data-animation-override>

“TH400, Powerglide, Tremec — we’ve all heard the names, but what’s the difference and what’s the best transmission to use in your next project?”

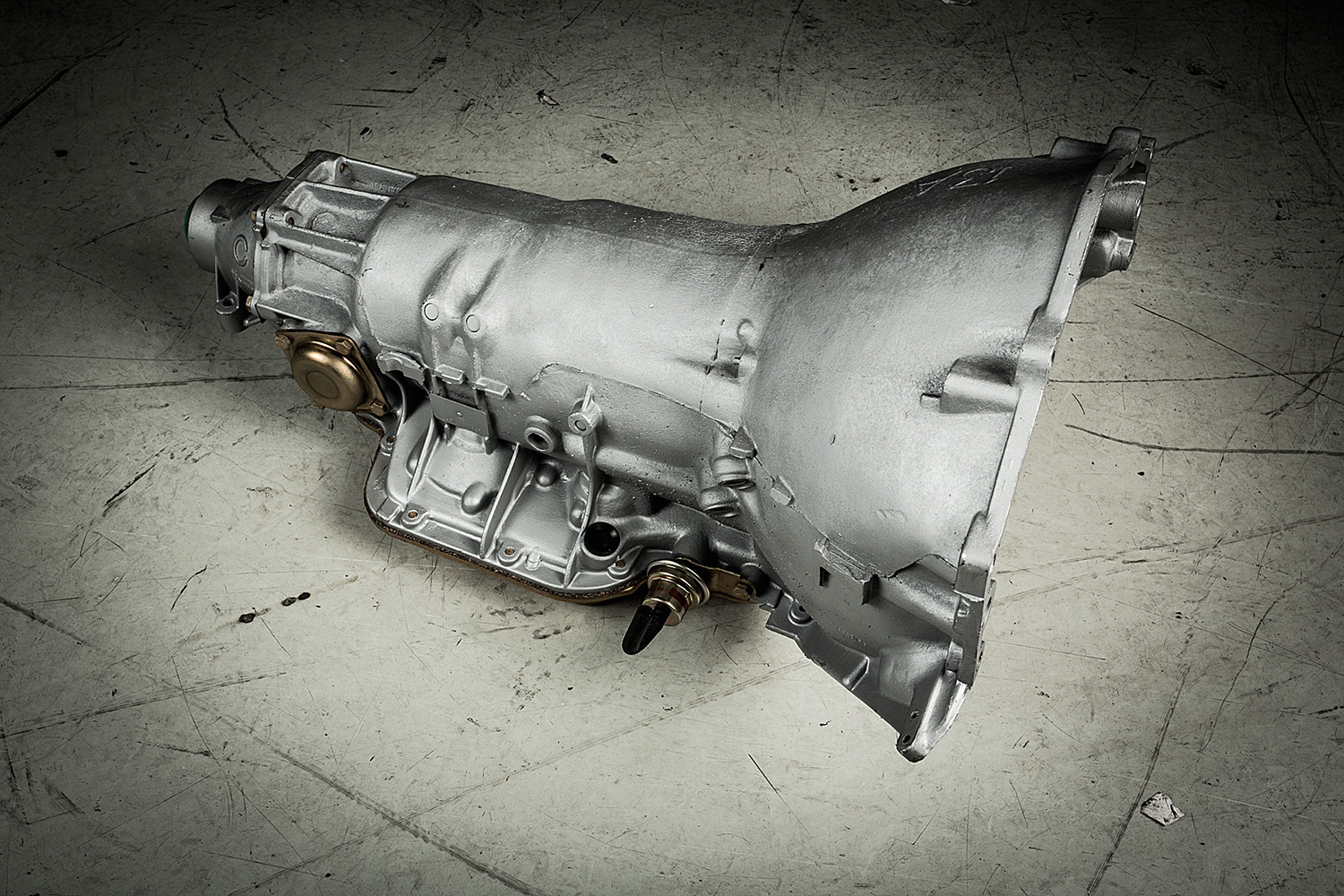

TH400

The Turbo Hydramatic (TH) series of transmission was developed and produced by General Motors and is now used in a wide variety of factory and aftermarket applications. First introduced in 1964 in Cadillacs, the three-speed plus reverse transmissions ended up replacing all of GM’s other automatics by 1973.

Some of the Buick, Cadillac, and Oldsmobile TH400s produced between 1964 and 1967 were equipped with a switch pitch torque converter and variable pitch stator, so is sought after by collectors and drag racers. These can be identified externally (with the torque converter removed) by a narrow front pump spline. Externally, the switch pitch version has two electrical connections, whereas the non–switch pitch TH400 has only one.

A variant of the TH400, known as a TH375, is a TH400 with a long output shaft that mates to the smaller TH350 driveshaft yoke. It can be identified by ‘375TH’ cast into the tailhousing.

Much of the TH400’s strength comes from the use of a cast-iron centre support to suspend the transmission’s concentric shafts that join the clutch assemblies to the gear train. The centre support, which is splined to the interior of the transmission’s case, also provides a robust reaction point for first gear.

By 1980, the relatively heavy TH400 was starting to be phased out of passenger cars in response to demand for improved fuel economy. However, it was used in GM pickups and vans until 1990, when GM switched over to the 4L80E, so it is much more readily available than some other options.

Towards the end of the ’70s, far more Cadillac/Buick/Oldsmobile/Pontiac bellhousing TH400s were produced than Chev ones, so make sure to check the pattern before committing to a purchase. Various other manufacturers have also used the TH series of transmission, including Jaguar, Rolls Royce, Nissan, and even Ferrari, so there are a wide range of bellhousing designs out there, and that can easily trap the uninformed.

The TH400 was the first three-speed, Simpson-geared automatic to use overrunning clutches for both first and second gear reaction. This eliminated the need to coordinate the simultaneous release of a band and application of a clutch to make the two-to-three gear change. As such, the TH400 is able to withstand very high input torque as well as a high number of shifting cycles; hence its popularity in aftermarket uses.

For 1987, GM changed the name of the TH400 to 3L80 (three forward speeds, longitudinal positioning, and an arbitrary ‘strength’ of 80 — the second highest such rating assigned). A heavy-duty version, the 3L80HD, was introduced in passenger trucks in 1987. In 1991, a four-speed overdrive version, the 4L80-E, replaced the TH400 altogether.

With the TH400 being popular with the aftermarket, a large range of parts and support are available, making this transmission a great option for a street car or even a mild drag car.

Expert’s opinion

Ian Hunter from Kaspa Transmissions says:

“A Turbo 400 is a good choice no matter what. It’s super strong and it’s very agricultural and heavily built; you can’t go far wrong. If the oil in it looks good, you can probably just bolt it in and drive it. Just check the suitability to your vehicle, as there’s long shaft and short shaft options and a few differences between them.”

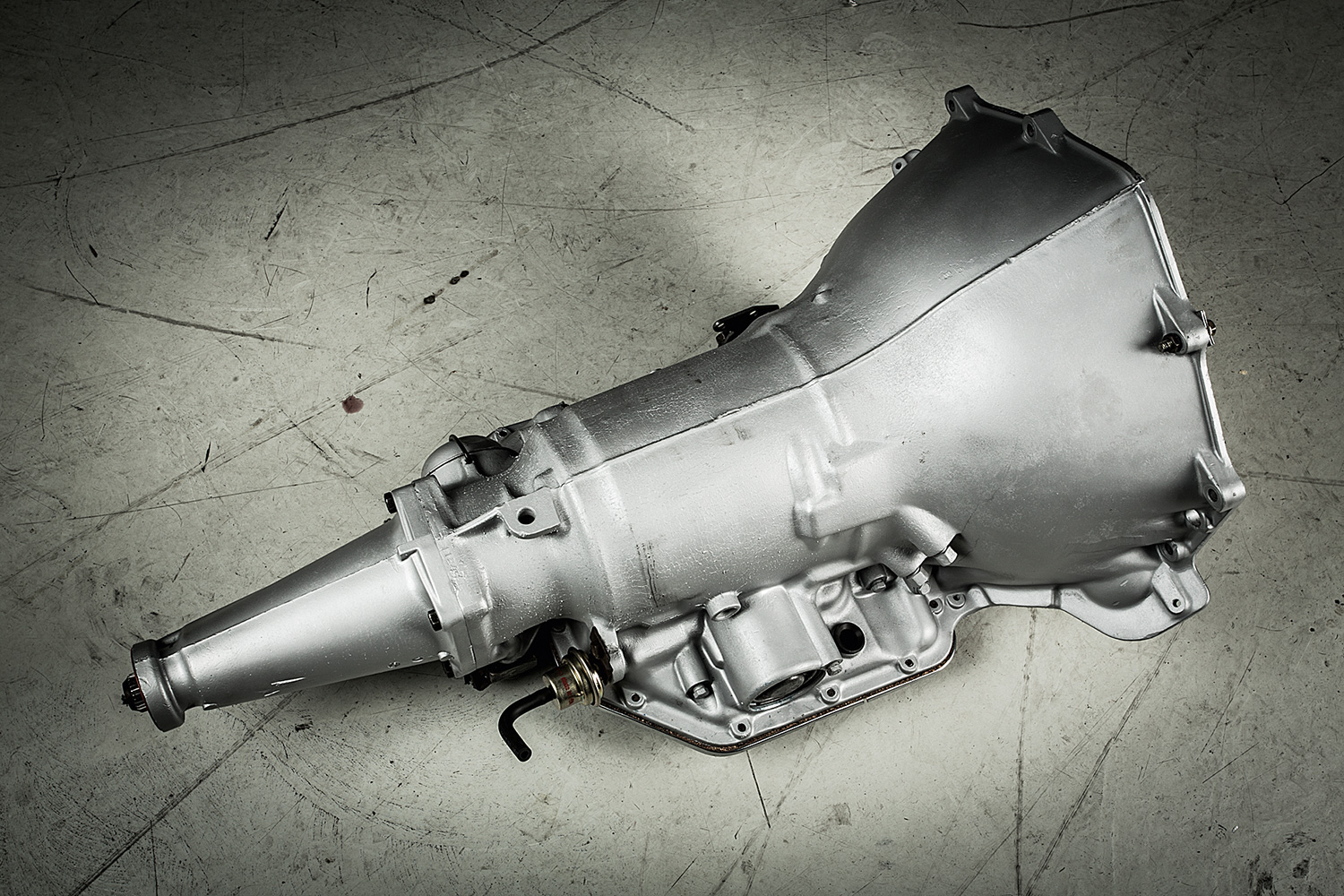

TH350

The Turbo Hydramatic TH350 was first used in 1969 models produced by General Motors. It was developed as a joint venture between Buick and Chev to replace the two-speed Powerglide.

Although it uses the same torque converter as the TH400 (minus the variable pitch stator), it has a familial resemblance to the 1962–’73 aluminium-bodied Powerglide. One important difference between the TH350 and the TH400 is that the former has no fixed centre support midway through the gear train.

There is a rumour that the reason for the TH350’s release after the TH400 is that, although the TH350 had been in development for longer, it often failed under heavy torque loads. Whether this is true has not been verified, but it does indicate that a TH400 is a stronger option than a TH350. Some weakness can be removed from the TH350 by fitting an inexpensive aftermarket case-saver kit.

Around 1980, a lock-up torque converter was introduced but this transmission was phased out in GM passenger cars in 1984 in favour of the 700R4. Chev/GMC trucks and vans continued to use it until 1986.

Expert’s opinion

Chuck Mann from Rotorua V8 Performance says: “The weak link in a 350, and in a 400, is the intermediate sprag — there’s no way to check externally, pulling the pan off is the best indicator. The 350s have a bushings inside which always needs replacing. Normally the high clutch ends up pretty tired with them. They’re all pretty much the same, but some of the V6 ones, which will bolt up to the V8s, have one less clutch in each pack, but that’s easy to remedy. All the planetaries, etc., are all the same though.”

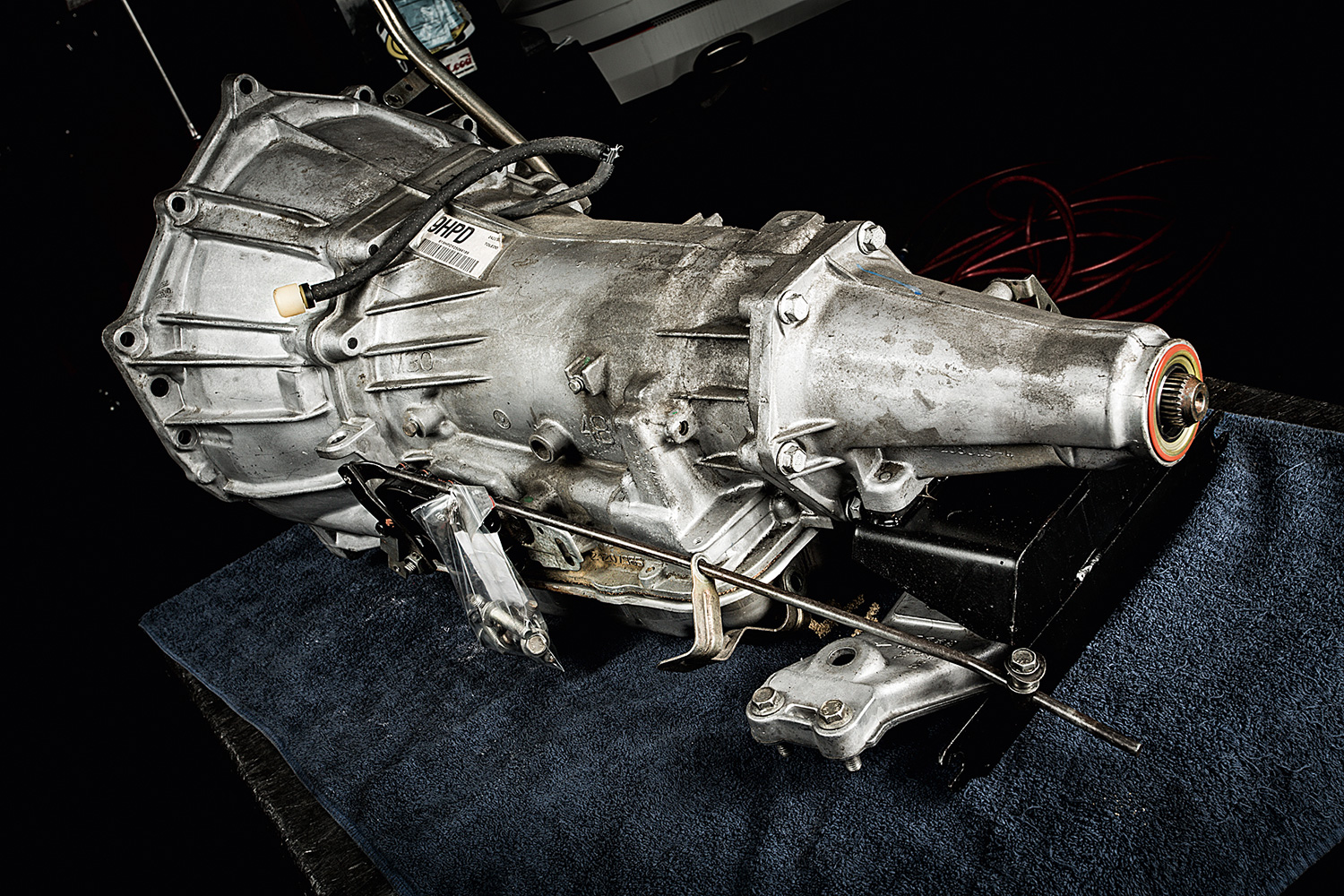

4L60E

The 4L60E is a four-speed electronically controlled automatic transmission produced by General Motors from 1992 onwards and commonly found in VR-VZ Commodores on this side of the globe.

In 1995, the 4L60E had a second control solenoid added to it to allow control over the way the lock-up felt. The original on-off solenoid enables lock-up, and the new solenoid (often referred to as the ‘apply’ solenoid) controls a slide valve in the valve body to regulate the amount of fluid released by the solenoid.

Essentially, the 4L60E is a modern and improved version of the 700R4. However, there is also a non-electronic version, the 4L60. In 1996, a bolt-on bellhousing was phased in (along with a six-bolt tailhousing). By 1998, it was used on all 4L60Es. Also in 1998 came a new 300mm torque converter with improved higher capacity internals. The 4L60E is rated to handle up to 360 ft·lb of torque, making it a good trans for a medium-performance road car. With its electronically adjustable shift points, it can be customized to shift as harshly or smoothly as you like. With many of these being fitted to LS engines from stock, they’re a great option if you’re looking at running one in your next build.

In 2001, an updated version — the 4L65E — was introduced, complete with five-pinion planetaries and a slight improvement in strength. This was to allow it to work behind the 300ft·lb 6.0-litre Vortec engines.

Expert’s opinion

Kris Geurts from Motortech Transmissions says: “They’re a good box, but wear out the third clutch. They’re easy enough to get parts for and there are a lot of upgraded parts available too. In standard form they’re OK for around 250kW but if you’re going too much over that you’d want to build them up stronger. There’s a wide range of aftermarket controllers available if people want to use them in older cars, lots just plug and play, usually programmed overseas, it’s pretty simple.

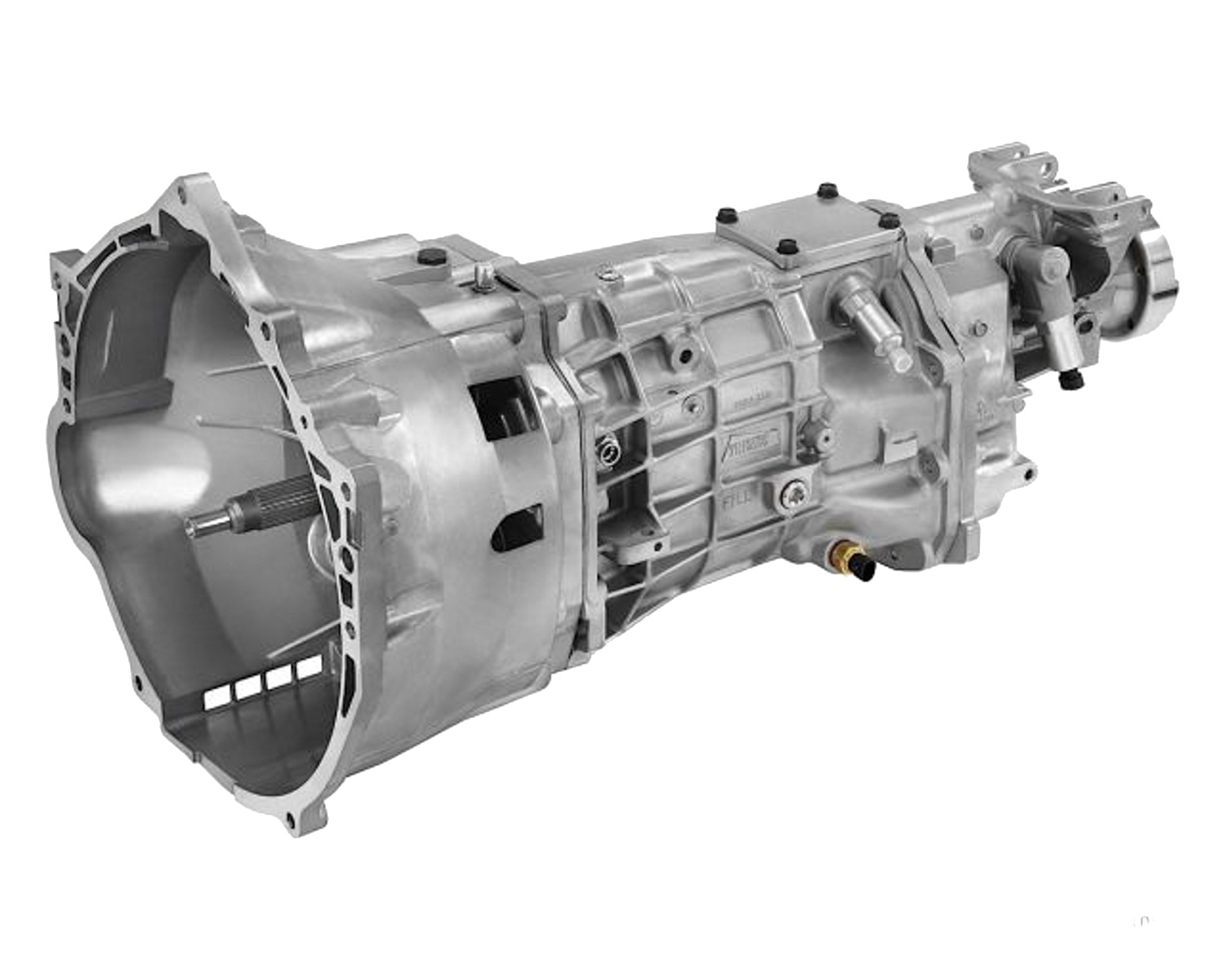

T56

BorgWarner was taken over by TTC, which owns Tremec, partway through the T56’s lifespan, so there’s often confusion about who manufactured the T56. The reality is that the six-speed manual T56 is available as both a Tremec- and a BorgWarner-branded item. The T56 was used in a wide range of vehicles produced by the big three American manufacturers — GM, Chrysler, and Ford — and was originally designed and built by BorgWarner for the Dodge Viper. It was used in Commodores from 1998 until 2008 and Corvettes from 2007 on as well as in numerous other vehicles. These days, the T56 has been succeeded by the Tremec TR6060, which offers greater strength.

The T56 predominantly uses a hydraulic clutch. However, a few were fitted with a mechanical variant. The entire case, including removable bellhousing, is made of aluminium, while the syncros are brass in GM and Ford applications and stainless steel in the Dodge versions. The transmission also features internal stops, which render stop bolts on the shifter mechanism unnecessary.

The T56 was made in a wide range of ratios and various spline combinations, with the strongest second-hand option being that sourced from the Dodge Viper.

Expert’s opinion

David Jensen from Wellington Automotive Gearbox Specialists says: “The T56 is a great gearbox, but it does tend to rattle under load. If it does that, it generally means it’s showing a few signs of wear, but it may be rattly for 10 years before it gives any real problems. They’re a good size for use in hot rods, etc. and they shift beautifully. They are far nicer to drive than, say, a four-speed Muncie, Toploader, or any of those boxes, which are all like a truck to drive. I, personally, like the TKO600 more than the T56. The T56 is a simpler gearbox, but in my opinion it has more issues and more potential problems. The TKO is more complicated, but its design is better. It can be easy to spend a few grand just rebuilding a second-hand T56, so it does pay to be careful and make sure you buy a good one to start with. The old saying ‘Anything will only be as good as what you start with’ applies: start with a crap gearbox, and it’s always going to take more effort to make it a nice one. The cost saving from buying one that’s broken can easily be offset by the amount you’re going to have to spend on improving it.”