Across this great nation there are racers of all backgrounds, ages and interests who devote their time and energy to the octane-fuelled passion of motor racing. Some race at the tier-one level and others, well, they are what we like to call backyarders, competing at the grassroots level where nine times out of 10 the sponsors are the drivers, corporate boxes are non existent, and as for grid girls, if there are girls there, they’re behind the wheel of the car next to you. It’s this level of motor sport that tends to bring out that Kiwi number-eight-wire attitude, when you’re only limited by your ideas, budget and commitment level.

For the Wheeler family, it’s the dirt track at Meremere where their motor-sport passion lies, so much so that they run five cars there on any given weekend. As for Mike Wheeler, it’s a passion he has successfully managed to combine with another passion, the rotary engine.

The car you see here is Mike’s second rotary-powered dirt car. The package from the first car was transferred to the new chassis, and in the process refined to the point that its potential was proven at the very first outing, when it took three first places and two seconds. So although he is one of only two rotaries running at his track, he is clearly doing something right.

His previous build was a tube-framed FD RX-7 which ran a 13B turbo with T70 Master Power turbo, which was serving its purpose well. Mike had won the championship two seasons earlier, and had no intention to build a new car. That was until a Super Saloon rolling chassis popped up for sale, and even then, his first thoughts were only to use it for parts. “We were just going to buy it and use the quick-change diff it had, transplanting it into the old car, but as everything does, we had a few beers and it snowballed. We ended up deciding to sell off the RX-7 and started building a brand-new frame,” Mike explained.

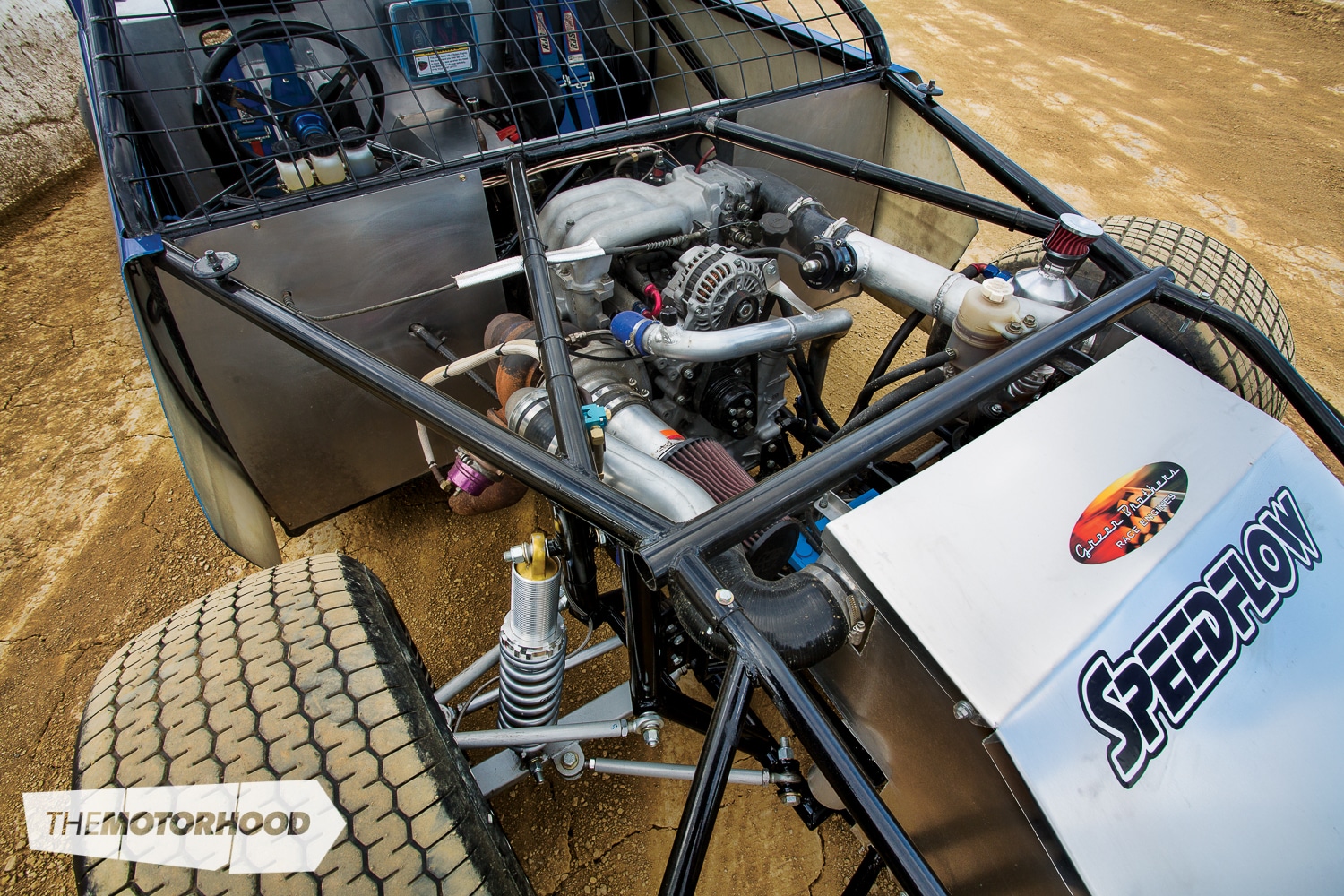

The reason they didn’t just use the Super Saloon chassis was the rule differences between SNZ tracks and Meremere. The biggest factor was that at Meremere you can run with passengers, but also the track runs clockwise, so the driver is located on the right-hand side. As the chassis was built and previously run under SNZ rules, it sat the driver on the left and positioned inside a plated single-seat area. Which is why it was much easier to simply cut out the chassis’ centre section and build a new, wider frame, ready for two seats. Mike tells us the best thing about running at Meremere is the fact you can take passengers out with you to experience it first hand, even during races.

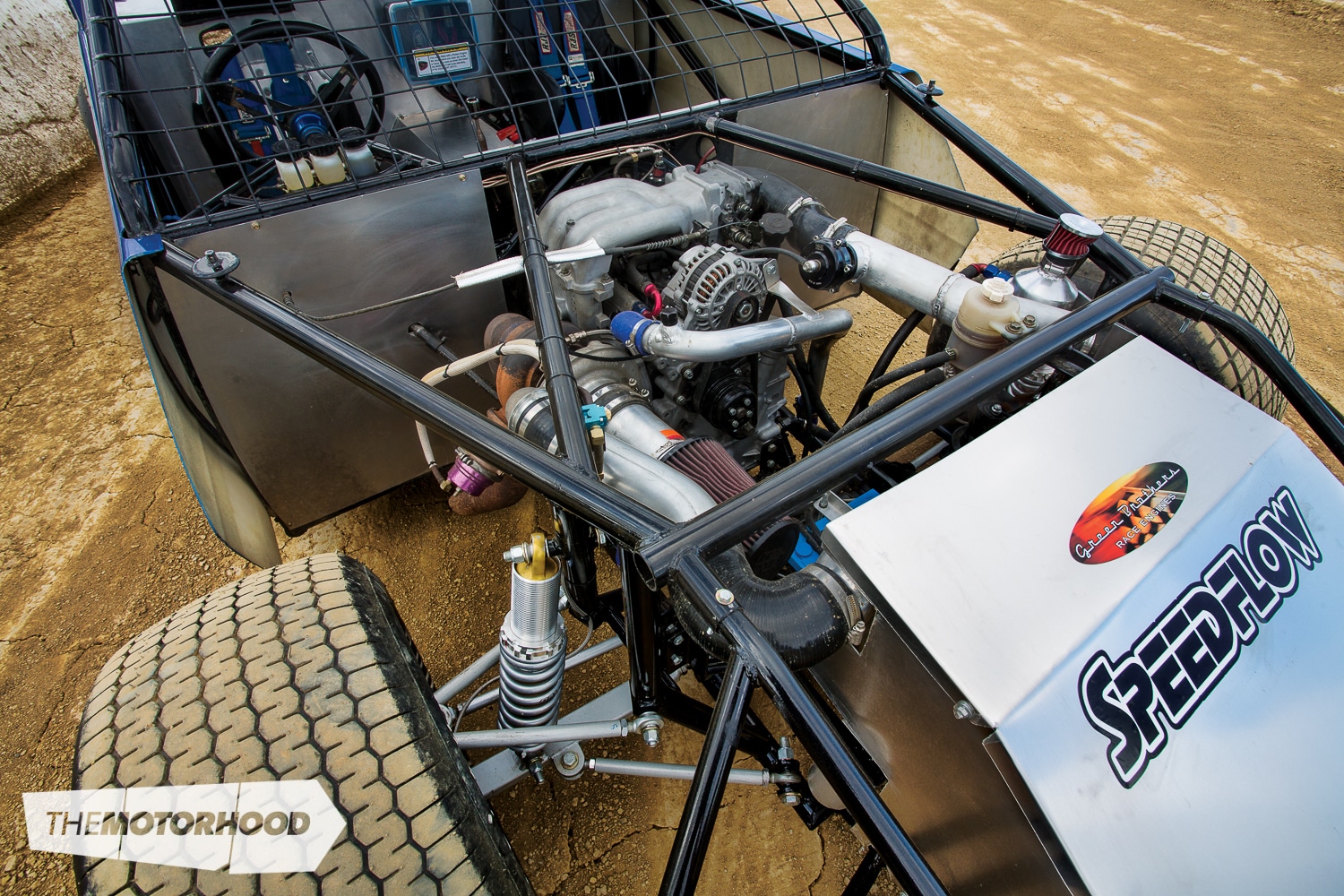

The replacement parts didn’t stop there, Mike enlisted the help of Green Brothers Racing and the Abbott brothers to build up a new engine package, taking what they could from the old bridge-ported FD 13B, and combining it with new parts. The Greens had been working with Mike on the previous machine, so they knew the unique requirements of the dirt.

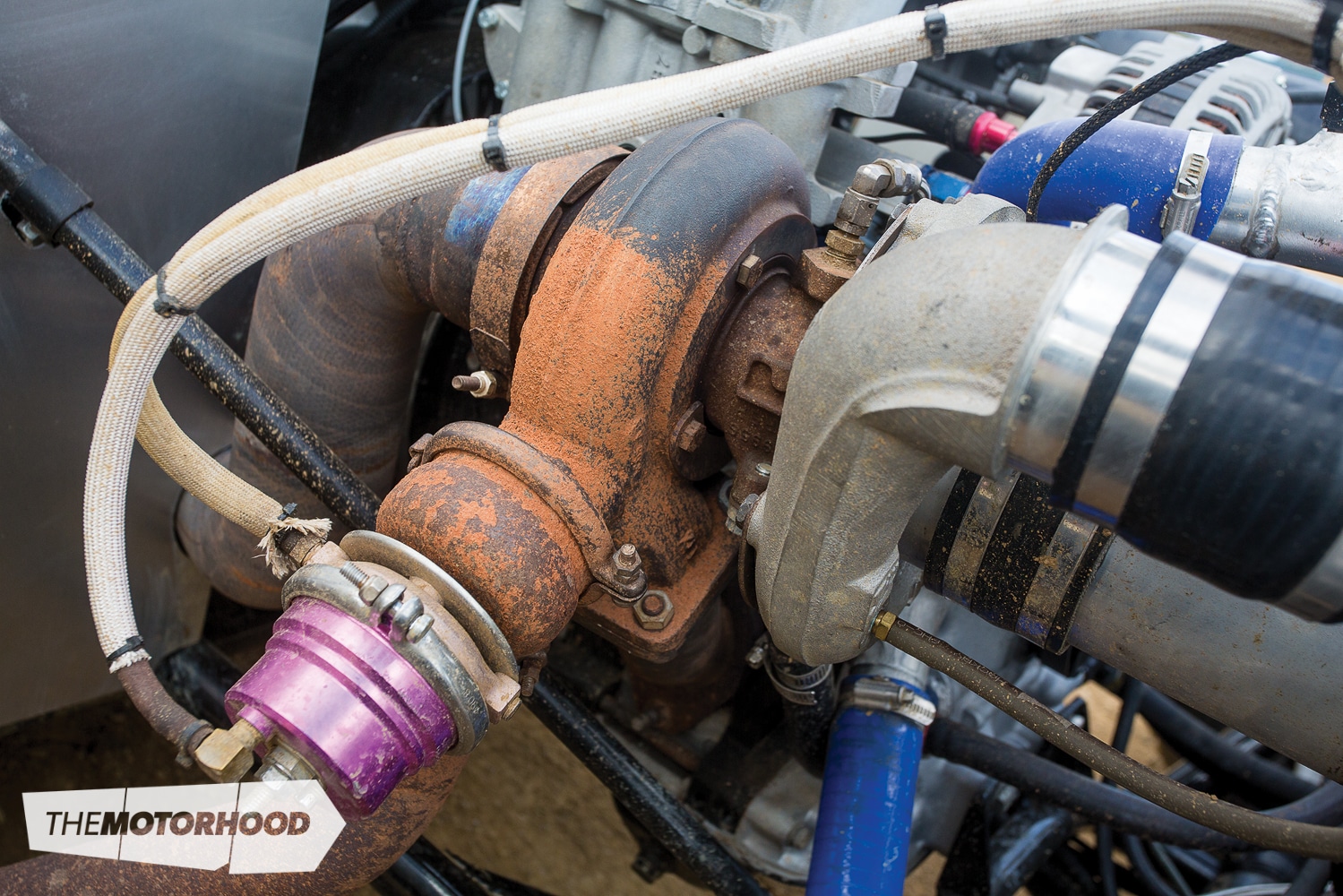

The new engine received housings and Stage 2 ported plates to replace the bridge-port stuff. The T70 turbo was ditched in favor of a BorgWarner SX300 turbo, and a Link G4 once housed in the Green’s infamous 323 wagon was wired in.

Making a bunch more power is all well and good, but you have limited grip on a surface like dirt, and the track constantly evolves throughout a meeting, so your focus is as much about being able to control your power delivery, and that giant set of rear tyres. The MAC boost control is set up to come on progressively based on rpm, as Mike explained. “Unlike in a normal street car, you want the boost to come on fast and be constant, but with this the boost is tuned relative to revs. The more revs, the more boost [up to 22psi]. From what I have felt in testing, its seems to be working. Instead of delivering all 500 notes at the start of the straight, it’s delivering them three quarters of the way down.”

But even with this boost control Mike said the rears spin easily, and there is a very fine line between keeping it in the power band, and losing all that forward momentum through wheelspin. It’s the art of driving a rotary, a specialized art, as anyone who races one when corners are involved can attest. To stay in front, you have to keep it in the power band.

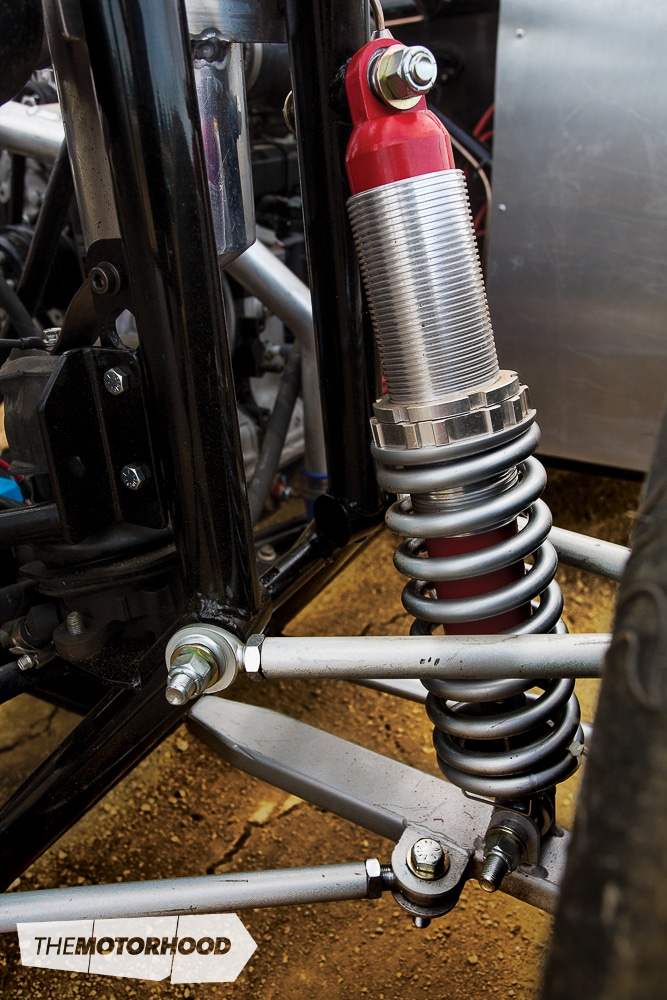

This is where the new chassis should come into play, with its torsion-bar rear set-up compared to the four-link FD chassis. “Basically everyone runs torsion rear end, it’s old tech but it’s basically in every car in speedway. The four-link worked well, but we found that with the rotary, unlike the V8s that have low-down torque to pull you out of the corners, this thing you need to keep the revs up. We were getting a lot of wheelspin exiting the turns. The torsion is predominantly famous for being a bit lazier, so the thought was, now the way Rich has tuned it we are getting out of the corner instead of barking the rears, and getting super sideways, it feels mean, and sounds mean, but everyone is going past you.”

Which is not something that Mike plans to allow. He wants to be able to stick it to the big dogs, the V8s, and show them what the little rota can do. This coming season it’s all about learning the new chassis, and what works and what doesn’t. The new car is bigger and badder in every area over the old chassis, it is now just a matter of making it work. It’s running much larger rubber than the old chassis, and with brand-new suspension components on all four corners, he just has to figure out what works and what doesn’t. If all goes to plan this season, Mike will move up to the big-capacity A Altered V8 class next season, and really push himself and his 1.3-litre screamer to see what they can produce.

Modified dirt-track saloon

Heart

- Engine: S6 13B turbo, two-rotor, 1300cc

- Block: Green Brothers–built block, Stage 2 plates

- Intake: Four-inch alloy intake, air filter, custom intercooler

- Exhaust: 3.5-inch steel exhaust, single rear muffler

- Turbo: BorgWarner SX300

- Wastegate: Street Spec 60mm

- BOV: TiAL

- Fuel: Two Bosch 044, four 1600cc injectors

- Ignition: AEM smart coils, Magnecor leads

- ECU: Link G4 RX

- Cooling: Rear-mounted alloy radiator, alloy oil cooler

- Extra: Mac boost controller, LC1 wideband AFR

Drive

- Gearbox: Mazda S6 RX-7

- Clutch: 9.5-inch Carbonetic single-plate

- Flywheel: Lightweight

- Diff: Winters saloon-car quick change

Support

- Struts: QA1 coilovers

- Brakes: Wilwood pedal box, Tilton master cylinder, Wilwood proportioning valve (F) Wilwood two-piece (R) Wilwood single inboard rotor and caliper

- Extra: Torsion rear end, adjustable double A-arm front

Shoes

- Wheels: (LF) 11×15-inch widen D window, beadlocker, (RF) 10.5×15-inch widen D window, beadlocker, (LR) 18×15-inch widened D window, beadlocker (RR) 15×15-inch widened D window, beadlocker

- Tyres: (LF) 28.5x11x15-inch Hoosier (RF) 28×10.5×15-inch Hoosier (LR) 105x18x15 inch Hoosier (RR) 94x15x15-inch Hoosier

Exterior

- Paints: Custom

- Enhancements: Custom two-piece FRP body

Interior

- Seats: Kirkey alloy

- Steering wheel: Speedway quick release

- Instrumentation: Auto Meter liquid-filled gauges, AFR gauge

- Power: Between 350-400kW on 22 psi, E85

Driver profile

- Driver/owner: ‘Magic’ Mike Wheeler

- Age: 25

- Location: Auckland

- Occupation: Foreman at City Pavements

- Build time: 12 months

- Length of ownership: 12 months

- Thanks: Onehunga Car Clinic, Steve at GSS, Graeme at City Pavement, Darren at Autotreads, Mark at Ultra Intelligent Linings, Ben, Ants, Stew, Mikey Smalls, Daryl, Richard and Chris Green, Lee and Trevor, Jeremy Abbott, Brent and Jason at Dynopower

This article was originally published in NZ Performance Car Issue No. 231. You can pick up a print copy or a digital copy of the magazine below: