data-animation-override>

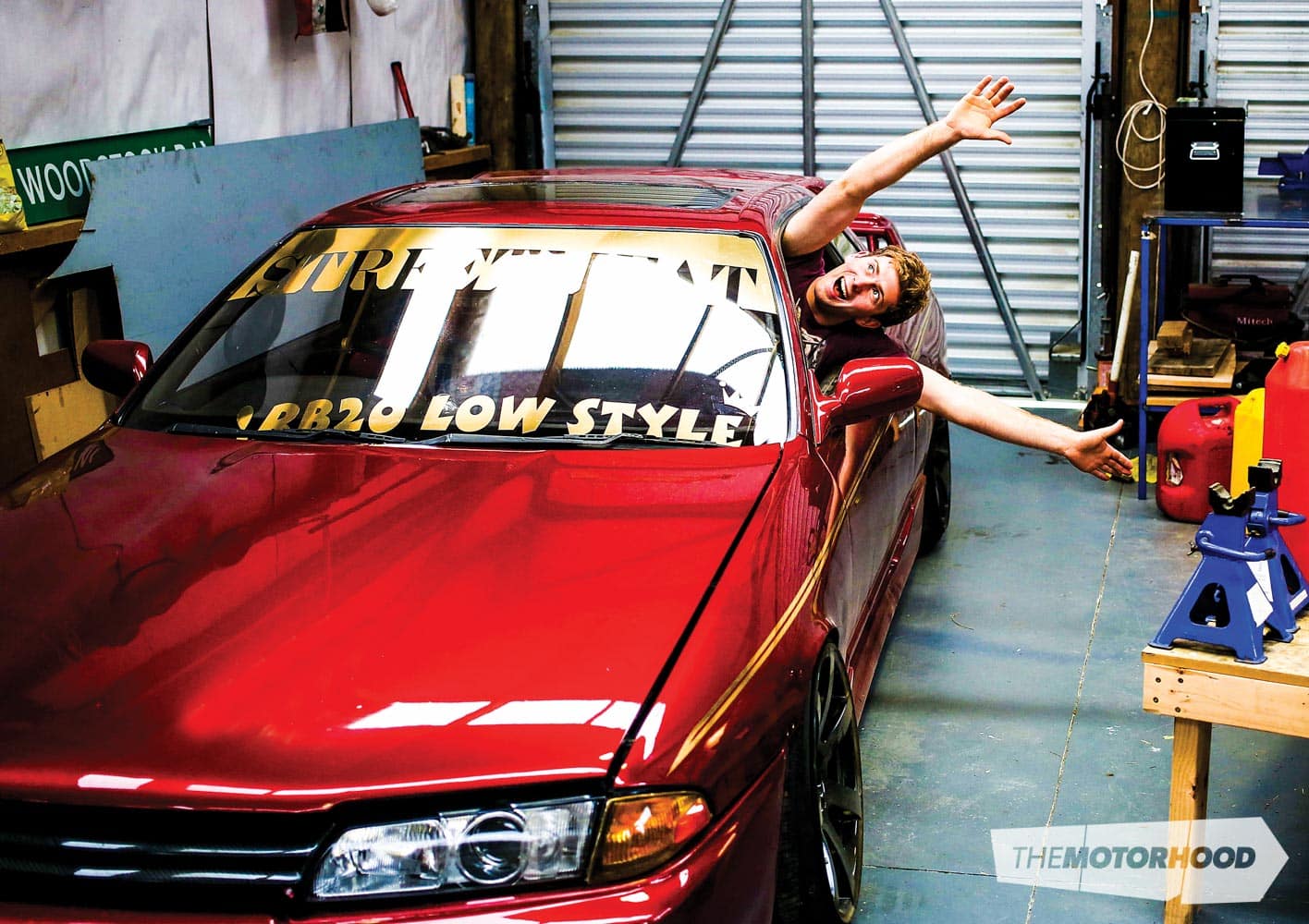

“Jonny has been there and spent the big bucks on a drift car, but this R32 is all about simplicity at its finest”

Keeping up with the drifting Joneses is not always all it’s cracked up to be; a drift life lesson that many learn the hard way with a broken-arse car, no money, and a dream crushed.

One of those who nearly fell victim was ex Drift South competitor Jonny Martin. Jonny’s old R32 was what we like to call a demon car, one of those builds that just never seems to come right, with the owner forever under the damn thing or throwing more cash at it at an attempt to get it right. The four-door demon was a seven-year project, built up from an auto GTE shell into a Drift South machine, which Jonny competed in for a very frustrating season, with some good results before parting the car out. “I wanted to put the money toward different goals, and felt like I had too much money tied up in it,” Jonny told NZ Performance Car.

But his retirement from tyre killing was short-lived, and the itch became a scratch when a friend offered his two-door R32 project for a very cheap price, one Jonny couldn’t refuse, and thoughts of a budget long-term project began.

“I jumped on it with the intention of letting it sit for a while, and slowly just accumulated parts as they popped up on Trade Me, etc.” The coupe came with a decent stack of parts already installed as Jonny explains, “Slotted brake rotors, upgraded coils, alloy radiator, adjustable arms, coilovers, and more or less everything needed to get it driving again.” There were also a few parts like the engine, gearbox, and clutch where condition wasn’t known, which turned out to be a little worse for wear and suitable only for the scrap bin.

The so-called slow project soon became a full-steam-ahead assault, with a self-imposed deadline of the Street Meat Expression session we featured in Issue No. 221.

From the outset there was a solid plan of exactly what he wanted it to look like and how he wanted it to handle, it was just a matter of putting it all together in only 12 weeks. A new RB20DET was sourced from a car he had already drifted, along with an RB25 box, and GT-R fuel pump. “I spent my entire Christmas holidays working on it every day, with help from friends. My buddy Russ helped me a lot in this period, often stopping progress on his S13 to help me out. He played a big part in getting the motor in and running, and he also did my rack relocation, and modified my LCAs for me.”

Despite the tight deadline Jonny wasn’t keen to fall back into the traps that killed the joy for his four-door. Seven years of struggling with that car had taught him a few lessons.

“The main focus of the build was to avoid Chinese/low-quality parts at all costs. I’d had so many bad experiences with them on my previous R32 that I had learned to just buy quality. Second-hand Japanese was still better than new Chinese. I knew I was far better off to spend a little bit extra on something that isn’t going to break, and ruin my day at the track, like I had happen time after time before on the old car. The motto in my head was ‘factory knows best’, so I tended to stick to that. I told myself ‘why mess with a good thing; if it works well, leave it’.”

Predictably the 12-week build cycle flew by as the boys worked away, for the most part on Jonny’s gravel driveway. From the rugged shell they started with, to the finished product it was 100 per cent a project handled without any paid professional help (we aren’t including a few cold beverages), a fact that makes Jonny proud.

As seen in Issue No. 221, he made it to the track. But the first session saw the rear subframe crack. Not to worry, it was loaded on the trailer, taken home, welded up and was back at the track ahead of the next session, where it finished the day without drama. “It’s fun to drive. It does third gear pretty happily, and gets awesome steering angle. Turn-in is a bit slow, but once it’s sideways it’s all sweet. The car fills with smoke though, and blinds me pretty bad, so I need to seal up the guards better.”

But those are pretty minor things, and nothing to keep Jonny from hitting the track again and again. He tells us it’s proving to be a strong and solid set-up, proof you don’t need to reinvent the wheel or take out a second mortgage to be out on track, shredding tyres and blowing up the internet. In our books, that’s some pretty ‘wise fab’.

Photos: Matt Speedy

1991 Nissan Skyline R32

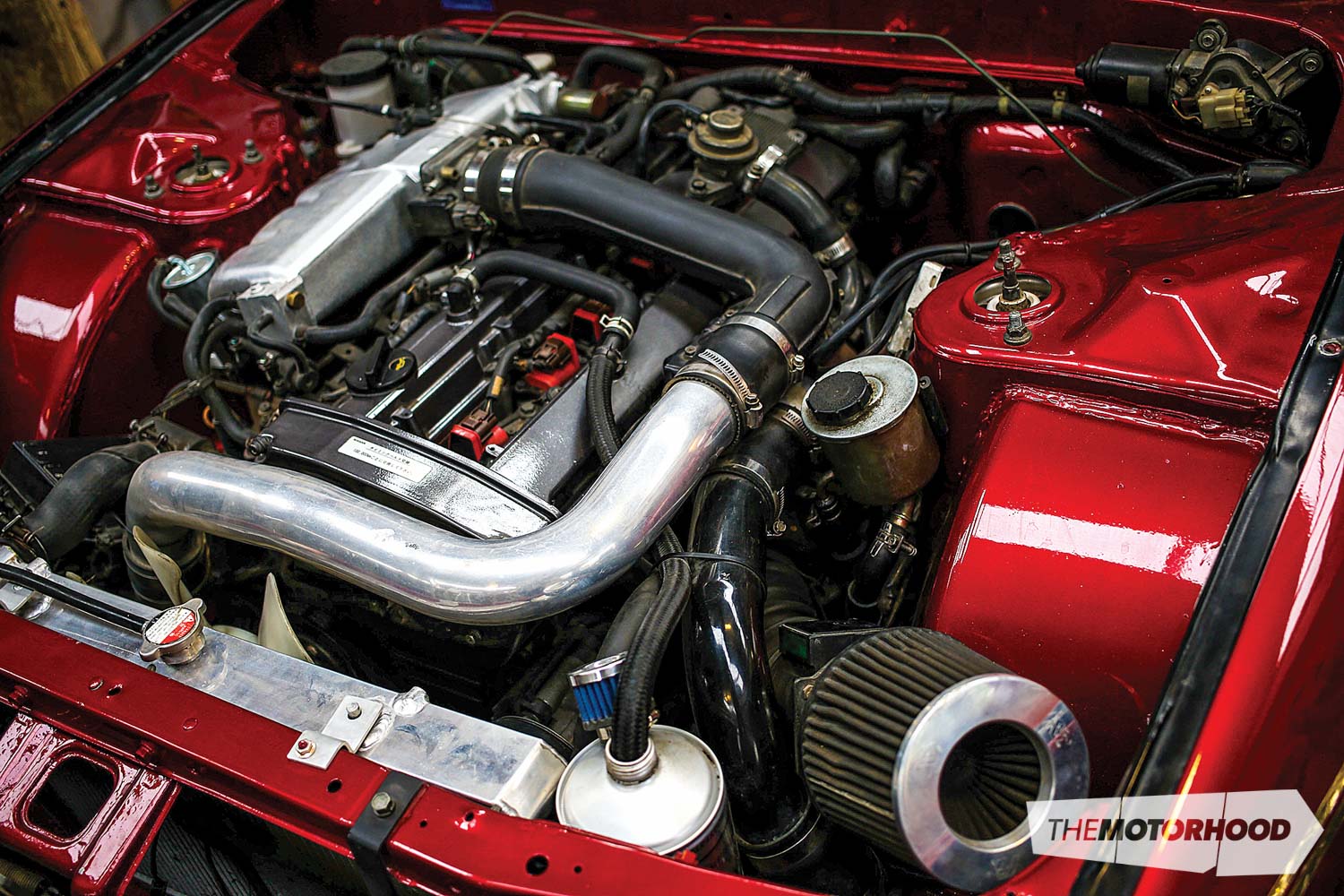

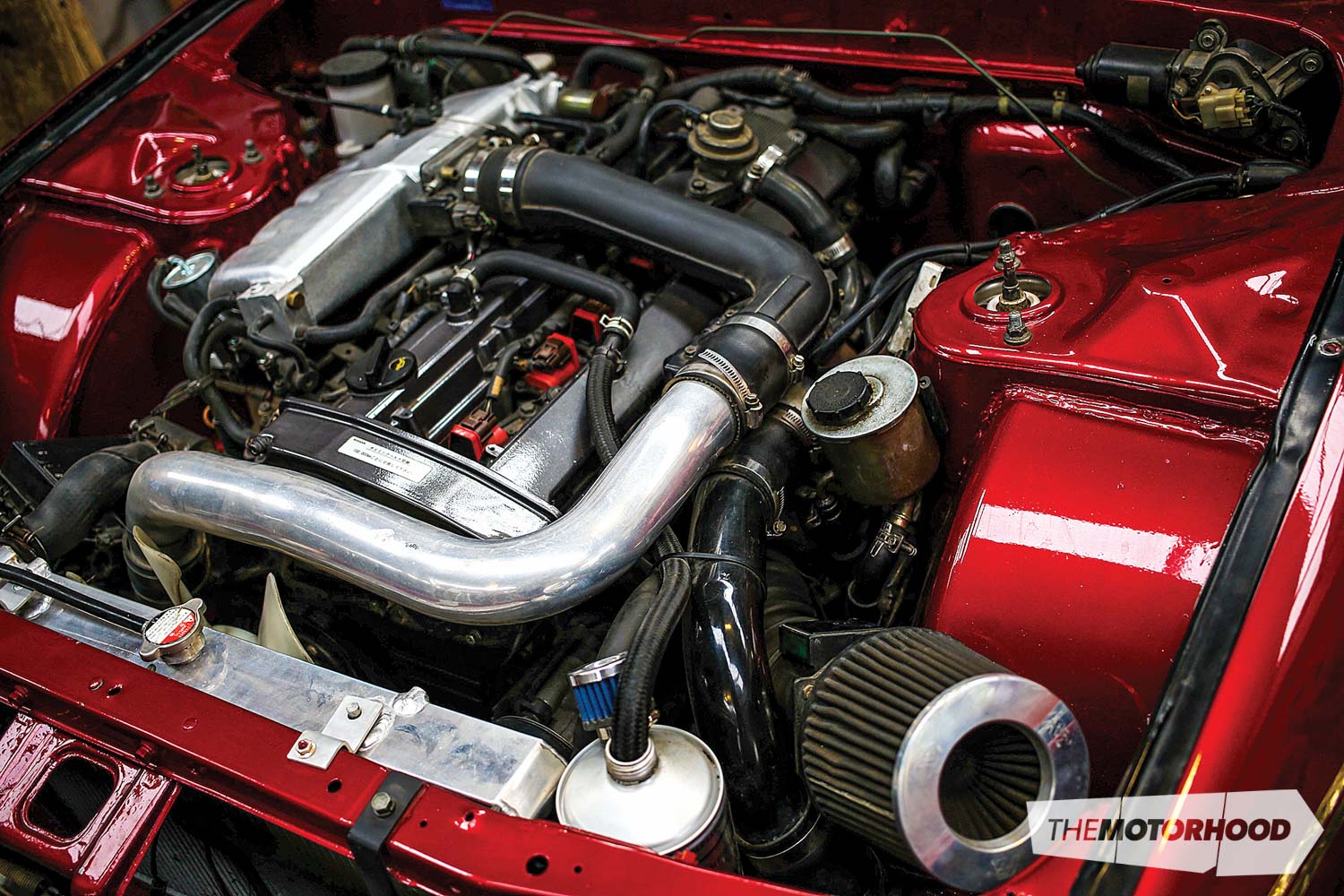

Engine

Model: RB20DET, 2000cc,

Block: Factory

Head: Factory

Intake: Factory

Exhaust: Three-inch mild steel, three-inch straight-through muffler, three-inch stainless-steel rear section

Turbo: VG30

Wastegate: Factory

BOV: Factory

Fuel: R32 GT-R fuel pump

Ignition: Ultra spark plugs

ECU: Factory

Cooling: Twin-core alloy radiator, factory viscous fan

Extra: HKS EVC 5 electronic boost controller, tubbed wheel arches, Asahi two-litre catch can, braided line

Support

Struts: (F) Tein coilovers (R) S13 D2 coilovers

Brakes: (F) Factory four-pot, slotted rotors (R) Factory two-pots

Extra: Shortened adjustable castor arms, offset castor bushes, deleted front sway bar, extended LCAs, Tomlin Power knuckles, A32 tie rods, steering rack shifted forward, adjustable toe arms, subframe lock collars

Drive

- Gearbox: RB25DET

- Clutch: NZAD five-puck clutch

- Flywheel: Factory skimmed

- Diff: Locked 4.3

Shoes

Wheels: (F) 17×9.5 (+15) Origin DRF-S7, 25mm spacers (R) 18×9.5 (+15) Origin DRF-S7, 15mm spacers, Parts Shop Max wheel nuts

Tyres: (F) 215/40R17 (R) 215/40R18

Interior

- Seats: Bride Vios, S14 Bride rail, Jamex harness

- Steering wheel: Momo

- Instrumentation: HKS EVC5

- Other: Nismo gear knob, Parts Shop Max handbrake, Wilwood cylinder, Parts Shop Max braided line kit, GT-R cup holder / tray unit

Exterior

- Paint: Ferrari Rosso Corsa with rainbow flake, pinstriping, Street Meat graphics

- Enhancements: Plastic GT-R bumper, modified GTS bonnet, modified guards, D-MAX roof wing, GT-R rear spoiler, MSpec sideskirts, MSpec end caps, gold mirror tints, red-tinted tail lights, yellow-tinted indicators