Those who follow me on social media or read any of the tech pieces in NZ Performance Car will know that when I’m not putting the magazine together, I can be found in my workshop building cars. I’m a slave to the cord, as all my power tools require an electrical umbilical line to be plugged into the wall. I was a bit of a non-believer in battery technology, as I wasn’t confident that it’d give the power and run time I need, but I’m happy to report that I was a fool.

For the past week, I have, as Milwaukee likes to say, ‘cut the cord’ — I ditched all my power tools and replaced them with Milwaukee’s M18 ™ brushless technology range, and a couple of its new 9.0Ah Redlithium ™ batteries — yes 9.0Ah!

Walk into any power-tool store today, and you will find a range of cordless products around the 6.0Ah range — so, 9.0Ah is a huge step. In fact, its advertised run time is twice that of the existing M18 ™ 5.0Ah battery. It’s a claim backed up by some simple stats — 20 minutes of continuous grinding, 537 cuts on the M18 ™ circ saw in 2×4-inch pine, and 76 times drilling 20mm holes in 6mm plate steel using the mag drill.

As we tested these before the on-sale date, the batteries we used ran the American branding. The New Zealand product has a slightly different look.

The battery casing is rugged and includes a rubber lower casing. We dropped the battery a few times on the hard concrete floor without a worry.

The new 9.0Ah works on all but one of Milwaukee’s existing 50 tools available in New Zealand. At my disposal for this test were the M18 FUEL ™ Sawzall, M18 FUEL ™ half-inch impact wrench, M18 FUEL ™ hammer drill/driver, M18 FUEL ™ five-inch angle grinder, and all-new M18 LED handheld light. My weekend task list included a new front bash bar with integrated oil-cooler mounts and removing the rear-panel steel to build a new fuel-cell enclosure in my E36 BMW.

M18 FUEL ™ sawzall in hand, I removed the old bash bar in minutes. It was easy to hold, easy to control, and the Milwaukee blades made short work of the roll-cage tubing. The slow start-up meant the blade didn’t grab and attempt to pull out of my hands.

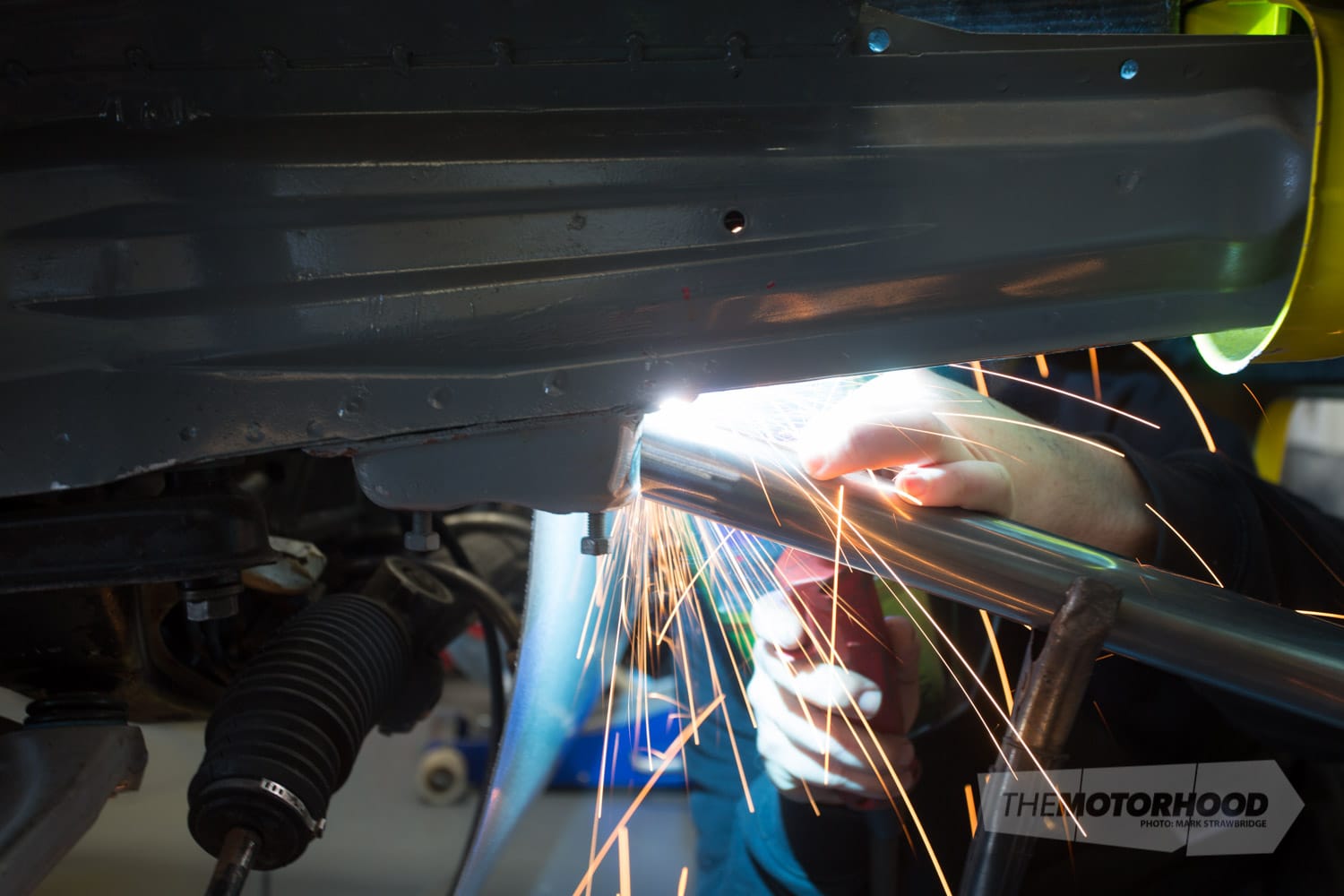

Popping the battery off and onto the grinder was when the real test began, as grinders certainly suck some juice. For the next few hours, I cut, shaped, notched, and sanded the new pieces of tubing and the mounts. While I’ll openly admit that I don’t usually use a shield on my own tools, I left this one’s on, and, with the one push-to-slide adjustment, it was never in my way.

The other great feature that made swapping between discs a breeze was the FIXTEC ™ nut, which requires no tool or the need to stress the cutting disc. I found the revs per minute of 8500 much nicer to work with and more controllable than that on my corded tool, which spins at 10,000rpm. This speed difference also caused the 1mm cut-off disc to last longer, which is a bonus. Weight-wise, it was comparable to any corded unit — even with that 9.0Ah strapped on the base.

Still on only the one battery, I cut out the oil-cooler mounts using a hole saw to achieve a radiused end where it would weld onto the bash bar. I used three different-sized hole saws on the hammer drill/driver. I found it was easy to achieve a tight grip on the keyless chuck and easy to release it. The fact that the drill has two speeds (550 and 2000rpm) was a bonus, as I could select a slower speed for metalwork. It also has three settings — drill, screw, and hammer — and torque settings up to a maximum 135Nm, which is impressive for such a physically small unit.

It was around halfway through the second lot of holes (each mount has four holes — three different sizes) that the battery finally stopped. This was six hours into my work day. I had a second battery there ready and waiting — this second one lasted Sunday, with a bunch more grinder and some rattle-gun work, and Monday, with some LED light work, as I welded the bash bar on. I had the M18 ™ six-pack charger, which has a 180-minute charge time, but, for those in a hurry, there is a rapid charger available that takes only 70 minutes.

If I’m honest with you guys, the truth is that I didn’t believe that battery tech could outperform my current stable of corded tools. If you had a couple of batteries in circulation — perhaps three in a commercial situation — there’d really be no downside to cutting the cord that I can see. So, would I convert? Yes I most certainly would.

As a side note, there is some new technology we will soon take a closer look at that will change the game in a very big way — more on that in a few months. For more details visit milwaukee.co.nz.