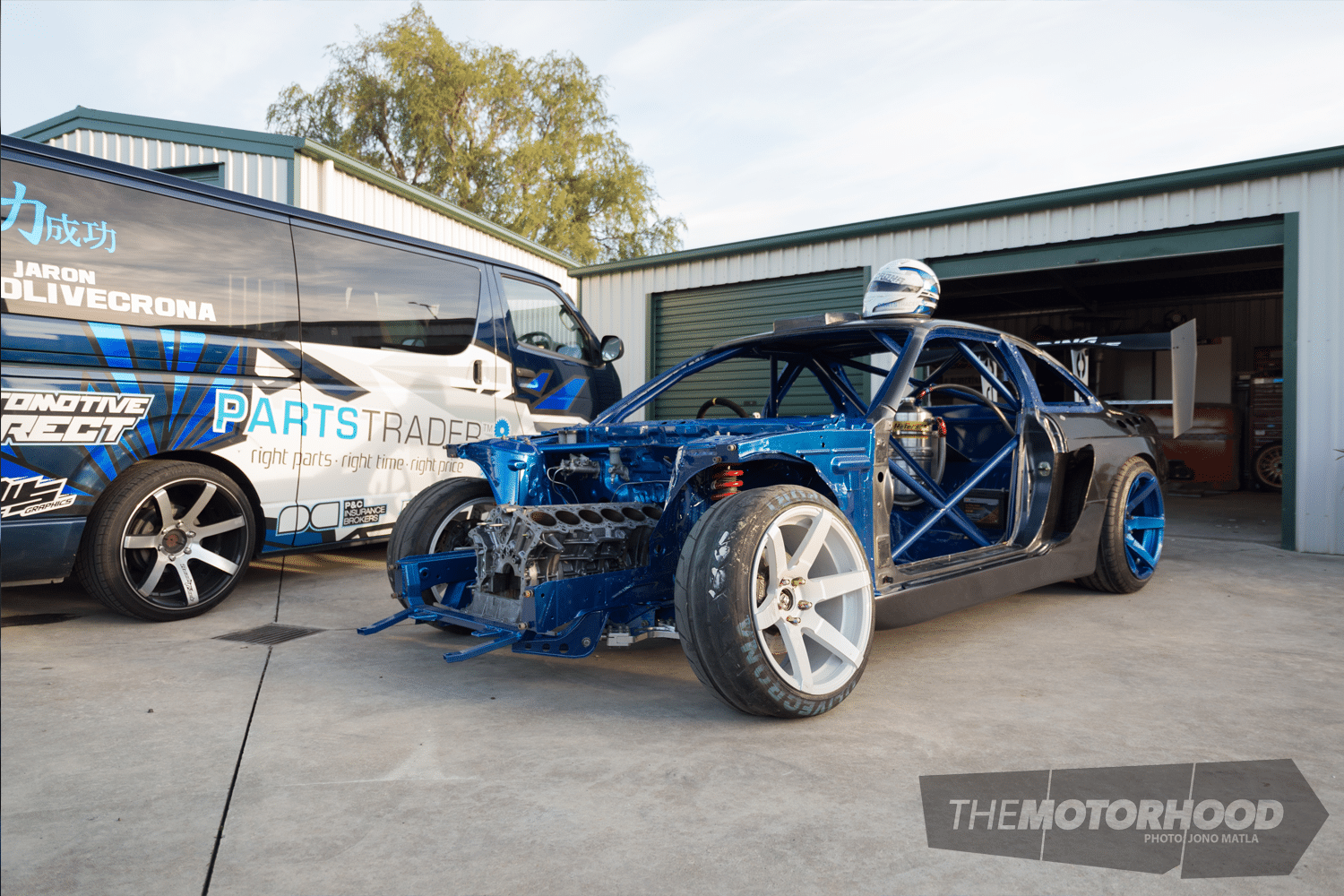

Fresh off the back of his first full-season Demon Energy D1NZ Pro campaign, Manawatu local Jaron Olivecrona has hit the shed to transform his already gnarly 500kW RB26DETT-powered S14. The Olivecronas have earned a reputation around the Manawatu for their back-shed engineering, and now, with new sponsor PartsTrader, Jaron and his dad Kester have embarked on arguably one of their wildest builds yet — shoehorning a Toyota Century V12 1G-ZE into the S14.

The V12 will be the first on the D1NZ grid, and one of a dying bred of naturally aspirated competitors — although the intention to pull a minimum of 522kW with 950Nm-plus of torque out of the V12 will certainly level the playing field with anything boosted.

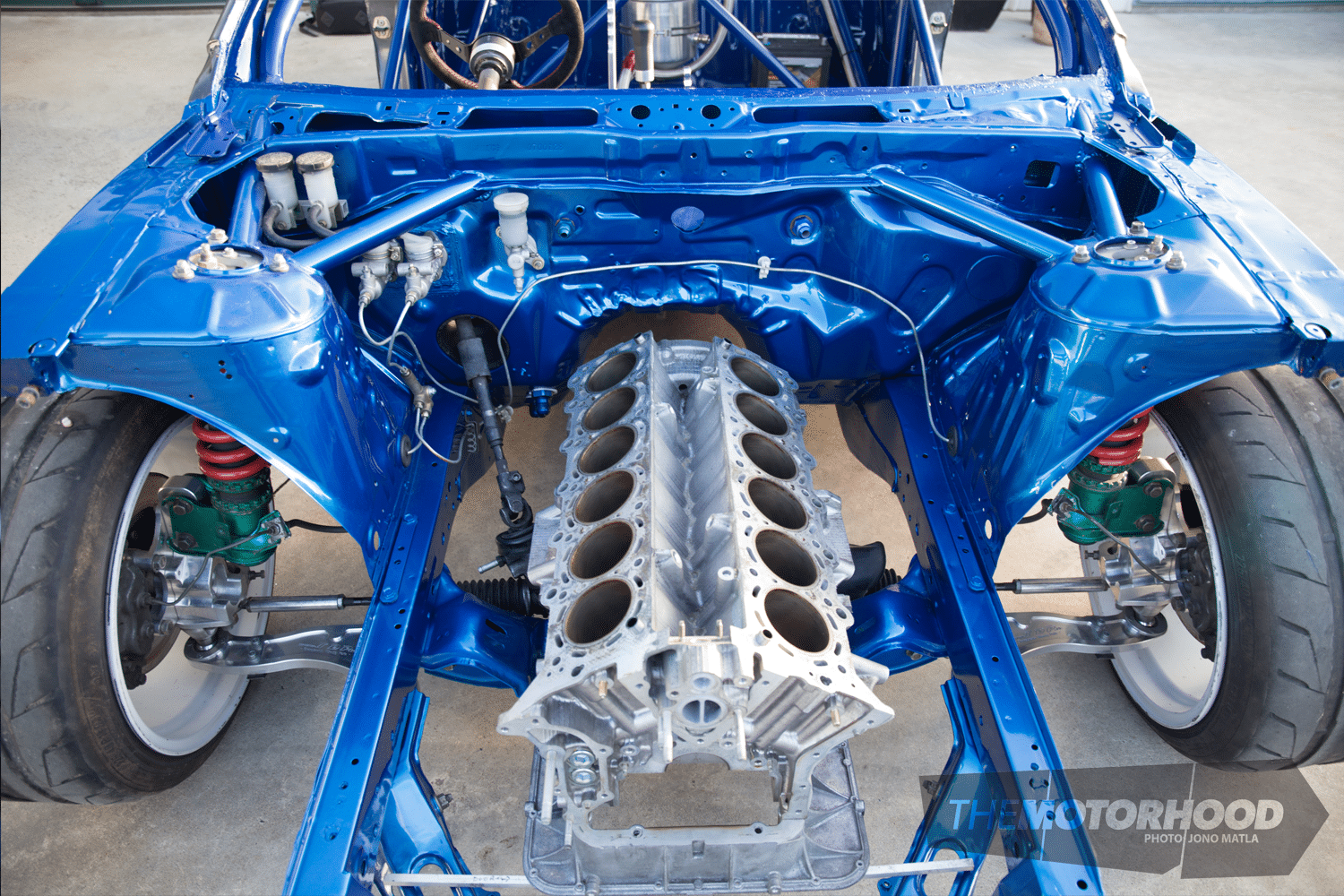

Unsurprisingly, making those figures on factory internals is a no go, and off-the-shelf options for a Toyota V12 are non-existent, which has meant Jaron had to source a collection of custom-made parts, which includes the forged high-compression CP pistons and custom-made forged Honda rods.

Entrusted with building the engine is local shop Hartley Engines and Motorsport, who are custom making camshafts with a final compression ratio of 13:1. One of the more amazing custom pieces that the Hartelys are building is the custom set of 12 billet individual throttle bodies breathing at 10,000rpm through custom carbon bell mouths.

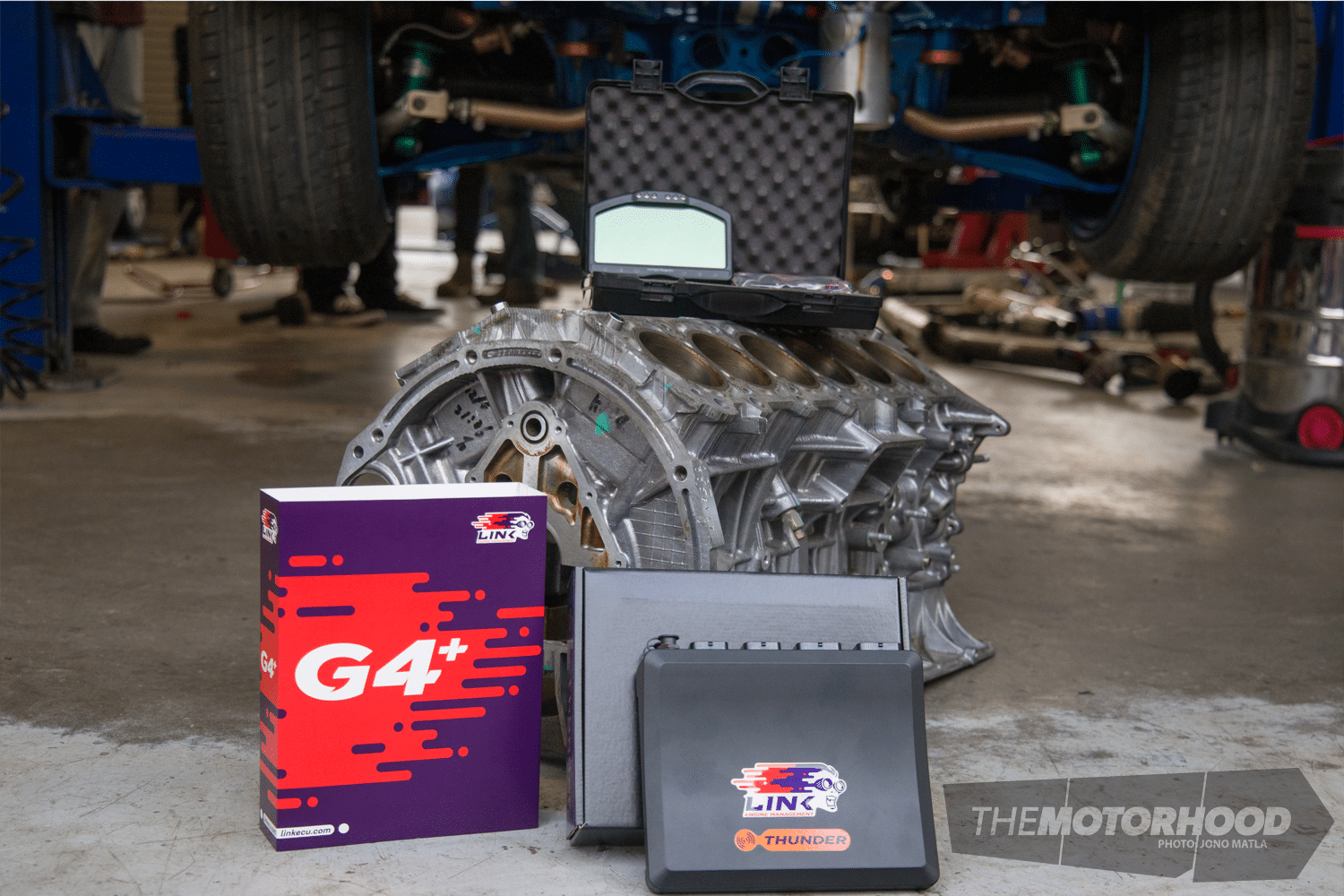

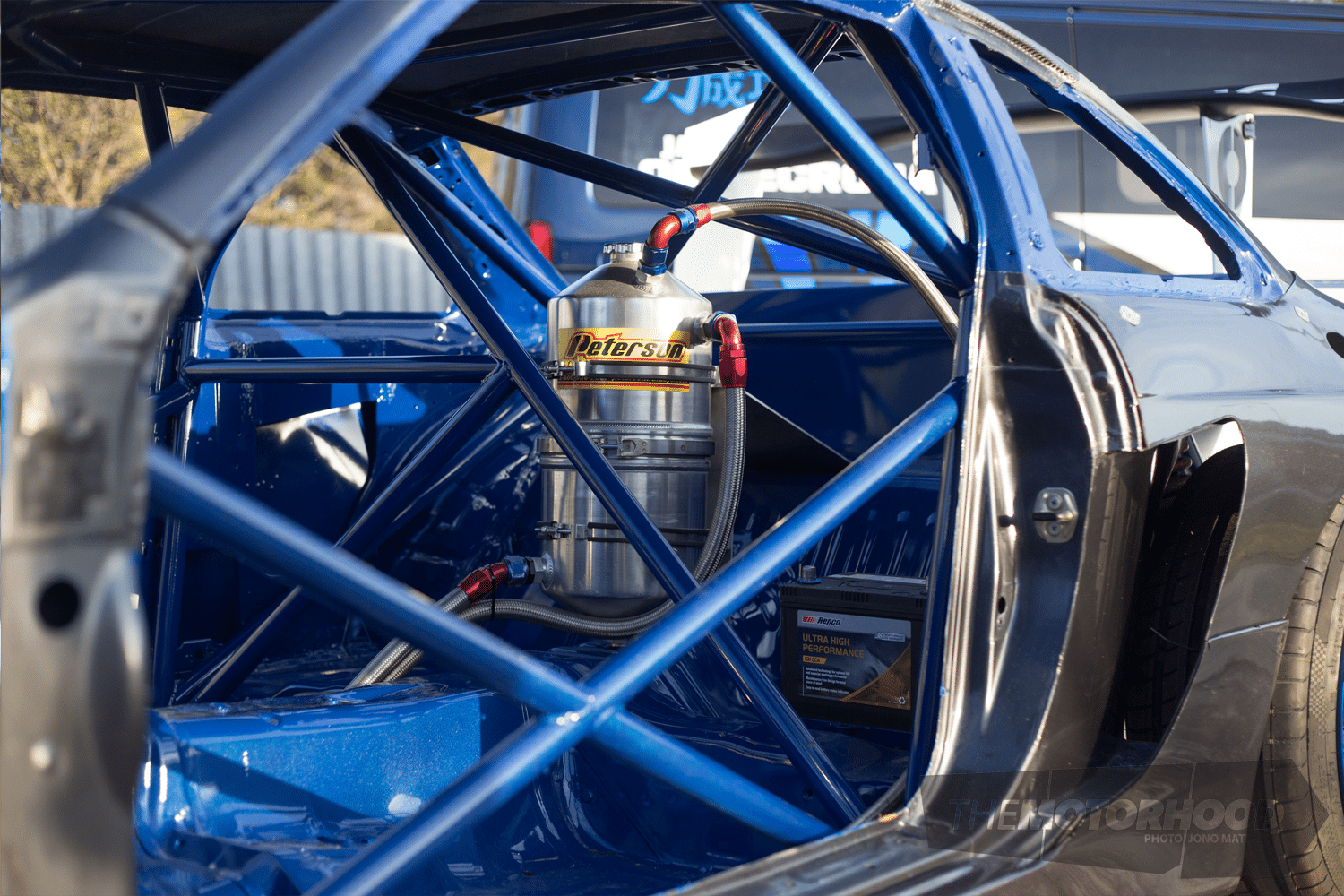

With effectively double everything, going from six to 12 cylinders, the electronics also needed upgrading. Link ECU have come on board and supplied their latest G4+ Thunder, which has dual digital wideband, 16 inputs, and 20 outputs — yip, a V12 is a complicated beast to control. All the vitals will be displayed through Link’s latest Pro2 dash.

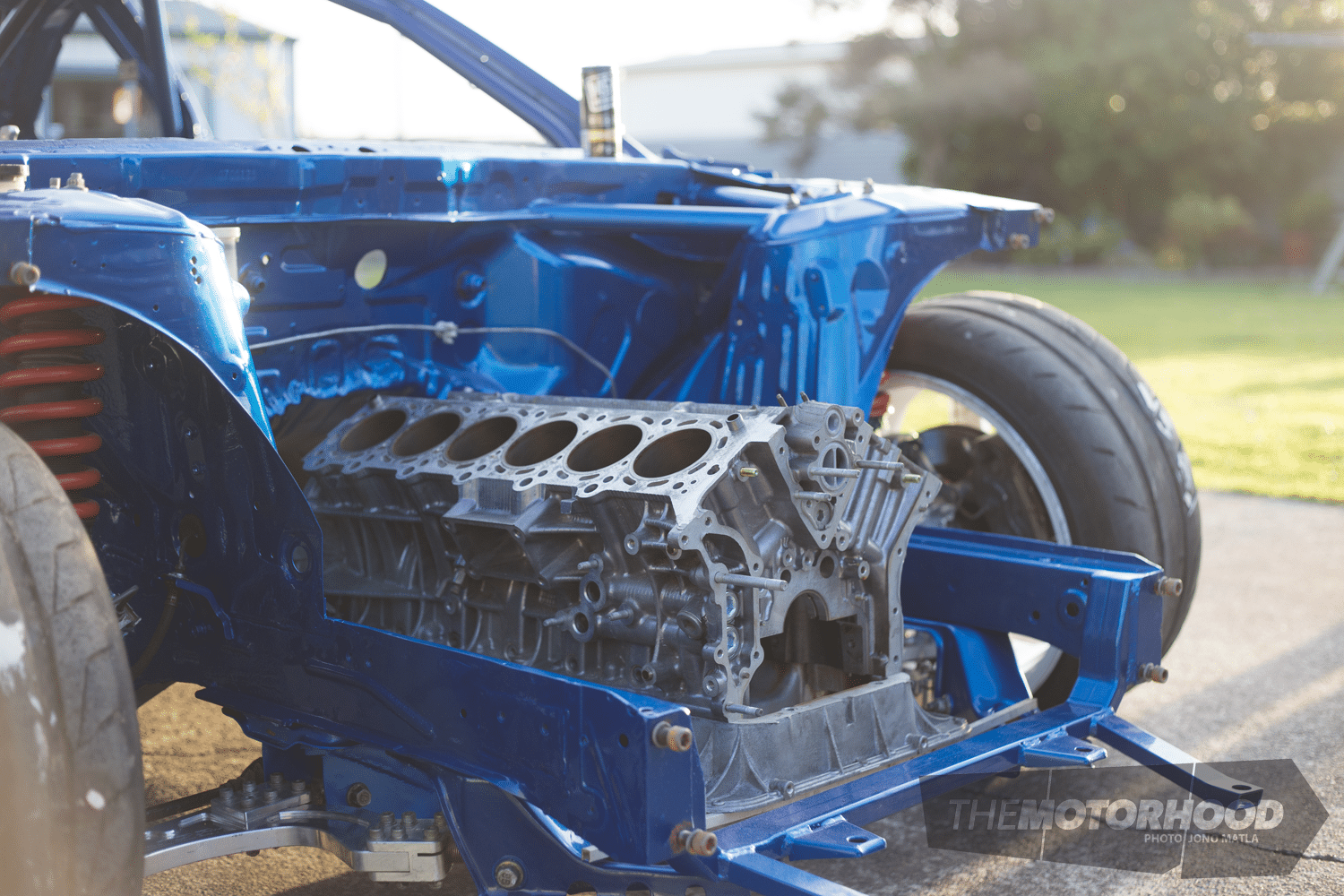

Through a bit of clever machining inside the bell housing, the V12 bolts directly up where the RB26 once sat. This has saved the team a ton of messing around with parts, like gearbox cross members and drive shafts. But the real reason behind this was to give Jaron a spare engine in case of failure at the track. “This way if we had a problem with the V12 during practice, we could easily swap in the RB over night,” he explained.

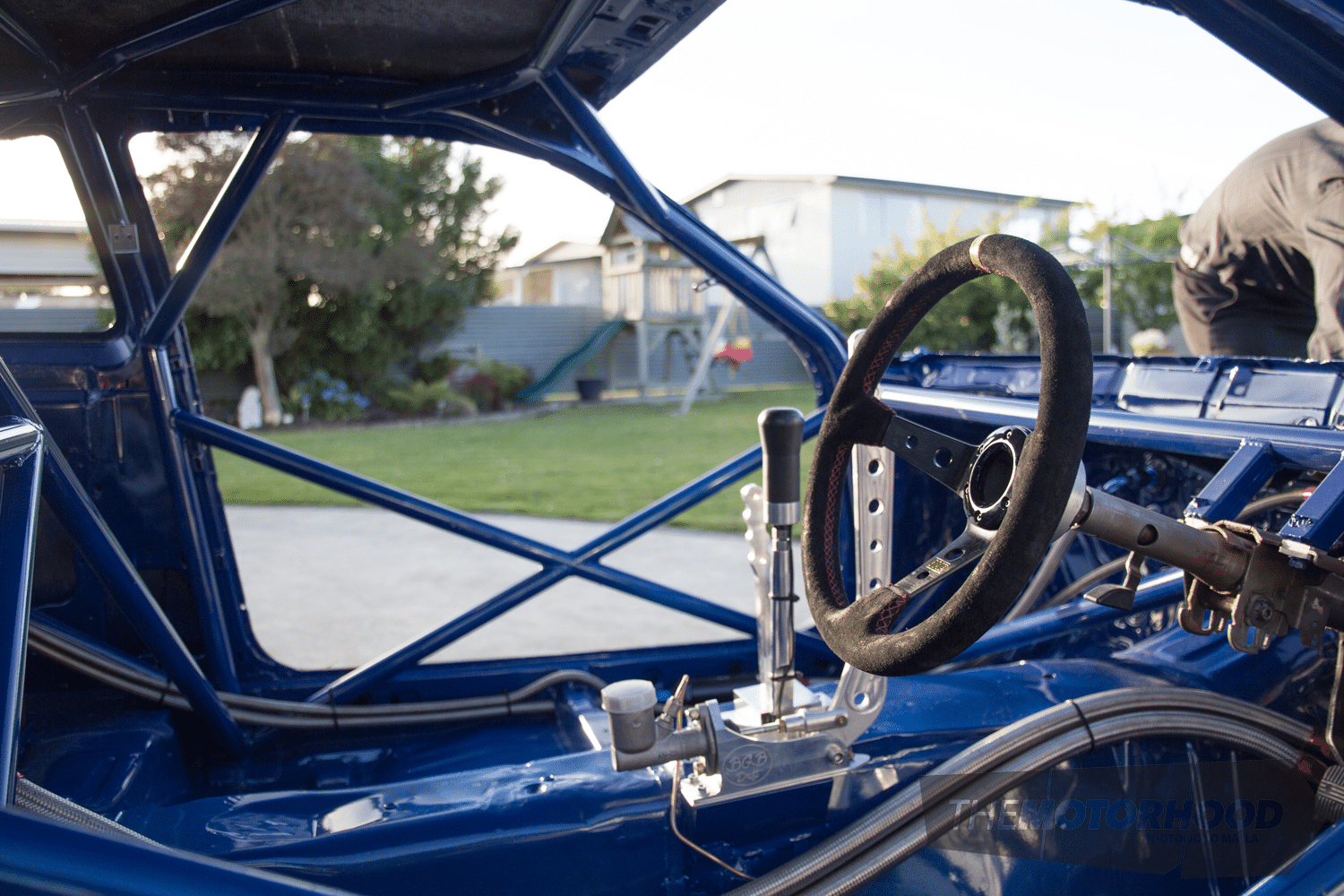

Backing the V12 is the TTi six-speed sequential that Jaron ran last season, and the R230 with Nismo two-way LSD. The diff will either run a 4.1- or 3.6-ratio crown and pinion depending on the track.

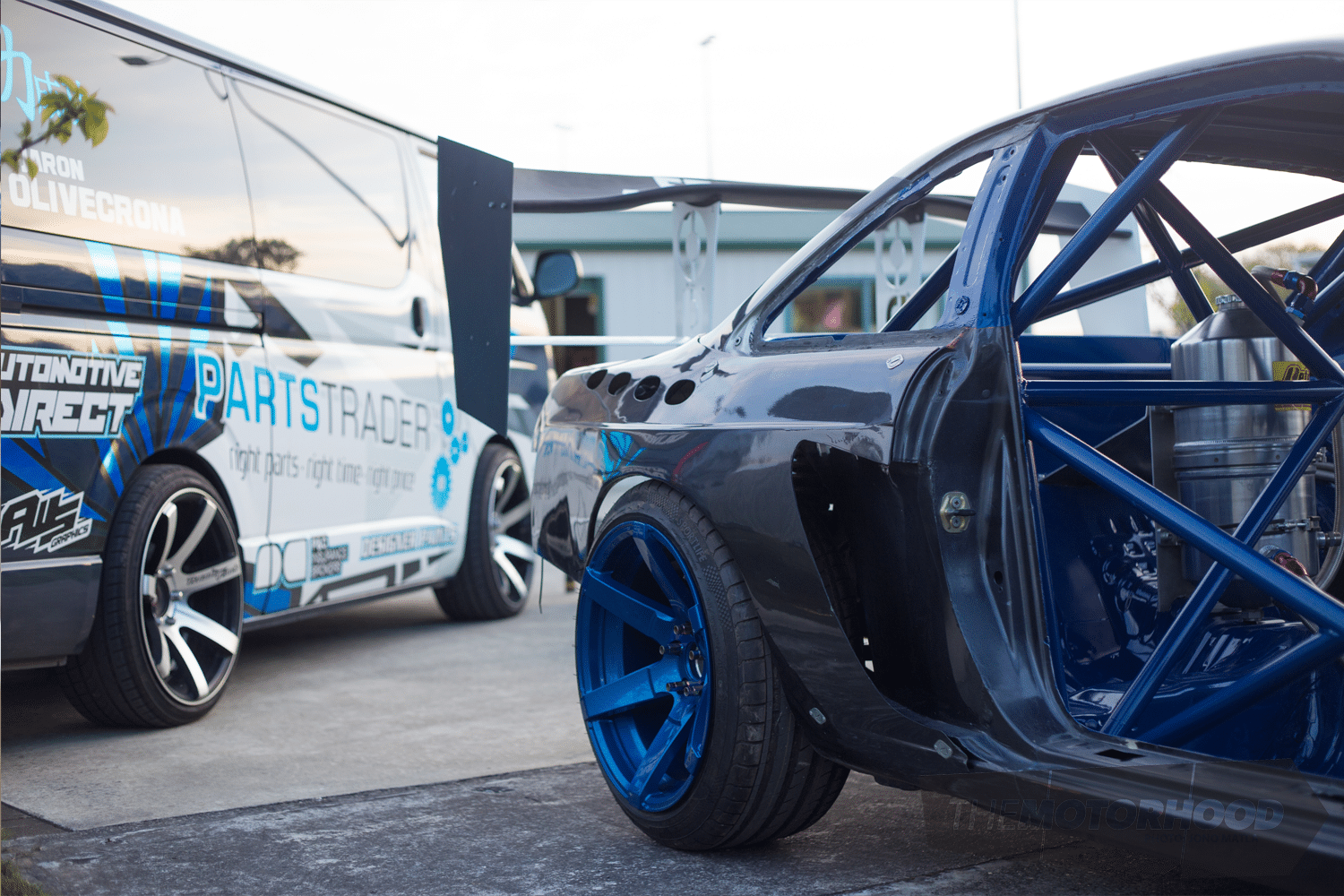

What we have always loved about the Olivecrona S14 was its wild looks. The Kiwi No. 8 wire can-do approach has seen the team build all the panels at home in the shed, including the one-piece rear end. This not only cuts the weight down, but makes repairs a much faster process.

This season the roof has been moulded and a carbon item produced. Again in the shed at home, it was vacuum bagged to ensure the strongest and lightest part possible. This has saves a ton of weight, but more importantly it brings the COG lower. Last season the car weighed 1250kg wet, with driver, so it will be exciting to see what it now weighs.

Other carbon bits joining the party will be doors, front guards, bonnet, and dash. Like the rear, the front features a bolt-on tube frame to hold the coolers, etc. The front bumper is based on a Super Made one from last season, but widened and the guards made to suit. The reason for going wider was to accommodate the TDP track width.

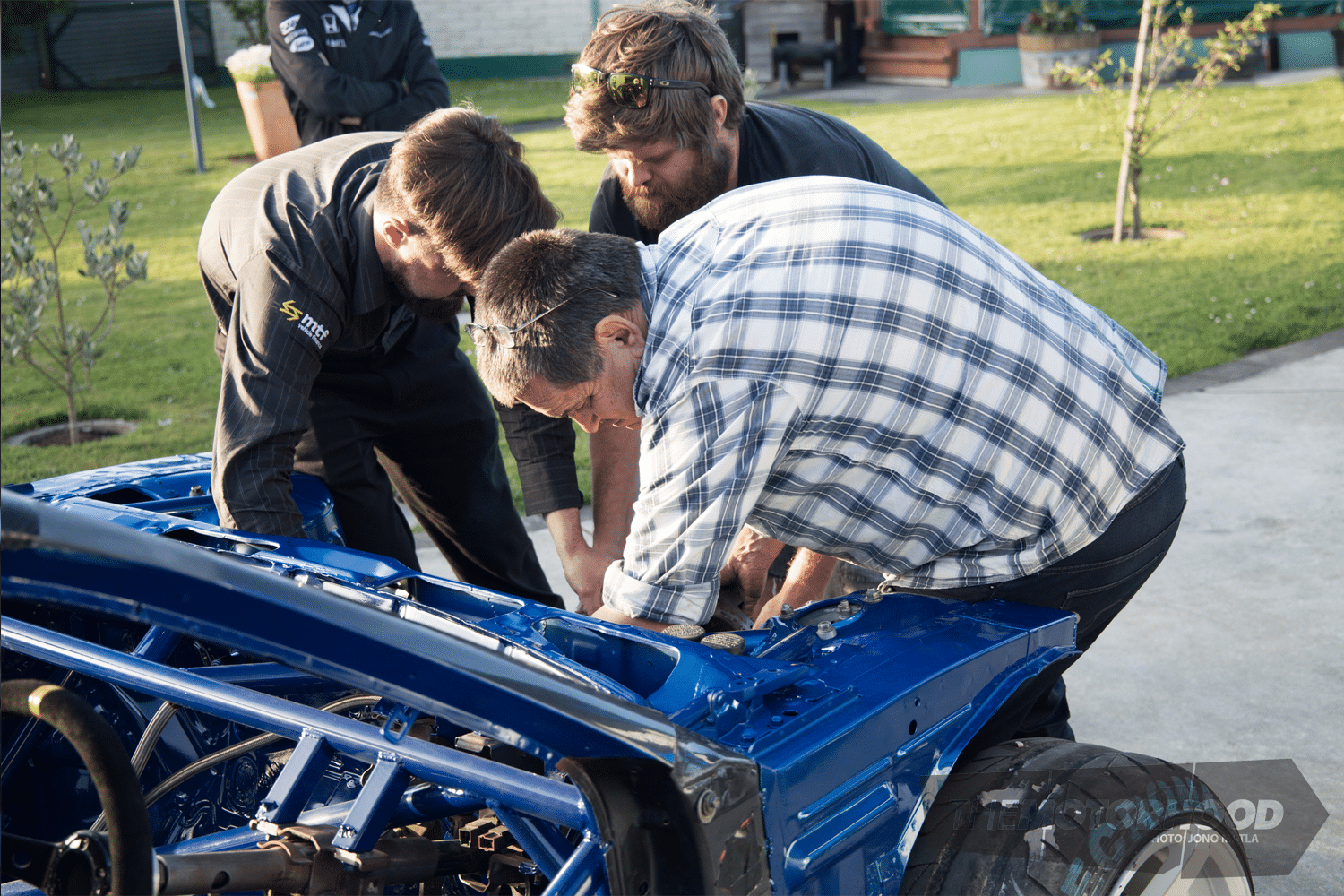

During our first visit, the block had only been mocked in the engine bay so that the team could get an idea about mounting it, which has now taken place (we will check this out in a later post). Thanks to the Brennan four-stage dry sump, it can be mounted very low in the engine bay. Again, Hartleys are on the job building a billet sump pan. Kester is also currently mounting and relocating the accessories.

With only a few weeks to go, the boys are working night in and night out to get ready for testing. We will be keeping you all up to date with one of the most exciting Demon Energy D1NZ builds in the lead up to round one at Forsyth Barr Stadium in Dunedin on December 2–3.