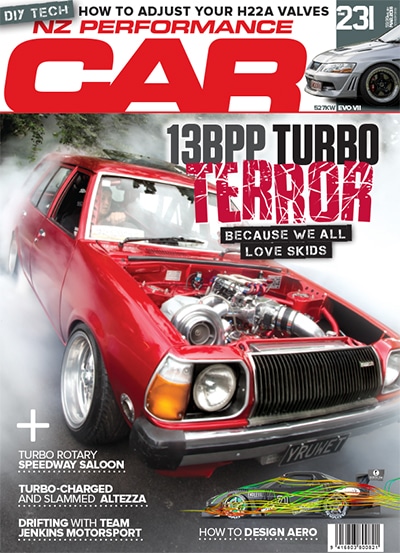

“After scoring it for cheap when he was 17, Cody Martin’s 323 was never meant to end up like this — but, six years on, you are staring at one angry little Mazda”

Each and every country’s car scene has its own little defining characteristics that make it instantly recognizable to outsiders. Take the Scandinavians with their insane engine swaps, Thailand with its wild street attack style front-wheel drives, Great Britain’s amazing fitment and interiors, and the Aussies’ show-spec burnout cars. What about New Zealand? Well, one thing we do really well is engine bays — in particular, those containing rotary engines. They’ve always been something that we’ve done exceptionally well, so it’s no surprise that the younger generation coming through the ranks is now carrying on that tradition.

One of those guys is Cody Martin, a West Aucklander who grew up surrounded by hot rods and V8s. But it was rotary engine bays that saw him veer down a different path — or, into the ‘dark side’, if you ask his family. He’s built a life devoted to building Mazda rotaries and made damn sure that his own engine bay was where he put in the most effort.

It was back in 2009, at the young age of 17, when Cody picked up his 1985 323 wagon for little more than a song and dance, as he explained to NZPC: “It was listed for $8K, but the price kept going down and down; I eventually got it for $4K. It wasn’t running, but, after getting it home that night, we got it fired.” For a young 17-year-old, the flat-front high-roof wagon might not have been the most desirable model 323 on the market, but it was the right price, and Cody was soon out there disturbing the peace with the 12A bridgeport.

Little did he know that, six years on, it would still be in his possession, albeit in a wildly different guise, and that that initial $4K investment would turn out to be little more than a small drop in a very large bucket. But, as you will have learned from reading NZPC, most projects start out with a few minor upgrades, and they get the ball rolling — for Cody, that ball hasn’t stopped rolling since 2009.

It wasn’t long before he began transforming the car. On went a bug-eye nose cone from an earlier-model 323, and out came the back seat in favour of a half cage. Then, a year later, a deal was struck to swap his 12A for a 13B turbo block.

It was at this point that the engine bay really started its transformation, with the addition of items like a custom plenum and custom stainless water pipes. For the young rota-head, the swap to the 13B-bridgeport turbo, marked the start of the steep learning curve that all home builders go through, learning each and every step of how to do things along the way. Jobs like wiring in the ECU were a first-time experience, and Cody told us that, looking back at it, it was probably one of the worst parts of the car to tackle. But, hey, you have to start somewhere, right?

Little is now left of that original 13B conversion, as the 323’s constant state of evolution has seen the car changing on almost a monthly basis. In fact, we shot it around four years ago for a feature, but, as Cody was continually upgrading stuff, it had changed so much so fast that, when we went to run the feature, we decided we had to hold off running it until a time when he considered it finished. And, ladies and gentlemen, that point is now! Gone are the MicroTech ECU, bridgeport block, half cage, Wilwood swing-mount pedal box, first paint job, and a swag of other components, and, in their place, you will find a mouth-watering combination.

A full roll cage now extends to the front struts and dominates the interior, alongside some trick tinwork covering the new four-link rear end and shortened Hilux LSD. The rear inner tubs were also widened to allow 10-inch-wide wheels at a very Kiwi ride height. The Sparco Evo seat was set back as low as possible to allow for a floor-mount Wilwood pedal box. Yes, you may have noticed the passenger seat was missing at the time of the shoot — don’t worry, it’s on Cody’s to-buy list, having to set priorities being something anyone building a car on a budget can relate to.

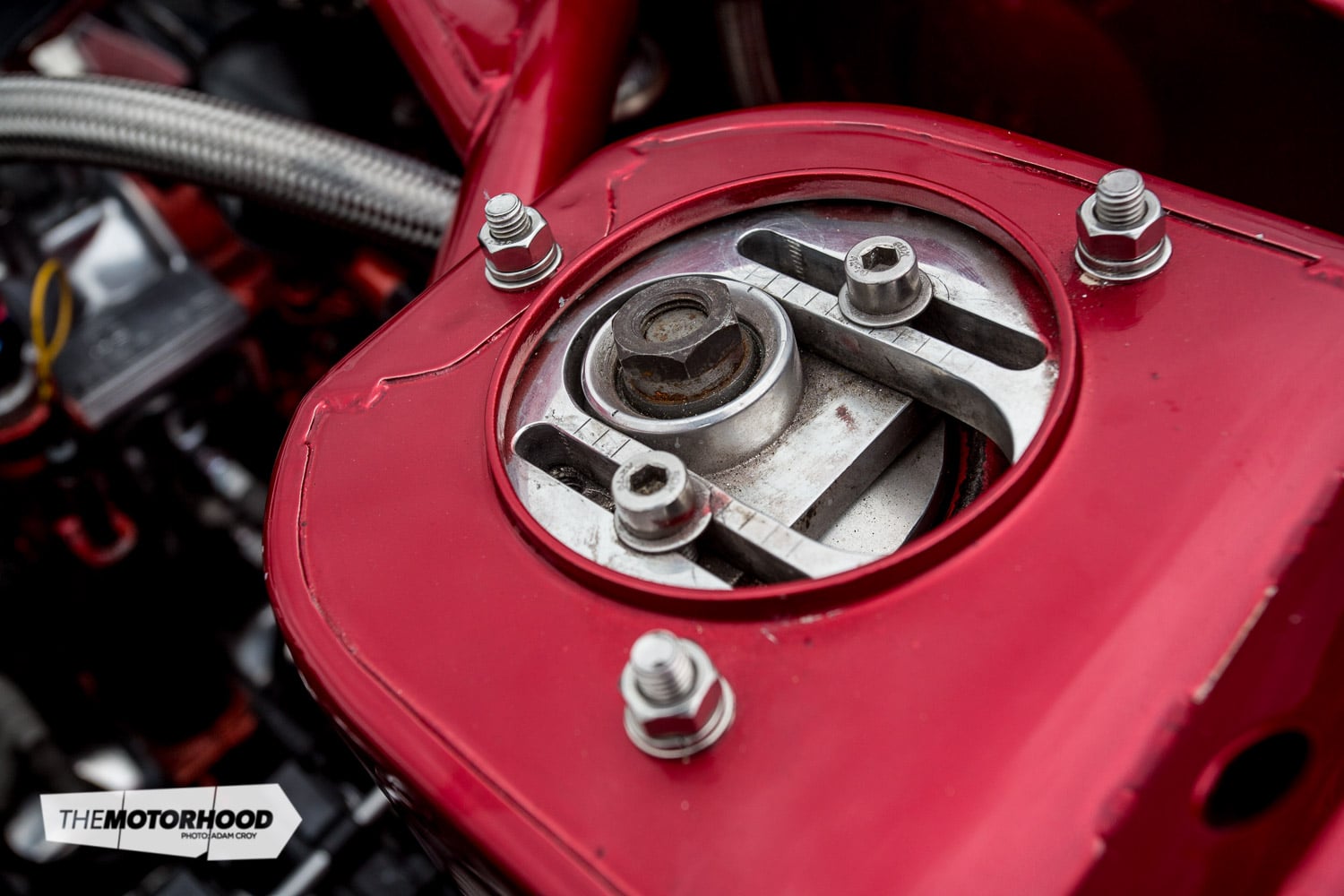

Once that seat does make it in there later this month, the passenger will share the space with the new wiring board. Cody told us that though most of the build has been a little frustrating, due to the time it takes to get any one job done, the wiring was one of the lengthier tasks. But, after months of reworking it all and studying diagram after diagram before swapping to a Link G4 RX ECU and Racepak dash, those wiring gremlins that moved in with the old job he did as a teen have long gone. Meanwhile, things were also ramped up in the engine bay. Tim from Shores NZ, Cody’s go-to fabricator, let the grinder loose on the front sheet metal and built a tubular structure in its place, while behind the engine now sits a three-point tubular strut brace. As for the motor itself, Cody had some wild plans to fulfil a childhood dream to build himself one of those engines that all rota owners dream of a 13B PP turbo. “I just loved the sound of them. I have always loved the sound.”

Cody’s combo of an FD RX-7 rotating assembly and FC plates and housings was screwed together by Jason ‘MR12A’ Trelor. Then on went the Master Power turbo and manifold, which were joined by a Dyson Racing intake plenum and a 100mm throttle body to allow the engine to hit big revs. The plenum and super-short charge pipe from the PWR cooler give the PP some great boost response.

A few days before our shoot, the 323 received a run-in tune from Craig Dyson, with only a 7psi spring sitting in the TiAL 60mm wastegate to get the party started. Cody was happy with the run-in tune, and the car already looks and sounds as if it will be a handful to drive. But, with a fully studded and dowelled block just begging for much more boost, he can’t wait for a full tune, which we estimate will see power figures north of 450kW. The journey from ugly duckling in 2009 to one of the wildest street 323s around has meant a six-year learning curve for Cody, but the end result speaks for itself — finally, he has a 323 that he is happy to call done, and it’s time to get in and enjoy it at as many events as possible.

So what’s next in the pipeline? Cody tells us that it will be a rotary and likely a 20B: watch this space.

985 Mazda 323 station wagon

Heart

- Engine: Mazda 13B, 1300cc, two-rotor

- Block: S4 housings with peripheral porting, S4 plates, S6 rotating assembly, 3mm apex seals, stud kit, clearanced and balanced

- Intake: Custom Dyson Racing intake manifold, PWR intercooler, Green Brothers Racing water-injection kit

- Exhaust: Four-inch stainless down pipe, 3.5-inch steel exhaust, Adrenalin R rear muffler

- Turbo: Master Power MP-R76, mild steel manifold

- Wastegate: 60mm TiAL

- BOV: 50mm TiAL

- Fuel: Carter lift pump, two Bosch 044 main pumps, two 1000cc injectors, two 1600cc injectors, billet pump mount, braided lines and AN fittings throughout, fuel cell

- Ignition: Smart coils, MSD leads

- ECU: Link RX

- Cooling: Custom alloy radiator, Real Deal Radiators oil cooler, Davies Craig EWP, braided lines and AN fittings throughout

- Extra: Billet alternator side mount

Drive

- Gearbox: S7 RX-7 five-speed

- Clutch: Quarter Master twin-plate

- Flywheel: Custom

- Diff: Shortened Toyota Hilux LSD

- Support

- Struts: (F) Custom Bilstein coilovers (R) QA1 coilovers

- Brakes: (F) RX-7 S4 four-pot calipers, slotted S4 rotors (R) Wilwood two-pot calipers, slotted rotors

- Extra: Four-link rear end, camber plates

Shoes

- Wheels: (F) 15×8-inch Prostars, (R) 15×10-inch Prostars

- Tyres: (F) 195/45R15 Durun (R) 205/45R15 Durun

- Exterior

- Paint: Respray in Mazda3 red

- Enhancements: Bugeye nose-cone swap

Interior

- Seats: (F) Sparco Evo

- Steering wheelL: Momo

- Instrumentation: Racepak dash, Auto Meter speedo, tacho

- Power: Still on run-in tune

Driver profile

- Driver/owner: Cody Martin

- Age: 23

- Location: West Auckland

- Occupation: Foundation specialist

- Build time: Six years

- Length of ownership: Six years

- Thanks: My family, Steven Ujdur, Daniel (BUGGNU), Jason Brown, Cam McKay, Adrian Milne, Jimmy Stevens, Glenn at BCR Concrete, Tim at Shores NZ, Daniel at STA Parts, Jason (MR12A), Ants and Richard Healy at BNT, Craig Dyson, Scott Elliot, Brendon Hopkins, all the boys who helped with a spanner

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

View fullsize

This article originally appeared in NZ Performance Car Issue No. 231. You can pick up a print copy or a digital copy of the magazine below: