data-animation-override>

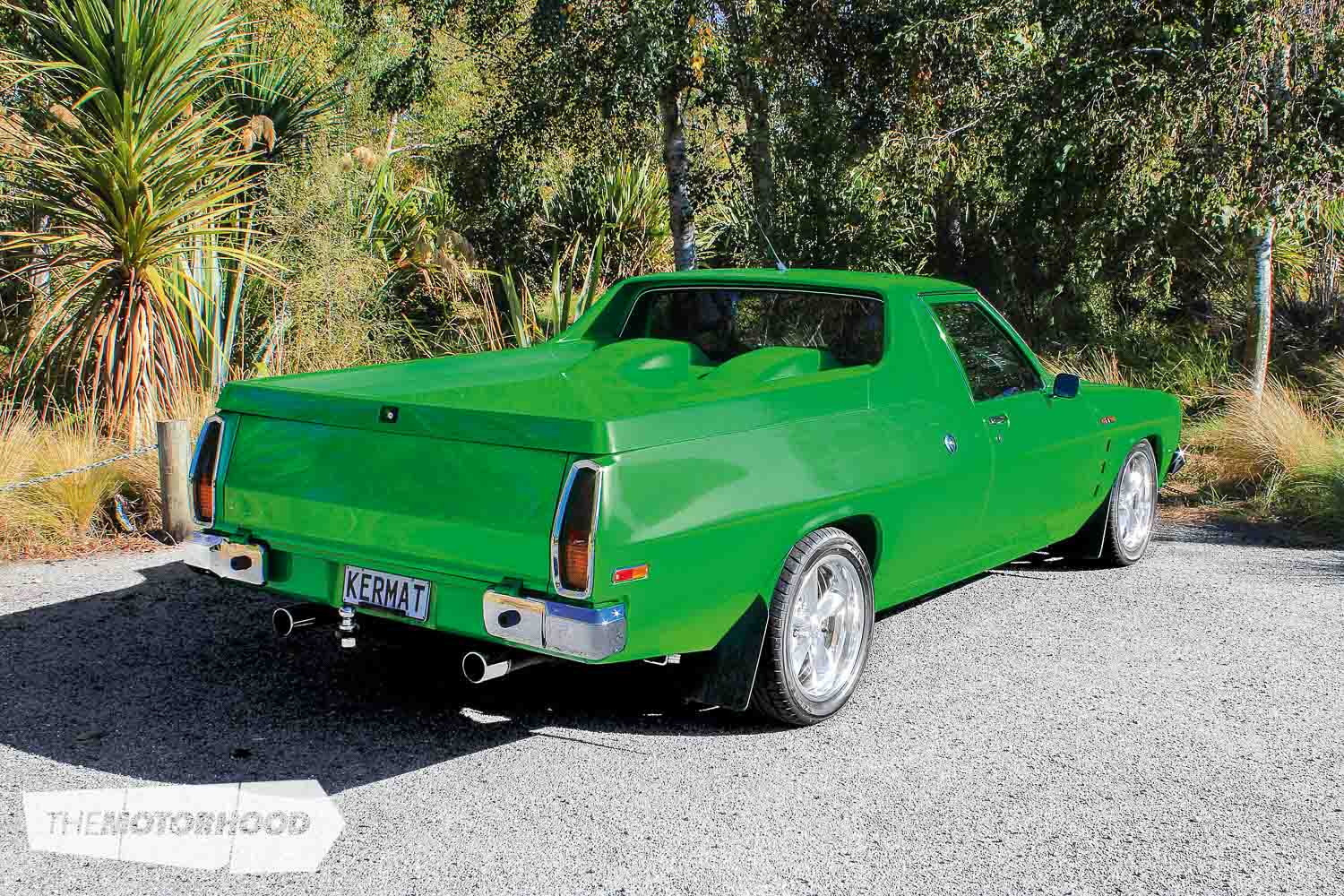

“Instead of scrapping the rusty old ute he picked up as a donor car, Steve Fabish decided to combine it with the bones of a new one”

Taranaki builder Steve Fabish is a pretty dead-set Holden guy, having owned everything from early Commodores to first-generation HSVs, a few in between, and some more recent HSV offerings. For some time, the pride of his collection was a 1977 four-door GTS that he spent years restoring to better-than-new condition.

Anyone who’s been involved with old Holdens knows just how hard it is to find rust-free panels these days, and it was during the hunt for a few doors for the GTS that Steve stumbled upon this 1980 WB ute. It had no running gear, but the doors looked like they were in OK condition. As the ute was being sold complete, he bought the whole vehicle.

In Steve’s own words, “I started to sandblast the door frames for use on my Monaro, but unfortunately found they were all full of bog. Needless to say, at that stage, I was a bit disgruntled, to put it mildly. I was thinking I had wasted my money on that purchase. So I left it sitting in the shed till I finished the GTS.”

Fast forward to the GTS being completed, and suddenly Steve had nothing to do at night, so he started thinking about the rusty ute. He spent several hours just looking at it, trying to come up with a plan. Finally, on a cool, calm Taranaki evening, he had the brainwave to build something unique, something he knew would test him, and — according to his wife, Joy, more important — something that would keep him busy and out of the house.

Calling into local Holden wrecker Holdin Heaven to bounce a few ideas off the team there, Steve almost walked right into the answer he was after: a 2004 Holden VY Crewman with significant damage to the left-hand side, which would be able to provide him with the late-model running gear he was keen on fitting.

