data-animation-override>

“I wanted to make it my own, so it isn’t known as someone else’s car”

Graeme Smyth is probably better known to most readers for podium snatching in his S15 drift car in the Demon Energy D1NZ series (NZPC Issue No. 199) or pedalling one of the Trass Family Motorsport Ferraris, but it’s what he’s been up to in the workshop that’s really caught our interest.

A staunch competitor in the SS2000 class, Graeme and his dad, Kerry, were looking to retire their well-used Series 1 RX-7 in favour of something that had more parts readily available than does the ageing chassis. This hunt turned up an ex-GT2 FD RX-7 that had only ever seen four race meetings before being stripped down and listed for sale. Recognizing its potential, and wanting to stick with the RX-7 family, the rolling body was purchased.

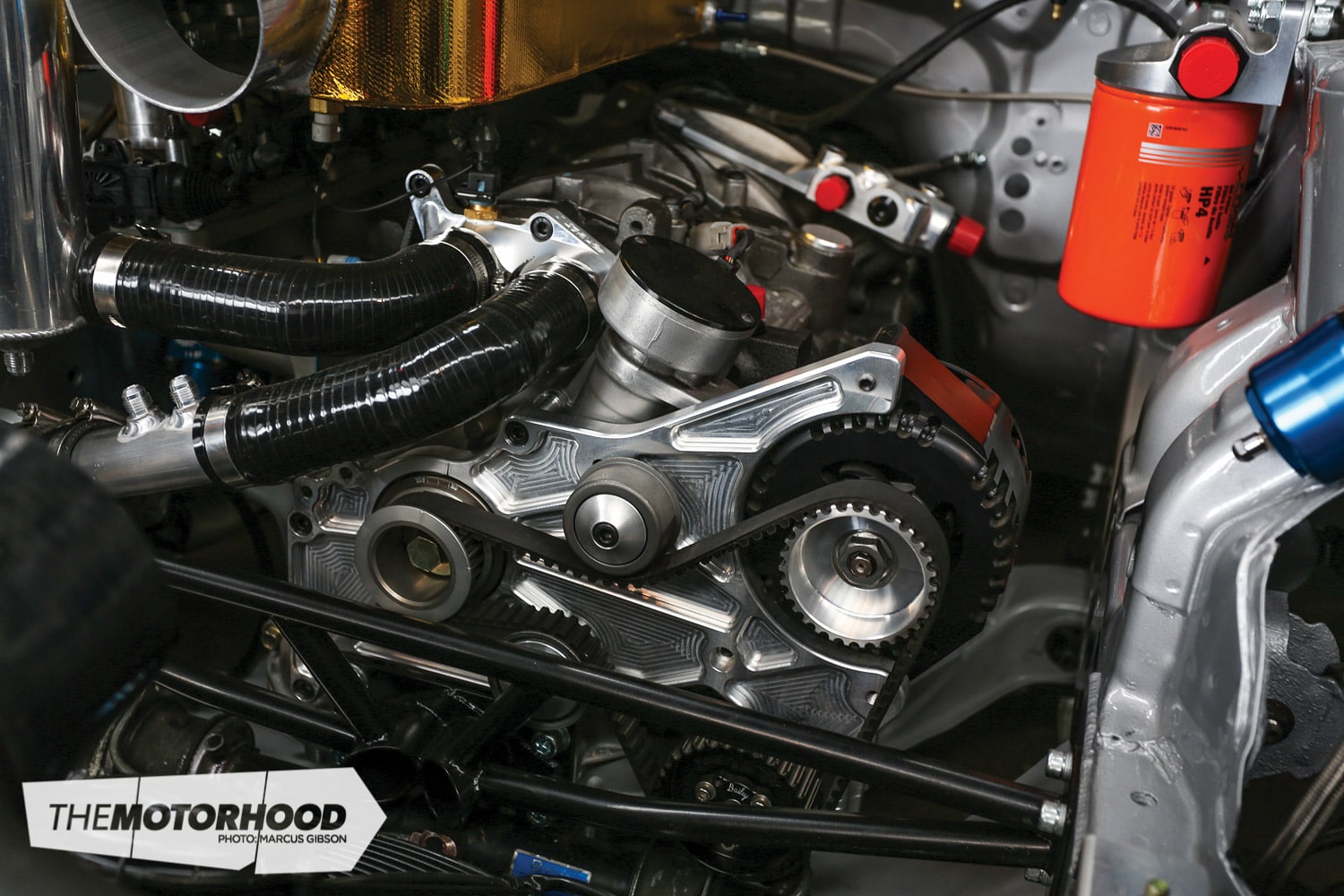

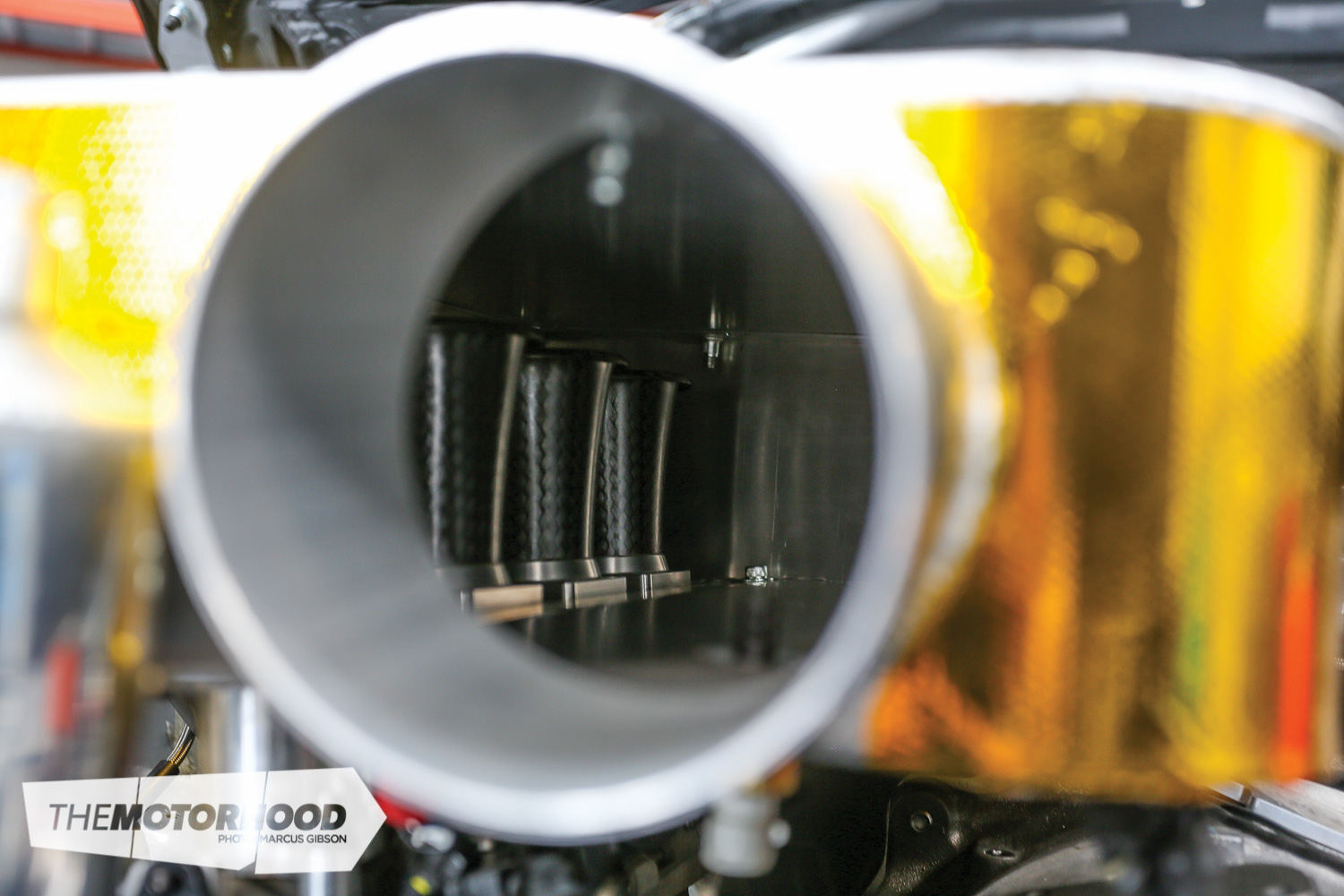

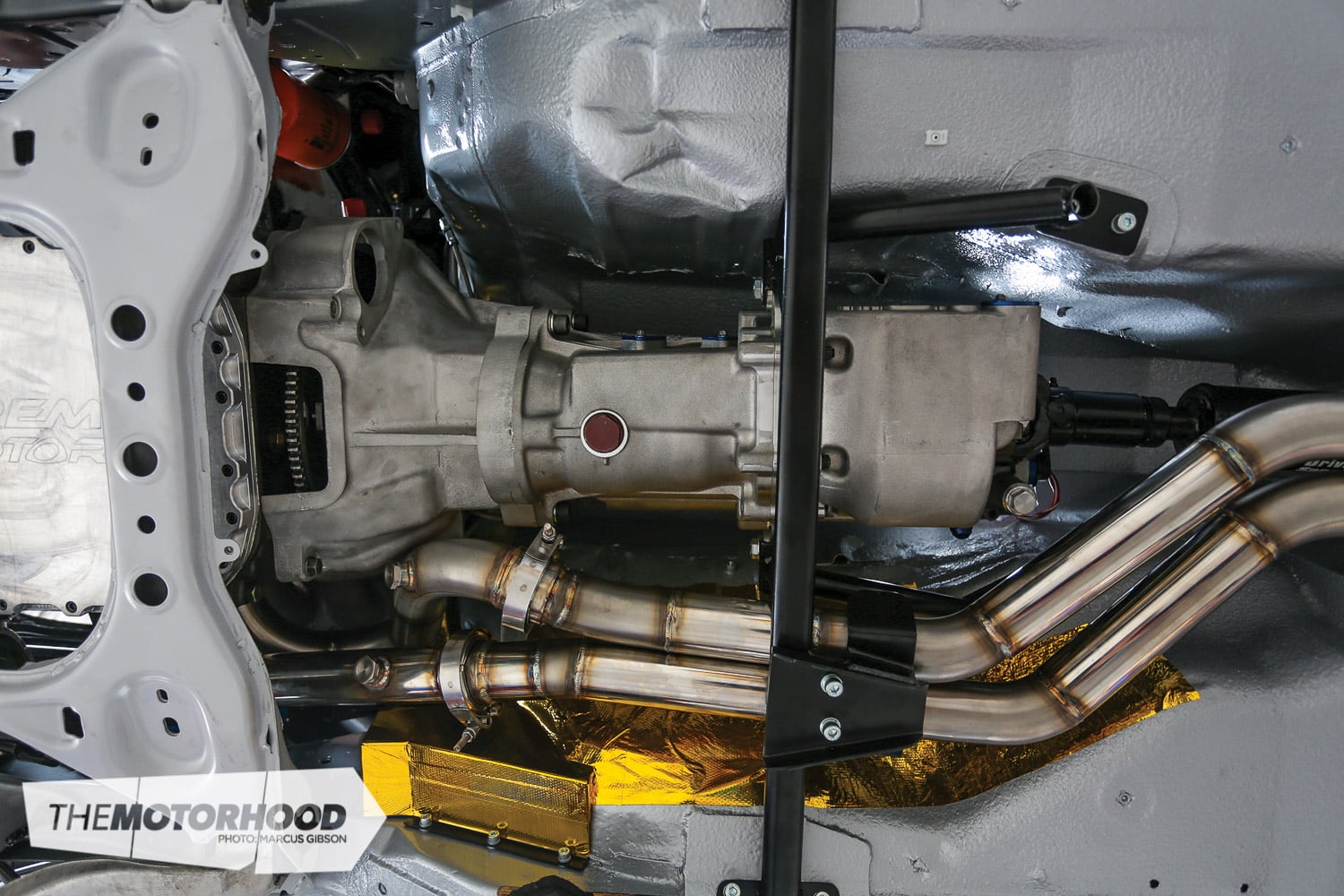

In went the Xtreme Rotaries dry-sumped 13B bridgeport–and–six-speed Modena dogbox package that had once been destined for the first-generation chassis. Already proven to make 275kW (369hp) on the engine dyno, the quad throttle bodies with carbon-fibre trumpets aren’t the only hint that this beast has some serious bite to it.

