data-animation-override>

“Mixing old-school styling with modern technology can make for a hell of an on-track marriage”

There is nothing quite as appealing as vintage racing tin. It has a certain romance about it, the shapes, the noises, the smells — they all add to, and deliver a wider appeal than anything modern. Better yet, from a racer’s point of view, many of the headaches and compromises that are made to run an older machine can now be erased with the help of a little modern technology. The result can be a marriage made in heaven, if you have a clever tuner behind the project.

For keen racer Layton Hammond, that dream partnership became a reality the day his daughter brought home her new partner. Now, for some dads, that guy will never be the man he dreams of for his daughter, and to-be-fair they often fall well below par. But the day Louise brought Chris Wall home was different — though, at the time, Layton probably didn’t fathom quite what it would mean for his well-used Escort circuit car.

When Chris came on to the scene, the Escort was in need of some love, and the old rally car was showing its age. Originally built and campaigned by the Hartleys, it ran a highly strung and stroked 1710cc Kent four-banger with overhead-cam conversion. It was a stout little engine package for sure, but the old tech had its downsides. It required a rebuild every season; the block was on its last oversize; the super-exotic pistons were hard to come by; and, no matter who rebuilt it, the damn thing just wouldn’t stop dripping oil. “We wanted to move to a modern engine, so I started doing some research on the Duratecs, as they are really popular in the UK. We picked up a complete 40,000km engine for $400 off Trade Me,” Chris told us. He then set about building up the 2.0-litre using a succession of custom-spec parts to suit the rev range and power output he was after. But Chris found that the UK-based stuff was based on engines that were built to rev, with little-to-no torque. So, he engineered everything to bring the power on lower in the rev range and introduce some more torque.

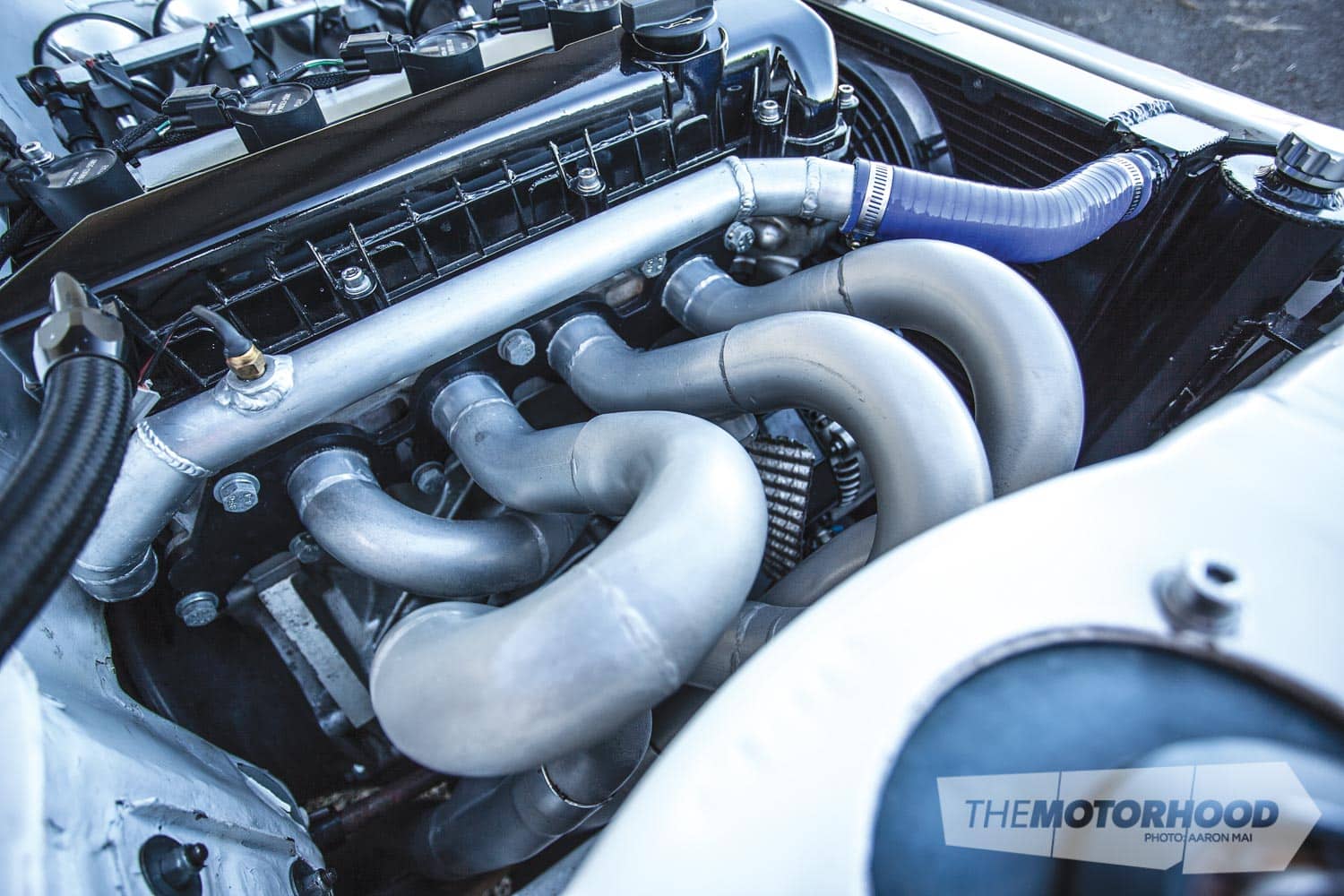

Custom Wiseco pistons and K1 Tech rods brought compression up to 12.5:1, while the head received a good dose of porting, modified combustion chambers, and a five-angle seat job. “I had the head flowed and then sent Kelford all the info to build a custom set of cams,” said Chris. The last piece of the power-delivery equation was a set of headers to suit. Again, anything found off the shelf was suited for top-end power, so Chris put together his own-design four-into-two-into-one stepped headers and then a stepped exhaust.

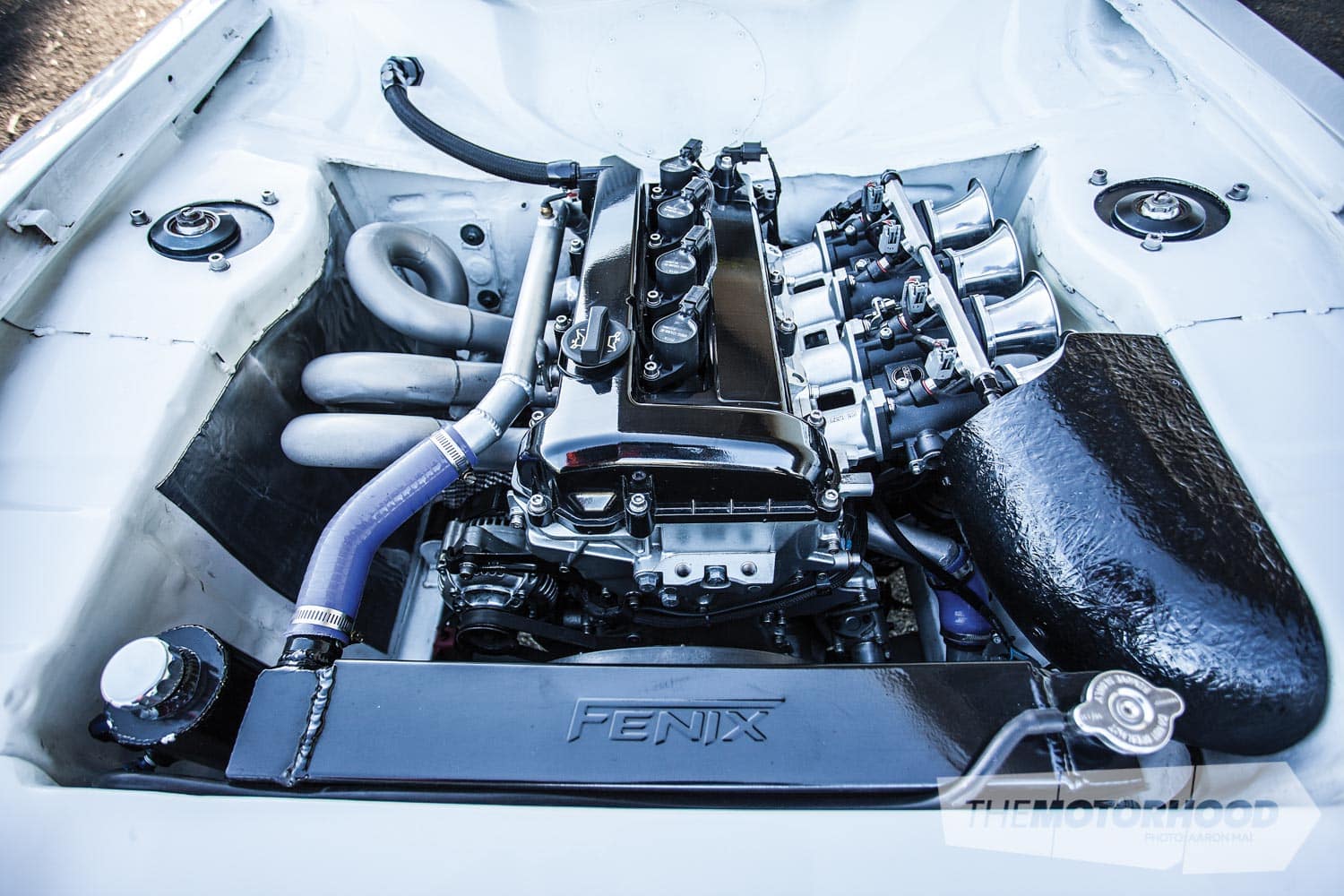

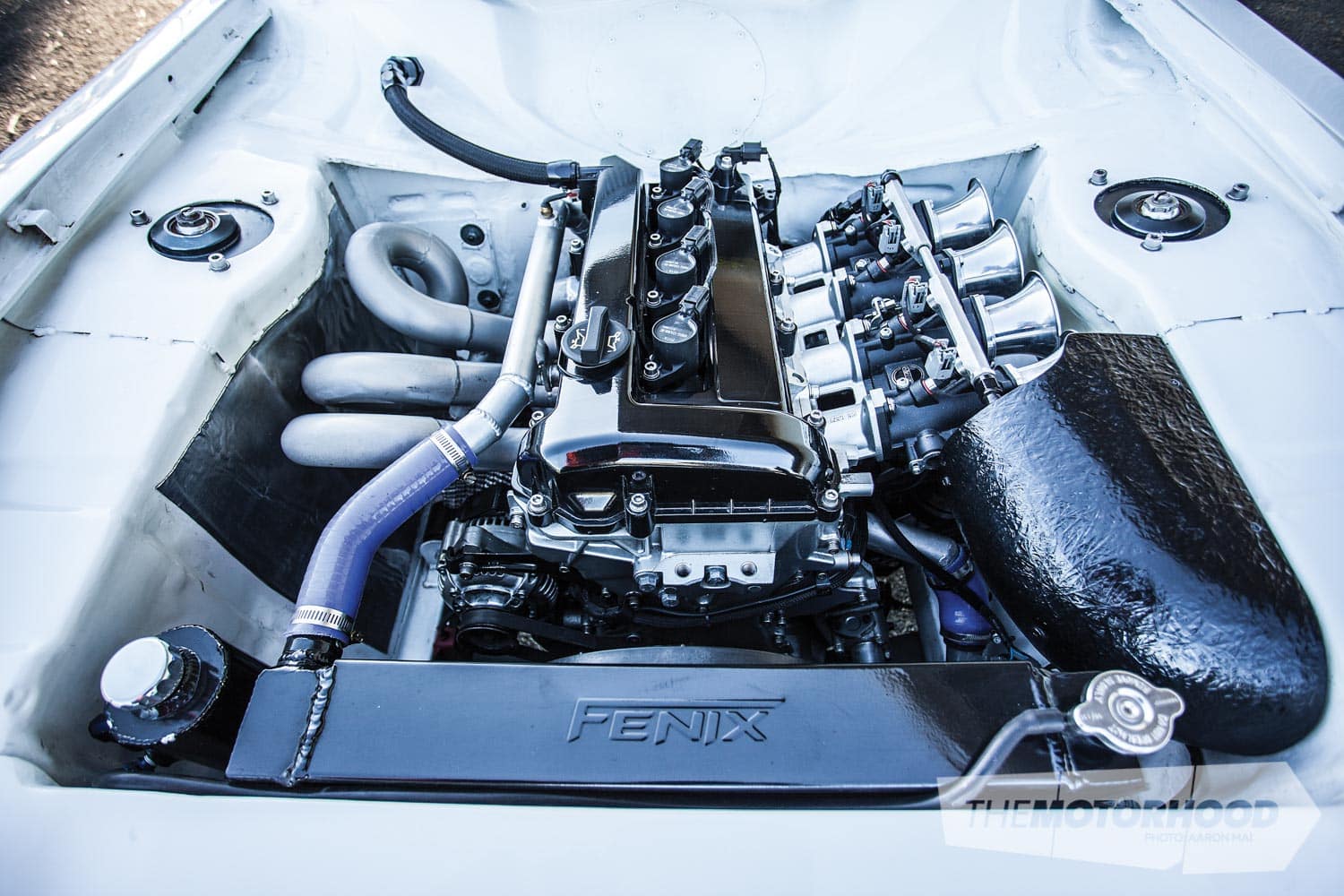

Originally, the engine was going to run twin side-draughts, as per the class rules in Classic Cup, although a change to those rules meant electronic fuel injection (EFI) was welcomed onboard. A set of Jenvey 48mm quad throttle bodies with 60mm bellmouths is controlled not by cable but electronics — Chris adapted a BMW electronic throttle and a Commodore pedal. From a tuner’s point of view, it was a no-brainer, as Chris explained: “Now, I’m able to tune the throttle to suit the conditions. If it’s wet, I can give the car a much less linear power curve to help get out of corners.” It’s this type of modern racing with data logging that is changing the game for these old machines. There are also a few other tricks Chris has wired in, such as traction control, although he is yet to get if fully dialed before it can be useful. On the dyno, the set-up eclipsed the power goal of 171kW (230hp), laying down 179kW (241hp) to the rear wheels at 8500rpm, which is around 52kW (70hp) more than the old Kent set-up, although they aren’t stopping at the status quo. “There is plenty more in it,” said Chris. “We could easily push it to around 193kW [259hp] with some different-spec cams and a bit more porting. It also still has the stock valves.”

But, as we all know, circuit racing is more than just putting down big dyno figures. After the engine build was completed, the next area of focus became the suspension. It was still running the rally stuff from its early days, so spring rates were well outside the optimal window, and the shocks were too long and in desperate need of a rebuild. The coilovers took a trip to Auckland, where Chris from Suspension Tech dyno’d, rebuilt, re-valved, re-sprung, and also modified the spring perches to suit the new ride height. Back in Wellington, Chris reworked the rest: “I dropped the roll centre and added camber arms and a separate sway bar and castor arm set-up in the front so that I can adjust the sway bar to suit the track.” First time out on the new suspension, Layton dropped a full second off his Manfeild PB straight out of the gate, and there are still more adjustments Chris will make to get the Escort even more hooked up than it already is.

The other big area of change was in rewriting all those wrongs that come with panel beating a rally car. Zac from Carboglass took charge and removed all the bog that had found its way onto the repairs-on-top-of-repairs. The front end had been converted to a removable one with questionable brackets, so that was also reversed, and the hundreds of excess holes that had been drilled over time were welded up, before a fresh coat of white was applied. Zac also took care of a new set of flares to fit the wheels and a few other fibreglass components to drop some weight.

The complete transformation was nothing short of extensive and, at the same time rapid — the entire rebuild took place inside a six-month window between the summer and winter race seasons. All the time Chris spent on the car came outside normal day-job hours, which meant many late nights and long weekends, helped along by his flatmate, Jason from Kaizen Works. “In the last month leading up to the first meeting, I was working eight to five then starting on the Escort and working till 10 most nights. Then, on the weekend, I would start at eight and work through till 10 that night. In the last week before the meeting, it was one or two in the morning,” he told us. But the car made it on time to the first race without a moment to spare, even after a 2am drill-versus-braided-line incident we won’t mention.

That weekend, Layton took two of the three race wins, and set himself up to go on and take another season championship, making it three in a row.

It’s a marriage made in heaven — the car, that is … With a little old-school from the outside and plenty of new-school tech lurking beneath the guards, it’s hard to beat on a bad day and impossible on a good.

Tuning Menu

MAKE AND MODEL: 1973 Ford Escort (MkI)

Heart

ENGINE: Ford Duratec, 2000cc, four-cylinder

BLOCK: Wiseco forged pistons (12.4:1), K1 Tech H-beam rods, ARP main studs, ARP head studs, modified steel crank, custom mechanical chain tensioner, lightened crank pulley

HEAD: Custom-ground Kelford cams, Supertech dual valve springs, enlarged and flowed intake and exhaust ports, five-angle seat cut, modified combustion chamber

INTAKE: Modified Jenvey 48mm individual throttle bodies, electronic throttle, ported Jenvey intake manifold, 60mm trumpets, cold-air ducting

EXHAUST: Custom 4-2-1 stepped headers (1¾-inch to 1⅞-inch primaries), 2.25-inch to three-inch exhaust, Coby muffler

FUEL: 30-litre Jaz fuel cell, Walbro 373kW/500hp pump, Aeromotive fuel filter, -8 braided feed line, -6 braided return line, Sard FRP, 500cc injectors

IGNITION: Factory COP, NGK R5671A-8 racing plugs

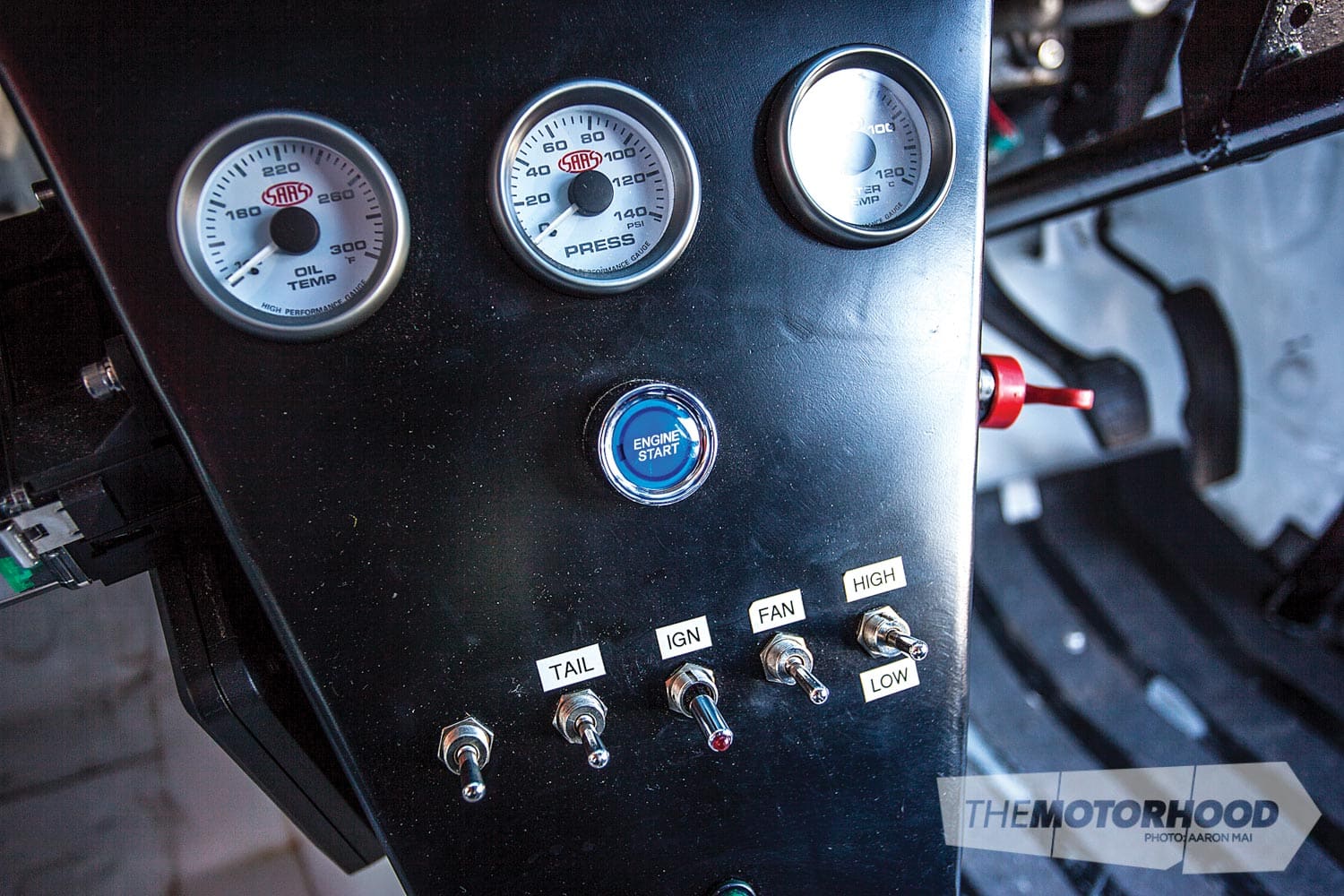

ECU: Link G4+ Fury with modified inputs for oil pressure, oil temp, fuel pressure and fuel temp compensations, wheel-speed inputs for traction control and electronic throttle control

COOLING: Modified Fenix radiator, Fenix oil cooler, Davies Craig electric water pump, custom water rails, Flextech radiator hoses

EXTRA: Pace three-stage dry-sump system, Peterson crankcase vacuum regulator, deloomed engine bay, custom overflow bottle, FRP intake duct

Drive

GEARBOX: Mazda MX-5 five-speed

CLUTCH: UltraRev single-plate HD clutch

FLYWHEEL: UltraRev lightened steel

DIFF: Shortened Toyota F Series, Toyota Altezza Torsen LSD, 4.3 ratio

Support

STRUTS: Modified and revalved Ford Motor Company adjustable Bilstein racing shocks, (F) 400lb King Spring, (R) 200lb King Spring

BRAKES: High-mounted pedal box (F) MRP 285mm vented rotors, Wilwood four-pot calipers, Ferodo DS3000 pads (R) 260mm Peugeot 405 rotors, U13 Bluebird calipers, EBC Yellow Stuff pads, custom brackets, hydraulic lock valve for handbrake

EXTRA: Burton Power adjustable camber arms, Burton Power adjustable caster mounts, modified and lowered steering knuckles and rack, custom 24mm front sway bar, eccentric camber plates, parallel four-link, custom panhard, six-point roll cage, custom gearbox tunnel, strengthened and gusseted chassis rails, seam-welded chassis

Shoes

WHEELS: 15×7-inch FR Design Minilite-style

TYRES: 205/50R15 Yokohama Advan A048

Exterior

PAINT: Ice white by Zac at Carboglass

ENHANCEMENTS: Satin-black roll cage, custom-work group 4 rally style front grille, Carboglass custom FRP flares, Carboglass FRP bonnet, Carboglass FRP boot, Lexan side and rear windows

Interior

SEATS: (F) Racetech (R) Factory as per classic-class rules

STEERING WHEEL: Personal

INSTRUMENTATION: Saas oil temp, Saas water temp, Saas oil pressure, Auto Meter tacho, MoTeC shift light

Performance

POWER: 180kW (241hp) at 8500rpm, 258Nm

CIRCUIT TIMES: Manfield 1:18.9, Taupo 1:45.8

Driver Profile

Driver/owner: Layton Hammond

Age: 63

Location: Marton

Occupation: Agricultural sprayer

Build time: Seven months

Length of ownership: Nine years

Thanks: Chris Wall at Dtech (formally STM) and Jason Foote at Kaizen Works for designing and building the car, my daughter Louise for keeping the boys fed, Zac at Carboglass, Paul, Corey and the boys at Bridgestone Wainui, Reuben at Fenix Radiators Wellington, Link ECU, Pete Zivkovic and Zedtech for the headwork, Watermark signs for the graphics, Michael Keen for the trips north, Adam Hedges, Jamie Ross, Shayne Freeman, Andre Simon, and finally my wife Vena for all the support and ‘sponsorship’ during the build