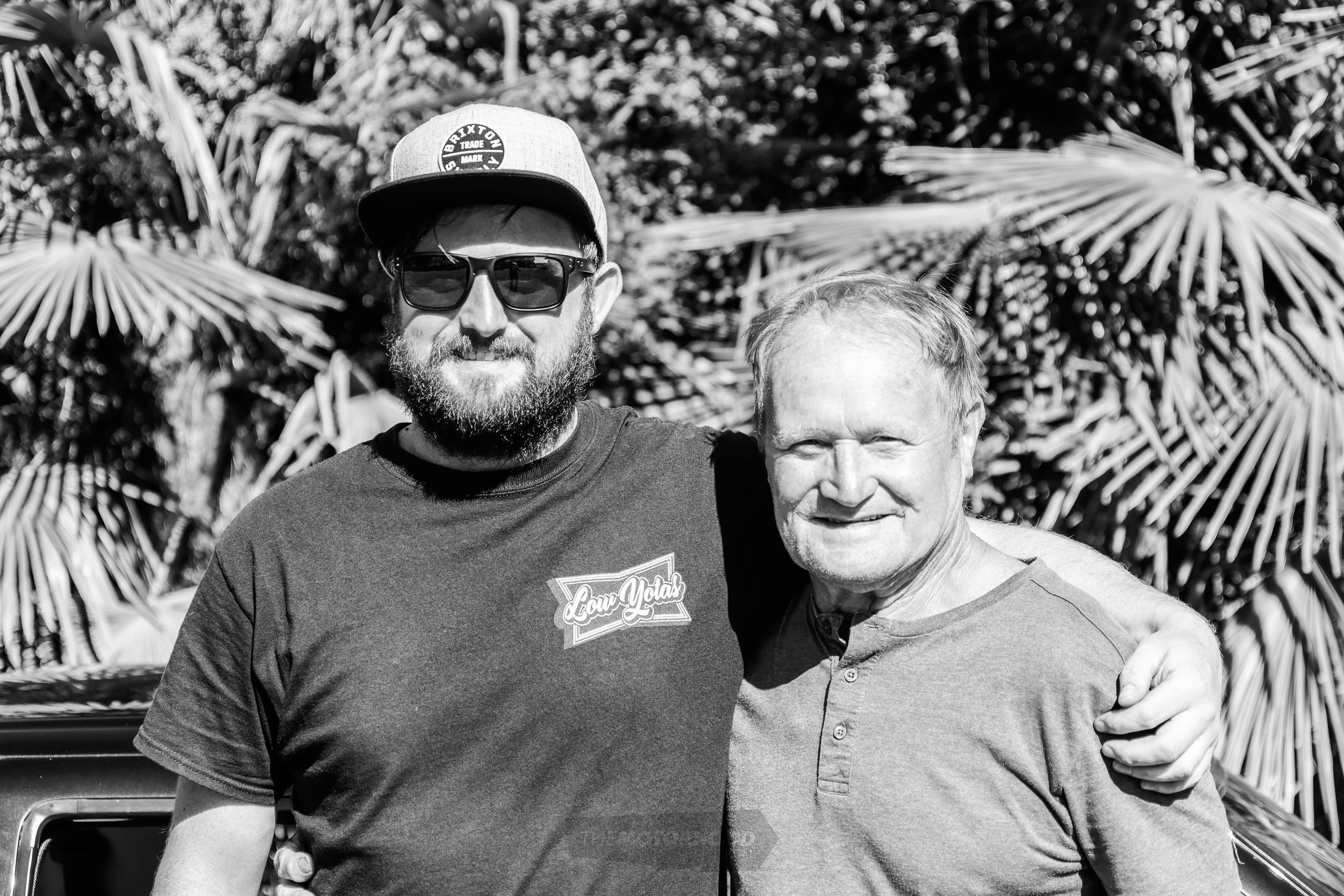

A 10-year labour of love put together largely by its owner and his father in their garage while learning a lot along the way

Words: Waren Sare Photos: Rod Dunn

Growing up in England, Will Dickinson always had an interest in cars and, as a young lad, grabbed any copy of M ower magazine he could, turning pages and dreaming of a ride inspired by the English style of big body kits, wheels, and over-the-top sound systems. With a father who was a mechanic, it was perhaps inevitable that young Will was destined for a passion for things on four wheels, as the young lad grew up around tools, grease, and learning how With a father who was a mechanic, it was perhaps inevitable that young Will was destined for a passion for things on four wheels, as the young lad grew up around tools, grease, and learning how things both came apart and went back together.

The family relocated to New Zealand when Will was the ripe old age of 17 from a place near Leeds, having never even seen the country, and one of Will’s first purchases was a 1974 Toyota Corolla KE20 for the princely sum of $430. This went on to become the first father and son Dickinson family project in New Zealand. Through the course of this build, Will discovered he greatly enjoyed the process and developed a particularly strong interest in the fabrication aspects of the modifying process. Just how Kiwi does a 4K engine, blood-red paint, and Spitfire mags sound as a combo, with its proud owner doing many a Colombo Street lap. We’re told this particular car didn’t get sold until money was needed to fund the sound install for the truck, and no doubt it held quite a few memories.

Around 2007, having dabbled in a bit of 4WD as a way to enjoy some of the southern scenery, it was time for Will to make a call on what he wanted next, and he says it was a choice between an Evo or mini truck. He had started to buy mini truck mags once settled in NZ, and, given a nudge by father Billy, due to his preference for his son taking the slower and safer route, Will made the decision to buy this very Toyota Hilux off a local diesel mechanic.

The plan was simple — fit a set of airbags and, once complete, ‘daily drive and drag’ in the way that only a mini truck can, with sparks flying as the chassis makes contact with our always well-maintained New Zealand roads. In this build guise, the Hilux was literally dragging itself along the seal, although Will tells me that is no longer quite so appealing with the amount of work that has now gone into the rebuild.

Every major project seems to start with one particular moment or incident, and with daily use, there was an unfortunate incident involving some ice, a bridge, and what was referred to as some panel damage. This led to more than 10 years off the road and thousands of hours of Dickinson family input, which turn led to ‘DR4G1N’ as it now sits.

“It’s over designed and over engineered,” Will says of the extensive CAD work used throughout the process due to his skills as an architectural designer. Everything has been drawn and redrawn, then laser cut, and this is a build that drew a lot of eyes and punters taking time to look it over during its 2021 appearance at the 4&Rotary Nationals. The level of detail is intricate and completed to a high standard by Will, Billy, and, where needed, a couple of trusted workshops. There really is so much work here that I’m not sure what you would find that came factory standard.

Externally, every single part of the fully customised body wears an expertly applied coat of Dupont Candy Scarlet Night. There is more shaving, tucking, widening, filling, and hiding going on than your average night out on the town in — since it’s Will’s story — let’s say Leeds.

Toyota might have made this body and Crumpy might have made the Hilux the stuff of New Zealand legend, but this takes things to the next level. I’d never quite been able to work out how these vehicles navigate our roads, but with the use of widened 4×4 guards, apparently this vehicle has full lock while sitting only 60mm off the ground — yes, we know 100mm is the minimum, officer!

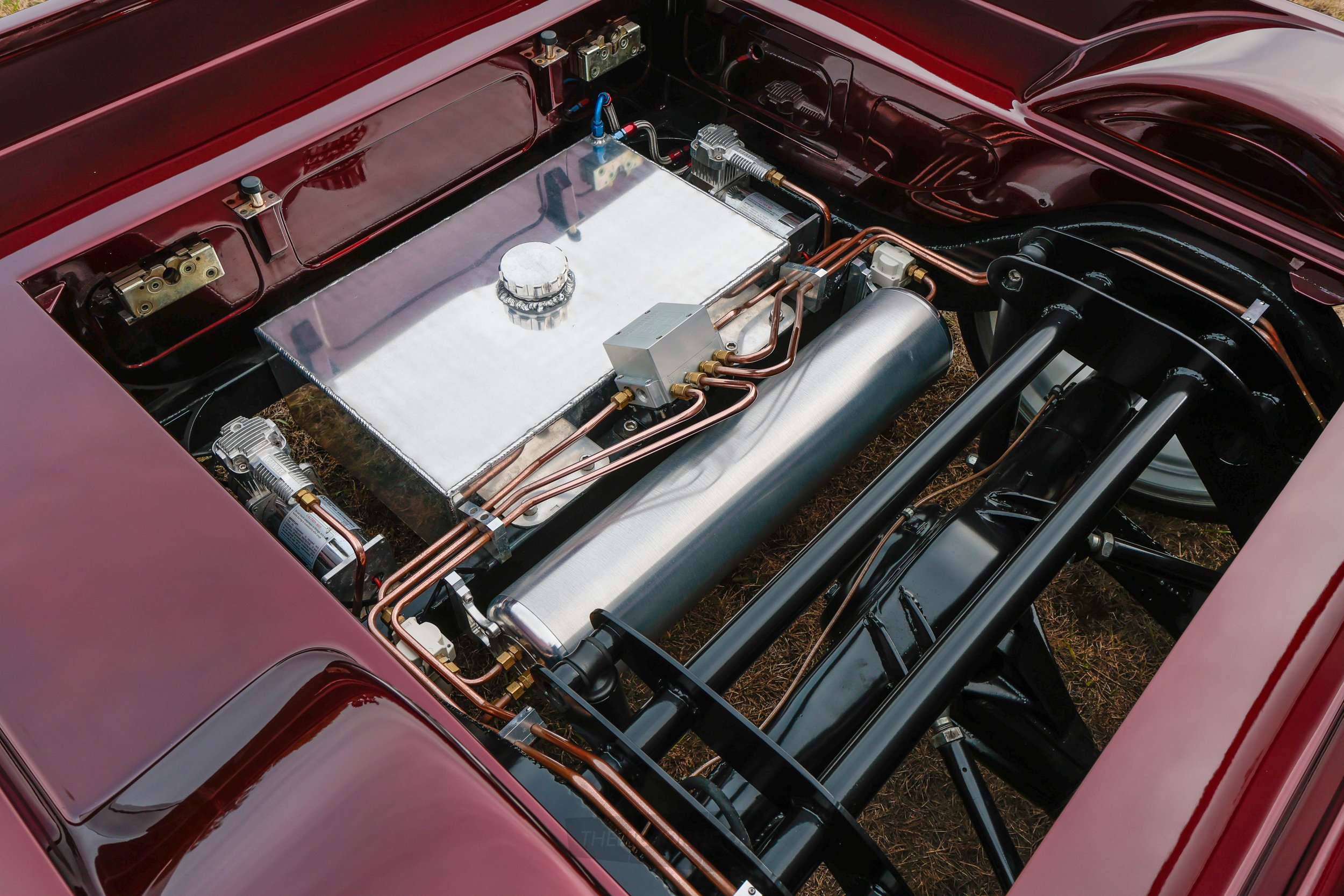

To get that slammed look, Slam Specialties RE6 and SS6 sit in the front and rear respectively on remounted shocks, mated to custom four-link bottom arms. Everything here is of Will’s design, including the entire rear interlocks. The airbag system comprises 400cc ViAir compressors, a spun aluminium air tank by Flo Tanks, Thirty3 machined alloy valve block and copper lines throughout, all managed by an AccuAir e-Level. You can’t sit that low and not have the right rim and tyre combo, so Rotiform joins the party with a set of 20×8.5-inch SPF rims with 245/30 R20s.

Okay, so it’s got to be all show and not much go, right? Wrong — it turns out that there is a Lexus V8 sitting under the hood here, although it did take a bit of work to get it in there. One of the challenges of doing things yourself and sitting a ride lower than Mr Toyota intended is that you can only see by doing. Finding the motor sticking two inches out of the bonnet created a challenge for the team along the build path. The motor, while largely standard for now, sports a set of custom headers that dumps just before the diff and drinks from a custom-made alloy fuel tank with the lines running in the chassis. It doesn’t take much to get a bit of power from the 1UZ and everything here is very much future proofed, just in case.

There are plenty of nice custom touches throughout the engine bay — again it’s more a case of trying to spot what was once factory, with everything smoothed and painted, and a whole heap of custom pieces created. A full de-loom and rewire has been done to keep the surgical look; it all hides away nicely while talking to a Link ECU.

When you are rolling low ’n’ slow, you want to do it in style; in this case it’s a full tan interior trim with everything either smoothed, painted, or replaced. You can listen to either the Toyota V8, the sound of metal scraping, or whatever is being fed to the custom-built sound system, which has been cleverly integrated, needing to be slimline with the minimal room available. You’ll never struggle to find which switch to hit, with LED lighting used throughout the build.

So, with the build now nearing completion and on the road, I thought back to when I first met Will and he mentioned the build was always evolving. It turns out that, with the main work now completed, the team is creating a custom airbagged trailer to match so the family can tour the South Island on holiday in style. Guess there’s just no limit to what a strong family team can do when they put their minds to it.

This article originally appeared in New Zealand Performance Car issue 295