When we last checked in with current Demon Energy D1NZ champion Darren Kelly and his Nissan R35 GT-R build, the car was about to head to DKM Fabrication to have the fabrication work completed. That work has been taking place, but more importantly there is now an engine sitting in that giant engine bay.

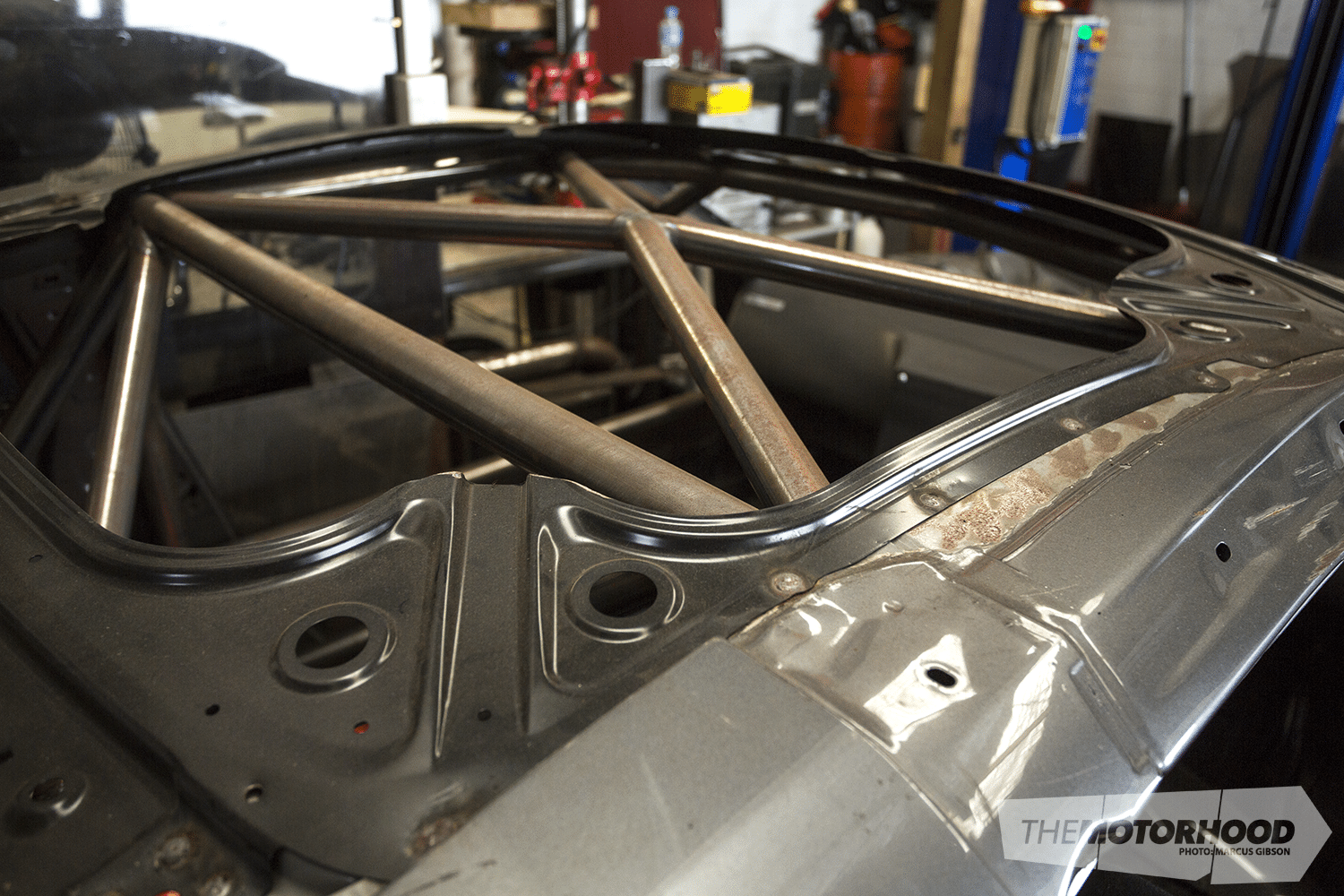

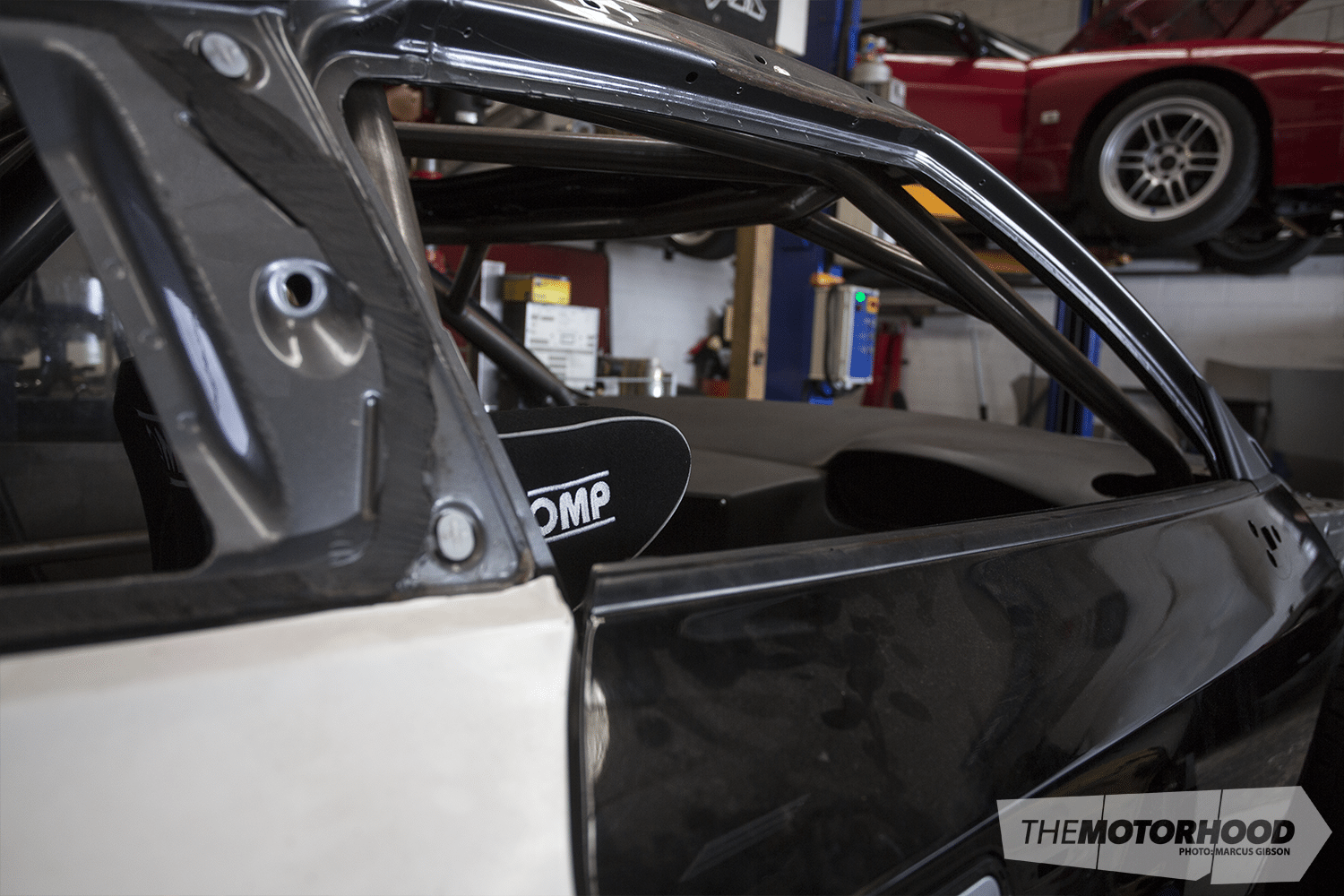

The Formula D–spec roll cage is in the final stages, with only the side intrusion to go. As the team are running an FRP roof skin, the roof cross was deemed a necessary added piece of protection.

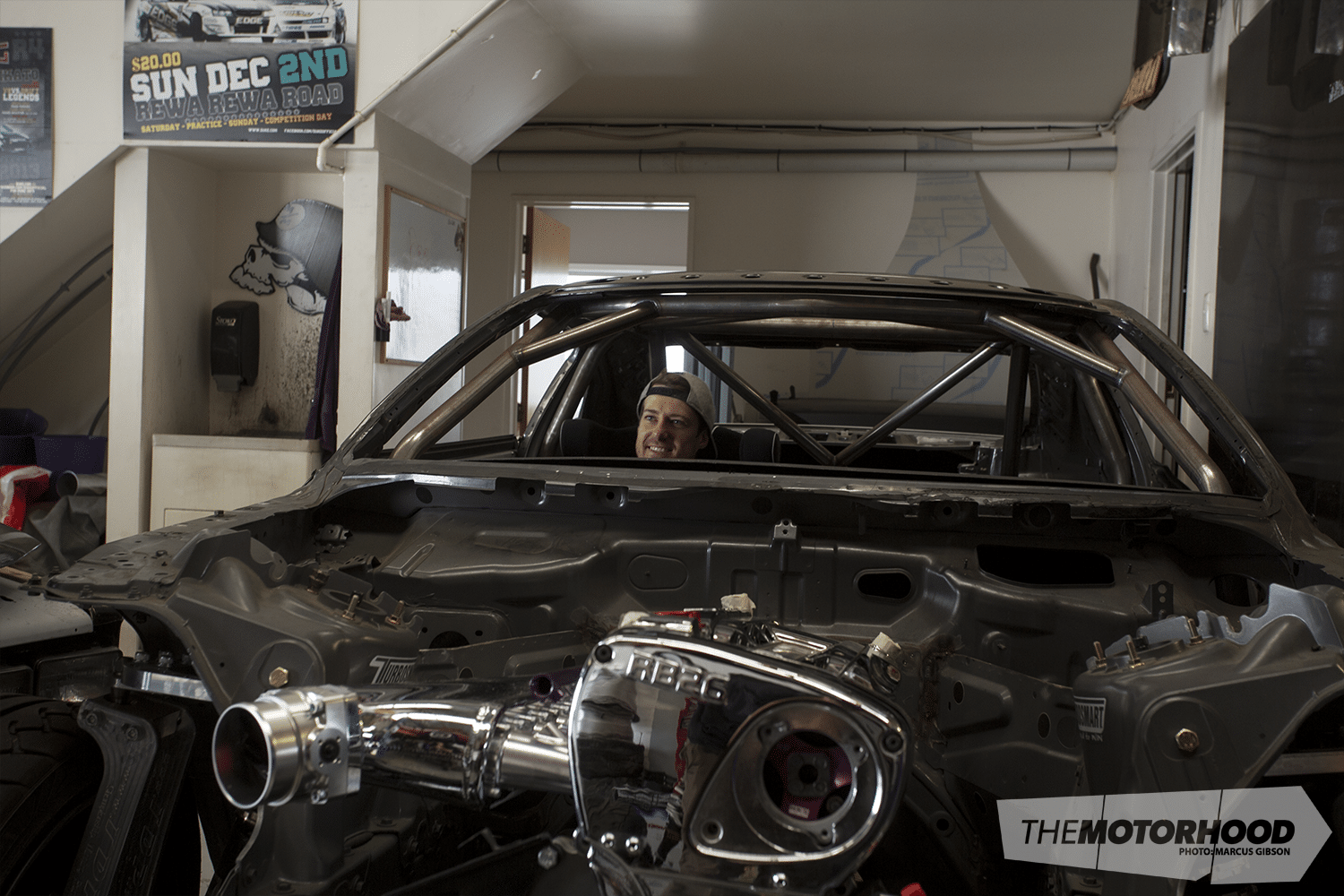

Darren has been trying out his new seat position for the FIA OMP seat. The depth of the R35 floor allows the seat to sit deep within the cabin. At this height any normal person would be staring directly at the dash, but for the very-tall Darren, it’s perfect.

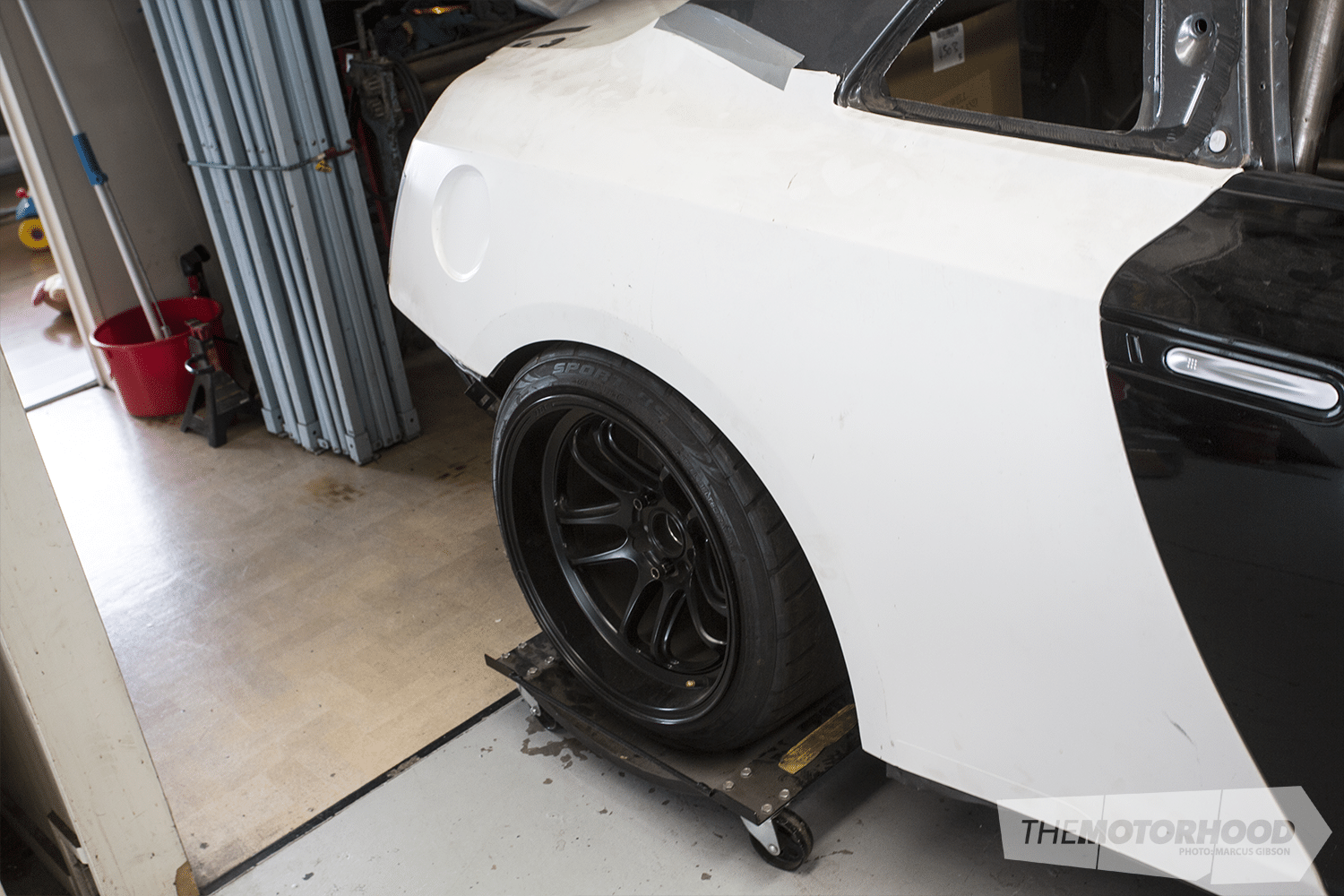

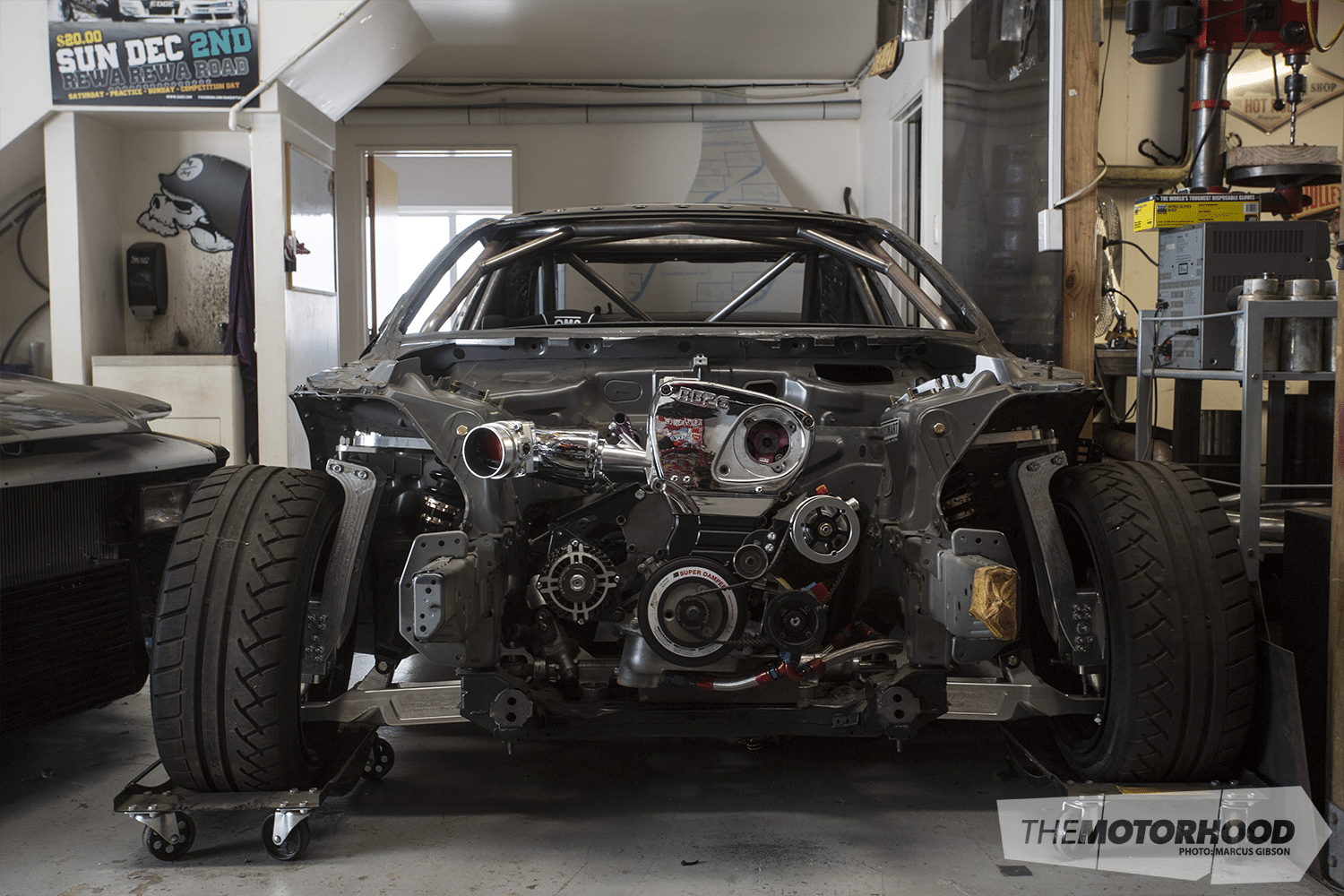

With the R35 now rolling, its been the first chance to put on some spare 18s and try them for size. There was a little concern that 18s would not fill the guards, but they do the job without too much drama. These are not the actual wheels that he plans to run — expect a ton more dish on those. But enough of the teasing, we all know you’re reading this post to see exactly what will be powering the GT-R …

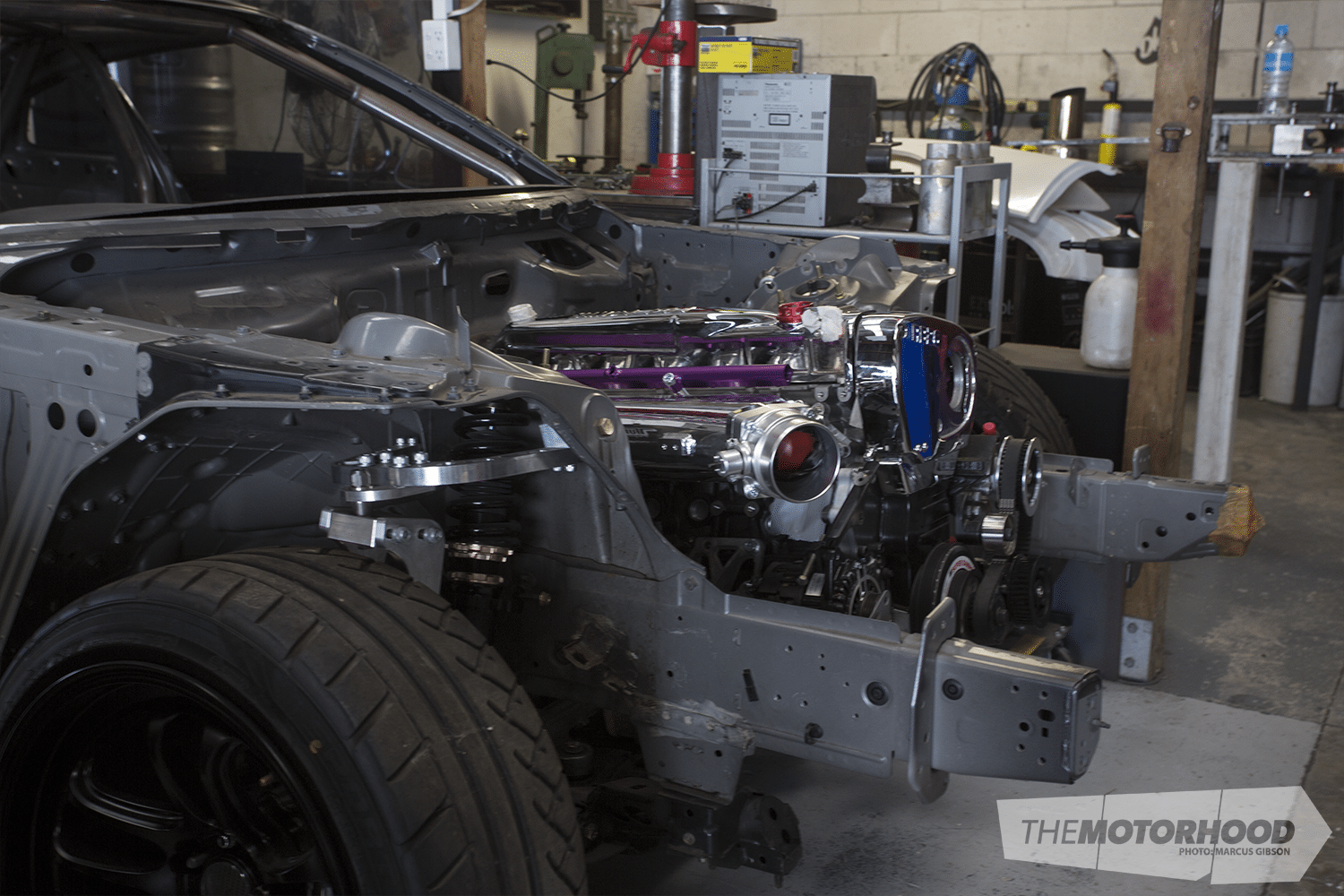

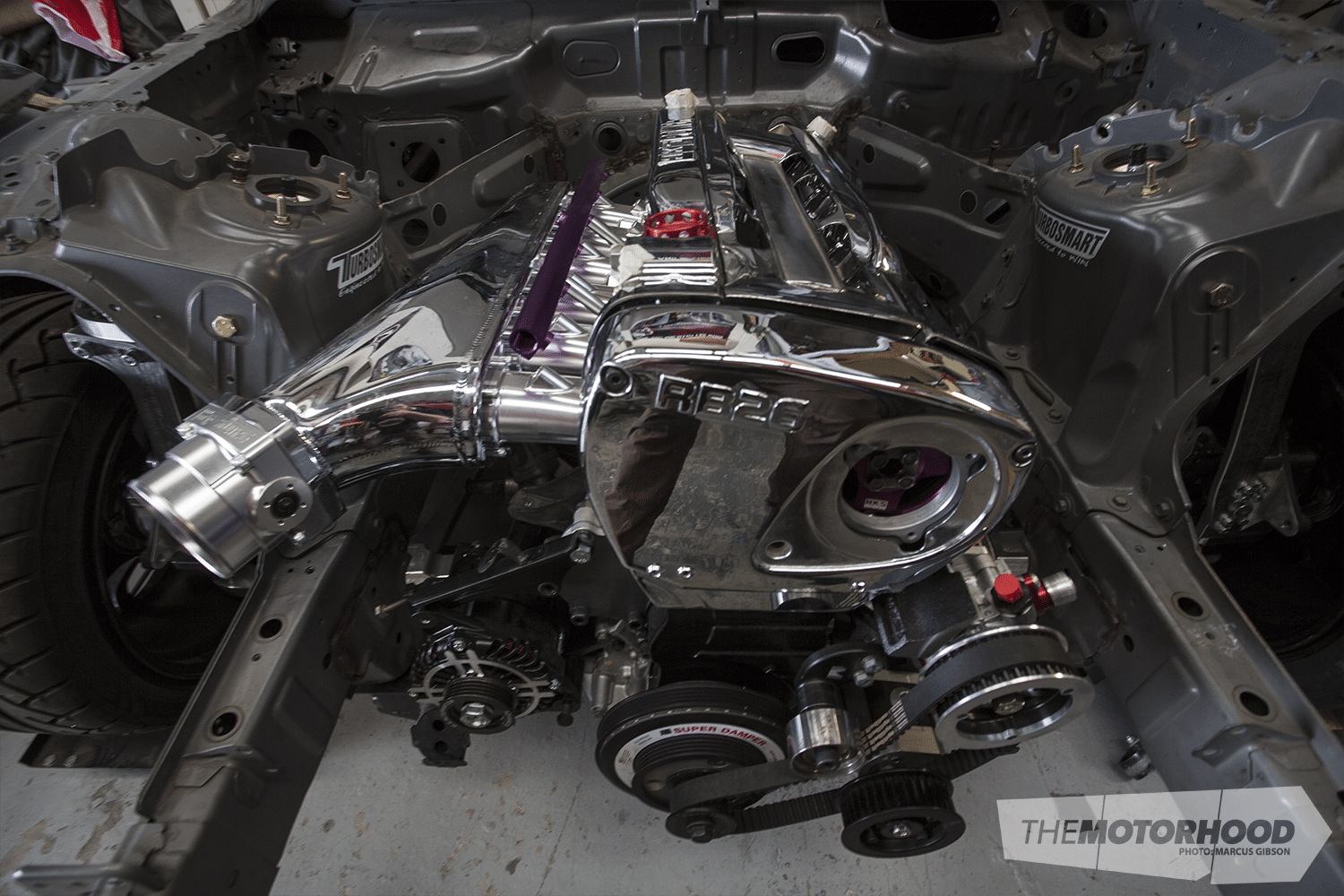

Well the wait is finally over, as sitting in the hole will be an RB32 stroker with an RB26 head. There was a lot of speculation surrounding Darren’s engine of choice; many hoped it would be the factory VR38DETT, and others rumoured of an LS. But any wise man was always going to back an RB as the preferred choice. Why? Because the team know these engines inside out, and swapping to a new platform would mean going back to square one.

We will delve into the full engine details in the next blog, but what we can tell you is that the RB26 head has received extensive work, including around five hours on each port. It has also been modified to take massive-lift Franklin cams. The team will run a factory intake plenum with the ITBs (not pictured).

Darren explains, “With the people we talk to, it seems [that] the factory intake has a much better flow over aftermarket, especially with what we are trying to do with low-down power and consistent power through the power band.”

The engine sitting in the car currently is actually for another DKM project, but the real deal is coming together at Engine Specs as you read this. Expected power output is over 500kW, although its capability will be much higher. But as Darren explains it, finding the balance between power and grip needs a fine-tooth comb, and having a 700kW engine is all well and good, but you need to have the grip, driveline, and budget to support that.

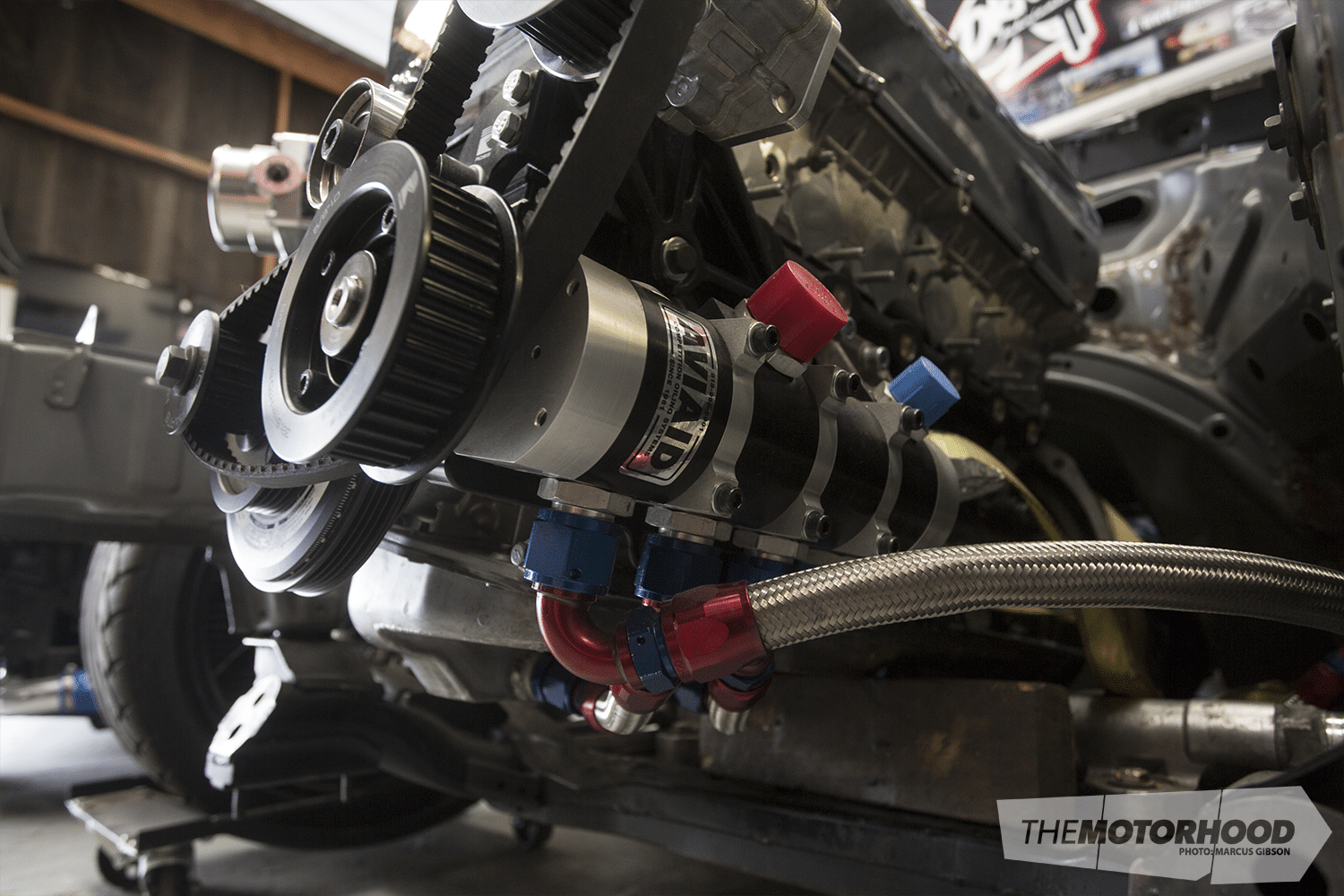

One of the keys to making big power reliably is oiling. This will be taken care of by a Ross Performance four-stage dry-sump system. This will also make it easier to get the steering rack in the perfect position. We will check back in real soon to run over the engine hardware and mounting of the motor.