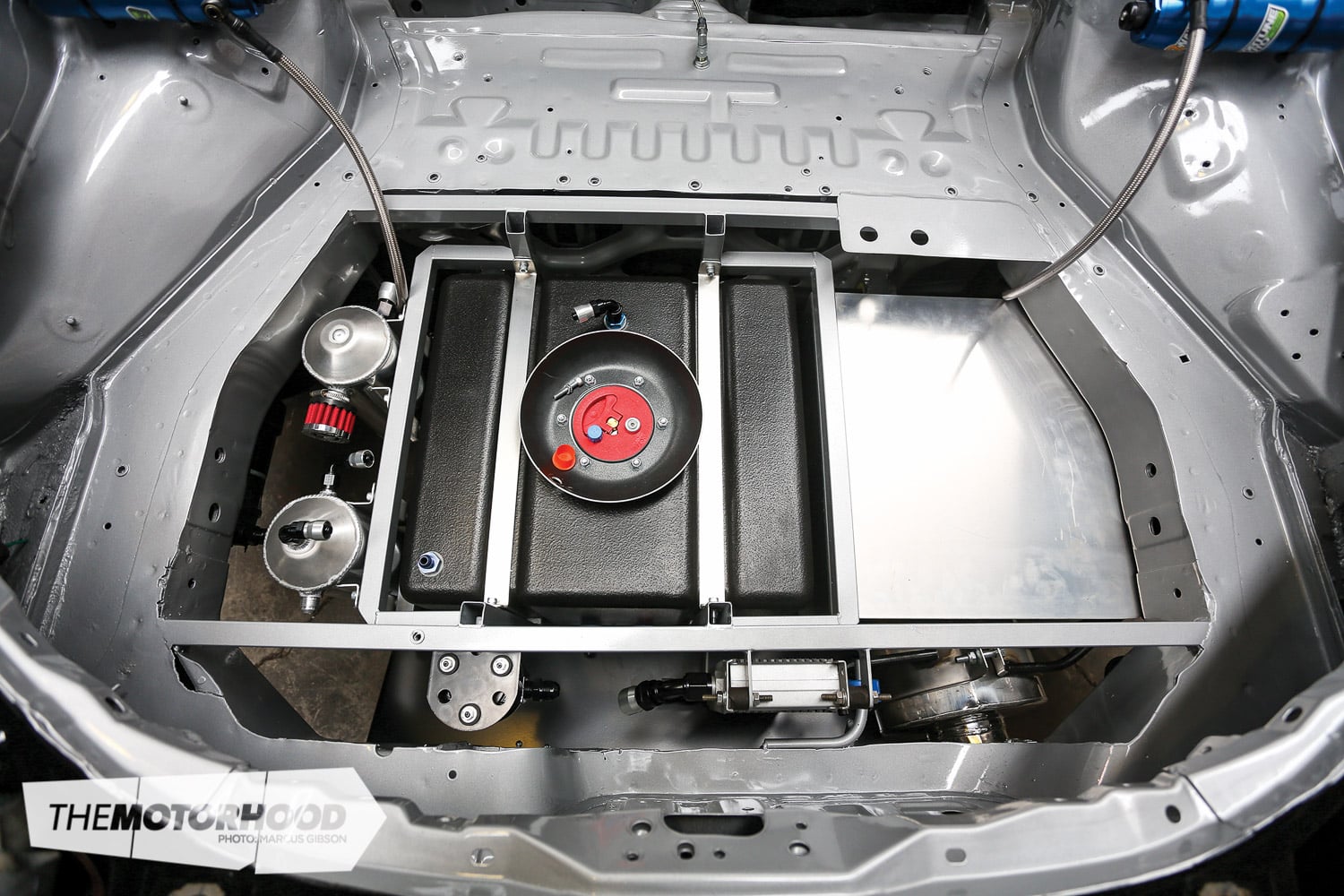

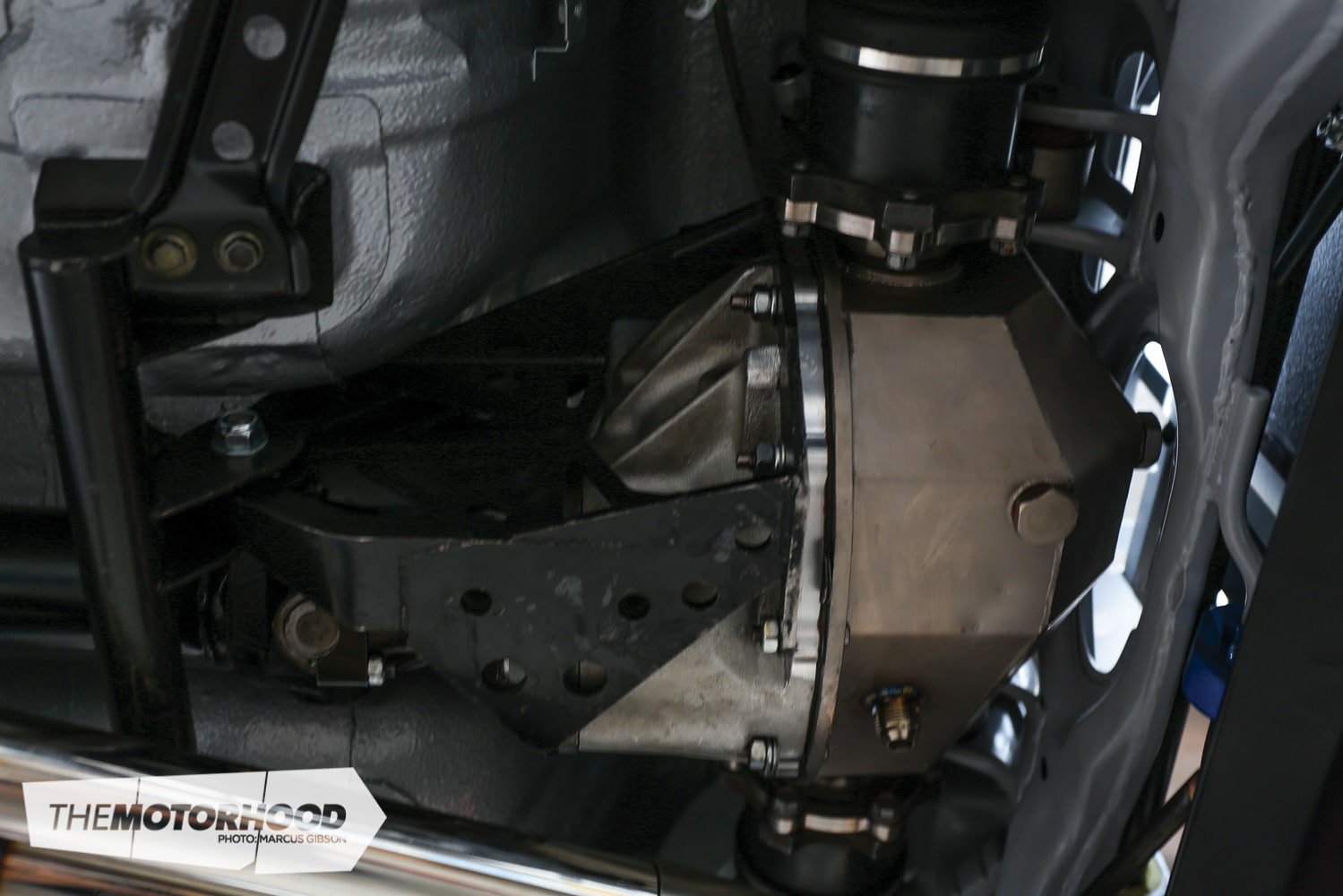

Graeme, who runs SMS Fabrication, has put his skills to good use, spending endless hours doing top-notch engineering work for the car — most notably on the in-car adjustable hydraulic sway-bar system. Controlled by two levers mounted on the tunnel, by rotating the blade-type end from dead flat to upright, the eight-point adjustment changes how soft or stiff each bar is. The hydraulic system is more commonly found in the likes of V8 supercars and isn’t hard to find over the ditch, but it’s yet to fully make the leap over to our shores.

To keep the cooling under control, an intake duct from a VE Commodore feeds air straight into the custom cooler box that looks after the four carbon-fibre trumpets. The aim was to duct as much air through the radiator as possible to keep the temperatures down in the 13B, “It’s a rotary thing,” Graeme explained. “They all run hot, so you have to use all the cold air you can get.” The rest of the air that goes through the bumper gets split off to Graeme’s own set-up of oil coolers, gearbox cooler, exhaust air feed, and down to the AP Racing six-pot front calipers.

A bit of a spare-time project, Graeme is happy to have something to tinker with and make his own. Admittedly, there is not much time left over on the weekends between his racing commitments and work, but the talented wheel man looks forward to pedalling a car he’s built himself — something for fun, a toy but one that’s still serious enough to be competitive. For now, he plans to run the car for a couple of seasons and get it dialled in. He’s even told us that, a few years down the road, it might get a birthday present in the form of a 20B turbo — maybe.

This article originally featured in NZ Performance Car Issue No. 233. You can pick up a print copy or a digital copy of the magazine below: