Most cars are purely temporary items. Throw-away machines, useful tools to be utilized until they are no longer required, or you’ve found the means to get something better. Others, like Dave Roberts’ 1992 Nissan 200SX, can be a little more challenging to shake.

“This was the first car I ever bought,” Dave says of his sultry black S13. “I was 17 and I love rear-wheel drive, turbo, manual cars, so this was perfect for me.” The New Zealand-new S13 was confusingly badged as a 200SX, as all the later-model local ones were, despite still being fitted with the 1800cc CA18DET motor, as opposed to the bigger 2000cc SR20DET. It was low kays, factory silver and completely stock standard. “I didn’t know jack shit about cars, so it started out like most ‘boy racer’ cars — down to Pitstop for a 2.5-inch exhaust and a big muffler, an Auto Meter boost gauge, pod filter and HKS SSQV blow-off valve. At the time I was happy with my cool-sounding beast, and I boosted around every day to my heart’s content until the engine started to run like shit, smoking and missing all over the place. After getting the car checked out at many different places, I finally concluded that even though the old CA[18DET] had good compression, it had massive cylinder leakage and recessed valves: it would definitely require a rebuild.”

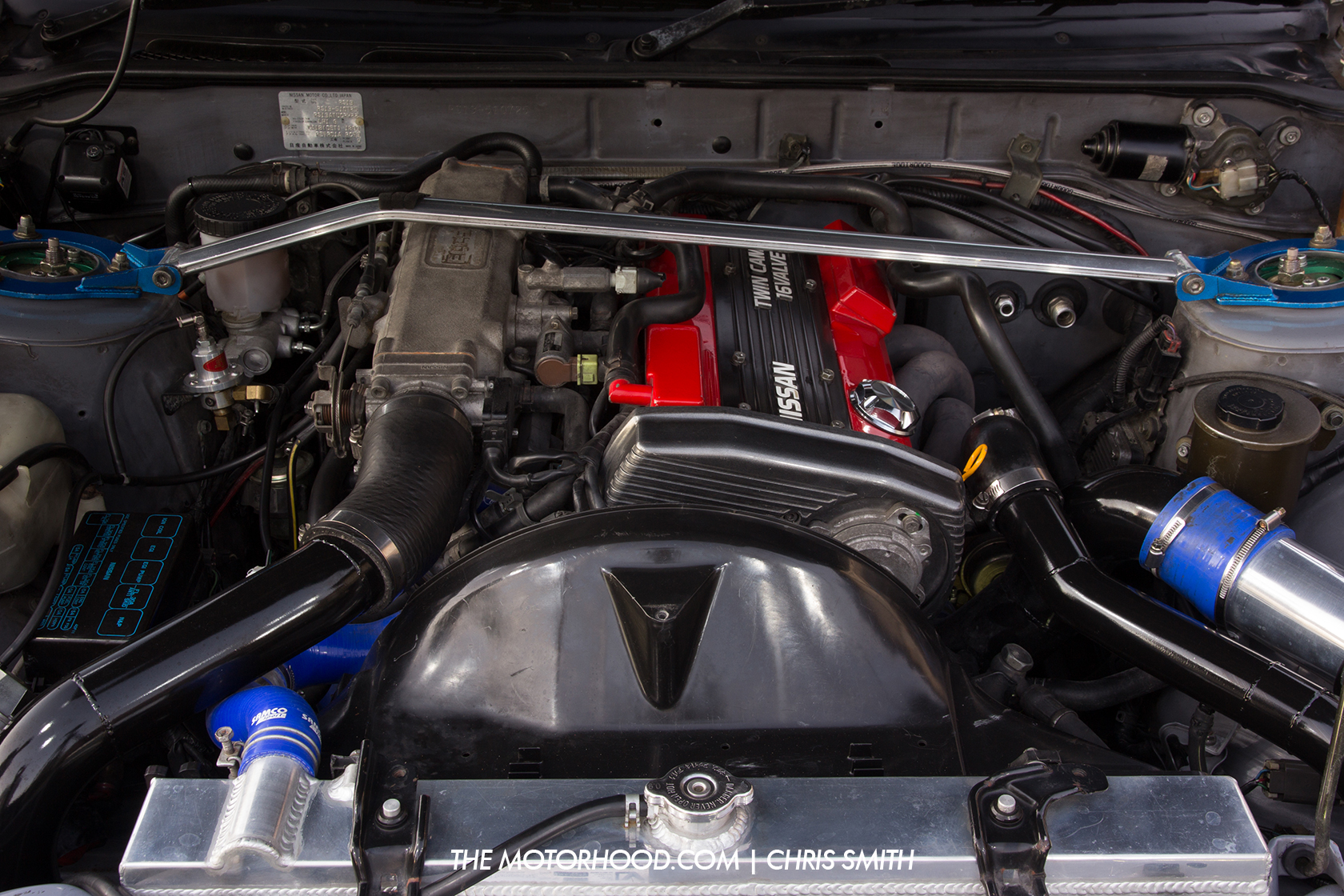

It was at this point that Dave found himself with a tough decision to make. Most people would have simply chucked the CA18DET and replaced it with the newer, bigger and more popular SR20DET, but Dave isn’t most people. “Originally, when I was daily driving the car, reliability was my main concern, and I was faced with the option of installing a high-kilometre SR20DET, or rebuilding the old CA. As a point of difference from most other Nissans, I kept the original CA motor, plus after some exhaust work and changes, we got the CA putting out a very nice sound, better than SR in my opinion.” Instead of simply rebuilding the motor to the original factory state, Dave is one of those guys who always has to make things better when they break — which is essentially how this car came to be in the state it is today — so a raft of upgraded parts were ordered for the tired four cylinder. Oversized JE forged pistons and rods went into the bottom end, while the head also received a complete refresh, plus Tomei cams and cam gears. After the new motor was run in, Dave chucked it on a dyno, complete with stock turbo and tiny intercooler, where it ran up a pretty healthy 130kW at the wheels at 11psi. A good starting point, but much more was to come, as things started to break and were replaced with superior gear. “I was just about to do a big front-mount [intercooler] when the car started smoking like crazy — it was the turbo seals this time, so I went to a bigger GTiR T28 before chucking on the new intercooler.” Over the next few years the upgrades slowly came: a GReddy boost controller, a bigger fuel system and airflow meter, and another trip to the dyno then revealed a nice jump up to 188kW at 15psi. It was more than enough to have fun in, and there were more pressing issues, like the tractor-esque ride height, to contend with.

Over the next few years Dave drove the absolute arse off the car, slowly upgrading it and attending as many drift track days as he could. The T28 was eventually replaced by a GT28R ball-bearing turbo sitting on a low-mount steam-pipe manifold, which helped boost power to 238kW at the wheels, while brand-new Tein coilovers, accompanied by the mother of all aftermarket handling upgrade lists, found their way underneath the car. Eventually though, all these on-track beat downs took their toll on the S13, and Dave knew he had to do something about it. “I originally never wanted to change to a widebody, however, after seven or eight track days in the car the rear guards were showing signs of abuse, with a few dents here or there. It was at this stage I decided widebody would be best. From there it was a matter of sourcing Origin front and rear guards from Japan. For me, widebody guards really work well with the BN Sports bodykit along with the D-MAX bonnet, Ganador mirrors and 326 Power wing. Overall the car came out better than expected, everybody loves wide and low!” Going from a banged-up factory silver with a multitude of different-coloured panels to being one of the best-looking Silvias in the country must make a man a little more nervous when hitting the track for a session? Dave admits, “Yes, unfortunately at this stage the car became more a thing of beauty for me than a drift car, which absolutely made me more hesitant to go to drift days in fear of damaging her.”

That didn’t stop him altogether though, and the car was seen out at casual track days hacking up, complete with what we have to say is the absolutely perfect wheel choice for this machine, even if they were a mission to obtain. “I have always loved the Work Meister design and look, but never thought I would ever be able to afford a set. After trialling various different wheels in New Zealand, but never finding that perfect size and offset, one day I decided to order a brand-new set from Work Japan in bright buff finish, which I knew would look great on a black car. It was around this time the Japan tsunami occurred, which partly destroyed the Work factory. This meant an 18-week wait time for my wheels to arrive, which felt like an eternity: $5200 for the wheels alone certainly drained the bank account, but when I saw them for the first time I was like a kid on christmas day.”

And fair enough, too. With the huge amount of work that has gone into the body, the suspension and the interior with its J-spec Bride seats and awesome Miracle drop rear strut brace by Next, Dave’s car oozes pure JDM style, and it has the on-track handling and slightly left-of-field power to back it up.

As many readers will know, the final twist to this story is that after nine years of building and driving this machine, Dave has on-sold it to a proud new owner. After all that time having a car like this as a constant companion, it must have been an extremely hard thing to let go of. “The car got to a stage where I would struggle to drive it on the streets. I would refuse to raise the car to an acceptable level in order to keep it looking at its best, but this meant that any steep driveways, speed bumps, even slight changes in road surface would cause the fibreglass bodykit to chip, tear, or in some cases simply explode. Because of my pedantry, I would tend to repair this every time it happened, so it seemed to be a never-ending money pit — my panel and paint guy loved it, though! The car stopped being a drift car and simply became eye candy for me: it was when I realized it was only being driven a few times a year that I decided it was time to let her go. It was quite emotional after owning it for nine years and pouring my heart and soul into it. I learned everything I know today about cars from my tinkering and changing things on the 200SX, so I have no regrets.”

In the end, though the car may have gone to a new owner — who we hear has been using it to its full potential — nothing can take the build process away from Dave, nor the experience he gained from it. He built the car exactly how he wanted it, using all the best parts from around the world, and though it has now gone, there’s no detracting from the satisfaction and the pride that comes with undertaking such a big project, and having it appreciated by so many people. Sometimes if you love something, you’ve just got to let it go, and who knows, maybe one day the car will return to Dave, something he says he’d definitely consider if it comes back up for sale in future. Until then, let’s just hope it stays in one piece!

TUNING MENU

ENGINE:

MODEL: Nissan CA18DET 1800cc four-cylinder

BLOCK: JE oversized forged pistons, JE rods

HEAD: Tomei 265 duration camshafts, Tomei cam gears, ACL 1.3mm three-layer head gasket

INTAKE: Custom air intake, K&N pod filter, custom intercooler piping and front-mount intercooler

TURBO: Garrett GT28R

BOV: HKS Super Sequential

FUEL: Walbro 373kW fuel pump, Sard fuel pressure regulator, 450cc injectors

IGNITION: NGK race plugs

EXHAUST: Custom-built low-mount steam-pipe manifold, three-inch downpipe, three-inch ST Hi-tec system, dual three-inch tips

COOLING: Alloy radiator, Samco radiator hoses, GReddy radiator caps

ECU: HKS F-Con V Pro, GReddy Profec B-II electronic boost controller

Driveline

GEARBOX: Stock five-speed manual

CLUTCH: Exedy heavy-duty single plate, lightened flywheel

DIFF: Nissan R200 4.3

Support

STRUTS: Tein Super Drift coilovers

SPRINGS: (F) 10kg/mm, (R) 8kg/mm

OTHER: Tein tie rods, Tein tie rod ends, Tein steering lock spacers, Ikeya Formula traction arms, Ikeya Formula toe arms, Ikeya Formula castor arms, Kazama Auto camber arms, Cusco stabilizer rod bar, Cusco front strut brace, Miracle drop rear strut-brace by Next, Whiteline 27mm front sway bar, Whiteline 22mm rear sway bar, urethane D-bushes and link bushes, Gktech alloy steering spacer, metal subframe collars

BRAKES: (F) R33 GTS25T hubs, R33 GTS25T four-pot calipers, slotted DBA rotors, (R) two-pot calipers, slotted DBA rotors

Shoes

WHEELS: (F) 18×9.5-inch -1 Work Meister S1, (R) 18×10.5-inch -9 Work Meister S1

TYRES: (F) Nitto NT555 225/35R18, (R) Nitto NT555 235/40R18

Exterior

PAINT: BMW Sapphire Metallic Black

ENHANCEMENTS: BN Sports Type II front bar, BN Sports Type II rear bar, BN Sports Type II sideskirts, 326 Power wing, Origin widebody front fenders, Origin widebody rear fenders, D-MAX carbon fibre bonnet, Ganador wing mirrors, 35 per cent window tints, Type X tail-lights and centre garnish, HID 8000k headlights

Interior

SEATS: Bride Zeta III driver, Bride Brix passenger, Bride super-low seat rails

STEERING WHEEL: Sparco

GEAR KNOB: Nismo

INSTRUMENTATION: A’PEXi warning control unit, A’PEXi boost gauge, A’PEXi water temp gauge, A’PEXi oil pressure gauge, A’PEXi oil temp gauge

OTHER: Broadway 300mm rear view mirror, Pivot RHU-M headlight height adjuster, remote turbo timer

Performance

POWER: 238 kilowatts (319hp) at the wheels