The RX-3

Built as a tribute car to the RX-3 that Rod campaigned in the New Zealand Rally Championship in 1975–1977, this Mazda might look like it came from the ’70s, but the recently completed project goes like a modern-built machine. Rod had been searching for his original car, but, sadly — like most rally cars — it had all but been destroyed, as he explained: “I found the guy that now owned the original, but he had crashed it, cut it up, and disposed of it. So, my brother-in-law Peter Davidson built this RX-3 up over about five or six years. There was talk of recreating the old car just as it was, but maybe we had a few beers one night and expanded on that.”

Having raced for Mazda over a 15-year period, Rod had accumulated plenty of those elusive Mazda Factory Racing (MFR) components, which Peter was able to utilize throughout. Alongside those are plenty of modern components, like the external-reservoir coilovers, power-assisted rack-and-pinion steering, and a Holinger six-speed sequential. The engine, like many in Rod’s Mazda collection, is an MFR 13B peripheral-port (PP) making around 224kW. “Sure, it’s got the 13B PP engine the same as what we ran, although this one would make more power than we did,” Rod said. This is again thanks to modern advancements in things like ignition systems and apex seals. Peter paid extra attention to all the little details and making it light. “It’s really fun to drive,” Rod noted, “and runs pretty damn good. Last year, I ran it in the pre ’75 class [at Leadfoot] and, even with the misfire it had developed, we were able to hold off the others.”

View fullsize

View fullsize

The championship RX-7

Taking Rod to his first North American Race and Rally championship wins in 1979 and 1980, the 4WD first-generation Mazda RX-7 is powered by an MFR 13B PP and MFR-equipped five-speed. The 13B runs a modified 51mm IDA carburettor sitting on an MFR cast manifold. A large airbox feeds the carb, and ignition was a simple affair in the early 1980s, with a distributor and twin coils. This car was one of the early 4WD conversions built by the team, which developed its own system, as RWD could not keep up with cars like the Audi Quattros. The firewall has been reset, allowing the engine to be set back and the Alfa Romeo diff to mount in front, and, like all of Rod’s 4WD builds, it ran a 50/50 drive torque-split. The steering rack is a Stock Car Products left-hand-drive one, and the uprights and half shafts are factory FWD Mazda 626 items. “It was wonderful. The balance was great. We were lacking a bit of power in those days, but, if it was a wet, slippery, or a snow-covered rally, you would get them. This was a fun car,” Rod said.

Works RWD RX-7

“Rhys [Rod’s son] now owns this car; he found in Belgium [in 2012]. I ran the Scottish Rally [Championship] and [the] RAC Rally in 1985 in it. I went over and drove for Mazda Europe. [The RAC Rally] … was an interesting event. There was a lot of pressure on that event. Mazda Europe was trying to convince Mazda Japan that this was its Group B car, that 2WD was OK, and that 4WD was not necessary. I had already been in 4WD for two years. Mazda Japan told Europe that it wanted me to drive it. So, I went there and ended up beating their team car — shit, it was hard work: 2WD, it was hopeless. I came ninth overall, we were one of only two RWD cars in the top 10. Shit, it was hopeless,” Rod remembered.

A works-built RX-7, it runs a similar dry-sumped MFR 13B PP and MFR five-speed as the 4WD car, but with the block only sitting 10mm back from factory and with an uncut firewall. The widebody is a European-spec kit including the moulded six-light front bar and fibre-reinforced-plastic (FRP) doors, although, surprisingly, Rod’s own 4WD RX-7 (first gen) is lighter. The wheels are 15-inch Enkei items, and, like a 4WD car, it runs Mazda gauges, including a 12,000rpm tacho.

View fullsize

View fullsize

“Rhys found this car and asked what I thought about buying it. I said, ‘You know what, it’s got a good story behind it’. [Back in 1985], although it was hard to go back to 2WD, I really did enjoy driving it, despite the situation. The German team was horrible to me. We went to Donington track and they told me they had no race tyres, so I had to run on forest tyres. I beat the team driver on forest tyres, and my navigator says to me, ‘You keep that up, and we are going to die’. We came in and the tyres were absolutely shagged. But they told us that we had to stay on those tyres. By then, I just wouldn’t communicate with them. The co-driver came back to me and said ‘I have told them we are withdrawing if [they] … don’t give us new tyres’. So, we eventually got new tyres. The entire rally went that way for us.”

After importing the car to New Zealand, Rhys had it registered, and ran it in the Silver Fern Rally.

The back-flip truck

Another one of Rhys’s machines taking up shed space is this truck, but Rod can’t think of a better place to keep the vehicle from his son’s least-favourite project to date. He went on to say that he hated the Red Bull stunt, and we understand why. Rhys’s first attempt, on New Year’s Eve 2007, left him with a broken back and fractured neck after he hit the ramp 6kph too fast, causing him to overshoot the cardboard landing on the 16th test run and not fully rotate, landing the truck on its roof. Although during his lengthy recovery he swore never to attempt it again, exactly one year later, the team returned to Las Vegas and completed the jump to bring in the new year.

Learning from the first approach, the team built a new truck. The original was a Championship Off Road Racing (CORR) Superlite machine running a V8, whereas the new one was a modified Superlite with a much lighter 2.4-litre four-cylinder positioned more centrally to reduce the pendulum effect a forward-positioned engine caused. The specialized ramp, with mechanical kicker at its peak that would kick up the front wheels, was also modified. Rhys’s team pioneered this ramp technology, and it has become the accepted way to flip vehicles, including monster trucks.

The Stadium truck

Mickey Thompson’s Grand National Sport Truck Racing was the first short-track off-road racing series. It ran through the late 1980s and early ’90s and came as a welcome relief to a weary Millen: “The bit I loved was coming off running the Asia-Pacific rally, where each rally was three to four weeks to run — I was just so tired of being on the road. With this, I would do the testing during the week, which was wonderful. It would be nothing to do 100 laps in a day and roll it a few times either, just because we wanted to make it better and better, so we were constantly pushing. Race day was Saturday, and we would be home by Saturday night or Sunday morning.”

View fullsize

View fullsize

View fullsize

View fullsize

Racing inside stadiums like Anaheim in front of 75,000 people must have been a buzz, and Rod was successful, winning three consecutive championships in ’92, ’93, and ’94.

The truck was built in-house at MillenWorks and featured a tube frame and 24 inches of wheel travel, with the rear struts transversely mounted and all billet alloy suspension arms. The engine, an injected 3.0-litre Toyota V6 with only one forward and one reverse gear, had a top speed of 64mph.

The Tundra

Rod raced the Tundra during the ’99 and 2000 season of the CORR series. It dominated the more powerful Ford- and Chevy-powered trucks, winning six of the 10 races. This truck was the only one on the grid running a manual transmission, and Rod told us that the team had it dialled so it would beat the autos off the line. Running a cast-iron 5.0-litre Toyota V8, it makes 474kW, up against 595kW pushrod engines.

Rod believes power is not always the winner and weight is more important: “We ran lighter than everybody else just because of our chassis design and suspension. Because we ran a multi-valve engine, we had to run another 2.5 pounds per cubic inch than the pushrods. So, we [had] … quite a penalty to pay, but it turned out all the other guys were over[weight] and couldn’t get down to the minimum, and we ended up carrying 600 pounds of ballast to bring it up to weight, but it allowed us to put that weight exactly where we wanted it, down low.”

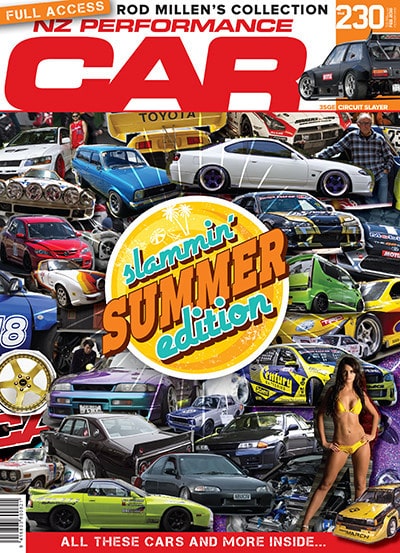

You can find part one of the ‘Geekfest: Rod Millen’s world-beating toys’ series here. This article was originally published in NZ Performance Car Issue No. 230. You can pick up a print copy or a digital copy of the magazine below: