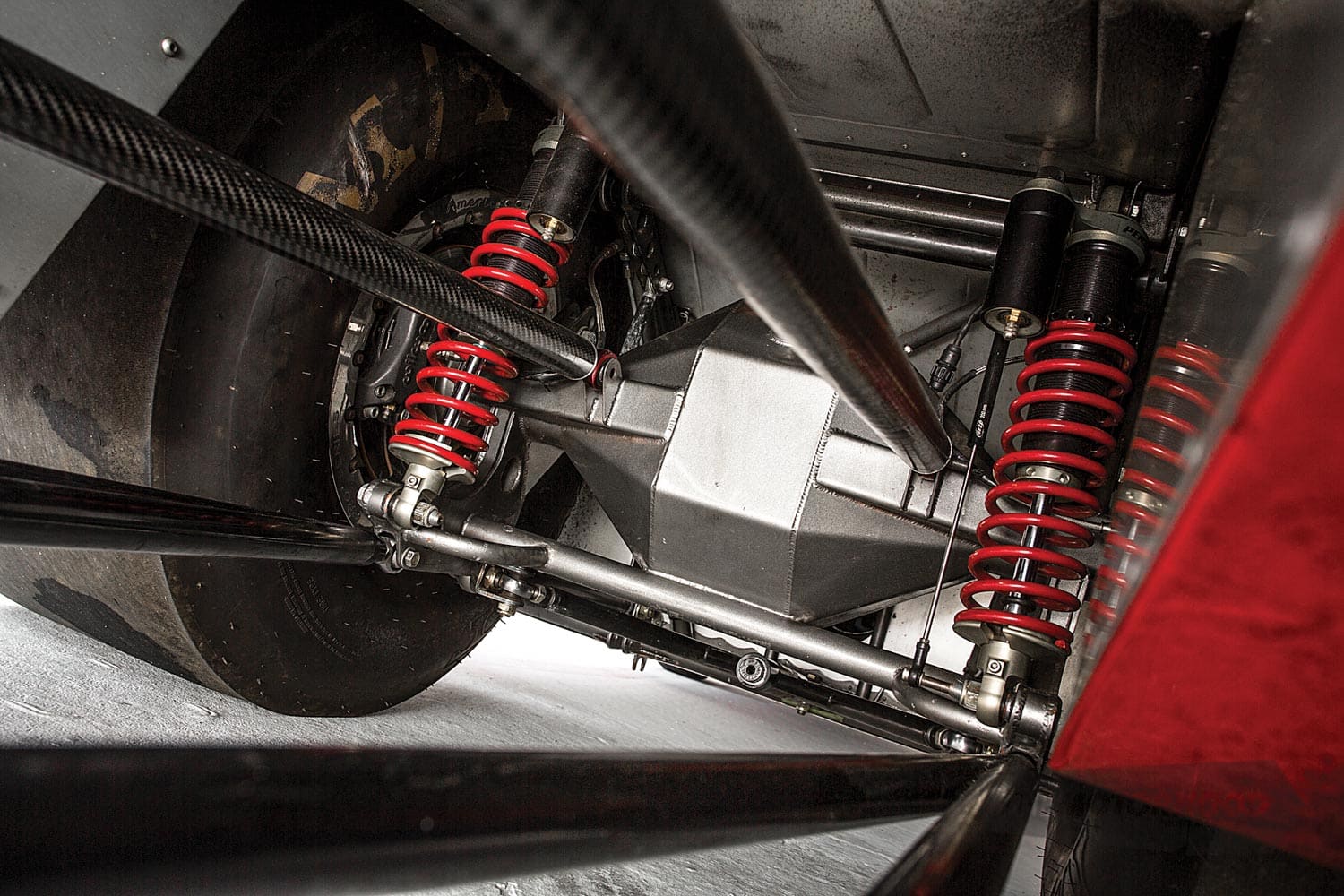

STRUTS: (F) Strange uprights, Hyper Co springs (R) Koni coilovers, Eibach springs

BRAKES: (F) Strange Engineering calipers, Strange slotted rotors (R) Wilwood four-pot calipers, Wilwood rotors

EXTRA: Terry’s Chassis Shoppe SFI 25.1 chromoly ¾ chassis, carbon/chromoly wheelie bars, chromoly suspension arms, chromoly rose joints

Shoes

WHEELS: (F) 15×3.5-inch American Racing (R) 15×15-inch American Racing beadlockers

TYRES: (F) 25×5 Goodyear Front Runners (R) 32×14 Mickey Thompsons

Exterior

PAINT: Mazda red by Gavin at Sulphur Point Car Painters

ENHANCEMENTS: Big doorslammer wing by Terry’s Chassis Shoppe, one-piece carbon-fibre front clip, carbon-fibre doors, carbon-fibre rear bumper

Interior

SEATS: Custom carbon-fibre seat

STEERING WHEEL: Grant

INSTRUMENTATION: PCS Dash Logger

Performance

POWER: Lots

E.T: 6.96 at 195.99mph (315.4kph)

DRIVER PROFILE

Driver/owner: Cory and Jeremy Abbott

Age: 36 and 38

Location: Tauranga

Occupation: Builders

Build time: Five years

Length of ownership: 10 years

Thanks: Terry’s Chassis Shoppe, JSE Engineering, MicroTech EFI, Dynopower, Green Brothers. The crew — Arni, Jason, Gump, Matt and Kane.