Steve recalls, “A match made in heaven is what happened next, as, two days later, it was sitting in my shed beside the ute and the metamorphosis was in full motion. First, I removed the interior, motor, gearbox, wiring loom, diff, fuel tank, steering column, and pedal box. Next, I unstitched the floor to make it possible to transplant part of it into the ute. Part of the firewall was needed to carry the pedal box and other important parts.”

As you can see, Steve’s plan wasn’t just to fit the later model engine and driveline, as has been done countless times before, but, effectively, to transform the ute into a modern vehicle, simply keeping the character of the old. Part of the motivation for going to such extremes was that people began telling him it couldn’t be done — and we all know that’s like a red flag to a bull for most car builders.

Steve knew that the key item he had to get fitted in there was the ABS system, as everyone he turned to said that would be the biggest stumbling block, and, to a degree, they were right. With some clever home fabrication work to get the ABS rings adapted to the WB’s hubs, and with some assistance from local brake expert Brake & Clutch Rebuilders, Steve was soon heading in the right direction. However, while the basics could be completed with the ute as a shell, it really needed panel and paint work before Steve could get too carried away assembling things. With the condition of the body not being great, and with Steve determined to get it looking better than new, it took the team from Kevin Davis Panelbeaters 12 months to get it to a point at which all involved were happy with it. Once panelled and primed, the ute went home to have the bones of the VY dashboard fitted before returning for final paintwork.

While the team at Kevin Davis was spraying the body in layer after layer of DuPont Centari Atomic Green paint, Steve was busy making trips to Auckland to Dashboard Restorations. While in Auckland, he also visited Retro Vehicle Enhancement, which took care of the interior trim on the rest of the ute. As with the dashboard, the plan was to make it all appear to be stock VY Commodore, which was a whole lot harder than it sounds, given the 24-year age difference between vehiclesWhile the door skins could be made from scratch, and the seats required a few alterations, the dashboard was a major headache. The hard work was well worthwhile, though, as it has become the talking point of the whole vehicle. Those who manage to take a close look soon realize how much shorter than stock the dash is, and that it’s ever so slightly visible through the windscreen.

With the dash fitted, the reason behind adding the firewall and floor sections from the donor vehicle soon became obvious: the VY’s pedal box, centre console, and steering column are now all fitted in, too. The whole ‘keep-it-appearing–stock-VY’ theme was carried over to the engine bay, where even the accessories look stock, such was the effort put into their modification. The brake set-up is a similar story, with the ABS pump appearing factory, as do the VY booster and master cylinder. Having got the ABS sorted, Steve upgraded the discs and calipers to HSV-style items, complete with 330mm rotors all round.

In the beginning, the stock 5.7-litre LS1 was fitted along with the VY’s six-speed manual gearbox. However, somewhere along the way, Steve decided this was a bit too stock for his liking and a MagnaCharger supercharger kit was fitted. To make the most of the forced induction, Steve had Larry Taylor at March Holdings rebuild the motor to include ported heads, Comp Cams valve springs, and a cam from Kelford Cams. The result of the work, which includes a custom ECU reflash, is an impressive 304kW at the wheels at 6100rpm.

The other finishing touch was the creation of a VE HSV Maloo–inspired tonneau cover, for which Steve turned to Hamilton’s Fibre Prospec-s. It’s this custom work that lets passers-by know that there’s much more going on here than a set of shiny wheels and some nice paint.

Since the completion of the three-and-a-half–year build, Steve’s been enjoying the vehicle as much as possible and has been entering it in shows around the country, including ones as far away as Christchurch. While the results have been mixed, and people’s reactions the same, there are a couple of things that everyone agrees on: they are all blown away by the workmanship involved and impressed that Steve appears to have made the impossible happen. We can’t wait to see the next thing he is told is impossible!

Photos: Dayna Jury/Rod Dunn

1980 Holden Kingswood Ute

- Engine: 5.7-litre LS1, Comp Cams springs, Kelford camshaft, ported heads, MagnaCharger supercharger, intercooler, Pacemaker headers, custom three-inch exhaust, Flowmaster mufflers, aluminium radiator

- Driveline: VY Commodore six-speed manual transmission, steel flywheel, heavy-duty clutch, four-spider Salisbury LSD

- Suspension: Lovells front springs, reset leaves, Monroe shocks, Nolathane bushes

- Brakes: HSV-style calipers, 330mm slotted rotors all round, braided hoses, VY booster, VY ABS pump and computer

- Wheels/Tyres: 17×7-inch Foose rims, 235/45R17 and 265/40R17 Falken tyres

- Exterior: Custom hard cover, DuPont Centari Atomic Green paint

- Interior: VY Commodore dashboard, VY Commodore seats, VY Commodore steering wheel

- Performance: 304.9kW at the wheels at 6100rpm

Driver profile

- Owner: Steve Fabish

- Age: 58

- Occupation: Builder

- Previously owned cars: 2011 HSV GTS, 2004 HSV Clubsport, 1990 HSV GTS, 1987 Holden Calais, 1982 VH Commodore

- Dream car: 2014 HSV GTS

- Why the ute? For the challenge

- Build time: 3½ years

- Length of ownership: 5 years

- Steve thanks: Kevin Davis Panelbeaters, Mike Foreman at Autotech Taranaki, Steve Hall at Brake & Clutch Rebuilders, Larry Taylor at March Holdings, Steve at Dashboard Restorations, Retro Vehicle Enhancement, Holdin Heaven, and Fibre Prospec-s

This article originally appeared in NZV8 Issue No. 109. You can pick up a print copy or a digital copy of the magazine below: